Construction and Implementation of a Biomaterials Properties

advertisement

Construction and Implementation of a

Biomaterials Properties Database

Zi Wang

Department of Biological Engineering, Cornell University

This project aims to construct and implement a user-defined Matereality Database for

biomaterial properties data, and also create data transfer link between the database and external

analytical software.

I.

INTRODUCTION

This paper introduces a user-defined database that is constructed and implemented to help store

biomaterial data, and facilitate the use of these data in external analytical software. A well

organized database reflects your organization’s effective planning, management, and control. A

well organized database should employ database, technology, and above all else, clear thinking

and common sense. All four elements are to achieve database with minimum effort and

maximum effectiveness.

The database constructed for this study is data centered: data that come from experimental

procedures as well as formulation. While built from common components, the sum total of the

database would be unique to each set of conditions. The database requires both initial

organizational commitment and the continuous participation of the users to complete its

functions.

II.

ORGANIZATION OF BIOMATERIAL

Trauma, degeneration and diseases often make surgical repair or replacement necessary. When a

person has a joint pain the main concern is the relief of pain and return to a healthy and

functional life style. This usually requires replacement of skeletal parts that include knees, hips,

finger joints, elbows, vertebrae, teeth, and repair of the mandible. The worldwide biomaterials

market is valued at close to $24,000M. Orthopaedic and dental applications represent

approximately 55% of the total biomaterials market. Orthopaedics products worldwide exceeded

$13 billion in 2000, an increase of 12 percent over 1999 revenues [1]. Expansion in these areas is

expected to continue due to number of factors, including the ageing population, an increasing

preference by younger to middle aged candidates to undertake surgery, improvements in the

2

technology and life style, a better understanding of body functionality, improved aesthetics and

need for better function. As biomaterials enjoy an ever expanding role in modern society, it

becomes very important to be able to organize and classify the various different biomaterials for

research purposes.

Classification of biomaterial in this database is performed based first on the material’s physical

structure. For this biomaterial database, there are three major classes with different physical

structures – tissue, body fluid, and composite material.

Tissue is a cellular organizational level intermediate between cells and a complete organism. A

tissue is an ensemble of cells, not necessarily identical, but from the same origin, that together

carry out a specific function. These are called tissues because of their identical functioning. In

this database, tissue is subdivided into different groups according to their structures and

properties (Table 1).

Table 1: Subdivision of Tissue

Bone

Muscle

Tissue

Cartilage

Fat

Skin

Organ

Body fluid, in the most basic terms, is a biological fluid — a liquid made by the body itself.

Body fluids can be excreted through sweat, secreted through bile, obtained through a needle

when blood is drawn, or they may develop from a blister or cyst. Body water is also a body fluid,

as is ear wax, amniotic fluid, cerebrospinal fluid, pus, and saliva, among many others. In this

database, body fluid is subdivided into just one category: blood.

3

Composite materials are bio-compatible materials. A biocompatible material (sometimes

shortened to biomaterial) is a synthetic or natural material used to replace part of a living system

or to function in intimate contact with living tissue. Biocompatible materials are intended to

interface with biological systems to evaluate, treat, augment or replace any tissue, organ or

function of the body. Biomaterials are usually non-viable, but may also be viable.

A biocompatible material is different from a biological material such as bone that is produced by

a biological system. Artificial hips, vascular stents, artificial pacemakers, and catheters are all

made from different biomaterials and comprise different medical devices. In this database, there

are no subdivisions for composite material.

III.

DATABASE PLATFORM INTRODUCTION AND DATA ENTRY

The database platform used in this study is provided by Matereality. Inc. Matereality® is a first of

its kind, material data management technology that permits organizations to house all their

material properties on a single platform without limits. This 'No Limits' approach removes

existing hurdles that currently force organizations to sequester their data in disparate and

inconsistent formats such as limited capability databases, pdf document management systems.

