display

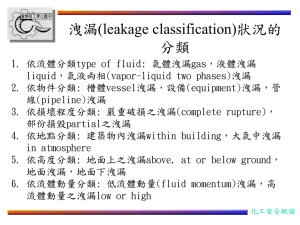

advertisement

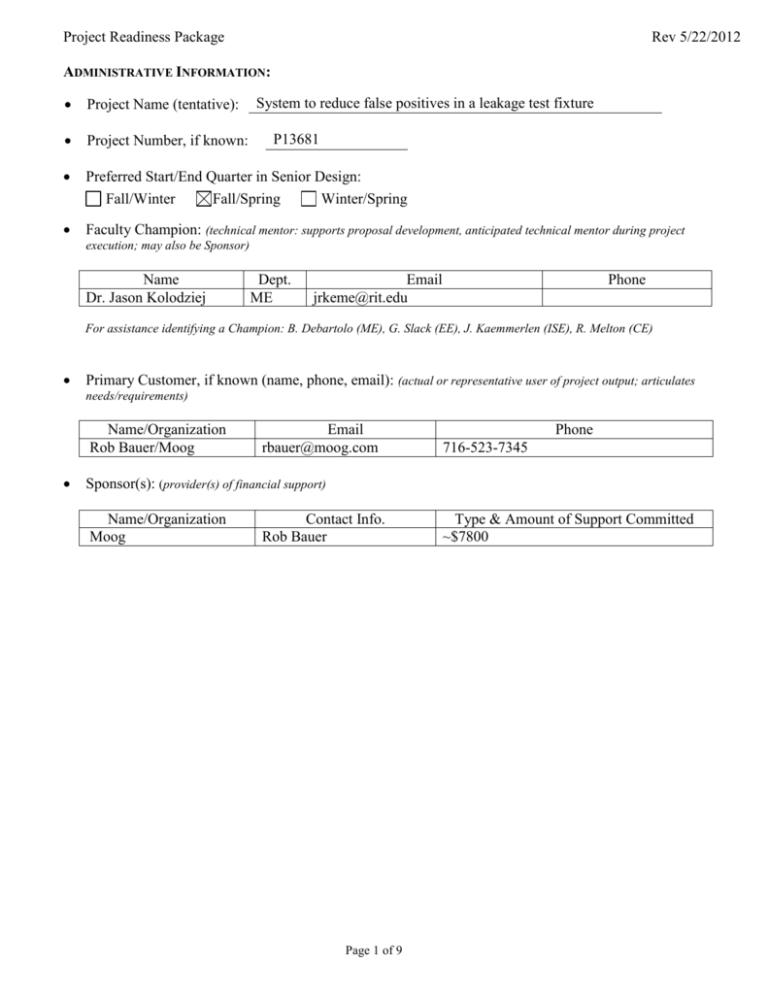

Project Readiness Package Rev 5/22/2012 ADMINISTRATIVE INFORMATION: Project Name (tentative): Project Number, if known: Preferred Start/End Quarter in Senior Design: Fall/Winter Fall/Spring Winter/Spring Faculty Champion: (technical mentor: supports proposal development, anticipated technical mentor during project System to reduce false positives in a leakage test fixture P13681 execution; may also be Sponsor) Name Dr. Jason Kolodziej Dept. ME Email jrkeme@rit.edu Phone For assistance identifying a Champion: B. Debartolo (ME), G. Slack (EE), J. Kaemmerlen (ISE), R. Melton (CE) Primary Customer, if known (name, phone, email): (actual or representative user of project output; articulates needs/requirements) Name/Organization Rob Bauer/Moog Email rbauer@moog.com Phone 716-523-7345 Sponsor(s): (provider(s) of financial support) Name/Organization Moog Contact Info. Rob Bauer Page 1 of 9 Type & Amount of Support Committed ~$7800 Project Readiness Package PROJECT OVERVIEW: Rev 5/22/2012 One of the ways in which Moog proves the effectiveness of the products they sell is leakage testing (See figure below). Valve assemblies are tested for leakage through the valve components, but then they myst also be tested for leakage through the valve body (This is primarily applicable for low-atomic-radius gases that can permeate solid metal). The valve body is fixtured atop a high-pressure gas port inside a vacuum chamber. Ideally, when high-pressure test gas is introduced, the valve body does not leak and a vacuum is maintained. A mass spectrometer is used to sample the vacuum environment for test gas contamination that would indicate a leak in the valve body. The current test configuration relies on o-ring seals around the high-pressure test gas port to ensure that the only way test gas can enter the vacuum environment is through the valve body. However, falsepositive tests are not unusual, due to test gas leakage around the o-rings and diffusion of test gas through the o-rings. Additionally, the room where the testing is done is test-gas-rich, and other o-ring seals around the test chamber may be contributing to the false positive results. Moog has modified the test configuration in the past with improved results, but false-positives are still an issue. The senior design team is charged with reducing the leakage of test gas into the vacuum chamber by means other than that being specifically tested. The Customer provides Moog a specification that the product must meet, and they have to comply. Most of the time this is not an issue, because the products do not leak significantly. However, because of the pressure differential being tested across, the fixturing does leak. Moog wants the Senior Design Team to create a system using pneumatic equipment to replace high concentrated test gas areas in the fixturing with Nitrogen Gas. It is also well known that if the product were actually leaking, the leakage values would be much higher than provided. Various iterations to the test stand design have been implemented, providing lower leakage with each iteration, proving that this is where the majority of the fixture leakage occurs. Two different systems are being analyzed in this project: The ambient test gas in the room leaking through the lid and bottom of the can, and the concentrated test gas space between the vented o-rings Page 2 of 9 Project Readiness Package Rev 5/22/2012 Page 3 of 9 Project Readiness Package DETAILED PROJECT DESCRIPTION: Rev 5/22/2012 Customer Needs Assessment Affinity Group Avoid false positive for leakage Customer Objective Description Provide accurate test data 10 7 Minimize increased cycle time 8 yes or no System should run concurrently with existing system User Safety 12 CDR/FMEA (Critical Design Review/Failure Mode Effects Analysis) Provide Data in a timely Manner Safe and easy to use Minimize Cost Withstand Everyday Use Withstand Everyday Use Maintainable Maintainable Test Data proof test Historical records, and comparative data. Preserve Vaccume Reduce delay caused by false failures Safe and easy to use Comments Is a concern overall, but new system should not contact existing system other than with pressure, and therefore is not a concern for the project. This till be done after the system had been implemented Avoid false positive for leakage Provide Data in a timely Manner Safe ad easy to use Measure of Effectiveness (How will Customer you demonstrate that you have met Ranking the need). 