report - sigi.ca

advertisement

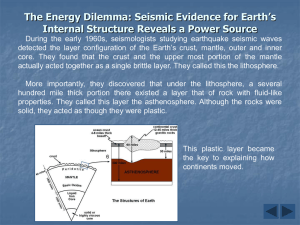

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

BROOK ROBAZZA AND SHILIN SUN

desired to have an open space uninterrupted by brace bays or walls.

This SFRS was the favoured seismic system in the USA prior to

the 1994 Northridge Earthquake [10]. This seismic event exposed

that the welded beam-to-column connections in these frames were

often the weak links in the seismic systems. It is therefore of

significant importance to continue the extensive study which has

already been performed on moment resisting connections for

seismic applications.

Abstract

A chain is only as strong as its weakest link. For structural design,

it can be restated as “a structure is as strong as its weakest

connection [7].” In other words, connection design is crucial to the

entire structural design. One of the specific structural design issues

is the behaviour of connections during earthquakes where ductile

response is expected from seismic force-resisting systems (SFRS).

Since steel is known as a ductile material with a high strength-toweight ratio, it is a desirable material to be used in earthquake

design as a means of reducing the damage to the structure. Steel

moment resisting connections have been proven to have excellent

performance as a part of seismic force-resisting systems [1]. Steel

moment frames which make extensive use of these connections

and are often used as the SFRS for many structures where it is

UNIVERSITY OF BRITISH COLUMBIA

Table of Contents

Abstract ........................................................................................... 1

Table of Contents ............................................................................ 1

List of Figures ................................................................................. 2

1.0 Introduction ............................................................................... 3

1.1 Bolting and Bolted Connections ........................................... 3

1.2 Welding and Welded Connection ......................................... 4

2.0 Steel Design for Seismic Applications ..................................... 5

2.1 Post-Northridge Earthquake Construction ............................ 6

2.1.1 Member Size of Connections ......................................... 6

2.1.2 Inelastic Behavior of Connections ................................. 6

2.1.3 Weld Procedure .............................................................. 6

2/6/2016

PAGE 1 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

2.1.4 Shear Yielding of the Panel Zones................................. 6

2.1.5 Yield Stress of Structural Material ................................ 7

2.1.6 Stress Concentrations ..................................................... 7

2.1.7 After Northridge Earthquake Construction .................... 7

3.0 Objectives ................................................................................. 7

4.0 Plastic Design............................................................................ 8

4.1 Plastic Analysis ..................................................................... 8

4.2 Plastic Hinges........................................................................ 9

4.3 Prequalified Sections ............................................................ 9

4.4 Plastic Hinge Moment Calculation ..................................... 10

5.0 Investigated Moment Resisting Connections.......................... 11

5.1 Bolted Unstiffened End Plate Connection .......................... 11

5.2 Bolted Stiffened End Plate Connection .............................. 12

5.3 Reduced Beam Section Connection .................................... 13

6.0 Moment Resisting Connection Design ................................... 14

6.1 Canadian Code Governing Moment Connections for Seismic

Applications .............................................................................. 14

6.2 Design Procedure ................................................................ 14

6.2.1 Bolted Unstiffened End Plate Connection ....................... 15

6.2.1.1Bolt Diameter ............................................................. 15

6.2.1.2 End Plate Thickness .................................................. 16

6.2.1.3 Column Flange Thickness......................................... 16

6.2.1.4 Column Web Thickness ............................................ 17

6.2.1.5 Panel Zone Thickness ............................................... 17

6.2.1.6 Continuity Plates ....................................................... 18

6.2.1.7 Welded Joints ............................................................ 18

6.2.1.8 Bolted Unstiffened End Plate Connection – Summary

of Requirements and Limitations .......................................... 18

6.2.2 Bolted Stiffened End Plate Connection ........................... 19

6.2.2.1 Bolt Diameter ............................................................ 19

6.2.2.2 End Plate Thickness .................................................. 19

6.2.2.3 Column Flange Thickness......................................... 20

6.2.2.4 Column Web Thickness ............................................ 20

UNIVERSITY OF BRITISH COLUMBIA

BROOK ROBAZZA AND SHILIN SUN

6.2.2.5 Panel Zone Thickness ............................................... 20

6.2.2.6 Continuity Plates ....................................................... 21

6.2.2.7 Welded Joints ............................................................ 21

6.2.2.8 Bolted Stiffened End Plate Connection – Summary of

Requirements and Limitations .............................................. 21

6.2.3 Reduced Beam Section .................................................... 21

6.2.3.1 Flange Reduction Specifications............................... 21

6.2.3.2 Check Reduced Section Resistance to Applied Loads

............................................................................................... 21

6.2.3.3 Connection Shear ...................................................... 22

6.2.3.4 Panel Zone Thickness ............................................... 22

6.2.3.5 Continuity Plates ....................................................... 22

6.2.3.6 Weld Joint Details ..................................................... 22

6.2.3.7 Weld Access Holes ................................................... 22

6.2.3.8 Backing Bars ............................................................. 22

6.2.3.9 Welding Sequence for Bottom Beam Flange............ 23

6.2.4.0 Reduced Beam Section Connection – Summary of

Requirements and Limitations .............................................. 23

7.0 Changes between S16-09 and S16-01(R05) affecting

Connection Design ........................................................................ 23

8.0 Conclusion .............................................................................. 23

9.0 References ............................................................................... 24

10.0 Appendices ............................................................................ 23

List of Figures

Figure 1 Rivet Heading Procedure .................................................. 3

Figure 2 Anchor Bolts in Moment Connection............................... 4

Figure 3 Connection with Cover Plate ............................................ 7

Figure 4 Plastic Hinge Example [12] .............................................. 9

Figure 5 Plastic Hinge Location for an RBS Connection [20] ..... 10

Figure 6 Geometry of Bolted Unstiffened End Plate Connection [2]

............................................................................................... 12

Figure 7 Bolted Unstiffened End Plate Connection [10] .............. 12

2/6/2016

PAGE 2 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

Figure 8 Geometry of a Bolted Stiffened End Plate Connection [2]

............................................................................................... 13

Figure 9 Bolted Stiffened End Plate Connection Example [13] ... 13

Figure 10 Geometry of Reduced Beam Section Connection [2] .. 13

Figure 11 Reduced Beam Section Example [10] .......................... 14

Figure 12 Critical Section Calculation Diagram ........................... 15

1.0 Introduction

Steel connections are constituted by individual steel structural

members. These members are usually connected by three types of

fasteners or connectors which are rivets, bolts or welds. The

structural members can be connected or assembled either in steel

shops or in the field at construction sites. Prior to the 1950s’, rivets

were used as standard fasteners for all types of steel structures, but

have gradually become obsolete because of the tedious procedure

to form rivet heads (Figure 1). To complete a rivet joint, the second

rivet head must be formed by either hammering or using a

hydraulic press which is a messy, noisy and hazardous process [7].

Figure 1 Rivet Heading Procedure

UNIVERSITY OF BRITISH COLUMBIA

BROOK ROBAZZA AND SHILIN SUN

1.1 Bolting and Bolted Connections

Bolts and welds are now used as standard connectors in fabricating

modern steel structures [7]. Bolting is the procedure to connect

steel pieces by mechanical means [16]. Compared to welded

connections, bolted connections are relatively easy to make and

inspect. Connection strength depends on the bolt types and the

connected steel pieces for bolts installed without pretension [16].

The bolt types are either common (ASTM Standard A307) or highstrength (ASTM Standards A325 and A490) bolts [16]. A307 Bolts

are manufactured based on the American Society for Testing and

Materials (ASTM) Specification A307, from low-carbon steel with

a minimum ultimate tensile strength of 415 MPa. This type of bolt

is usually square-head and used for minor connections. In most

bolted connection applications, high-strength bolts are used, which

are designated as A325 or A490 bolts. The A325 bolts are made

from carbon steel with a minimum tensile strength of 830 MPa,

according to the ASTM A325 specification, and then subjected to

heat treatment. The A490 bolts are made according to ASTM

A490 and are composed of high-strength alloy steel, with a

minimum tensile strength of 1040 MPa and are also heat-treated.

