Laboratory work - University Wiki

advertisement

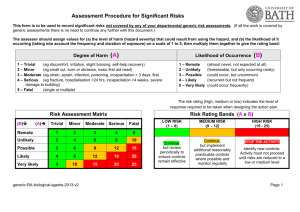

Assessment Procedure for Significant Risks This form is to be used to record significant risks not covered by any of your departmental generic risk assessments. (If all the work is covered by generic assessments there is no need to continue any further with this document.) The assessor should assign values for (a) the level of harm (hazard severity) that could result from using the hazard, and (b) the likelihood of it occurring (taking into account the frequency and duration of exposure) on a scale of 1 to 5, then multiply them together to give the rating band: Degree of Harm (A) (B) Likelihood of Occurrence 1 – Trivial (eg discomfort, irritation, slight bruising, self-help recovery) 2 – Minor (eg small cut, burn or abrasion, basic first aid need) 3 – Moderate (eg strain, sprain, infection, poisoning, incapacitation > 3 days, fire) 4 – Serious (eg fracture, hospitalisation >24 hrs, incapacitation >4 weeks, severe damage to building) 5 – Fatal (single or multiple) 1 – Remote 2 – Unlikely 3 – Possible 4 – Likely 5 – Very likely (almost never, not expected at all) (foreseeable, but only occurring rarely) (could occur, but uncommon) (recurrent but not frequent) (could occur frequently) The risk rating (high, medium or low) indicates the level of response required to be taken when designing the action plan. Risk Assessment Matrix (B) (A) Risk Rating Bands (A x B) Trivial Minor Remote 1 2 3 4 5 Unlikely 2 4 6 8 10 Possible 3 6 9 12 15 Likely 4 8 12 16 20 Very likely 5 10 15 20 25 generic-RA-basic-lab-work-2013-v2 Moderate Serious Fatal LOW RISK (1 – 8) MEDIUM RISK (9 - 12) HIGH RISK (15 - 25) Continue, but review periodically to ensure controls remain effective Continue, but implement additional reasonably practicable controls where possible and monitor regularly STOP THE ACTIVITY Identify new controls. Activity must not proceed until risks are reduced to a low or medium level Page 1 Generic Risk Assessment for basic laboratory work Drafted by Pete Jewell Location of activity: June 2013 Because there can be a large number of hazardous agents in laboratories care needs taking in ensuring they are handled safely. Policy and guidance for various aspects of laboratory work is available at the UHS&E website ( http://www.bath.ac.uk/hr/stayingsafewell/index.html) and the ‘1st Stop for Health & Safety’ wiki at https://wiki.bath.ac.uk/pages/viewpage.action?pageId=73829286. This risk assessment only covers basic laboratory work. Any significant hazards involved in the work activity must also be assessed in more detail using one of the more specialised generic, or specific, risk assessments available on the wiki. Once complete, all relevant workers must be informed, and their supervisor/manager must record their agreed ‘competence’ level (e.g. using a ‘supervision level’ of ‘low’, ‘medium’ or ‘high’) and get them to sign below. Date when will the activity is to start: Date when it is likely to finish: Assessor(s) names(s): Supervisor(s): Signatures of Date: Date of drafting assessment: Safety Coordinator: Date: Roughly how often will it be performed? Review date: Head of Department; Date: Supervision level. (Complete this after assessment is printed.) Supervisors and workers must jointly agree worker’s supervision level, defined as follows; 'LOW' - Workers are deemed to be adequately 'MEDIUM' - Activity cannot commence 'HIGH' - Activity cannot commence or proceed without direct senior supervision. trained and competent to perform this activity. without supervisor’s advice and approval. Worker’s name generic-RA-basic-lab-work-2013-v2 Worker’s signature Supervision level Supervisor’s name Supervisor’s signature Date Page 2 General Risk Control Measures. POWDERED LATEX GLOVES ARE PROHIBITED IN THE UNIVERSITY. Completion of departmental safety induction is mandatory for lab workers. Low-protein, non-powdered latex and nitrile disposable gloves (to EN374-2 Lab coats must be worn by all workers in “wet” laboratories. and EN374-3 Standard) should be available for use in laboratories. Food or drink must not be consumed or stored in “wet” labs. To avoid contaminating door handles and light switches lab gloves should Good standards of personal hygiene must be maintained at all times. not be worn outside labs. If necessary use one glove to carry lab items. Hand-to-face operations must be avoided. Hands must be washed when All laboratories must maintain an inventory of any ‘dual-use’ materials to leaving a “wet” laboratory. help with audits. This inventory must be checked at least annually. Mouth pipetting or the use of mouth-operated suction devices is prohibited. Spillages should be dealt