Matereality® is similar in concept to virtual parts libraries. Virtual parts libraries, which offer

easy-to-download ready-to-use virtual product descriptions, like solid models of common parts

and fasteners, have three major advantages. First, the product descriptions are created as per the

standards of the parts suppliers, ensuring that the part is properly represented in the client’s

design. Second, the product developer does not have to waste valuable time and effort recreating

the geometry. Lastly, users are guaranteed that the same virtual component is viewed and used at

4

all levels of cooperation within and between enterprises. Matereality® offers the same advantages

for product developers cataloging quantitative material models.

For this project, an existing database platform is chosen over developing an entirely new

database platform because Matereality database offers excellent framework for biomaterial data

storage due to its expendability and ease of access. However, there are major obstacles in

inputting biomaterial data into the database in the initial stage of the project because

Matereality database is not designed specifically to suit biomaterials, therefore many important

material classifications, such as tissue and body fluid, have to be incorporated into the database.

Also, parameters specific to biomaterials such as water content are also missing from the initial

database setup, therefore these parameters also have to be added into the database framework.

In Matereality database, simple point data entries are recorded into different property categories.

These categories include thermal conductivity, thermal diffusivity, specific heat, density,

diffusion coefficient, and permeability. There are several important steps in data entering process,

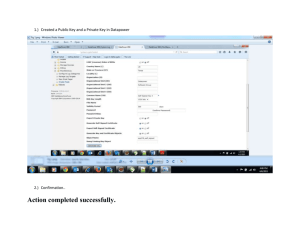

first of which is to specify the type of data to be entered (Figure 1).

Figure 1: Selecting Project Information and Property to be entered.

5

Figure 2: Declaring parameter values and variable parameters.

In this step, the project name associated with this data entry is named and the type of material

property to be entered is selected. Next, the second most important step involves declaring

parameter values and any variable parameters (Figure 2). For every data entry, one of the

parameters must be constant for the entry process to continue. The third and last important step

in data entry procedures is declaring materials (Figure 3).

Figure 3: Declaring the material used from which the data are extracted.

6

In this step, the material used from which the data are extracted is declared. If the material is not

listed in the database, a new material can be created with the appropriate class and subclass

names (Figure 3, red circle). These three steps are of the utmost importance in data entry process

because the data in the database are distinguished from each other based on the information

processed in these three steps. More detailed procedures that are needed to accomplish the data

entry are in Appendix II.

Other than simple data entry, the database is able to display other types of data, one of them

being equation. Equation, as a specific type of data entry, needs to be entered via an

administrator through a XML file that code specifically for the equation (Figure 4).

Figure 4: XML code fragment that declares an thermal conductivity equation.

Equation entry into the database has proven to be the biggest obstacle in constructing the

database. At the initial stage of the construction, entering equation as a form of data into the

database is not technically possible. Through negotiations with the database developers and by

working together with technicians from Matereality, inc., it is now possible to enter equations

into the database. For an equation to be entered into the database, it has to be first written in

7

XML format (Figure 4) in frames that are acceptable by the database. Then the XML codes are

loaded into the database structure and become part of the general database framework. The

results are that the equations declared by the XML code can now be viewed in the database as a

data entry (Figure 5)

Figure 5: Graphic display of equation entered into the database.

IV.

DATA TRANSFER TO EXTERNAL SOFTWARE: COMSOL

One of the most important parts of this database implementation is the ability to transfer data to

external analytical software, in this case, COMSOL. COMSOL is a multiphysics software

designed to solve heat and mass transfer problems. The ability to import material data from

database and store them in a user-defined material library in COMSOL offers great flexibility

and advantage to researchers when trying to apply various properties of materials to solve

problems.

8

The major problem in achieving this is importing data from database in a form that is readable by

COMSOL. Because COMSOL has a predefined XML structure for material properties, the

challenge is to formulate a XML file convertor that would convert existing data in the

Matereality database into XML file that would be accepted by COMSOL (Appendix I). The

resulting XML files can then be imported into COMSOL’s directory for later usages (Figure 6,

7).

Figure 6: A XML file containing a biomaterial’s property information from Matereality database.

Figure 7: Directory in COMSOL where the XML file shown in Figure 6 can be imported.

9

V.