1 operator understands process 3 System is controlled transparently by existing software system 9 Minimize cost by balancing initial cost, maintenance cost, and consumable materials 6 Sturdy and Robust System maximize time between maintenance Maintenance plans Maintenance can accomplished with minimal money and time Training Material yes or no Cost analysis provided 11 CDR 4 5 CDR Written yes or no 2 CDR and cost of maintenance analyzed Page 4 of 9 Operater should not have any extra tasks associated with system, other than maintenance, but should know what they are working with. Project Readiness Package Rev 5/22/2012 Functional Decomposition: Page 5 of 9 Project Readiness Package Rev 5/22/2012 Functional Interfaces: Page 6 of 9 Project Readiness Package Rev 5/22/2012 Specifications (or Engineering/Functional Requirements) Constraints: o Safety Considerations THE USER MUST BE SAFE AT ALL TIMES Failure Mode Effects Analysis(FMEA) Must be performed prior to implementation. This will cover all effects of the system being created and response to potential problems that the existing system could produce. o Contamination The clean room that this system will be implemented into will be a class 10,000 clean room. This means that the room cannot have more than 10,000 airborne particles per square meter. Most parts that are introduced to the test stand have their own specifications for cleanliness. For this reason Moog wants to do all the manufacturing, and the team much be aware when designing of these constraints o Existing Fixture The existing fixture cannot be modified. this would cost too much. Any changes made to the existing could potentially cause changes to other fixtureing that is mated to it, and the company is not willing to make that risk. The system developed should coordinate with existing interfaces. The only part that can be redesigned is the plug. This means that the team is constrained by the current interface. o Gas Flow The only gas available for use in flushing is Nitrogen Gas(GN2). This is because it is used in multiple systems throughout the building and is cheap, inert, and readily available. The Automatic Gas Tester (AGT) provides GN2 at 120 PSIA. A regulator can be purchased to reduce this value. The Building has a built in Vacuum System at 1 PSIA this cannot be changed. The Vacuum System cannot be introduced to high pressures. This means that a release valve or something equivalent must be put in place to make sure the system does not try to pull a vacuum on extremely high pressures. o Documentation Training Materials:. Although there should not be any additional procedural operations, the user must know what it is they are working with and how it works. Maintenance plans: Maintenance plans should be provided explaining what needs to be done to maintain the system and how often. A detailed maintenance procedure should be included. Page 7 of 9 Project Readiness Package Rev 5/22/2012 Project Deliverables: Budget Estimate: Manufacturing: All wetted (flow) surfaces will be manufactured at or purchased by Moog, including: valves, tubing, fittings, the plug, and flexline The support structure for the new system will be made by the RIT team. This includes any bracketing that is necessary to support the shelf. Intellectual Property (IP) considerations: Moog will supply all documents/data that the team needs. They will not be able to publish these documents or post them on the internet, but can use them as necessary. The reasoning is that even though the actual parameters won’t be published, it can be easily concluded that Moog pushed toward the Page 8 of 9 Project Readiness Package Rev 5/22/2012 extreme in most cases. The IP includes: Drawings Test Parameters Pass/Fail Criteria These documents do not affect the system being created, but are more to help the team understand the system enough to be able to optimize it. The system that the team designs and builds, up to but not including the details of the interface with the existing test system, may be published. This includes pressures, cycling rates, and whatever other conclusions come out of the team’s design. Will the team need to sign a non-disclosure agreement that states all this? STUDENT STAFFING: Anticipated Staffing Levels by Discipline: Name Marie Rohrbaugh Austin Frazer Discipline ME TBD Student ISE TBD Student ChemE ME Role/Skills Team leader/project manager, customer interface, manufacturing. Interface design with existing test stand Fluid control systems design, interface with all internal system components. Pressure effects analysis on equipment and plumbing. Control System Error-proofing user interface, maintenance, training, DOE for testing and validation Modeling of gaseous mixtures and flow patterns, specifications for DOE Page 9 of 9 Prepared by: Marie Rohrbaugh Date: 5/22/2012