with as soon as possible. Chemicals; Neutralise, if appropriate, and clear up. Hazardous chemical spillages may need specialised disposal and if you are not sure how to dispose of any hazardous waste please contact your Technical Manager or email waste@lists.bath.ac.uk. It may be appropriate to dispose of some spills to the drains or to the general “red-label” waste bins. If you are not sure SEEK ADVICE. In the case of volatile liquids, use tissues and consider removing them as soon as possible (to enable the vapours to dissipate) either to a ducted fume cupboard or outside the building. Biological spillages. If appropriate use the recommended decontaminant. Residues may need autoclaving. First aid. For chemical or biological spillages on body surfaces (exposed skin and eyes) the main aim must be to remove contaminating material as soon as possible. This is almost invariably achieved by flushing the affected area with cold tap water for up to 15 minutes. Each “wet” lab should have a hand-held emergency shower by each hand-wash basin adjacent to exit doors. (Additional advice on first aid treatment should be included in any specific risk assessment.) For heat or cold burns the same remedy applies. Cold water effectively removes heat from a heat burn or increases the temperature of a cold-burn affected area. Flood the affected part for up to 15 minutes. For needlestick injuries, encourage the wound to bleed, rinse the wound site under cold water and follow any guidance given in specific risk assessments. Minor cuts can be treated locally. Basic first aid materials (adhesive wound dressings) should be readily available. For any injury at work, if irritation persists then you should seek medical attention. If your injury cannot be controlled then you should report to your GP, the University Medical Centre (200 metres to the west of the Building 2 South), the NHS Walk-in Centre in Bath or the Accident and Emergency unit at the Royal United Hospital in Bath. For emergency help the University internal telephone number 666 should be used. University Security staff are trained first aiders. A list of departmental or building first aiders should be displayed in departments. Incident reporting mechanisms. Injuries (even minor ones) dangerous incidents, and hazards should be reported on the A4 Incident report forms, available online at http://www.bath.ac.uk/hr/stayingsafewell/accidents-emergency/docsaccidentsandemergencies/Incident_report_form_V2.docx. generic-RA-basic-lab-work-2013-v2 Page 3 Particularly vulnerable groups at risk How could they be harmed? Risk before controls implemented A B Control measures needed to minimise risk A AxB Inexperienced workers (including undergraduate students, school pupils on “work experience” schemes and visitors). By proximity, skin contact, inhalation, ingestion. 5 4 20 Supervisors must ensure all lab workers are provided with – a. Pertinent information. b. Competent instruction. c. Basic safety induction training. d. Relevant training for specialised tasks. e. Appropriate supervision. f. Suitable and sufficient risk assessments. Pregnant, or breast-feeding, women By being exposed to some chemical, biological, physical or radiological hazards. 5 3 15 Woman must inform supervisor or HR manager of her pregnancy Supervisor must perform specific risk assessment. 5 3 15 If worker is aware of a particular sensitivity they must declare this to their supervisor or HR manager. Supervisors must identify work with known sensitisers, compile a risk assessment and request HR refer workers to the OH provider. Supervisor must perform specific risk assessment. 5 3 15 Supervisor must ensure a PEEP (personal emergency evacuation plan) is provided. Volume of personal music player must not be set too loud to mask emergency alarm or verbal warnings from others in the vicinity. Persons with a history of particular medical conditions such as allergies to laboratory animals or latex gloves, respiratory disorders, those whose immune system could be impaired due to illness or medication or those with skin conditions such as eczema By exposure to some agents capable of sensitising workers or exacerbating their condition. People who might be less mobile or have a hearing or sight impediment or are listening to music with earphones (during an emergency evacuation of either building) By being isolated in a burning building and unable to escape. By not hearing warnings from other people in the vicinity. generic-RA-basic-lab-work-2013-v2 Risk after controls implemented B Page 4 AxB Hazard Fires and burns caused by the ignition of flammable reagents (including organic solvents) and other materials and by faulty electrical equipment), carries the risk of