Both of these types of bolts are specified with their nominal

diameter in millimeters and the steel type used in their

manufacture. For example, M22 A325M stands for a 22 mm

diameter bolt made according to the specifications of ASTM A325.

The commonly used A325 bolt sizes are M16, M20, M22, M24,

M27, M30 and M36. A490 bolts are used in a connection with

heavier loads to reduce the number of fastener needed [7].

The bolted connections can be classified based on the types of

resultant force transferred. These connection types are concentric

connections (force transfer in tension and compression member),

eccentric connections (in reaction transferring brackets) and

moment resisting connections (in beam to column connections in

2/6/2016

PAGE 3 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

frames) [9]. The moment resisting connections are more complex

to analyze than the first two types of bolted connections. This is

due to the fact that they involve moment transferred from the beam

to the column in moment resisting frames. When a connection is

designed to transfer moment from the beam to the column, the

connection is formed by connecting the flanges of the beam to the

column where the moment is transferred by the pair of tension and

compression forces in the top and bottom flange of the beam.

Meanwhile, shear force is usually transferred through moment

connections when the web of the beam is also connected to the

column. In general, this type of connection is used to connect beam

and column by the method of anchor bolts (See Figure 2). The

bolts in the connection are subjected to a combination of shear and

axial tension [9].

Figure 2 Anchor Bolts in Moment Connection

1.2 Welding and Welded Connection

Welding is a process of joining steel or metal parts by fusing or

melting them together at a joint to produce a continuous member.

UNIVERSITY OF BRITISH COLUMBIA

BROOK ROBAZZA AND SHILIN SUN

The steel members are usually referred to as base metal and the

material “fusing” them together is referred to as weld metal or the

filler. Some welding processes have been developed since it was

first used. The oldest welding method is believed to be forge

welding where blacksmiths joined iron and steel by heating and

hammering them [22]. It was the only welding method until the

end of the 19th century. Arc welding, oxyfuel welding and

resistance welding were developed late in the 20th century [23].

After Second World War, modern welding techniques were

developed to meet the demand for a reliable, fast and inexpensive

joining method [23]. The most popular one is the shielded metal

arc welding technique (SMAW) which uses shielding gas and

welding electrode (filler) [22]. It is used to make groove or butt

welds as well as fillet welds. Other similar welding techniques

include gas metal arc welding, submerged arc welding, flux-cored

arc welding, and electroslag welding. Later development include

laser beam welding, electron beam welding and robot welding. In

steel structural practice, 80% of the welded joints made are fillet

welds and only 15% are groove welds. Fillet welds are used to join

pieces in various positions such as tee (90°), skewed and lap joints.

Fillet welds are a partial penetration weld type which has fusion

through part of the thickness of the joining pieces. Groove welds

can be partial or full penetration welds. Full penetration groove

welds are required in the more important welding joints in moment

beam-column connections [8].

Compared to bolted connections, welded connections have many

advantages. Through the process of welding, a strong metallurgical

bond is created between two steel members so that they can form a

continuous and load bearing joint which enables direct transfer of

stress between members. The strength of welded connections

depends on the weldability of the base metal, the strength of the

weld metal and the process of welding [16].

2/6/2016

PAGE 4 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

It also eliminates gusset and splice plates necessary for bolted

structures [9]. Without bolts and braces, the weight of the

connections can be simply minimized [9]. The absence of holes in

tension members improves the efficiency of the section.

Meanwhile, the cost of fabrication is less than bolted connections,

since the operations such as drilling and punching can be

eliminated. Due to the continuity of welded connections, stress

concentration effects are seldom discovered in welded connections.

Welded connections also have neat appearances even with

complicated shapes of structural members [7].

The disadvantages of welding are that it requires skilled welders as

well as inspectors [9]. Non-destructive inspections such as

magnetic particle, ultrasonic or radiographic methods, may be

carried out after welding to detect defects in welds in case the

cracks propagate from the defects under fatigue loading [9]. Field

welding may be problematic due to the location or environment

[9]. Large residual stresses may be increased by the distortion

developed in welded connections [16]. Therefore, it is important to

produce high quality welds with proper profiles, good penetration,

complete contact with base metal at all surfaces, no cracks,

porosity or inclusion [9]. However, the methods of connecting

steel structural members highly depend on the loads applied to the

structures and how to successfully achieve the design goals.

2.0 Steel Design for Seismic Applications

An earthquake is a sudden tremor or movement of the earth’s crust

that can cause the ground to shake. A violent earthquake can

trigger landslides, floods and cracks in the land. These can then

lead to large-scale destruction to life and property [6]. The most

basic property of earthquakes however is the ground accelerations

UNIVERSITY OF BRITISH COLUMBIA

BROOK ROBAZZA AND SHILIN SUN

imposed to masses on the surface of the crust. Buildings are prime

examples of these masses. As a result, structural designers and

engineers have been making efforts to improve earthquake

resistant structural design and to design structures that can

withstand earthquakes with no or minimum damage in most cases

[6]. It is difficult to design for earthquake loads, since they are

unpredictable with their amplitude, duration and frequency [6].

Buildings codes therefore present response spectrums and other

guidelines to analysis to provide a better approximation of these

seismic loads. Structures are primarily designed to carry vertical

loads, and therefore are prone to poor lateral load performance if

they are not designed for it. However, it is generally not

economically acceptable to design buildings to remain elastic in

regions where strong ground motions are anticipated. In these

regions, inelastic deformations must be accommodated as a means

of reducing the seismic demand during a moderate to high seismic

event. Therefore, the common seismic resistant design goal is

specified as “to ensure elastic behaviour under a moderate

earthquake which has a return period equal to the life of the

structure and prevent collapse under the extreme probable

earthquake” [6]. In other words, the designed structures can remain

elastic under moderate seismic events and experience damage, but

do not collapse, under severe seismic events.

Since steel is well known as a ductile material, and is strong under

compression and tension, it is widely used as an SFRS to resist

load reversals induced by cyclic motions under earthquake loading

[6]. However, the Northridge earthquake in 1994 was the starting

point where failure was discovered in the critical beam-to-column

connections. One year later, in the earthquake of Kobe, the beamto-column connections suffered severe damage and 10% of these

structures collapsed [1]. The failure of the beam-to-column

connections is because they prevented the formation of energy-

2/6/2016

PAGE 5 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

BROOK ROBAZZA AND SHILIN SUN

dissipating plastic hinges and failed in a brittle manner. Following

the earthquakes in Northridge and in Kobe, the extensive damage

which occurred in many steel structures initiated intensive research

and testing undertaken by the Federal Emergency Management

Agency (FEMA) and a number of universities to produce better

seismic resistant steel frame design and construction [10]. A

number of improved beam-to-column connection design strategies

have been developed with the purpose of providing adequate

ductility response to seismic motion to prevent failure and collapse

[5]. From the research emerged an overall concept to avoid

damage to the columns of the structure. Therefore central to this

philosophy of considering the effect of yielding members on the

column is to prevent strong beam-weak column behaviour and

weak stories [10]. Weak story collapse is one of the most

undesirable failure mechanisms as it destabilizes the entire

structure above. It is thus essential to design efficient connections

so that ductile energy-dissipating plastic hinges can form at desired

locations to maintain continuity in force flow path and avoid

structural collapse [15].

However, the buildings damaged in the Northridge earthquake

employed W30 or larger beams connected to heavy W14 columns.

Therefore the initial testing was not representative of actual

practice. It appears that size plays a significant role in the behavior

of WSMF connections and that details that behave well for

connections using small sections do not necessarily behave as well

for larger sections.

2.1 Post-Northridge Earthquake Construction

2.1.3 Weld Procedure

An investigation conducted by FEMA addressed the factors which

contributed to the poor performance of Welded Steel MomentFrame (WSMF) buildings during the 1994 Northridge Earthquake.

The following sections examine the discoveries and notes

presented in FEMA 351 and FEMA 355.

