Application for a manufacturer`s or importer`s authorisation

advertisement

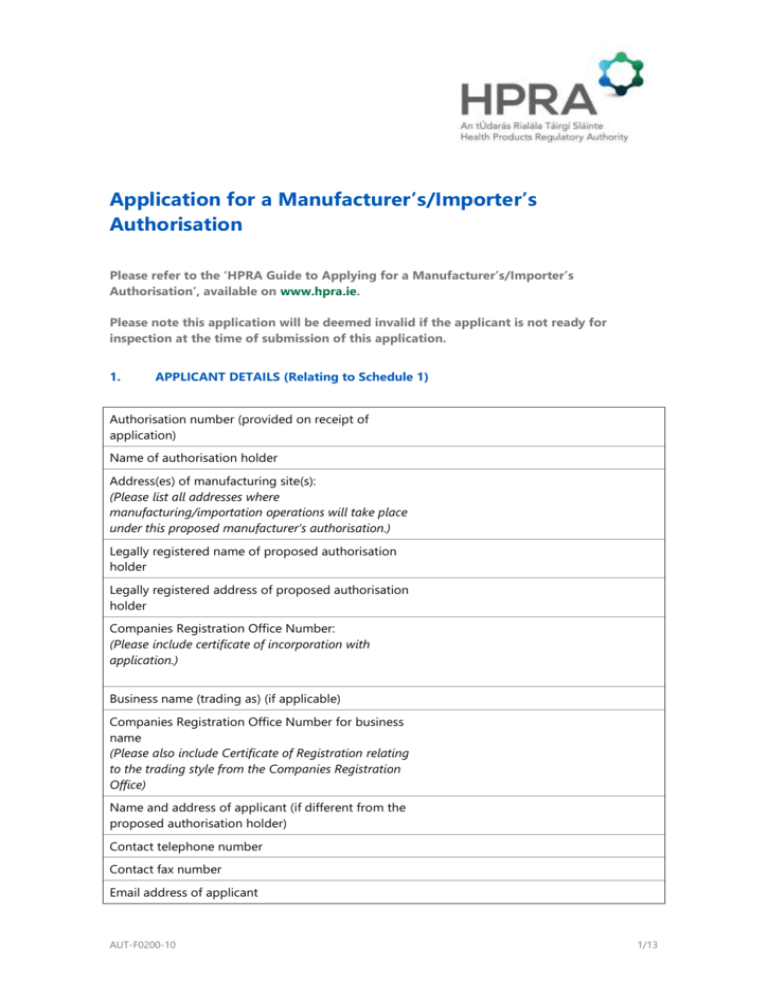

Application for a Manufacturer’s/Importer’s Authorisation Please refer to the ‘HPRA Guide to Applying for a Manufacturer’s/Importer’s Authorisation’, available on www.hpra.ie. Please note this application will be deemed invalid if the applicant is not ready for inspection at the time of submission of this application. 1. APPLICANT DETAILS (Relating to Schedule 1) Authorisation number (provided on receipt of application) Name of authorisation holder Address(es) of manufacturing site(s): (Please list all addresses where manufacturing/importation operations will take place under this proposed manufacturer’s authorisation.) Legally registered name of proposed authorisation holder Legally registered address of proposed authorisation holder Companies Registration Office Number: (Please include certificate of incorporation with application.) Business name (trading as) (if applicable) Companies Registration Office Number for business name (Please also include Certificate of Registration relating to the trading style from the Companies Registration Office) Name and address of applicant (if different from the proposed authorisation holder) Contact telephone number Contact fax number Email address of applicant AUT-F0200-10 1/13 2. TYPE OF AUTHORISATION REQUESTED Manufacturer’s authorisation for medicinal products for human use Manufacturer’s authorisation for investigational medicinal products for human use Manufacturer’s authorisation for medicinal products for veterinary use Note: separate applications are required for each type of authorisation identified above. 3. SCOPE OF AUTHORISATION/LICENCE (delete the sections that do not apply) The information in this section of the form is relevant to Annex 1 or Annex 2 and will be designated in the final authorisation document depending on the type of authorisation selected in the previous step. Name and address of the site: Manufacturing operations (according to part 1) Importation of medicinal products (according to part 2) Part 1 Manufacturing operations Note: where a category is selected which includes a provision for <free text> then enter the relevant descriptive text in the <free text> box. 1.1 Sterile Products 1.1.1 Aseptically prepared (processing operations for the following dosage forms) 1.1.1.1 1.1.1.2 1.1.1.3 1.1.1.4 1.1.1.5 1.1.1.6 Large volume liquids Lyophilisates Semi-solids Small volume liquids Solids and implants Other aseptically prepared products <free text> 1.1.2 Terminally sterilised (processing operations for the following dosage forms) 1.1.2.1 1.1.2.2 1.1.2.3 1.1.2.4 1.1.2.5 Large volume liquids Semi-solids Small volume liquids Solids and implants Other terminally sterilised prepared products <free text> 1.1.3 Batch certification AUT-F0200-10 2/13 1.2 Non-sterile products 1.2.1 Non-sterile products (processing operations for the following dosage forms) 1.2.1.1 1.2.1.2 1.2.1.3 1.2.1.4 1.2.1.5 1.2.1.6 1.2.1.7 1.2.1.8 1.2.1.9 1.2.1.10 1.2.1.11 1.2.1.12 1.2.1.13 1.2.1.14 1.2.1.15 1.2.1.16 1.2.1.17 Capsules, hard shell Capsules, soft shell Chewing gums Impregnated matrices Liquids for external use Liquids for internal use Medicinal gases Other solid dosage forms Pressurised preparations Radionuclide generators Semi-solids Suppositories Tablets Transdermal patches Intraruminal devices Veterinary premixes Other non-sterile medicinal product <free text> 1.2.2 Batch certification 1.3 Biological medicinal products 1.3.1 Biological Medicinal Products (list of product types) 1.3.1.1 1.3.1.2. 