Comfort Slat Mats - Department of Agriculture

advertisement

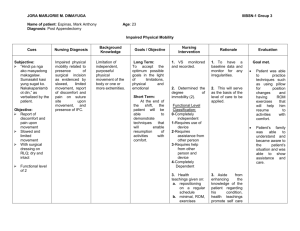

Use of Comfort Slat Mats to Reduce Ammonia and Methane Emissions on Cattle and Dairy Farms Submission to Department of Agriculture, Fisheries and Food for consideration to adopt the Comfort Slat Mat System as an option for farmers in the proposed new Agri-Environment Scheme to commence in 2010 Comfortslat Mats Ltd., Poppintree Industrial Estate, Finglas, Dublin 11 30th August 2009 Contents Introduction 2 Setting the Scene on Ammonia and GHG Emissions 3 Why Have Ammonia & Methane Emissions Become a Problem for Agriculture 4 Current Strategies to Reduce Ammonia and Methane Emissions 6 The Role of the Comfort Slat Mat in Reducing Ammonia & Methane Emissions 7 Appendices 9 Appendix 1: The Comfort Slat Mat System Appendix 2: Wageningen UR Animal Science Group Report 225 May 2009: Explorative emission measurements on Comfort Slat Mats for dairy cattle Comfort Slat Mat – A product which reduces ammonia and greenhouse gas emissions from slatted housing while improving the comfort and cleanliness of animals Introduction Comfort Slat Mats are designed and manufactured in Dublin . The company has a long track record in successful & innovative design, development and manufacture of extruded plastic products for the 2 construction, automotive, electrical, refrigeration and other industries. Working in conjunction with agriculture research organisations in Ireland, The Netherlands and the USA, we have developed a unique “clip-on” slat mat to fit to concrete slatted floors to improve animal comfort. Originally the Comfort Slat Mat1 was designed to alleviate the problems animals’ experience on slats where the void space in the floor increases the contact pressure on the animals’ hooves when they stand on slatted floors. In addition the suppleness of the product simulates the normal grassland surface on which animals graze and allows the animal to stand-up or lie-down in a more natural manner. The profiled design of the slat cover encourages urine and faeces to move through the gaps between the slats and into the storage tank below the floor resulting in cleaner floors and so cleaner animals. The product has been well received by farmers and is approved for grant aid by the Department of Agriculture, Fisheries and Food2. Following the success of the initial product further development work was undertaken with the Animal Science Group of Wageningen UR in the Netherlands to develop a system to reduce the problem of ammonia (NH3) volatilisation from slatted floors. The profile and surface characteristics of the Comfort Slat Mat ensures the quick removal of urine and faeces from the surface with associated reduction in ammonia volatilisation. The system was further developed to include the fitting of a flap valve to allow urine and faeces to pass through into the storage tank while minimising air exchange between the building and the slurry storage tank. This results in a further reduction of the NH3 emission. An added benefit is that the Comfort Slat Mat also reduces the emission of methane which is a greenhouse gas (GHG). Details of the system are shown in Appendix 1. The design has undergone field testing in The Netherlands and a report on this research is presented in Appendix 2. Setting the Scene (i) Ammonia Emission In the atmosphere gaseous ammonia NH3 reacts with acidic compounds to form ammonia aerosols that can be transported over large distances. Both gaseous NH3 and aerosols are returned, sooner or later, to the earth’s surface. The resulting enrichment of natural ecosystems with nitrogen, as well as the consequential implications of soil acidification, are both issues of environmental concern. As the NH3 can move across national borders the problem is an issue of international concern and is subject to evolving reduction targets. 1 http://www.comfortslatmat.com/ 2 Department of Agriculture Fisheries and Food S123m: Accepted Cattle Mats 3 The agricultural sector accounts for virtually the total of the NH3 emissions to the atmosphere in Ireland. Ireland generates approximately 120,000t of NH3 the highest per capita level of NH3 emission in Europe3. Cattle (dairy & beef) account for over 75% of total NH3 emissions from agriculture in Ireland. Animal housing and land spreading of manures account on an equal 50:50 basis for 79% of the emissions from cattle with the remaining 21% associated with grazing and conservation land4. The estimated monetary loss as a result of NH3 emissions from animal housing and subsequent land spreading of slurry is €63m taking the current cost of nitrogen at €0.90 per kg. In Ireland the predominant type of cattle housing uses slatted floors covering underground storage tanks with an estimated 70% of