Weld metal used to erect the previously used WSMF is low-notchtoughness weld metal which means it develops unstable brittle

fractures under high stress and strain demands. Meanwhile,

welding practice in many of the damaged structures was found to

be sub-standard such as inadequate fusion, failure to remove weld

backing. Compounding these factors led to many dangerous weld

connections and frequently resulted in brittle failure.

2.1.1 Member Size of Connections

Prior to the Northridge Earthquake, it was common that large

framing members were used even in relatively small buildings. The

initial testing of WSMF connections was conducted in the 1960s

and 1970s. All tested assemblies employed small-sized elements

which are W18 beams and light W12 and W14 column sections.

UNIVERSITY OF BRITISH COLUMBIA

2.1.2 Inelastic Behavior of Connections

Common steel design practice is to overdesign the connections so

the inelastic behavior occurs within the structural members.

However, typical detailing practice prior to the Northridge

earthquake relied on the large inelastic behavior occurring in the

beam-column connections, but the strength of ductility of any

connection is highly dependent on the quality of the workmanship

employed. Meanwhile, every process of making a connection such

as cutting, welding, and bolting, affects the behaviour of the

connection. Therefore, the probability of failure is very high in real

structures utilizing many moment resisting connections.

2.1.4 Shear Yielding of the Panel Zones

In the 1980s, some engineers believed that shear yielding of the

panel zones in a beam-column connection instead of flexural

hinging of the beam, was a more benign and desirable way to

2/6/2016

PAGE 6 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

accommodate frame inelastic behavior. As a result, the building

code allowed weak panel zones in steel frames. However,

excessive yielding actually produces large secondary stresses at the

beam-flange-to-column-flange joint, which can exacerbate the

initiation of fractures [20].

2.1.5 Yield Stress of Structural Material

Between the 1980s and 1990s, new steel mills were replacing old

mills in the United States. The new mills used scrap-based steel

production which tends to produce steel with higher-strength.

However, since the steel is stronger than the strength defined in the

code, the designers designed the weak beams with the code

strength instead of the real strength. Therefore the sections do not

yield at expected stress levels. This leads to miscalculation of the

yield moment. It also thus caused the desired location of the plastic

hinge to be less predictable.

BROOK ROBAZZA AND SHILIN SUN

connection from the code. FEMA suggests each connection design

should be qualified by a program of prototype laboratory testing.

Between 1994 and 1996, the University of Texas discovered that

cover plate (See Figure 3) on the connections can encourage the

plastic behaviour to be within the beam elements. As a result,

cover plates were widely used during this period. In 1995, FEMA

267 published defined rating criteria for weld metal and standards

of design and fabrication of moment connections. Meanwhile,

FEMA then used these studies to test and certify different moment

connections including haunched connections, reduced-beamsection connections, vertical rib plate connections, side plate

connections and slotted web connections.

2.1.6 Stress Concentrations

Steel moment connections in moment frames usually experience

stress concentrations. In the design calculations of connection

capacity, it was presumed stresses were uniformly distributed

across beam flanges and the flexural stresses are carried primarily

by the flanges while shear stresses are carried primarily by the

web. However, it is common that the flange also carries significant

local bending and shear stress and the stresses are not uniformly

distributed within flange elements, which leads to cracking of

welds and initiates brittle fractures of weld metal. These brittle

fractures cause failure of the joint as well as fractures spreading

into the column.

2.1.7 After Northridge Earthquake Construction

After the 1994 Northridge earthquake, FEMA removed the

prequalified status of typical bolted-web welded-flange moment

UNIVERSITY OF BRITISH COLUMBIA

Figure 3 Connection with Cover Plate

3.0 Objectives

Some types of rigid connections have been prequalified by FEMA

for seismic applications [1]. The scope of this paper is to

investigate three types of moment resisting connections for seismic

applications by providing detailed design drawings, calculations

2/6/2016

PAGE 7 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

and design procedures. A formatted spreadsheet as well is provided

for the design of practical examples from existing buildings. This

spreadsheet may be used to check not only the adequacy of a given

end plate, but also determines how much it is over or under

designed.

4.0 Plastic Design

Since it is economically impractical to design structures to resist all

seismic loads elastically, it is essential that plastic design be

utilized. This of course means that structures are designed to

undergo deformation and damage during large seismic events. The

main design philosophy of most building codes is thus intended to

protect for life safety by avoiding earthquake-induced collapse in

severe events, while permitting large amounts of structural and

nonstructural damage [12].

4.1 Plastic Analysis

Plastic deformation occurs after the specimen has been loaded past

its yield strength. As the specimen is loaded beyond its elastic

limit, the stress remains constant while the strain increases [17].

For structural members, when the moment capacity is exceeded by

the moment demand, a plastic hinge is formed which causes this

section of the member to rotate at the plastic moment capacity.

Plastic analysis is based on determining the maximum load that a

structure can withstand before the structure collapses. The final

collapse occurs when sufficient plastic hinging has occurred to

convert the structure into a mechanism [17].

In determining the collapse mechanism and the required plastic

moment diagram, there are a number of methods which may be

employed. The mechanism or the virtual work method is the

method to be studied here. This method incorporates a design

UNIVERSITY OF BRITISH COLUMBIA

BROOK ROBAZZA AND SHILIN SUN

procedure requiring the determination of the largest plastic

moment caused by a number of investigated failure mechanisms

[18]. This is because the method is a generalized one which is

based on upper bound theory of plastic design. This states that the

load corresponding to the assumed method of collapse must be

greater than or equal to the collapse load by definition. Therefore

the largest plastic moment calculated is associated with the

governing failure mechanism. The following is the procedural

steps for this method [18]:

Step 1: Assume a specific collapse mechanism.

Step 2: Calculate the amount of internal virtual work which is

defined as the sum of all the products of the plastic

moments and their corresponding internal virtual angle

changes. The internal virtual angle changes are computed

by designating any one angle as θ and calculating all

others in terms of θ and the geometry of the frame.

Step 3: Calculate the amount of external virtual work which is

defined as the sum of all the external loads times the

virtual distance through which they move at the collapse

mechanism. This distance is calculated by recognizing

that it is the product of the angle θ and the distance from

the angle change to the load.

Step 4: Equate external to internal work. The angle θ cancels out

and Mp can be solved for in terms of the loads and the

dimensions of the frame.

Step 5: Sufficient collapse mechanisms are tried so that the

designer is satisfied that the one with the largest Mp has

been found. This is done by drawing the plastic moment

2/6/2016

PAGE 8 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

diagram for each trial mechanism to see that there are no

moments larger than the plastic moment

Figure 4 Plastic Hinge Example [12]

4.2 Plastic Hinges

Steel moment frames, when properly designed, are a perfect

example of what the building codes desire in terms of seismic

performance. By utilizing moment resisting connections, moment

frames are intended to experience inelastic behaviour

accommodated through the formation of plastic hinges at beamcolumn joints and column bases. These locations are ideal for the

structure in that they prevent undesirable failure mechanisms. It is

a basic principle of plastic design to prevent undesirable

mechanisms by forcing more desirable failure mechanisms to fail

first. This is essentially providing a “fuse” for the structure. Plastic

hinges provide this fuse. Plastic hinges allow for rotation which

can only occur when the bending moment reaches the plastic

moment capacity. The area around the section of maximum

bending moment is a region of localized plastic deformations form

in which the curvature is much larger than elsewhere [17].

UNIVERSITY OF BRITISH COLUMBIA

BROOK ROBAZZA AND SHILIN SUN

Plastic hinges form through flexural yielding of beams and

columns and shear yielding in the panel zones [12]. A plastic hinge

usually forms due to large cyclic plastic deformations imposed to

the steel section and results in local buckling (See Figure 3).

Severe local buckling causes strength loss and is the reason that

plastic hinges are preferred to occur in the beam rather than the

column. Yielding of the columns is normally discouraged or

prohibited for the reason that frame systems built with weakcolumn behaviour are known to have significantly larger inelastic

story drifts and local ductility demands than comparable frames

with yielding in the beams [19]. An alternative to having a plastic

hinge form in the beam is to have it form in the panel zone.