1.3.1.3 1.3.1.4 1.3.1.5 1.3.1.6 1.3.1.7 1.3.1.8 Blood products Immunological products Cell therapy products Gene therapy products Biotechnology products Human or animal extracted products Tissue engineered products Other biological medicinal products <free text> 1.3.2 Batch certification (list of product types) 1.3.2.1 Blood products 1.3.2.2 Immunological products 1.3.2.3 Cell therapy products 1.3.2.4 Gene therapy products 1.3.2.5 Biotechnology products 1.3.2.6 Human or animal extracted products 1.3.2.7 Tissue engineered products 1.3.2.8 Other biological medicinal products <free text> 1.4 Other products or manufacturing activity 1.4.1 Manufacture of: 1.4.1.1 1.4.1.2 AUT-F0200-10 Herbal products Homoeopathic products 3/13 1.4.1.3 1.4.2 Other <free text> Sterilisation of active substances/excipients/finished product 1.4.2.1 1.4.2.2 1.4.2.3 1.4.2.4 1.4.2.5 1.4.2.6 Filtration Dry heat Moist heat Chemical Gamma irradiation Electron beam 1.4.3 Other <free text> 1.5 Packaging 1.5.1 Primary packing 1.5.1.1 1.5.1.2 1.5.1.3 1.5.1.4 1.5.1.5 1.5.1.6 1.5.1.7 1.5.1.8 1.5.1.9 1.5.1.10 1.5.1.11 1.5.1.12 1.5.1.13 1.5.1.14 1.5.1.15 1.5.1.16 1.5.1.17 Capsules, hard shell Capsules, soft shell Chewing gums Impregnated matrices Liquids for external use Liquids for internal use Medicinal gases Other solid dosage forms Pressurised preparations Radionuclide generators Semi-solids Suppositories Tablets Transdermal patches Intraruminal devices Veterinary premixes Other non-sterile medicinal products <free text> 1.5.2 Secondary packing 1.6 Quality control testing 1.6.1 1.6.2 1.6.3 1.6.4 Microbiological: sterility Microbiological: non-sterility Chemical/Physical Biological Any restrictions or clarifying remarks related to the scope of these manufacturing operations <free text> AUT-F0200-10 4/13 Part 2 Importation of medicinal products 2.1 Quality control testing of imported medicinal products 2.1.1 2.1.2 2.1.3 2.1.4 2.2 Microbiological: sterility Microbiological: non-sterility Chemical/Physical Biological Batch certification of imported medicinal products 2.2.1 Sterile Products 2.2.1.1 2.2.1.2 Aseptically prepared Terminally sterilised 2.2.2 Non-sterile products 2.2.3 Biological medicinal products 2.2.3.1 2.2.3.2 2.2.3.3 2.2.3.4 2.2.3.5 2.2.3.6 2.2.3.7 2.2.3.8 2.3 Blood products Immunological products Cell therapy products Gene therapy products Biotechnology products Human or animal extracted products Tissue engineered products Other biological medicinal products <free text> Other importation activities (any other relevant importation activity not covered above) 2.3.1 2.3.2 2.3.3 2.3.4 Site of physical importation Importation of intermediate which undergoes further processing Biological Active Substance Other <free text> Any restrictions or clarifying remarks related to the scope of these importation operations <free text> AUT-F0200-10 5/13 ANNEX 3 CONTRACT MANUFACTURER(S) Please complete a separate Annex 3 for each contract manufacturer. Name and address of the contract manufacturing site: Located within the EEA: Yes No (if no add details relating to each medicinal product imported from outside the EEA in Annex 8). Authorisation Number (for sites located in the EEA): Date of last EEA inspection: Please check the relevant items and delete any checkbox items below which are not applicable. 