animals housed on standard slatted floors or variants of the slatted floor system. The number of these systems has substantially increased over the last two years with the requirements placed on farmers by the Nitrate’s Directive. The Farm Waste Management Scheme5 funded by the Department of Agriculture, Fisheries and Food has provided grant aid to assist farmers to carry out these construction projects. (ii) GHG Emissions The Earth’s energy budget is controlled by the composition of the atmosphere. Ninety-nine % of the mass of the atmosphere lies below 30 km altitude with 75% being in the troposphere, the lowest layer ranging in thickness from 8 km at the poles to 16 km over the equator. Most of the world’s weather systems develop within the troposphere. Incoming visible and ultraviolet radiation from the Sun heats the Earth’s surface. Infrared radiation is emitted from the Earth’s surface and radiated back out into space. Gases in the atmosphere trap some of this long-wavelength infrared radiation making the temperature of the atmosphere rise. The atmosphere is acting just like the glass in a greenhouse. This natural greenhouse effect keeps the Earth 33 oC warmer than it would be without an atmosphere at an average 15 oC. The gases responsible for the greenhouse effect include water vapour (H2O), carbon dioxide (CO2), methane (CH4), nitrous oxide (N2O), and chlorofluorocarbons (CFCs)6. Ireland is unique among the EU countries in that there are a relatively high number of bovine animals in comparison to the human population. This results in 26.5% of our greenhouse gas (GHG) emissions originating in agriculture with these emissions dominated by methane (CH4) and nitrous oxide (N2O). In countries with a higher proportion of humans relative to animals the GHG emissions associated with transport and industrial activity change the balance of GHGs away from agriculture. CH4 and N2O are more potent GHGs compared to CO2 with global warming potentials of 21 and 310 respectively compared to CO2. CH4 emissions are primarily due to livestock enteric fermentation and manure management and account for 12.4% of total GHG emissions in Ireland7,8. Total GHG emissions for Ireland are 70mt CO2 Equivalent9 with cattle thus responsible for approximately 9mt of CO2 Equivalent. Why Have Ammonia & Methane Emissions Become a Problem for Agriculture? 3 http://www.epa.ie/environment/air/emissions/ammonia/ Hyde, B.P., Carton, O.T., O’Toole, P.and Misselbrook, T.H. (2003). Atmospheric Environment 37:55-62. 5 http://www.agriculture.gov.ie/media/migration/farmingsectors/livestockandanimals/dairy/farmwastemanagementsc heme/FWM_Scheme2006.pdf 6 Stevens, J. (2003) Ammonia and Greenhouse Gas Emissions – Setting the Scene. IFBA Journal 2003 7 http://www.teagasc.ie/publications/2008/20081110/reps2008_paper02.asp 8 http://www.aesi.ie/aes2009/ghgworkshop/hyde.pdf 9 http://www.epa.ie/downloads/pubs/air/airemissions/ghg_provisional_20061.pdf 4 4 For centuries, livestock manure was utilised on farms as an important, if not only, source of nutrients for crops. As agriculture intensified in Ireland from the mid–sixties, combined with the availability of relatively cheap artificial sources of fertiliser, there was a dramatic reduction in the importance given to animal manures as a source of nutrients for crop growth. The land area of Ireland is 6.9 million hectares of which 4.2 million hectares is used for agriculture and a further 0.7 million hectares for forestry. Almost 80% of agricultural area is devoted to pasture, hay and grass silage (3.34 million hectares), 11% to rough grazing (0.45 million hectares) and 10% to crop production (0.42 million hectares)10. While total bovine numbers increased from 5.5 million to 7 million head (corresponding to a 27% increase) in the 25 year period from 1965 to 1990 the use of artificial nitrogen increased from 60,000 to 360,000t – a dramatic 600% increase11. Clearly the value of animal manures as a fertiliser source was demoted and increasingly it was managed purely as a “waste” product with all the nutrient requirements of grassland and tillage land being provided by artificial sources of nutrients. The “surplus” nutrients in the animal wastes could subsequently “leak” out of the production system ultimately leading to environmental pollution problems for air and water. Artificial fertiliser has many advantages: The material originally was relatively cheap. Artificial fertiliser can be purchased in exact quantities and blends to match crop requirements. The material can be applied at many times throughout the growing season to match crop demands. Machines used to apply the material can provide uniform application across the field. As the nutrients were “concentrated” there are no logistical problems with applying the