doc

advertisement

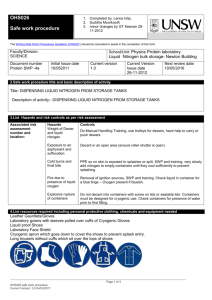

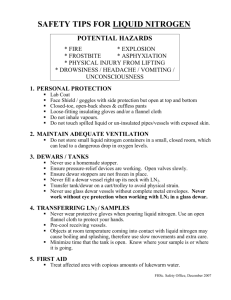

ohsrm PART B School of Molecular Bioscience. HAZARDOUS PROCEDURE: CRYOGENICS – LIQUID NITROGEN & DRY ICE Step 3. Assess the risk Assess the risk for the top priority hazards identified in PART A ie., begin with those rated 1, then 2 etc. Ref. # 1 2 Description of the hazard or hazardous job Priority Identification Date 5 31/03/2010 5 31/03/2010 Dispensing and working with Liquid Nitrogen or Dry Ice (frozen carbon dioxide). Direct contact with skin or eyes may result in severe burns (frost-bite) or permanent tissue damage and loss of sight. Serious injury can result within seconds of contact. Transporting, Short Term Storage, and Disposal of Liquid Nitrogen & Dry Ice. Transporting liquid nitrogen and dry ice between two locations exposes the carrier and other persons encountered en route who are not wearing personal protective equipment to potentially severe cryogenic related injuries. Transport and storage in small confined spaces (ie lift, car, room etc) may result in asphyxiation. Transport and storage in unsuitable containers may result in the vessel exploding. What makes it hazardous? Consult with the workers to find out which factors are relevant: Tick relevant boxes and record observations or comments. The work environment Movement between areas (eg. between supply area and laboratory) presents a significant risk of injury to persons encountered en route who are not wearing personal protection equipment. Enclosed areas such as lifts and small rooms with the doors closed provide an environment where asphyxiation (suffocation) is possible due to rapid release of nitrogen excluding oxygen from the area. The nature of the hazard itself Certain laboratory techniques require the use of cryogenics to prepare samples for analysis or storage, and for transportation. Failure to observe safety measures exposes user, and potentially other colleagues, to significant risk of physical injury, and in extreme cases, unconsciousness, or death due to asphyxiation. The individual(s) involved Requires specific training by authorised staff in the safe use of the hazardous cryogenic materials. Record the names of those consulted when assessing the risk Nick Coleman, Peter Kerr, Joe Dimauro, Jenny Phuyal, Zia Ahmad, Angela Nikolic, Robert Czolij. Date 31/03/2010 Step 4. Control the risk(s) Control the risks(s) by addressing the risk factors found in Step 3. Consider the hierarchy of hazard control and record what controls will be used in the short term and longer term. Record also who is responsible for implementing the control(s) and the due by date(s). Describe the risk control(s) Who is responsible Due by date for implementation ALWAYS wear personal protective equipment (PPE) when handling either Individual user and liquid nitrogen or dry ice, including lab coat, insulating (cryogenic) gloves, and their supervisor. 21/04/2010 safety glasses or preferably full face shield (especially when dispensing liquid nitrogen from supply cylinder on Level 2 of SMB into dewar) ALWAYS use approved cryogenic vessels, eg metal dewars for liquid nitrogen Individual user and and Styrofoam box WITH lid for dry ice. Using vessels not intended for their supervisor. 21/04/2010 cryogenic agents risks rupture of the vessel and a SERIOUS spill and injury. When dispensing from liquid N2 cylinder, ensure supply pipe is a few inches inside the vessel, not just above it. Slowly turn the supply tap and adjust the Individual user and 21/04/2010 speed of dispensing to prevent splashing. Turn the tap off immediately when it their supervisor. starts to splash over. Never leave your dewar unattended. When collecting dry ice from another container use an appropriate scooping Individual user and 21/04/2010 instrument or gently tip container to direct the dry ice into your own container. their supervisor. Don’t pick up dry ice with bare hands – burns will result. When using either liquid nitrogen or dry ice in the laboratory ensure that you Individual user and work in a well ventilated area to prevent any risk of asphyxiation. NEVER their supervisor. TRANSPORT LIQUID N2 IN THE LIFT WITH PEOPLE IN IT! – in this case, 21/04/2010 send the cylinder or dewar to the destination floor alone, and put yellow plastic chain across the door to let others know not to enter the lift. Whenever transporting, handling or disposing of liquid nitrogen or dry ice, ensure you do so in well ventilated areas. Both liquid nitrogen and dry ice are colourless and odourless, therefore difficult to detect. The evaporation of either liquid nitrogen or dry ice in small enclosed areas reduces the oxygen concentration in the air, acting as an asphyxiant Use suitable cryo-stable equipment for working with cryogenic agents, such as: ceramic mortar and pestles, metals containers and instruments, and suitable plastics. Glass dewars and other receptacles are hazardous and can explode if the glass is fractured (SMB is phasing out glass dewars and replacing with all-metal ones). If dispensing liquid nitrogen to another receptacle pour slowly and carefully to minimise splashing. Do NOT create a gas-tight seal on any vessel containing either liquid nitrogen or dry. This can result in explosion and release of extremely cold vapours and/or liquid, and sharp fragments of the container. Proper training of staff / students is essential prior to use of cryogenic agents. Individual user and their supervisor. 21/04/2010 Individual user and their supervisor. Individual user and their supervisor. 21/04/2010 Supervisor of researcher / student 21/04/2010 Development and updating of Standard Operating Procedure (SOP) SMB Safety Committee. 21/04/2010 Consult SOP before using cryogenics, and observe all risk control recommendations. Individual user and their supervisor. 21/04/2010 21/04/2010 Record the names of those consulted when deciding on risk control measures Peter Kerr, Joe Dimauro, Jenny Phuyal, Zia Ahmad, Angela Nikolic, Robert Czolij, Craig Jackson . PART B completed by: Mr Craig JACKSON Date: 31/03/2010 31/03/2010