Research has found that there is high ductility in the panel zone but

high shear stress in the panel zone and high stresses in the column

flanges is found to possibly direct cracks that initiate at the welded

joint into the column [19]. Therefore, panel zone yielding can be

relied upon to provide plastic rotational capacity for seismic

resistant design, but total reliance on this ductility is generally in

appropriate [19]. The state of stress in the panel zone is also

extremely complex and deformations must be divided into axial,

flexural, and shear [21]. Excessive yielding actually produces large

secondary stresses at the beam-flange-to-column-flange joint and

exacerbates the initiation of fractures [19]. These factors all

contribute to the conclusion that flexural yielding is best

accommodated in the beams of the structure.

4.3 Prequalified Sections

Some moment resisting connections are prequalified by the AISC

to help reduce difficulties arising from the qualification process

which requires extensive full-scale testing [12]. All of the

connections investigated in this report are of this prequalified

variety. These connections have exhibited adequate performance

2/6/2016

PAGE 9 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

BROOK ROBAZZA AND SHILIN SUN

reinforcement, and other connection conditions.

Calculated as:

𝐹𝑦 + 𝐹𝑢

𝐶𝑝𝑟 =

𝐹𝑦

based on extensive testing and from review by an expert review

panel. Therefore, for these connections a set of design procedures

have been developed such that adequate plastic design is utilized.

The plastic hinges locations for these prequalified connections are

valid for beams with gravity loads representing a small portion of

the total flexural demand and for conditions of strong columnweak beam behaviour. For frames in which gravity loading

produces significant flexural stresses in the members, or frames

that do not have strong-column, weak-beam configurations,

locations of the plastic hinge formation should be determined

based on a method of plastic analysis such as the mechanism or the

virtual work method described earlier in Section 4.1.

A value of 1.2 may be used for all cases, except

where otherwise noted in the individual

connection design procedure provided for

prequalified sections

RyFy = expected yield stress of the beam sections

as defined in Clause 27.1.7 of S16-01

Ry = 1.1 according to Clause 27.1.7 and RyFy need

not be less than 460 MPa for HSS section or 385

MPa for other sections.

Ze = the effective plastic modulus of the beam

section at the location of the plastic hinge. For

Bolted End Plate Connections, Ze = the plastic

modulus of the unreduced beam section, Zb

4.4 Plastic Hinge Moment Calculation

FEMA 351 gives a detailed analysis of how to calculate the plastic

hinge moment as well as the plastic hinge location, where this

moment is attained. The analysis was based on data collected from

tests on the prequalified connections. A similar, slightly modified

analysis for calculating the probable plastic hinge moment is

stipulated by CISC and presented below. The plastic hinge location

for each connection is provided in Section 6. See Figure 4 for a

diagram indicating the plastic hinge location.

For fully restrained connections designed to develop plastic

hinging in the beam or girder, the probabilistic plastic moment at

the location of the plastic hinge should be determined as:

𝑀𝑝𝑟 = 𝐶𝑝𝑟 𝑅𝑦 𝑍𝑒 𝐹𝑦

where:

Mpr = probable peak plastic hinge moment

Cpr = a factor to account for the effects of strain

hardening, local restraint, additional

UNIVERSITY OF BRITISH COLUMBIA

Figure 5 Plastic Hinge Location for an RBS Connection [20]

2/6/2016

PAGE 10 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

5.0 Investigated Moment Resisting

Connections

In order to provide a highly ductile response and reliable

performance for beam-to-column connections, two key concepts

were developed: strengthening the connection or weakening the

beam framing into the connection or both [5]. These concepts are

recognize the fact that a strong column-weak beam configuration is

difficult to design due to large column size requirements since

beams in typical moment frame buildings will be deeper than 350

mm to support dead and live loads alone [10]. Large columns with

moment capacity exceeding that of the beams will usually result in

thick column flanges which are prone to welding problems [10]. In

addition, columns with depths greater than 350 mm present

problems when attempting to accommodate Canadian drift

limitations [10]. For these reasons, the given two concepts are

employed.

Reinforcing the connection is designed to provide a beam-tocolumn connection which is stronger than the beam section. By

providing this strong connection, the plastic hinge is forced away

from the face of the column. This causes large stresses and

inelastic strains to be developed in the beam with enough distance

from the column to prevent unacceptable stress and strain levels

arising in the column. This method of beam-to-column connection

is exhibited in the below Bolted Unstiffened End Plate and Bolted

Stiffened End Plate connections.

Weakening the beam framing into the connection is an alternative

method which provides similar benefits to reinforcing connections.

The idea of weakening relies on the fact that portions of the beam

flange are trimmed away in a region adjacent to the beam-to-

UNIVERSITY OF BRITISH COLUMBIA

BROOK ROBAZZA AND SHILIN SUN

column connection [5]. This method produces a “ductile fuse”

which forces yielding to occur within the reduced section of the

beam where large inelastic strains can be sustained [5]. By

providing this measure, limited stress and strain is developed near

or at the column. This beam-to-column method is best described

by the Reduced Beam Section connection.

Each connection type has its respective advantages and

disadvantages. Bolted End Plate connections aid in reducing the

drift in moment frames but also increase the cost, and with large

bolted end plate connections, can result in very large welds and

higher degrees of restraint [5]. Reduced Beam Section connections

often have a lower cost than Bolted End Plate connections but also

have increased the elastic drift due to the reduction in beam

stiffness [1]. As always when considering cost however, one must

also consider a number of factors varying from craftsmen wages

and geographical location to weather climate.

The following connections are believed to cover most practical

applications in Canada according to the Canadian Institute of Steel

Construction [1]. The first two connections represent the design

philosophy of reinforcing the connection while the last connection

investigated represents the design philosophy of weakening the

beam. All of these connections are prequalified and each has a

corresponding appendix in the report provided by CISC which

outlines a summary of the requirements and limitations stipulated

by the CISC

5.1 Bolted Unstiffened End Plate Connection

The Bolted Unstiffened End Plate (BUEP) connection utilizes an

extended end plate and is a common form of field-bolted moment

connection [1]. This connection is made by shop-welding the beam

to the end plate using a complete joint penetration groove (CJPG)

2/6/2016

PAGE 11 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

BROOK ROBAZZA AND SHILIN SUN

welded joint for the beam flanges to the end plate and fillet welds

for the beam web to end plate joint [3]. After completion of the

shop-welding, the end plate is then field-bolted to the column

using eight bolts. See Figure 6 for the geometry of a bolted

unstiffened end plate connection.

Figure 7 Bolted Unstiffened End Plate Connection [10]

5.2 Bolted Stiffened End Plate Connection

Figure 6 Geometry of Bolted Unstiffened End Plate Connection [2]

The BUEP connection should be designed such that yielding may

be accommodated either as a combination of beam flexure and

panel zone yielding or solely due to beam flexure. The end plates,

bolts, and welds should be designed to prevent significant yielding

from occurring in these elements [1].The design procedure for the

proportioning of this type of connection is provided in Section 6.

See Figure 7 for an example of a bolted unstiffened end plate

connection.

UNIVERSITY OF BRITISH COLUMBIA

The Bolted Stiffened End Plate (BSEP) connection is identical to

the bolted unstiffened end plate connection but in this case the

outstanding flanges of the end plate at the top and bottom of the

beam are stiffened by a vertical fin plate that extends outward from

the beam flanges [1]. These stiffener plates are CJPG double-bevel

groove welded to the beam flanges and end plates [2]. See Figure 8

for the geometry of a bolted stiffened end plate connection.

As with the unstiffened variety of Bolted End Plate connection, the

BSEP connection should be designed such that yielding may occur

either as a combination of beam flexure and panel zone yielding or

due to beam flexure alone. The end plates, bolts, and welds should

be designed to prevent significant yielding from occurring in these

elements [1]. The design procedure for the proportioning of this

type of connection is provided in Section 6. See Figure 9 for an

example of a bolted stiffened end plate connection.