CONCLUSION

The aim of this project is to create a biomaterial property database and be able to transfer data

from the database to external analytical software, COMSOL. At the end of the project, the

database contains material property data from a range of biomaterials, and is able to export XML

file that can be read by COMSOL. The Matereality database for biomaterials displays flexibility

in dealing with demanding situations and expandability in dealing with unknown territory.

Despite the accomplishments, there are still aspects of this database that can be improved. The

part need to be improved most is the equation entry process. Despite the efforts made during this

project, the process of entering equation is still very user-unfriendly and also very restrictive. In

the future, such aspects of the database need to be improved.

10

Appendix I: Data Convertor: from database to XML file

This work is done under collaboration from Matereality. Inc.

<xsl:stylesheet version="1.0"

xmlns:xsl="http://www.w3.org/1999/XSL/Transform"

xmlns:msxsl="urn:schemas-microsoft-com:xslt"

xmlns:xsi="http://www.w3.org/2001/XMLSchema-instance"

xmlns:merUtil="urn:matereality-scripts"

xmlns:tensile="urn:matereality-conversion-tensile"

xmlns:compressive="urn:matereality-conversion-compressive"

exclude-result-prefixes="msxsl merUtil tensile compressive">

<xsl:output method="xml" encoding="utf-8" indent="yes" />

<xsl:strip-space elements="*" />

<xsl:variable name="glossary" select="document('glossary.xml')" />

<!-- DocRoot -->

<xsl:template match="//MerDocRoot">

<lib type="class">

<name>comsol_basic_material_lib</name>

<descr>basic_material_lib_descr</descr>

<version type="class">

<name>COMSOL 3.5</name>

<ext>a</ext>

</version>

<mat type="array">

<xsl:apply-templates select="//MERMaterial" />

</mat>

</lib>

</xsl:template>

<xsl:template match="MERMaterial" >

<object type="class">

<name><xsl:value-of select="Name" /></name>

<appearance>ROUGH SPECULAR 230 120 50 DIFFUSE 229 131 76

AMBIENT 230 230 230 NOISESCALE 0.5 NOISEFREQ 0.3</appearance>

<variables type="class" >

<xsl:apply-templates select=".//MERPropertyMeasurementResult"/>

</variables>

</object>

</xsl:template>

11

<xsl:template match="MERPropertyMeasurementResult[ ResultName = 'Poissons

Ratio' ]">

<nu><xsl:value-of select="ResultValue" /></nu>

</xsl:template>

<xsl:template match="MERPropertyMeasurementResult[ ResultName = 'Tensile

Modulus' ]">

<E><xsl:value-of select="ResultValue" />[Pa]</E>

</xsl:template>

<xsl:template match="MERPropertyMeasurementResult[ ResultName = 'Thermal

Conductivity' ]">

<k><xsl:value-of select="ResultValue" />[W/(m*K)]</k>

</xsl:template>

<xsl:template match="MERPropertyMeasurementResult[ ResultName = 'Specific

Heat' ]">

<C><xsl:value-of select="ResultValue" />[J/(kg*K)]</C>

</xsl:template>

<xsl:template match="MERPropertyMeasurementResult[ ResultName = 'Solid

Density' ]">

<rho><xsl:value-of select="ResultValue" />[kg/m^3]</rho>

</xsl:template>

<xsl:template match="MERPropertyMeasurementResult" />

</xsl:stylesheet>

12

Appendix II: Matereality Database User Manual

2012

Compiled by the author of this paper

MATEREALITY DATABASE

USER MANUAL

Cornell University

5/3/2012

13

Table of Content

I. Getting Started

............................................................................................................... 15

II. Load Your Data

............................................................................................................... 18

III. Accessing and Editing Existing Data …......................................................................... 27

IV. Accessing Model …........................................................................................................ 29

V. Data Transfer to COMSOL ….......................................................................................... 34

14

I. Getting Started

Click on “Login” as circled in the figure below.

15

Enter Passport and Password accordingly.

16

After logging in, click on “My Database” as shown in the figure below. You can chose a range of

acitivities with regard to your database at this interface.

17

II. Load Your Data

Click on the “Load Data” as circled in the figure below.

18

Enter Project ID as shown in circle 1 and the appropriate property as shown in circle 2.

