supplemental material

advertisement

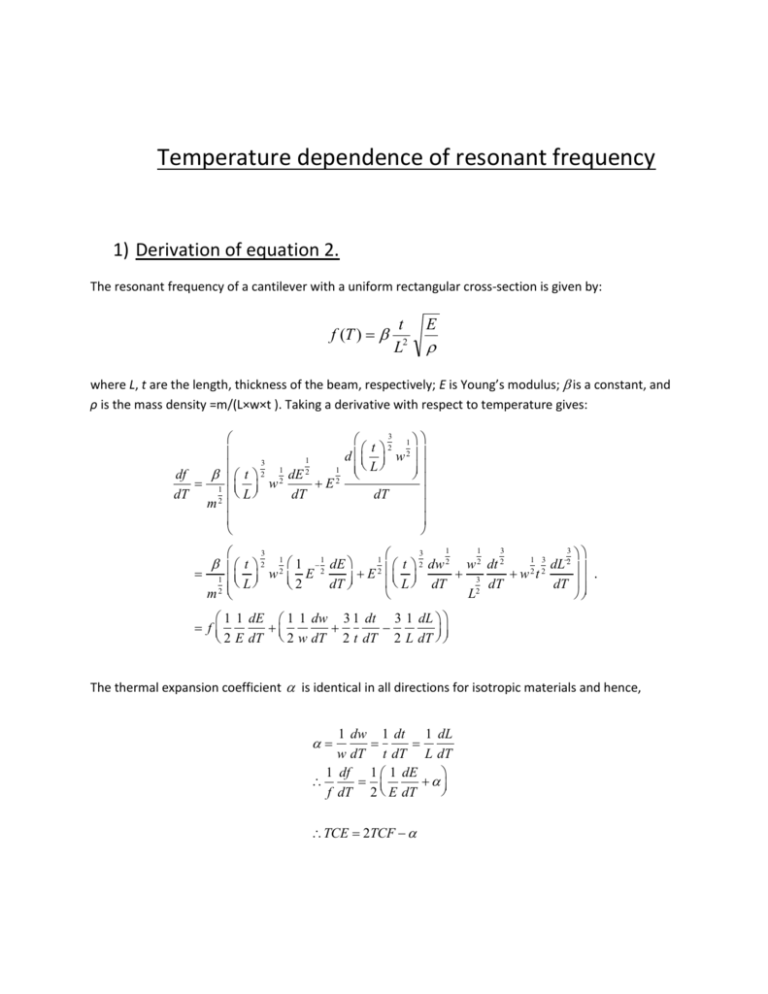

Temperature dependence of resonant frequency 1) Derivation of equation 2. The resonant frequency of a cantilever with a uniform rectangular cross-section is given by: f (T ) t L2 E where L, t are the length, thickness of the beam, respectively; E is Young’s modulus; is a constant, and ρ is the mass density =m/(L×w×t ). Taking a derivative with respect to temperature gives: 3 1 2 t 2 d w 1 3 L 1 1 2 df t 2 dE 1 w2 E2 dT L dT dT m2 3 3 1 1 3 3 1 1 3 t 2 1 1 1 dE t 2 dw 2 w 2 dt 2 dL2 2 2 2 1 w2 E 2 E w t . 3 L L dT dT dT dT 2 m 2 L2 1 1 dE 1 1 dw 3 1 dt 3 1 dL f 2 E dT 2 w dT 2 t dT 2 L dT The thermal expansion coefficient is identical in all directions for isotropic materials and hence, 1 dw 1 dt 1 dL w dT t dT L dT 1 df 1 1 dE f dT 2 E dT TCE 2TCF where TCE is the temperature coefficient of modulus and TCF is the temperature coefficient of frequency. A somewhat similar expression is given in reference 1. However, that reference deals with doubly clamped beams where one must to take into account the stresses due to thermal expansion mismatch. Cantilevers presented in this study are stress-free, which enables us to extract intrinsic properties provided they do not have very large overhangs as discussed below. 2) Relative change in Young’s modulus: The relative change in Young’s modulus with respect to low temperature value in terms of resonant frequency is given by: E (T ) f (T ) 2 E ( 0) f ( 0) 2 1 T 1 (T ).dT 0 where (T ) is coefficient of thermal expansion which is given by 2 as (T ) =4.34×10-14T3 . 3) Temperature dependence of resonant frequency of cantilevers with stress relaxed overhangs: Fixed-free cantilevers are stress-free structures and hence the frequency shifts are intrinsic to the material. However, even though the cantilevers are free of stress, the overhangs at their base are not. In our earlier publication 3 we have shown that resonant frequency of the cantilevers strongly depends on the extant of the overhang at the cantilever base. If the overhanging length is long enough, then residual compressive stresses in UNCD films will result in wrinkles, as discussed in references 3,4 . Residual stresses are partly due to thermal mismatch stresses which change as a function of temperature, as does the period and amplitude of the wrinkles at the cantilever base 3-5 . A discussion regarding the evolution of this curvature is provided in references 3,4. Even though changes in the thermal expansion coefficient contribute negligibly to the changes in resonant frequency of cantilevers with no overhang, the changes in thermal stresses can significantly alter the temperature-dependent response of the resonant frequency for resonators which have wrinkles at their base depending on the position of the cantilever on this undulating base. Figure 1. Temperature dependence of the resonant frequency for cantilevers with overhangs ranging from 0 (no overhang) to 85 m overhang 5, and with lengths ranging from 200 µm to 460 µm 4. Cantilevers are ~1 µm thick. The square of resonant frequency is proportional to modulus, and is compared with that