2/6/2016

PAGE 12 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

BROOK ROBAZZA AND SHILIN SUN

weld metal to join the flanges of the beam to the column [1]. The

web joints for these connections may be either complete

penetration groove welds, or bolted or welded shear tabs [3]. When

the RBS connection is used in design it is important to take into

consideration the reduction in beam stiffness which occurs due to

the trimming of the flanges in the “dog-bone” region. Unless a

detailed analysis is conducted, a 7% to 9% increase in elastic drift

should be accounted for flange reductions of 40% and 50%

respectively [1]. See Figure 10 for the geometry of a reduced beam

section connection.

Figure 8 Geometry of a Bolted Stiffened End Plate Connection [2]

Figure 9 Bolted Stiffened End Plate Connection Example [13]

5.3 Reduced Beam Section Connection

The Reduced Beam Section (RBS) connection utilizes circular

radius cuts in both top and bottom flanges of the beam to reduce

the flange area over a length of the beam near the ends of the beam

span [3]. This connection uses no reinforcement other than the

UNIVERSITY OF BRITISH COLUMBIA

Figure 10 Geometry of Reduced Beam Section Connection [2]

2/6/2016

PAGE 13 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

The RBS connection should be proportioned to allow yielding to

occur as either a combination of flexural yielding of the panel zone

and reduced section yielding or as the reduced section yielding

alone [1]. The beam-flange-to-column joints and the beam web

connection should be designed to prevent significant yielding from

occurring in these elements. The design procedure for the

proportioning of this type of connection is provided in Section 6.

BROOK ROBAZZA AND SHILIN SUN

these detailed design procedures for the three connections

investigated in this report.

6.1 Canadian Code Governing

Connections for Seismic Applications

Moment

The CISC Handbook contains detailed information regarding the

design and detailing of structural steel in SI metric units.

The Tenth Edition has been updated to reflect changes to CSA

S16-09 and the steel sectional data. This code uses the limit state

design procedure and factors up load demands while factoring

down material resistances. The factoring procedure is based on

probabilistic distributions of resistances and loads produced by

numerous experimental testing data in order to provide an

acceptable level of safety in a given structure. The code is intended

to be used in conjunction with the NBCC 2010. Clause 27 of CSA

Standard S16-09 is used for seismic design and stipulates the

performance criteria for beam-to-column connections for Ductile

(Type D) and Moderately Ductile (MD) Moment-Resisting

Frames.

6.2 Design Procedure

Figure 11 Reduced Beam Section Example [10]

6.0 Moment Resisting Connection Design

The general design objectives of the three types of moment

connection studied is to provide large, stable, plastic rotational

capacity with an aim to mobilize at least one ductile element

precluding any undesirable failure modes [1]. According to the

Canadian Institute of Steel Construction (CISC) [1], the design

procedures of moment connections include the following:

In order to help engineers design moment resisting connections,

the CISC provides detailed design procedures for prequalified

moment resisting connections. The following section will present

UNIVERSITY OF BRITISH COLUMBIA

2/6/2016

Identify the undesirable failure modes and all yielding

mechanisms

Determine the probably peak capacity of the primary

yielding mechanism and the onset of yielding in some cases

PAGE 14 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

Proportion the connection to ensure that the nominal

resistances against each of the undesirable failure modes at

least equal the probably peak capacity of the primary

yielding mechanism

In order to achieve the most desirable sequence of yielding

for connections in Type D and Type MD fames, each

connection should be proportioned to prevent yielding of

any secondary yielding mechanism prior to the onset of

yielding of the primary yielding mechanism.

Clause 27.2.5 stipulates code limitations on beam-to-column joints

and connections. The beam-to-column joint shall maintain strength

at the column face of at least the plastic moment resistance of the

beam, Mpb, through a minimum interstorey drift angle of 0.04

radians under cyclic loading according to Clause 27.2.5.1. In the

case of reduced beam section connections or when local buckling

limits the flexural strength of the beam, the beam need only

achieve 0.8Mpb at the column face when an interstorey drift angle

of 0.04 radians in developed under cyclic loading. Clause 27.2.5.2

states that the factored resistance of the beam web-to-column

connection shall equal or exceed the effects of gravity loads

combined with shears induced by moments of 1.1RyZFy acting at

plastic hinge locations. If the plastic hinge is to be located in the

column, which will not be the case for these moment-resisting

connections, Clause 27.2.8 for protected zones must be considered

as well as Clause 27.2.3. When the plastic hinge is designed to

occur in the beam, Clause 27.2.2 must come into effect. This

clause stipulates that the beam sections be Class 1 sections, be

laterally braced in accordance with Clause 13.7(b) and the forces

acting on other members and connections due to plastic hinging

shall be calculated using 1.1Ry times the nominal flexural

resistance, ZFy. It is important to note here that the following

design procedures are done assuming that the beams and columns

UNIVERSITY OF BRITISH COLUMBIA

BROOK ROBAZZA AND SHILIN SUN

of the connection have already been checked to have adequate

resistance to the design forces. These design procedures are thus

only for designing a moment-resisting connection to perform is a

desirable manner.

Figure 12 Critical Section Calculation Diagram

6.2.1 Bolted Unstiffened End Plate Connection

The following design procedure for the BEUP connection has been

laid out with guidance from CISC [1]. The procedure examines the

restrictions on the proportioning of the connection in no particular

order but they must all be satisfied in order to obtain a safe

connection. Guidelines for continuity plates and welded joint

design are presented as well.

6.2.1.1 Bolt Diameter

Bolt diameter must be large enough and of the correct type to resist

Mcf and Vcf. The following conditions check whether the bolt

configuration is appropriate.

2/6/2016

PAGE 15 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

In order to prevent a Mode 1: Bolt Tension failure in BUEP

connections, the following equation must be satisfied. Otherwise

the bolt size or type must be reconsidered in order to resist Mcf.

𝑀𝑐𝑓

0.75𝐴𝑏 𝐹𝑢 ≥ 2(𝑑

1 +𝑑2 )

𝑡𝑝 ≥

𝑀𝑐𝑓

𝑏

𝑏𝑝 𝑑

√

1

2

1

𝑝 1

0.8𝐹𝑦𝑝 {(𝑑𝑏 − 𝑝𝑡 ) [ 2 (𝑝 + 𝑠 ) + (𝑝𝑓 + 𝑠) 𝑔] + 2 (𝑝𝑏 + 2)}

𝑓

𝑓

where:

where:

Fu = Specified minimum tensile strength (MPa)

Ab = bolt area based on nominal diameter

Mcf is defined in Figure 6

d1 and d2 are defined in Figure 6

To prevent a Mode 2: Bolt Shear failure in BUEP connections, the

following equation must be satisfied. Bear in mind here that the

bolt threads should not intercept the shear plane.

𝑠 = √𝑏𝑝 𝑔

See Figure 6 for the geometry definitions above.

To prevent a Mode 4: End Plate Shear failure, end plate shear

yielding should be precluded by selecting an end plate thickness

satisfying following condition:

𝑡𝑝 ≥

3𝐴𝑏 (0.5𝐹𝑢 ) ≥ 𝑉𝑐𝑓

where:

Vcf = is defined in Figure 12

Ab and Fu are defined above

6.2.1.2 End Plate Thickness

The end plates which are used in the BUEP connection should be

composed of CSA G40.21 300W or ASTM A36 steel. For both of

these types of steel, 𝐹𝑦𝑝 should be taken as 250 MPa. The

following restrictions are imposed to the configuration of the end

plate thickness 𝑡𝑝 .

BROOK ROBAZZA AND SHILIN SUN

𝑀𝑐𝑓

1.1𝐹𝑦𝑝 𝑏𝑝 (𝑑𝑏 − 𝑡𝑏 )

6.2.1.3 Column Flange Thickness

The BUEP connection configuration is dependent on the column

flange thickness. The following conditions check whether a

continuity plate is required for the connection depending on the

thickness of the column flange.

To prevent a Mode 5a: Beam Flange Tension Effect on Column

Flange failure in BUEP connections without continuity plates the

following equation must be satisfied. If the column flange is

thinner than is required for this condition, then continuity plates

should be provided.