1.1 Sterile Products 1.1.1 Aseptically prepared (processing operations for the following dosage forms) 1.1.1.1 1.1.1.2 1.1.1.3 1.1.1.4 1.1.1.5 1.1.1.6 1.1.2 Large volume liquids Lyophilisates Semi-solids Small volume liquids Solids and implants Other aseptically prepared products <free text> Terminally sterilised (processing operations for the following dosage forms) 1.1.2.1 1.1.2.2 1.1.2.3 1.1.2.4 1.1.2.5 Large volume liquids Semi-solids Small volume liquids Solids and implants Other terminally sterilised prepared products <free text> 1.2 Non-sterile products 1.2.1 Non-sterile products (processing operations for the following dosage forms) 1.2.1.1 1.2.1.2 1.2.1.3 1.2.1.4 1.2.1.5 1.2.1.6 1.2.1.7 1.2.1.8 1.2.1.9 1.2.1.10 1.2.1.11 1.2.1.12 1.2.1.13 1.2.1.14 1.2.1.15 AUT-F0200-10 Capsules, hard shell Capsules, soft shell Chewing gums Impregnated matrices Liquids for external use Liquids for internal use Medicinal gases Other solid dosage forms Pressurised preparations Radionuclide generators Semi-solids Suppositories Tablets Transdermal patches Intraruminal devices 6/13 1.2.1.16 1.2.1.17 Veterinary premixes Other non-sterile medicinal product <free text> 1.3 Biological medicinal products 1.3.1 Biological Medicinal Products (list of product types) 1.3.1.1 1.3.1.2. 1.3.1.3 1.3.1.4 1.3.1.5 1.3.1.6 1.3.1.7 1.3.1.8 Blood products Immunological products Cell therapy products Gene therapy products Biotechnology products Human or animal extracted products Tissue engineered products Other biological medicinal products <free text> 1.4 Other products or manufacturing activity 1.4.1 Manufacture of: 1.4.1.1 1.4.1.2 1.4.1.3 1.4.2 Herbal products Homoeopathic products Other <free text> Sterilisation of active substances/excipients/finished product 1.4.2.1 1.4.2.2 1.4.2.3 1.4.2.4 1.4.2.5 1.4.2.6 Filtration Dry heat Moist heat Chemical Gamma irradiation Electron beam 1.4.3 Other <free text> 1.5 Packaging 1.5.1 Primary packing 1.5.1.1 1.5.1.2 1.5.1.3 1.5.1.4 1.5.1.5 1.5.1.6 1.5.1.7 1.5.1.8 1.5.1.9 1.5.1.10 1.5.1.11 1.5.1.12 1.5.1.13 1.5.1.14 1.5.1.15 1.5.1.16 1.5.1.17 AUT-F0200-10 Capsules, hard shell Capsules, soft shell Chewing gums Impregnated matrices Liquids for external use Liquids for internal use Medicinal gases Other solid dosage forms Pressurised preparations Radionuclide generators Semi-solids Suppositories Tablets Transdermal patches Intraruminal devices Veterinary premixes Other non-sterile medicinal products <free text> 7/13 1.5.2 1.6 Secondary packing Quality control testing 1.6.1 1.6.2 1.6.3 1.6.4 AUT-F0200-10 Microbiological: sterility Microbiological: non-sterility Chemical/Physical Biological 8/13 ANNEX 4 CONTRACT LABORATORY Please complete a separate Annex 4 for each contract laboratory. Name of contract laboratory: Address of contract laboratory: Tick relevant testing operations below: Microbiological: sterility Microbiological: non sterility Chemical/physical Biological Stability testing (This is applicable only where all testing operations carried out at the contract laboratory relate to stability testing only. If the contract laboratory carries out multiple testing operations and only some of these apply to stability testing, then this is not applicable.) Located within the EEA: Yes No Authorisation number (where applicable): Date of last EEA inspection: site) (as per date referenced on last GMP certificate issued for the Where the laboratory will only be used for testing in relation to IMPs or stability testing of medicinal products, submit a declaration of GMP compliance from a QP named on the authorisation. The HPRA reserves the right to perform its own inspection if deemed necessary or to request another relevant authority to inspect where appropriate. Evidence of satisfactory inspection by an MRA authority: For contract laboratories located in an MRA territory, please provide evidence of a satisfactory outcome to any inspection which has taken place within the last three years and is relevant to the activities which are (or will be) carried out at the site. AUT-F0200-10 9/13 ANNEX 5 QUALIFIED PERSON(S) Please submit a curriculum vitae, copy of QP Qualification and training records for the following personnel: - Qualified person(s) (please specify primary