death, personal injury and severe property damage. Burns can also be received from Bunsen flames, handling hot objects (such as sterilised wire loops and materials from the autoclave) and scalds from steam and superheated liquids (as can happen when melting small volumes of agar in a microwave oven). Ultra-cold materials (liquid nitrogen and solid carbon dioxide) can cause cold burns. (Corrosive chemical burns are dealt with later under Chemicals.) Electrical apparatus carries the potential hazard of electric shock which can be fatal following contact with live components. High voltage/current apparatus (such as electrophoresis rigs) carries a particularly high risk. Who could be harmed? How could they be harmed? Worker and those nearby Work involving; flammable organic solvents. naked flames (e.g. Bunsen burners) cryogenic materials (liquid nitrogen and solid carbon dioxide - “Cardice” or “Dry-ice") using microwave ovens hot water from the taps can be up to 65oC. incorrect operation of electrical equipment Worker Using domestic equipment for laboratory purposes. Using unsafe portable electrical equipment. Use of apparatus involving high voltages (HV) or currents (e.g. electrophoresis equipment) “Live” working in workshop Tampering with electrical equipment to attempt repairs. generic-RA-basic-lab-work-2013-v2 Risk before controls implemented A A AxB Control measures needed to minimise risk 5 4 20 Ensure familiarity with fire emergency procedures (signs by fire alarm call points). Remove wastes promptly. Store flammable organic solvents only in dedicated fireretardant cabinets or in spark-free refrigerators and use Winchester carriers for carrying bottles. Segregate flammable liquids from oxidising agents, naked flames and electrical equipment. Ensure portable electrical equipment is regularly safety tested. Use a heat-resistant bench mat under gas rings when heating pressure cookers. Avoid dipping red-hot cork-borers or tweezers in alcohol. Use heat resistant gloves for handling hot or cold items. Operate all electrical equipment according to the manufacturer’s instructions. 5 3 15 Only use electrical equipment designed for the purpose. Ensure portable electrical equipment is regularly safety tested. Before use in the department new or personallyowned equipment must be submitted to the workshop technicians, as must equipment with an out-of-date test label. Check re-test dates on portable electrical equipment and do not use if date has expired. Refer the equipment to the workshop technicians for re-test. Keep water away from mains electrical sockets. Always turn off HV power packs before lifting the lid of an electrophoresis gel box or disconnecting the cables. Only competent workshop personnel should attempt repairs to electrical equipment. Risk after controls implemented A B AxB Page 5 Hazard Chemicals. Depending on the specific compound these have the potential to poison (toxics, including carcinogens, teratogens and mutagens), burn (corrosive), irritate, produce allergenic reactions, explode, ignite or asphyxiate. They can affect us by inhalation, skin contact and ingestion. Biological agents may have the potential to cause disease (pathogenic micro-organisms and possibly prions) by inhalation, ingestion or contact with wounds and mucous membranes, physical damage (animal bites and scratches) and allergies (by physical contact and inhaling allergenic dusts). Who could be harmed? How could they be harmed? Risk before controls implemented A A AxB Worker and those in vicinity Not clearing up spillages. Releases of hazardous gases, aerosols, volatile liquids or dusty solids. Working in poorly ventilated areas. Using thin disposable gloves. 5 3 15 Worker and those in vicinity, and those in contact with them Potential routes of exposure are via breathing in an aerosol, ingestion puncture wounds, contaminated dust or aerosols contacting mucous membranes. 4 3 12 generic-RA-basic-lab-work-2013-v2 Control measures needed to minimise risk Risk after controls implemented A B AxB Clear up all chemical spillages as soon as possible. Ensure pertinent hazard data is known. Certain hazardous chemicals cannot be used without Home Office notification or DEFRA approval. Ensure appropriate storage, use, disposal and emergency procedures are in place before commencing work. (Basic details for dealing with emergency spills and first-aid should be included in specific risk assessments.) Clear up spillages as soon as they happen. Work involving airborne releases should be done in a fume containment facility. Wear appropriate disposable gloves with hazardous chemicals. Avoid contact with latex gloves if you have developed a sensitivity to latex. Refer to policy for chemical work