To prevent a Mode 3: End Plate Flexure failure, end plate yielding

must be precluded by ensuring that the end plate thickness

satisfies:

UNIVERSITY OF BRITISH COLUMBIA

2/6/2016

PAGE 16 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

𝑀𝑐𝑓

(

)𝐶

𝑑

√ 𝑏 − 𝑡𝑏 1

𝑡𝑐 ≥

2𝐹𝑦𝑐 𝑐

𝐶2 =

𝑏𝑐 − 𝑔

2

𝑠=√

where:

c is defined in Figure 8

𝑔

𝐶1 = − 𝑘1

2

k1 = distance from the centerline of the column web

to flange toe of fillet as provided in Table 4.1

and in Part 6 of the CISC Handbook 10th

Edition

To prevent a Mode 5b: Beam Flange Tension Effect on Column

Flange failure in connections with continuity plates, the following

equation must be satisfied. If the column flanges do not satisfy the

below equation, either a new connection must be considered or a

new column section must be selected.

BROOK ROBAZZA AND SHILIN SUN

𝐶1 𝐶2

(2𝑏𝑐 − 4𝑘1 )

𝐶2 + 2𝐶1

6.2.1.4 Column Web Thickness

In the BUEP connection, continuity plates must be provided if the

column web thickness does not satisfy the following condition.

This prevents against Mode 6: Beam Flange Compression Effect

on Column without Continuity Plates failure. Otherwise continuity

plates must be provided.

𝑤𝑐 ≥

𝑀𝑐𝑓

(𝑑𝑏 − 𝑡𝑏 )(6𝑘𝑒 + 2𝑡𝑝 + 𝑡𝑏 )𝐹𝑦𝑐

where:

𝑘𝑒 = the k-distance of the column section for

engineering design.

𝑀𝑐𝑓

√ 2(𝑑𝑏 − 𝑡𝑏 )

𝑡𝑐 ≥

0.8𝐹𝑦𝑐 𝑌𝑐

where:

𝑐

1

2

4 2

𝑌𝑐 = ( + 𝑠) ( + ) + (𝐶2 + 𝐶1 ) ( + )

2

𝐶2 𝐶1

𝑐 𝑠

𝑔

𝐶1 = − 𝑘1

2

UNIVERSITY OF BRITISH COLUMBIA

6.2.1.5 Panel Zone Thickness

Connections for Type D and Type MD frames should be

proportioned to allow yielding to occur either as a combination of

beam flexure or panel zone yielding or beam flexure alone. Beam

flexure yielding is the primary yielding mechanism and panel zone

yielding the secondary yielding mechanism. In order to prevent

Mode 7: Panel Zone Shear failure it is necessary for one-sided

connections to have a panel zone thickness satisfying the following

condition.

2/6/2016

PAGE 17 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

ℎ − 𝑑𝑏

)

ℎ

𝑤′ ≥

0.9(0.6𝑅𝑦𝑐 𝐹𝑦𝑐 𝑑𝑐 )(𝑑𝑏 − 𝑡𝑏 )

𝐶𝑦 𝑀𝑐 (

1) For two-sided connections, the thickness of the continuity

plate should be at least equal to the thicker of the beam

flanges.

2) For one-sided connections, the continuity plate thickness

should be at least one-half of the thickness of the beam

flange.

where:

h = average storey height of the stories above and

below the beam-to-column intersection, except:

a) where the column below has a pinned base, h = sum of the

storey height below and one-half the storey height above

and

b) for top level connections, h = the storey height but twice

the storey height where the column has a pinned base,

𝑆𝑒

𝐶𝑦 =

𝐶𝑝𝑟 𝑍𝑒

𝑀𝑐 is defined in Figure 12

𝑅𝑦𝑐 𝐹𝑦𝑐 = the probable yield stress of the column section in

accordance with 27.1.7 of S16-01 and

𝑆𝑒 = effective elastic modulus of beam section at the plastic

hinge location

6.2.1.6 Continuity Plates

Continuity plates may be required in some BUEP connections

when the column flange and/or web thickness is inadequate to

provide resistance against undesirable failure modes. These failure

modes are corresponding to limitations just described. Continuity

plates are also referred to as panel zone horizontal stiffeners and

column transverse stiffeners. When using continuity plates it is

important to consider that increasing the column strength may be

more economical than adding the continuity plates. This is due to

high labour costs associated with welding in many countries

including Canada. The following requirements must be met for the

design.

UNIVERSITY OF BRITISH COLUMBIA

BROOK ROBAZZA AND SHILIN SUN

6.2.1.7 Welded Joints

The beam flange-to-plate joints should be complete-penetrationgroove-welded joints (CJPG). This type of joint has special

requirements as access holes are not permitted. One sequence for

welding each single-bevel T-joint is the following:

a) install an 8-millimetre fillet on the inner flange face,

serving as backing,

b) gouge root of backing to sound metal, then

c) complete the groove weld in a horizontal or flat position

The beam web-to-end plate joint should be either a fillet CJPG

welded joint or a fillet-welded joint. A fillet-welded web should

have welds on both sides of the web and the welded web

connection should be proportioned to resist the more severe load

effect of the following two effects:

a) flexural yielding capacity of the web,

b) 2Vcf, where Vcf is defined in Figure 12

6.2.1.8 Bolted Unstiffened End Plate Connection –

Summary of Requirements and Limitations

See Appendix A for the summary of requirements and limitations

for the Bolted Unstiffened End Plate Connection.

2/6/2016

PAGE 18 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

6.2.2 Bolted Stiffened End Plate Connection

The following design procedure for the BSEP connection has been

laid out with guidance from CISC [1]. The procedure examines the

restrictions imposed on the proportioning of the connection in no

particular order but they must all be satisfied for a safe connection.

Guidelines for continuity plates and welded joint design are

presented as well.

To prevent a Mode 2: Bolt Shear failure in BSEP connections, the

following equation must be satisfied. Like the BUEP connection,

the bolt threads should not intercept the shear plane.

6𝐴𝑏 (0.5𝐹𝑢 ) ≥ 𝑉𝑐𝑓

where:

Vcf = is defined in Figure 12

Ab and Fu are defined above

6.2.2.1 Bolt Diameter

Bolt diameter must be large enough and of the correct type to resist

Mcf and Vcf. The following conditions check whether the bolt

configuration is appropriate.

In order to prevent a Mode 1: Bolt Tension failure in BSEP

connections, the following equations must be satisfied. Otherwise

the bolt size or type must be reconsidered in order to resist Mcf.

0.75𝐴𝑏 𝐹𝑢 ≥

𝑀𝑐𝑓

3.4(𝑑2 + 𝑑3 )

2.58

3.25 × 10−6 𝑝𝑓 0.591 𝑃𝑐𝑓

1.91 0.327 0.965

𝑡𝑝0.895 𝑑𝑏𝑡

𝑡𝑠

𝑏𝑝

The end plates which are used in the BSEP connection should be

composed of CSA G40.21 300W or ASTM A36 steel. For both of

these types of steel, 𝐹𝑦𝑝 should be taken as 250 MPa. The

following restrictions are imposed on the configuration of the end

plate thickness 𝑡𝑝 .

+ 𝑇𝑏

where:

Fu = Specified minimum tensile strength (MPa)

Ab = bolt area based on nominal diameter

Mcf is defined in Figure 12

d1 and d2 are defined in Figure 8

dbt = bolt diameter

𝑀𝑐𝑓

𝑃𝑐𝑓 =

𝑑𝑏 − 𝑡𝑏

UNIVERSITY OF BRITISH COLUMBIA

6.2.2.2 End Plate Thickness

To prevent a Mode 3: End Plate Flexure failure mechanism, end

plate yielding must be precluded by ensuring that the end plate

thickness is at least equal to the larger of the following equations.

and

0.75𝐴𝑏 𝐹𝑢 ≥

BROOK ROBAZZA AND SHILIN SUN

𝑡𝑝 ≥

0.9

154 × 10−6 𝑝𝑓0.9 𝑔0.6 𝑃𝑐𝑓

0.9 0.1 0.7

𝑑𝑏𝑡

𝑡𝑠 𝑏𝑝

and

𝑡𝑝 ≥

267 × 10−6 𝑝𝑓0.25 𝑔0.15 𝑃𝑐𝑓

0.7 0.15 0.3

𝑑𝑏𝑡

𝑡𝑠 𝑏𝑝

where:

𝑑𝑏𝑡 is the bolt diameter

To prevent a Mode 4: End Plate Shear failure, end plate shear

yielding should be precluded by the use of an appropriate stiffener

2/6/2016

PAGE 19 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

plate. These plates should be clipped at the intersection of the end

plate and the beam flange.

below equation, either a new connection must be considered or a

new column section must be selected.