or deputy, if applicable) Title First name Last name Qualifications Additional information ANNEX 6 PERSONNEL FOR PRODUCTION OPERATIONS AND QUALITY CONTROL Please provide a Curriculum Vitae and training records for the following personnel: - Person(s) responsible for production operations - Person(s) responsible for quality control Name(s) of production personnel Title First name Last name Qualifications Additional information Qualifications Additional information Name(s) of quality control personnel Title AUT-F0200-10 First name Last name 10/13 ANNEX 7 (OPTIONAL) – NOT USED BY THE HPRA If completed, this information will not appear on the authorisation. Date of inspection following which authorisation was granted: <dd/mm/yyyy> Scope of last inspection: ANNEX 8 IMPORTATION OF PRODUCTS WHICH ARE CONTRACT MANUFACTURED AT A SITE OUTSIDE THE EEA Enter the name and address below of the contract manufacturer as already completed in Annex 3. Name and address of the contract manufacturing site: Product type: Product description Dosage form: Details of imported product Strength Active ingredient Activities by MIA holder Batch certification Site of physical importation Please add rows as necessary to the table above to cover all relevant products manufactured at this site. Please complete a separate Annex 8 for each relevant manufacturer. AUT-F0200-10 11/13 OTHER REQUIREMENTS FOR APPLICATIONS FOR A MANUFACTURER’S/IMPORTER’S AUTHORISATION Recall procedure Please submit a copy of the company’s recall procedure. Explanatory notes on the preparation of a recall procedure can be found on www.hpra.ie. Site master file Please submit a copy of the facility’s site master file. Explanatory notes on the preparation of a site master file can be found on www.picscheme.org. Other authorisations/licences held (Relevant only to other authorisations/licences granted by the HPRA) Name and address of authorised/licensed establishment: Authorisation/licence number: Fees/classification of facility Please submit an application fee with each request for a manufacturer’s authorisation. An annual maintenance fee is also payable in respect of each authorisation and is related to the size of the facility based on the numbers of relevant employees. (Tick as appropriate) A major site (>250 employees) A large site (150-250 employees) A medium site (50-149 employees) A small site (<50 employees) Please refer to the Guide to Fees for Human Products/Guide to Fees for Veterinary Products on www.hpra.ie and complete the appropriate fee application form. Declaration In the event of the authorisation being granted, I undertake to ensure fulfilment of the obligations arising by virtue of the terms and conditions of the authorisation and declare that the above particulars are, to the best of my knowledge and belief, correct. Signature: Date: Print name: Title/position: AUT-F0200-10 12/13 CHECKLIST OF DOCUMENTS The following information must be submitted with the application (except where not applicable). Please tick the checkboxes below to confirm the documents have been included with the application. Letter of application Certificate of incorporation Details (name, address and operation) of contract manufacturing sites Details (name, address and operation) of contract laboratories List of products (including name of API, dosage form and strength) imported from outside the EEA Details relating to proposed Qualified Person(s) Details relating to proposed Person(s) responsible for Quality Control Details relating to proposed Person(s) responsible for Production Operations Recall procedure Site master file Classification of facility size Fee application form Relevant fee Signed declaration AUT-F0200-10 13/13