19

Check for Project ID as shown in circle 3, select appropriate test method as shown in circle 4, if

the test method is unknown, select unknown. Select test data and instrument used as shown in

circle 5.

20

Enter appropriate parameter values and declare variables. At least one parameter value must be a

constant, this value should be declared under the “Value” column with the corresponding

parameter. If there are variable parameter values, click the “Variable” box with the

corresponding parameter. Proceed to the next step.

21

Select appropriate property results, then proceed to next step.

22

Enter the appropriate variable values as shown in circle 6, and click on “Add Data” as shown in

circle 7 to enter your data.

23

After entering data, click on “Material” as circled in the figure below to enter material

information

24

You can choose from existing materials in the database, or you can define your own material as

circled in the figure below.

25

After entering material information, click “Save” as circled in the figure below to save your entry

into the database.

26

III. Accessing and Editing Existing Data

On the interface shown in the figure below, click on “Manage” as circled.

27

For editing your data, click on “Editing” as circled in the figure below, then choose your desired

data entry for editing.

28

IV. Accessing Model

For some data, there are built in models available. To access model, click on “View” as circled in

the figure below.

29

To display model, click on “Model” as circled in the figure below.

30

Choose the appropriate model avaiblable, an example is shown as circled in the figure below.

31

Figures below shows an example, which has a specific heat equation displayed.

32

33

V. Data Transfer to COMSOL

In the beginning interface, a link to COMSOL can be found as circled in the figure below.

34

Select appropriate search constraints for available data.

35

The figure below displays a range of avaible data entry for transfer to COMSOL

36

After selecting a data entry, click “Start Conversion” as circled in the figure shown below.

37

After conversion completion, you can choose “View Model”, which displays a XML file

containing the information in this data entry in the format required for COMSOL, and

“Download”, which will download the XML file to be used for COMSOL.

38

Appendix III: Reference

[1] G. Heness and B. Ben-Nissan. Innovative Bioceramics, Materials Forum, Vol. 27, 2004.

Below are references for biomaterial data used in this database

[2]Balasubramaniam, TA and HF Bowman. Thermal conductivity and thermal diffusivity of

biomaterials: A simultaneous measurement technique. J. Biomech. Engr. 99, 148-154, 1977.

[3]Bowman, H.F., Cravalho, E.G., Woods, M.:Theory, measurement and application of thermal

properties of biomaterials. Annual Rev. Biophys. Bioeng. 4(1975)43-80

[4]Brazell, C.S, Peppas, N.A, Mechanisms of solute and drug transport in relaxing, swellable,

bydrophilic glassy polymers. Polymer 40(1999)3383-3398

[5]Bryers, J.D, Drummond, F, Local Macromolecule Diffusion Coefficients in Structurally NonUniform Bacterial Biofilms Using Fluorescence Recovery After Photobleaching (FRAP).

Biotechnology and Bioengineering (1097-0290); Volume: 60; Issue:4; Date: 1998.

[6]Chato, JC. A method for the measurement of the thermal properties of biological materials. In

Thermal Problems in Biotechnology, JC Chato, ed., ASME symposium series, American Society

of Mechanical Engineers, New York, 1968.

[7]Chato, JC. Fundamentals of bioheat transfer. In Thermal Dosimetry and Treatment Planning,

M Gautherie, ed., Springer-Verlag, New York, 1990, p.51.

[8]Coehn, ML. measurement of the thermal properties of human skin. A review. J. Invest.

Dermatol. 69, 333-338, 1977.

[9]Cooper TE and GJ Trezek. Correlation of thermal properties of some human tissue with water

content. Aerospace Med. 42, 24-27, 1971.

[10]Drane, CR. The thermal conductivity of the skin of crocodilians. Comp. Biochem. Physiol.

68A, 107-110, 1981.

[11]Dumas, A and GS Barozzi. Laminar heat transfer to bood flowing in a circular duct. Int. H

heat Mass Trans. 27, 391-398, 1984.

[12]Fang, Y.E, Cheng, Q, Lu, X.B, Kinectics of In Vitro Drug Release from Chitosan/Gelatin

Hybrid Membranes. Journal of Applied Polymer Science, Vol. 68, 1751

[13]Grayson, J. Internal calorimetry in the determination of thermal conductivity and blood flow.