6.2.2.3 Column Flange Thickness

The BSEP connection configuration is also dependent on the

column flange thickness. The following conditions check whether

a continuity plate is required for the connection depending on the

thickness of the column flange.

𝑀𝑐𝑓

√ 2(𝑑𝑏 − 𝑡𝑏 )

𝑡𝑐 ≥

0.8𝐹𝑦𝑐 𝑌𝑐

where:

𝑐

1

2

4 2

𝑌𝑐 = ( + 𝑠) ( + ) + (𝐶2 + 𝐶1 ) ( + )

2

𝐶2 𝐶1

𝑐 𝑠

𝑔

𝐶1 = − 𝑘1

2

𝑏𝑐 − 𝑔

𝐶2 =

2

To prevent a Mode 5: Beam Flange Tension Effect on Column

Flange failure on BSEP connections without continuity plates the

following equation must be satisfied. If the column flange is

thinner than is required for this condition, then continuity plates

should be provided.

𝑡𝑐 ≥ √

𝛼𝑚 𝑃𝑐𝑓 𝐶3

0.9𝐹𝑦𝑐 (3.5𝑝𝑏 + 𝑐)

𝑠=√

where:

1⁄

3

𝐴𝑓

∝𝑚 = 𝐶𝑎 ( )

𝐴𝑤

𝐶1 =

1⁄

4

𝐶3

( )

𝑑𝑏𝑡

𝑔 𝑑𝑏𝑡

−

− 𝑘1

2

4

and

Ca = 1.45 for A325 bolts and 1.48 for A490 bolts

Af = Area of beam tension flange

Aw = Area of beam web, clear of flanges

BROOK ROBAZZA AND SHILIN SUN

𝐶1 𝐶2

(2𝑏𝑐 − 4𝑘1 )

𝐶2 + 2𝐶1

6.2.2.4 Column Web Thickness

The BSEP connection has the same requirements on column web

thickness as the BUEP connection. Like the BUEP connection, if

the BSEP connection does not meet the requirements provided in

Section 6.2.1.4, continuity plates must then be provided.

6.2.2.5 Panel Zone Thickness

The panel zone requirements for the BSEP connection are the same

as those for the BUEP connection described in Section 6.2.1.5.

To prevent a Mode 5: Beam Flange Tension Effect on Column

Flange failure on connections with continuity plates, the following

equation must be satisfied. If the column flanges do not satisfy the

UNIVERSITY OF BRITISH COLUMBIA

2/6/2016

PAGE 20 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

BROOK ROBAZZA AND SHILIN SUN

6.2.2.6 Continuity Plates

6.2.3.1 Flange Reduction Specifications

The requirements on the continuity plates for the BSEP connection

are also the sameare identical to the BUEP connection listed in

When selecting the length and location of the beam flange

reduction, the following limits must be imposed:

are the same imposed on the BUEP connection as described in

Section 6.2.1.6.

0.5𝑏 ≤ 𝑎 ≤ 0.75𝑏

0.65𝑑 ≤ 𝑠 ≤ 0.85𝑑

6.2.2.7 Welded Joints

The welded joint specifications for the BSEP connection are the

same specifications imposed on the BUEP connection and

described in Section 6.2.1.7.

0.20𝑏 ≤ 𝑐 ≤ 0.25𝑏

where:

a and s are shown in Figure 10

b = beam flange width

d = beam flange depth

c = depth of cut

6.2.2.8 Bolted Stiffened End Plate Connection –

Summary of Requirements and Limitations

As can be noted from the above requirements, many of the

restrictions imposed on the BSEP connection are the same as

BUEP connection but there are a number of important differences.

See Appendix B for the summary of requirements and limitations

for the Bolted Stiffened End Plate Connection.

6.2.3 Reduced Beam Section

The following design procedure for the RBS connection has been

laid out with guidance from the CISC [1]. The procedure examines

the restrictions on the proportioning of the connection in no

particular order but they must all be satisfied for a safe connection.

Guidelines for continuity plates and welded joint design are

presented as well. The welded joint design includes the weld

details for the weld access holes, backing bars, and the welding

sequence for the bottom beam flange.

In addition, the reduced flange width should be equal to or less

than 14.6 times the flange thickness of the beam.

6.2.3.2 Check Reduced Section Resistance to

Applied Loads

Determine the factored resistance of the reduced section and check

its adequacy for the effect of the factored loads using Ze calculated

using c = 0.2b and be = 0.6b.

To preclude flexure failure of the connection the following

equation must be satisfied. Otherwise, increase c and recheck

conditions for the connection. The maximum value of c is 0.25b.

𝑀𝑐𝑓 ≤ 𝑅𝑦 𝐹𝑦 𝑍𝑏

where:

RyFy = 385 MPa and

Zb is the plastic section modulus of the gross beam section.

UNIVERSITY OF BRITISH COLUMBIA

2/6/2016

PAGE 21 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

bb = unreduced beam flange width

tb = beam flange thickness

RybFyb = the probable yield stress of the beam section

RycFyc = the probable yield stress of the column section

6.2.3.3 Connection Shear

The shear force at the column face should be calculated according

to the following equation.

2𝑀𝑐𝑓

𝑉𝑐𝑓 =

+ 𝑉𝑔

𝐿 − 𝑑𝑐

where:

Vg = shear due to companion gravity loads factored

L = length of span

For field-bolted shear tabs, the shear tab connection should be

designed for the previously defined shear force. The resistance

may be taken as nominal for bearing-type connections. This type

of connection needs to be connected to the column using either a

CPJ groove weld or full-depth fillet welds of 0.75 times the tab

plate thickness on each side of the tab plate.

6.2.3.4 Panel Zone Thickness

To prevent panel zone shear for the RBS connection, the panel

zone thickness should be proportioned the same as with bolted end

plate connections and outlined in Section 6.2.1.5.

6.2.3.5 Continuity Plates

Continuity plates are required if the column flange thickness does

not satisfy at least one of the following equations.

𝑅𝑦𝑏 𝐹𝑦𝑏

𝑡𝑐 ≥ 0.4√1.8𝑏𝑝 𝑡𝑏

𝑅𝑦𝑐 𝐹𝑦𝑐

and

𝑡𝑐 ≥

where:

UNIVERSITY OF BRITISH COLUMBIA

𝑏𝑏

6

BROOK ROBAZZA AND SHILIN SUN

6.2.3.6 Weld Joint Details

There are guidelines stipulated by the CISC for the use of weld

access holes, backing bars, and the welding sequence for the

bottom beam flange. These guidelines ensure that the welded

portions of the connections conform to a desired level of

performance.

6.2.3.7 Weld Access Holes

The weld access holes used in the connection design must meet the

dimensional requirements provided by FEMA-350 in Figure 3-5.

The access holes should be finished such that the surface

roughness is at most 13μm and there are no notches or gouges. The

welding should be done using controlled hydrogen electrodes that

meet H16 designator requirements. Following completion of the

welding, the area should be ground smooth and flush to meet the

contour and finish requirements for the access holes. To ensure

that the welds are free of cracks, weld access holes should be

inspected by means of magnetic particle testing or liquid penetrant

testing.

6.2.3.8 Backing Bars

Backing bars used when welding the bottom beam flange to the

column should be removed after welding. After the Northridge

earthquake it was found that there were failures stemming from the

failure to remove backing bars from the bottom beam flange region

and thus this new practice was acquired. The CISC provides

solutions for removing backing bars such as air carbon cutting,

grinding, chipping, or thermal cutting. A reinforcing fillet weld

2/6/2016

PAGE 22 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

should be provided in these cases. This weld should have a

minimum leg size of the maximum of 8 mm or the root opening

plus 2 mm.