material. Recycling nutrients in animal manures (slurry and farmyard manure) has many limitations: The nutrient content is variable12 (in the case of slurry the dry matter of the material has a huge influence on nutrient concentration). Timing of application events is difficult with a longer period required between application and grass usage (grazing or harvesting) than with artificial fertiliser. This resulted in a large Department of Agriculture, Fisheries and Food Fact Sheet – July 2009 http://www.epa.ie/downloads/pubs/other/events/oee/epanationalwaterconference2008/Martin%20McGarrigle.pdf 12 Nutrient and Trace Element Advice for Grassland and Tillage Crops, Teagasc Johnstown Castle ISBN 1-84170246-3 10 11 5 proportion of the material applied at the end of the growing season with associated problems of nutrient loss. Machines for applying manures may not consistently apply it uniformly across the field. As the nutrients are not concentrated (slurry is typically 95% water) large quantities have to be moved to provide the same quantity of fertiliser nutrients. This causes both logistical problems and also potential problems with soil compaction. These problems are exacerbated on sloping land with the additional issue in such cases of the risk of nutrient run-off causing pollution. The downgrading of manure as a nutrient source and its subsequent management (or mismanagement) as a waste to be disposed of increased the associated pollution risks on farms throughout Europe i.e. if the nutrients in the animal wastes are not being used by growing crops then they are potentially escaping from the production cycle and causing environmental problems13. Issues including ammonia (NH3) volatilisation, nutrient leaching, nutrient runoff, greenhouse gas emissions (GHG) etc. were identified as increasingly contributing to environmental problems. Problems were first identified in countries with very intensive agriculture in the early 1990’s and in The Netherlands action programs were put in place to reduce NH3 emission e.g. improved slurry application techniques and building design. As ammonia volatilisation was a trans-national border problem international agreements on NH3 emission abatement were subsequently implemented by the United Nations Economic Commission for Europe at Gothenburg in 199914. Similarly developed countries have agreed the Kyoto Protocol to limit GHG emissions15. There are continuing international commitments to review and update targets for NH3 & GHG emissions. In addition the EU Nitrates Directive16 was adopted with the aim to improve the management of nutrients (artificial and manure sourced) on farms and so reduce potential pollution risks. Ireland has undertaken its commitments to the relevant international agreements by: (i) (ii) (iii) implementing legislation e.g. Nitrates Directive by adopting programmes like the Rural Environmental Scheme(s) which encourage farmers by providing financial incentives to operate in a more environmentally friendly manner promoting better management of farm manures & slurry. 13 Monteny, G.J. Quantifying Ammonia Emissions from Buildings, Storage and Land Application. http://www.agriculture.de/acms1/conf6/ws4ammon.htm 14 http://www.unece.org/env/lrtap/multi_h1.htm 15 National Climate Change Strategy (2000). Department of the Environment and Local Government ISBN 0707665892 16 http://www.environ.ie/en/Environment/Water/WaterQuality/NitratesDirective 6 In the case of better management of animal slurries farmers are being encouraged to apply the material: At the correct time At the correct rate Applied uniformly in the field Applied by optimum equipment e.g. trailing-shoe for slurry Current Strategies to Reduce Ammonia and Methane Emissions Ammonia: Current advisory programs promote the more efficient use of slurry by spreading at the correct time of the year and by reducing the application rates of artificial fertiliser to take account of the nutrients in the slurry. With regard to the machinery type used application by the trailing–shoe system has been identified as a method to reduce NH3 emission. The system has the associated benefits in that (i) the nutrients are applied evenly (full width boom) with reduced odour levels, (ii) there is minimal contamination of the grass sward and (iii) there is a longer spreading window available as slurry can be deposited at ground level in a growing sward of grass. To encourage the uptake of these systems grants were provided to farmers under the Department of Agriculture, Fisheries and Food Farm Waste Management Scheme and the technique has been accepted as an Action Measure as part of REPS4. The market for these machines has been stimulated by these activities and it is estimated that 10 to 15% of slurry tankers now manufactured in Ireland