J. Physiol. 118, 54-72, 1952.

39

[14]Gribbon. P, Hardingham. T.E, Macromolecular Diffusion of Biological Polymers Measured

by Confocal Fluorescence Recovery after Photobleaching. Biophys J, August 1998, p. 10321039, Vol. 75, No. 2

[15]Holmes, KR and T Adams. Epidermal thermal conductivity and stratum corneum hydration

in cat footpad. Am. J. Physiol., 228, 1903-1908, 1975.

[16]Holmes, KR and MM Chen. Local thermal conductivity of Para-7 fibrosarcoma in hamster.

1979 Advances in Bioengineering, ASME, New York, NY, 147-149, 1979.

[17]Holmes, KR, W Ryan and MM Chen. Thermal conductivity and H2O content in rabbit

kidney cortex and medulla. J. Therm. Biol. 8, 311-313, 1983.

[18]Jacobson. K, Ishihara. A, Inman. R, Lateral Diffusion of Proteins in Membranes. Annual

Review of Physiology. Vol. 49: 163-175.

[19]Kvadsheim, PH, LP Folkow and AS Blix. A new device for measurement of the thermal

conductivity of fur and blubber. J. Therm. Biol. 19, 431-43, 1994.

[20]Kvadsheim, PH, LP Folkow and AS Blix. Thermal conductivity of Minke whale blubber. J.

Therm. Biol. 21, 123-128, 1996.

[21]Muller, G.J. and Roggan, A. (1995) Laser-induced interstitial thermotherapy, SPIE Optical

Engineering Press, Bellingham, Wash.

[22]Nicholson, C. 2001. Diffusion and related transport mechanisms in brain tissue. Rep. Prog.

Phys. 64: 815-884

[23]Peppas, N.A, Wright, S.L, Drug diffusion and binding in ionizable interpenetrating networks

from poly(vinyl alcohol) and poly(acrylic acid). European Journal of Pharmaceutics and

Biopharmaceutics 46 (1998)15-29.

[24]Prokopova-Kubinova, L. Vargova, L. Tao, K. Ulbrich, et Al. Poly[N-(2 hydroxypropyl)

methacrylamide] Polymers Diffuse in Brain Extracellular Space with Same Tortuosity as Small

Molecules. Biophysical Journal Volume 80 January 2001 542-548.

[25]Roger, P. Mattisson, C. Axelsson, A. Zacchi, G, Use of holographic laser interferometry to

study the diffusion of polymers in gels. Biotechnology and Bioengineering Volume 69, Issue 6,

Date: 20 September 2000, Pages: 654-663.

[26]Shin, S.C, Cho, C.W, Choi, H. K, Permeation of Piroxicam from the Poloxamer Gels. Drug

Development & Industrial Pharmacy, Mar99, Vol. 25 Issue 3, p273, 6p

40

[27]Siepmann. J, Podual. K, Sriwongjanya. M, Peppas. N.A, Bodmeier. R, A new model

describing the swelling and drug release kinectics from hydroxypropyl methylcellulose tablets.

Journal of Pharmaceutical Sciences Vol. 88(1) 1999, 65-72.

[28]Sjo’berga, H, Persson, S, Caram-Lelham, N, How interactions between drugs and agarosecarrageenan hydrogels influence the simultaneous transport of drugs. Journal of Controlled

Release 59 (1999) 391-400

[29]Valvano, JW, JT Allen and HF Bowman. The simultaneous measurement of thermal

conductivity, thermal diffusivity, and perfusion in small volumes of tissue. ASME 81-WA/HT21, 1981.

[30]Valvano, JW, JR Cochran and KR Diller. Thermal conductivity and diffusivity of

biomaterials measured with self-heated thermistors. Int. J. Thermophys. 6, 301-311, 1985.

[31]Valvano, JW and B Chitsabesan. Thermal conductivity and diffusivity of arterial wall and

atherosclerotic plaque. Lasers Life Sci., 1, 219-229, 1987

41