on the UHS&E website. Refer to the generic risk assessment for chemical work on the 1st Stop for Health & Safety wiki. Clear up all spillages of biological agents as soon as possible. Register GM projects and personnel with the GM Safety Committee (email gm@lists.bath.ac.uk). Categorise the infection hazard (Hazard Group 1 to 4). Minimise the production of aerosols and contain any that are produced in a microbiological safety cabinet. Working areas should be swabbed with appropriate decontaminant solution. Workers exposed to animal allergens are required to enrol on the health surveillance programme. Certain pathogenic micro-organisms cannot be used without Home Office notification or DEFRA approval. Refer to policy for biological agents on the UHS&E website. Refer to the generic risk assessment for biologocal work on the 1st Stop for Health & Safety wiki. Page 6 Hazard Non-ionising radiation sources (such as ultraviolet lamps and microwave ovens) have the potential to damage tissues (particularly the eyes with UV) if exposed. Lasers can permanently damage the eyes. Ultrasonic sound can damage hearing. Ionising radiations (produced by radioactive substances and X-ray generators) are potentially hazardous sources of energy that can effect chemical changes in biological molecules resulting in cell and tissue damage. It is assumed that there is a linear relationship between dose and damage implying there is no safe level of exposure. Who could be harmed? Worker and those in vicinity Worker and those in vicinity generic-RA-basic-lab-work-2013-v2 How could they be harmed? Use of ultraviolet lamps for microscopy, shortwave (UVC in the range 100nm to 280nm) lamps in clean rooms and biological safety cabinets, for mutating micro-organisms and for visualising bands on electrophoresis gels. Use of microwave ovens for heating aqueous liquids and melting small volumes of solidified agar. Using laser pointers or laser confocal microscopes. Using ultrasonic disintegrators. Use of radioactive “tracers” in experimental methods. Spillages/releases or improper disposals of unsealed materials. Use of X-ray crystallography apparatus. Use of unshielded sealed sources. Risk before controls implemented A A AxB Control measures needed to minimise risk 4 3 12 Ensure UV shield is in place on UV microscopes. Do not tamper with confocal microscopes. Replace UV “sterilising” lamps with manual decontamination and cleaning measures. Wear polycarbonate safety spectacles or face shields when unshielded short-wave UV has to be used. Regularly test microwave oven door seals for radiation leakage. Wear hearing protection when using ultrasonics. Refer to non-ionising radiation policy on UHS&E website. 5 3 15 People who need to use ionising radiation must be registered with the University by completing a Registration form and submitting it. Read and follow the relevant Local Rules for the particular source. Use unsealed sources on containment trays Wear disposable gloves with unsealed sources. Use appropriate shielding. Segregate high-energy (P-32, I-125 and S-35) waste. Record use and disposal of unsealed radioactive sources. Record use of X-ray machines. Refer to policy for ionising radiation on the UHS&E website. Refer to the generic risk assessment for ionising radiation work on the 1st Stop for Health & Safety wiki. Risk after controls implemented A B AxB Page 7 Hazard Excessively loud noise can lead to hearing loss and tinnitus. Wearing earphones can make emergency alarms and instructions inaudible. Sharps, such as hypodermic needles, blades (scalpel, razor and microtome) and shards of broken glass, can cause severe physical injuries. If contaminated with a biological, chemical or radiochemical entity then the contaminant can pass directly into the body. High pressures in gaseous and in liquid systems and vacuums can cause problems when components fail. The resultant release of energy can project solids (such as broken glass) or liquids at high velocity. Asphyxiant gases can deplete the oxygen in the air we breathe. When liquid nitrogen (LN) and solid carbon dioxide (Cardice or Dry-ice) warm up they produce large volumes of odourless gas which can accumulate, particularly in confined spaces (such as cold-rooms, other unventilated work rooms or lifts). Who could be harmed? How could they be harmed? Worker. Workshop machinery. Ultrasonic disintegrators (sonicators) can affect others in the vicinity. Worker, porters, lab support staff Resheathing hypodermic needles. Improper disposal of needles, blades and glass. Working in histology. Removing caps from glass containers. Worker and those in vicinity. Using gases from compressed gas cylinders. HPLC and Biolistic systems. Filter sterilising. Vacuum resin columns. Worker and those in vicinity, and those trying to rescue them Storing or transporting LN or solid carbon dioxide (CO2) in a confined space. Releasing large volumes of any asphyxiant gas from a compressed gas cylinder. generic-RA-basic-lab-work-2013-v2 Risk before controls implemented A A AxB Control measures needed to minimise risk 3 3 9 Reduce noise at source where possible (acoustic dampers). Ear defenders may be required. Put warning signs on lab doors when using a sonicator. Don’t use very loud volumes on personal music players. 