BROOK ROBAZZA AND SHILIN SUN

6.2.3.9 Welding Sequence for Bottom Beam Flange

not yield at the levels expected. This fact is unconservative when

sizing adjacent members. This is a change from S16-01(R05)

which has a RyFy = 385 MPa for HSS sections. Since HSS sections

are not usually utilized in moment resisting connections however,

this change is of little consequence.

When the less desirable field welds are required, the CISC

recommends the following sequence to be used:

8.0 Conclusion

1) Weld start-stops directly under the beam web should be

avoided.

2) Each layer should be completed across the full width of the

flange before the next layer begins.

3) The start-stops of any two consecutive layers should not

fall on the same side of the beam web.

6.2.4.0 Reduced Beam Section Connection –

Summary of Requirements and Limitations

See Appendix C for the summary of requirements and limitations

for the Reduced Beam Section Connection.

7.0 Changes between S16-09 and S1601(R05) affecting Connection Design

There are few changes from the steel code upgrade from S1601(R05) to S16-09 which are specifically affecting connection

design. There are a number of changes which affect the beam and

column sections connecting into the connection but these only

indirectly affect the connection design. The only change that has

direct affect on the calculations is a change in Clause 27.1.5.1

which affects the calculation of the probable plastic bending

moment in the form of the Ry factor. For HSS members Ry has

increased to 1.37 (therefore a RyFy = 460 MPa) which reflects the

cold working of the plates producing higher strength steel that does

UNIVERSITY OF BRITISH COLUMBIA

Moment resisting connection design has been recognized as a

crucial part of designing an adequate seismic force-resisting

system. Although researchers and practicing engineers have made

substantial revisions to the seismic design of moment resisting

connections after the Northridge and Kobe earthquakes, there still

remains some question about the adequacy of the revisions and the

new types of connections being used. As could be seen from the

connections that failed during these two major seismic events,

testing is not always representative of true engineering practice. In

order to prove that these connections are truly adequate, further

analysis must be undertaken to study the performance of these

prequalified moment resisting connections as well as the procedure

of their design. Since the three connections investigated in this

report are only a few of the numerous connections available, the

reader should look into FEMA 350 which provides many more

connection types and corresponding design procedures.

The procedure used for the design is implemented into a flexible

tool that has been developed into a spreadsheet program. This

program helps the designer design connections by not only

determining the strength and adequacy of a proposed connection

configuration but also provides an estimation of the efficiency of

the connection. Three types of common prequalified moment

resisting connections are chosen which are representative of

Canadian construction. The spreadsheet tool incorporates each of

these connection type design procedures to enable the designer to

2/6/2016

PAGE 23 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

consider several types of connection in their design. This attached

design tool provides the designer with substantial assistance in the

design of moment resisting connections for seismic applications.

9.0 References

[1] Canadian Institute of Steel Construction (2008). “Moment

Connections for Seismic Applications.” Lakeside Group Inc.

Ontario, Canada.

[2] Federal Emergency Management Agency (2000). “FEMA 350

3-48 Moment Resisting Connections.” Retrieved from

www.nehrp.gov. SAC Joint Venture. California, U.S.A.

[3] Federal Emergency Management Agency (2000).

“Recommended Seismic Design Criteria for New Steel MomentFrame Building: FEMA 350.” SAC Joint Venture. California,

U.S.A.

[4] Wilkinson, S., Hurdman, G., & Crowther, A. (2006). “A

Moment Resisting Connection for Earthquake Resistant

Structures.” Journal of Constructional Steel Research Volume 62.

BROOK ROBAZZA AND SHILIN SUN

[7] Rizkalla, S. H., & Thadani, B. N. (1983). “Structural Steel

Design.” Cantext Publications. Manitoba, Canada.

[8] Stiemer, S. F. (2011) “Connection Design and Cost Estimate.”

University of British Columbia, British Columbia, Canada.

[9] Satishkumar, S. R. (2005) “Design Steel Structure I.” NPTEL

Chennai, India.

[10] Metten, A. (2010). “Seismic Resisting Elements – Moment

Frames and Other Systems.” Bush, Bohlman& Partners. British

Columbia, Canada.

[11] Eliasova, M., Gomes, F. C. T., & Wald, F. (2002). “Stiffened

End Plates in Structural Steel Connections.”

[12] Adan, S. M., & Hamburger, R. O., (2010). “Steel Special

Moment Frames.” A Joint Publication of NCSEA, CASE and SEI.

[13] Steel Photo Gallery (2011). Retrieved from_http://www.meritsteel.com/PhotoGallery.html

[14] Canada Institute of Steel Construction (2010). “Steel

Handbook – Tenth Edition.” CISC Publications

[5] Pachoumis, D. T., Galoussis, C. N., & Christitsas A. D. (2009).

“Reduced Beam Section Moment Connections Subjected to Cyclic

Loading: Experimental Analysis and FEM Simulation.”

Engineering Structures Volume 31.

[15] Sehgal, V. K., Setia, S., & Murty, C. V. (2009). “Seismic

Behavior of Weak-axis Beam-column Connections.” CRC Press

Online.

[6] Institute for Steel Development & Growth (2006). “Earthquake

Resistant Design of Steel Structures.” Institute for Steel

Development & Growth. Kolkata, India.

[16] Unsworth, J. F. (2010). “Design of Connection for Steel

Members.” CRC Press Online.

UNIVERSITY OF BRITISH COLUMBIA

2/6/2016

PAGE 24 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

[17] Stiemer, S. F. (2011)“Plastic Design with Computers,”

retrieved from_http://www.sigi.ca/engineering/notes/plastic_

design_with_computers.pdf.

BROOK ROBAZZA AND SHILIN SUN

investigated connections. Similar tables of requirements and

limitations are also provided by FEMA 350.

[18] Stiemer, S. F. (2011)“Plastic Methods,” retrieved

from_http://www.sigi.ca/engineering/notes/plastic_

mathods.pdf.

[19] Federal Emergency Management Agency (FEMA)-355D,

(2000). “State of the Art Report on Connection Performance”

retrieved from_http://www.nehrp.gov/pdf/fema355d.pdf.

Appendix A: Bolted Unstiffened End Plate Connection –

Summary of Requirements and Limitations:

[20] Federal Emergency Management Agency (FEMA)-351,

(2000), “Recommended Seismic Evaluation and Upgrade Criteria

for Existing Welded Steel Moment-Frame Buildings” retrieved

from_http://www.nehrp.gov/pdf/fema355d.pdf.

[21] Charney, F. A., Downs, W. M., (2004). “Modeling Procedures

for Panel Zone Deformations in Moment Resisting Frames.”

Department of Civil and Environmental Engineering, Virginia

Tech, Blacksburg, Virginia, U.S.A.

[22] Cary, Howard B; Scott C. Helzer (2005). Modern Welding

Technology. Upper Saddle River, New Jersey, U.S.A.

[23] ASM International (2003). Trends in Welding Research.

Materials Park, Ohio: ASM International.

10.0 Appendices

The following appendices are tables from the CISC guidelines for

the connections investigated in this report. These tables provide a

summary of the requirements and limitations that are impost on the

UNIVERSITY OF BRITISH COLUMBIA

2/6/2016

PAGE 25 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

BROOK ROBAZZA AND SHILIN SUN

Appendix B: Bolted Stiffened End Plate Connection –

Summary of Requirements and Limitations:

UNIVERSITY OF BRITISH COLUMBIA

2/6/2016

PAGE 26 OF 27

CIVL 510

MOMENT RESISTING CONNECTIONS FOR SEISMIC APPLICATIONS

BROOK ROBAZZA AND SHILIN SUN

Appendix C: Reduced Beam Section Connection – Summary of

Requirements and Limitations:

UNIVERSITY OF BRITISH COLUMBIA

2/6/2016

PAGE 27 OF 27