are fitted with such devices. This figure will increase as conventional tankers are replaced in the future. Methane: While research is being undertaken on reducing methane emission to date there has been little practical success. Changing to concentrate based diets and feeding fish oil supplements do reduce emissions17. However, the fact that the competitiveness of Irish beef and dairy production is based on maximising the use of grass will limit the adoption of these solutions. Reduction in animal numbers could reduce the quantity of emission but this strategy would reduce farmer’s income and also reduce agriculture’s contribution to Ireland’s export earnings The Role of the Comfort Slat Mat in Reducing Ammonia & Methane Emissions Ammonia: As previously outlined, animal housing and land spreading of manures account for 79% of NH3 emission from cattle housing and associated land spreading of slurry on a 50:50 basis. Thus, while 17 http://www.ucd.ie/news/2009/04APR09/150409_fish_oils_reduce_cows_gas_emissions.html 7 the trailing-shoe system has been shown to reduce the emission of NH3 during the land spreading operation, a comparable amount of NH3 is potentially already lost by emission from the standard design of slatted accommodation. Trials in The Netherlands have shown that the Comfort Slat Mats reduces the “cattle accommodation element” of NH3 loss by up to 40%, while in the case of the Comfort Slat Mat and valve system the saving is up to 50%. The Dutch Ministry of Agriculture have introduced legislation in April 2008, requiring farmers building new housing for their Dairy or Beef animals to reduce Ammonia by 17% so the Comfort Slat Mat System allows the farmers to easily achieve & indeed to reduce emissions lower than the legislative limit. Thus a conservative estimate is that NH3 emission reductions of 30% from animal housing are consistently achievable in practice with the Comfort Slat Mat system. Methane: In the case of methane (CH4) the emission from the floor is reduced by 76% when Comfort Slat Mats are fitted. Taking that the floor contributes 25% of the actual methane emission from the animals in an accommodation system this means that the system reduces CH4 emission by 19% from housed animals. Thus a conservative estimate assuming that animals are housed for 40% of the year (5 months) is that CH4 reductions of 8% are consistently available in practice with the Comfort Slat Mat system. The Comfort Slat Mat has distinct advantages in reducing NH3 and GHC emissions: Cattle accommodation losses of NH3 are reduced by 30%. This can reduce Ireland’s ammonia emission and reinforce the nation’s sustainable agricultural production commitment to The efficiency of the use of trailing-shoe application technology, which is already supported by the REPS4 program, is dramatically increased i.e. there is more available N in the slurry from accommodation fitted with Comfort Slat Mats which can be utilised in the field. Trailing-shoe application technology is already supported by Department of Agriculture, Fisheries and Food support programmes. Using the Comfort Slat Mat in conjunction with the trailing-shoe system results in the increased efficiency of nitrogen recycling on farms. Note the 8 trailing-shoe application system is a higher cost system for the farmer or contractor so maximising the benefits of its use makes practical sense. Achieving an overall CH4 reduction of 8% using the Comfort Slat Mats while maintaining a grass based diet for bovines is a dramatic result. Other approaches being considered involve (i) a move from our low-cost grass based diets towards concentrate based diets with fish-oil additions or (ii) reducing animal numbers. The practical issues in implementing such emission reduction strategies would be more difficult to overcome than adopting the Comfort Slat Mat. The use of grass is a main pillar in Ireland’s competitive advantage in producing beef and dairy products. It is imperative that any initiatives to reduce CH4 emission allow farmers to continue to maximise the use of grass and silage in the animals’ diet. Reducing animal numbers as a means of reducing CH4 emissions will limit the export earning potential of agriculture. The Comfort Slat Mat provides a unique opportunity to reduce national CH4 emission while maintaining economically efficient production of beef and dairy products. Raw materials used in the manufacture of the Comfort Slat Mat System are 100% recyclable and environmentally friendly. _____________________________ Appendix 1: The Comfort Slat Mat System Comfort Slat Mat has designed & manufactured a mat for fitting to concrete slatted floors for the buildings used for the winter housing of Beef animals and for all year round housing for dairy & veal. The original concept was