4 4 16 Avoid resheathing needles particularly if contaminated with hazardous materials. Promptly dispose of used hypodermic needles, blades and broken glass in the appropriate designated containers (Sharpsbins). Take care with microtome and razor blades and when removing caps from glass containers. Do not use dangerously-damaged glassware 4 3 12 Shield areas where a sudden release of a vacuum or liquid under pressure could project materials likely to damage people or equipment. Wear safety spectacles or face visor. 5 3 15 The storage and use of LN and solid CO2 (Cardice or Dryice) is prohibited in cold rooms. Ensure LN is stored and transported only in a cryo-container with a loose-fitting lid (e.g. Dewar flask) or a pressure relief valve, and are only used in well ventilated areas. Pressurised LN containers must not be accompanied when being transported in a lift. Confined spaces are appropriately marked, and working with hazardous materials in them must be subject to a Specific risk assessment. Risk after controls implemented A B AxB Page 8 Hazard Machinery. Domestic machines (such as blenders and microwave ovens) can be hazardous when used for a purpose for which they were not designed. Workshop machinery can kill or severely maim people. Trips, slips, falls and manual handling accidents can lead to severe injuries in work areas where there may be inappropriate (such as high-level) storage of materials, wet floors (due to spillages or in aquariums), trailing cables or a build-up of waste materials. Repetitive movements or poor posture can lead to upper limb disorders in particular. Occupational stress. Excessive pressure can lead to stress, which undermines performance, is costly to employers and can make people ill. Who could be harmed? How could they be harmed? Risk before controls implemented A A AxB Control measures needed to minimise risk 4 3 12 The use of flammable organic solvents is prohibited in domestic blenders. Refer to warning and information signs on microwave ovens. Only authorised workshop personnel are permitted to operate workshop equipment. Worker and those in vicinity. Domestic blenders. Domestic microwave ovens. Workshop machinery. Worker. Aquarium floors. Liquid spillages on floors. Handling materials on shelves above head height. Lifting, or moving, heavy containers (of water, material for autoclaving or liquid nitrogen). 4 3 12 Mop up liquid spillages on floors as soon as practicable. Ensure that adequate material storage areas are provided. Use “Kiksteps” and not swivel chairs for standing on to reach items stored on high shelves. Implement manual handling training for those at risk. Staff Development offer training courses. Remove waste materials promptly. Worker. Work performed by users of display screen equipment DSE (such as computers). Repetitive manual pipetting. 3 3 9 Identify “users” of DSE. Assess all computer workstations. Use powered pipettors for intensive pipetting sessions. Worker excessive demands of the job little control over your work lack of support received from managers and colleagues your relationships at work lack of understanding of your role in the organisation changes in your work and how it’s managed stress emanating from outside work. 4 3 12 Systems and procedures must be in place for dealing with issues like absence and discipline. Managers should be familiar with advice provided on the HR website to help improve their understanding of stress and to take it seriously. They should talk regularly with those they supervise. Refer to the University’s Stress Management information. generic-RA-basic-lab-work-2013-v2 Risk after controls implemented A B AxB Page 9 Action Plan for additional control measures needed. Do any stated control measures need to be implemented before this activity can take place? Action Plan in respect of actions: Ref no. Prepared by: Action to be taken, including cost By whom Target date Responsible manager’s signature: Print name: Review date Outcome at review date Responsible manager’s signature: Date: Print name: Date: Assessment must be reviewed annually by responsible manager. generic-RA-basic-lab-work-2013-v2 Page 10