of single crystal diamond (averaged over all directions) normalized to room temperature value. We investigated the effects of the presence of wrinkles at the cantilever base on the temperature dependence of the resonant frequency for these cantilever beams. For cantilevers with small or negligible overhangs, the shift in the resonant frequency compares very well with that of the single crystal diamond, as shown Figure 1. However, for larger overhangs (for overhangs > 55 m, film thickness ~1 µm), wrinkles form at the base, and we observed that smaller cantilever beams had a higher temperature coefficient of frequency compared with larger ones. Figure 2. A white light interferometer image of a UNCD film where the left part is overhang due to etching of the underlying substrate. Above is a schematic of the same 4. Cantilevers protrude out of this stress-relaxed overhang. Above 55 m of overhang, wrinkles start to form and the temperature dependence of the frequency strongly depends on the length of cantilever, extant of the overhang and its position on the wrinkles. This indicates that wrinkles strongly influence the observed shifts. The observed frequency shifts were also strongly dependent on the position of the cantilever with respect to the wrinkle feature, i.e., on a trough, a ridge, or in between. We observed a slight increase in the resonant frequency for cantilevers with 85 m of overhang as we increased the temperature from 138 K to 160 K. The mismatch of thermal expansion coefficients between single crystal diamond 2 and silicon 6 decreases as the temperature is reduced and changes sign below 160 K. A slight increase in the resonant frequency with temperature from 138 K to 160 K is due to a reduction in the thermal mismatch stress due to the fact that thermal mismatch changes sign. Since observed resonant frequency depends on the extant of the overhang 3, cantilevers with very small or no overhangs do not suffer from any of these issues. Clearly, it is critical to use cantilevers with sufficiently small overhangs to investigate the true nature of the resonant frequency shifts and the associated thermo-mechanical properties in materials made of these cantilevers. Therefore, measurements taken on cantilevers with large overhangs were not used in our analysis. References: 1 2 3 4 5 6 R. Melamud, M. Hopcroft, C. Jha, B. Kim, S. Chandorkar, R. Candler, and T. W. Kenny, TRANSDUCERS '05. The 13th International Conference on Solid-State Sensors, Actuators and Microsystems, 2005. Digest of Technical Papers, 1, 392 – 395 (2005). S. Stoupin and Y. V. Shvyd'ko, Physical Review Letters 104, 085901 (4 pp.) (2010). V. P. Adiga, A. V. Sumant, S. Suresh, C. Gudeman, O. Auciello, J. A. Carlisle, and R. W. Carpick, Physical Review B (Condensed Matter and Materials Physics) 79, 245403 (8 pp.) (2009). V. P. Adiga, Ph.D. Thesis, University of Pennsylvania, 2010. V. P. Adiga, A. V. Sumant, S. Suresh, C. Gudeman, O. Auciello, J. A. Carlisle, and R. W. Carpick, Proc. SPIE - Int. Soc. Opt. Eng. (USA) 7318, 731818 (9 pp.) (2009). K. G. Lyon, G. L. Salinger, C. A. Swenson, and G. K. White, Journal of Applied Physics 48, 865-8 (1977).