designed so that it was fixed by drilling the concrete & fixing the mats by screwing into the concrete slat. It was clear that this method was unsatisfactory for a number of reasons and the R&D process started : a) Establish the criteria that the farmers were seeking in such a product & also to find out their comments & opinions on mats which were already in existence for this application. b) The design & manufacture of a system that would meet the needs of the farmer in terms of animal welfare & comfort. c) To also design a product that would have environmental benefits. As the Comfort Slat mat was the only mat which was curved on the top surface, this was a major advantage in despatching the animal waste from the floor, thereby keeping the animals dryer & cleaner. This also reduced the amount of Ammonia as it has been established that in housing for beef & dairy cows 50% of the ammonia came from the floor & 50% from the tank underneath. Comfort mats & valves are made from material that is recyclable. 9 d) The registered patented design also included for a valve or flap which could be fitted or retrofitted. This addressed the Ammonia which came from the slurry tank underneath, but at the same time permitting the animal waste to exit through the flap into the tank. As Ammonia is a soluble gas, if it is prevented from escaping into the atmosphere, it is retained in the liquid slurry in the tank. The combined mat and valve system is unique in that it is the only product of its kind which addresses Animal Welfare and Environmental issues. Trials commenced during 2002 & 2003 on various designs of mats & valves in farms. This process extended into 2004 before a design concept and an acceptable range of raw materials which would withstand the rigorous working conditions that it would be subjected to in wear & against chemical attack. With the help of Enterprise Ireland this research and development continued over the period until September 2006 and, a material, design and manufacturing capability was established to produce the Comfort Slat Mat. Ongoing research on the valve system was continued over 2007 & 2008 to design the system that would further reduce Ammonia emissions which came from the tank. In 2008 in conjunction with The Animal Science Group of Wageningen UR, Netherlands, Mats and mats with valves were fitted to three of their floors in their Experimental Dairy Farm where they have over 800 milking cows. During 2008 ASG took measurements on the gas emissions coming from: a) A reference floor of concrete slats. b) Floor fitted with Comfort Slat Mats only. c) Floor fitted with Comfort Slat Mat & Valves. The results of these measurements can be seen in detail in Appendix 2, but the main points can be summarised thus: 1. Ammonia reductions achieved between 20 to 40%, using Comfort Slat Mat only. 2. Ammonia reductions of between 40-50% where Comfort Slat Mat & Valve were used. 3. Methane was reduced by 75% compared with the reference floor, giving an overall reduction of (25% x 76%) or 19%. As 25% of the Methane comes from the barn only, the remaining 75% emanates directly from the animal. There are four groups of Dutch farmers who have applied for the Green Label status, using either Comfort Slat Mats or Comfort Slat Mats and Valves . In addition, an agreement has also been reached with one of the largest concrete slat manufacturers in the Netherlands- Holcim B.V. who are making slats specifically to suit our slat mat which is green in colour and has become known in the Netherlands as “The Green Floor”. The Animal Science Group of Waginingen UR has requested us to work with them on a system for the Calf Industry, as the Dutch Ministry of Agriculture is introducing new legislation in 2010 in the interests of Animal Welfare as a result of intensive lobbying in the Netherlands by the Animal Rights Groups. This is as a direct result of the work which we have carried out in the Dairy Industry with them. 10 An application for approval of the Comfort Systems has also been made to the Danish Ministry of Agriculture. In view of the acceptance by the Netherlands, it is anticipated that approval for the use of our system will be forthcoming quickly. Once this is achieved, grant systems available within Denmark will make our products extremely attractive there. During the largest Agricultural Exhibitions held in Denmark in July called Landskuet the Comfort Slat Mat won the Gold Medal Award for the best innovative product of the 17 entrants for this award. For details refer to the website- www.slatmats.com. Comfort Slat Mats also won the National Ulster Bank Business Achievers Award ( Green Category) 2009. Enquiries have also been received from other European countries and from the USA & New Zealand. ______________________________ 11