Glove Selection Guide - University of Leicester

advertisement

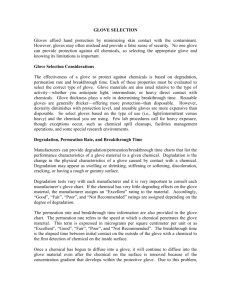

Glove Selection Guide Guidance for University Departments and Functions December 2001 Safety Services Office GLOVES AS PERSONAL PROTECTIVE EQUIPMENT ................................................................ 1 FIRST STEPS IN GLOVE SELECTION ............................................................................................ 1 CHEMICAL RESISTANCE ................................................................................................................. 2 DEFINITIONS ............................................................................................................................. 2 GLOVE MATERIALS ................................................................................................................ 3 GLOVE SELECTION CHARTS .............................................................................................. 4 EXAMPLE OF A GLOVE SELECTION (CHEMICAL RESISTANCE) CHART) .... 7 USE OF DISPOSABLE GLOVES ........................................................................................................ 8 CORRECT USE OF GLOVES ............................................................................................................. 9 SUMMARY: GENERAL RULES FOR HAND PROTECTION ..................................................... 11 REFERENCES ..................................................................................................................................... 12 Gloves as Personal Protective Equipment The Personal Protective Equipment (PPE) at Work Regulations 1992 require that: “Every employer shall ensure that suitable personal protective equipment is provided to his employees who may be exposed to a risk to their health or safety while at work except where and to the extent that such risk has been adequately controlled by other means which are equally or more effective.” PPE is always the “last resort” in a hierarchy of control measures, i.e. engineering controls and safe systems of work should always be considered first. It may be possible to do the job by another method which does not require the use of PPE. In some circumstances PPE such as gloves will still be required to control the risk adequately and the PPE at Work Regulations will then take effect. First steps in glove selection It is important to establish the exact purpose of a protective glove in any given situation. 1) Is a glove needed at all? Prolonged wear can lead to a weakening of the barrier properties of the skin because of occlusion. 2) Is a glove needed just to keep the hands clean? If the hazard is minor, e.g. cleaning up dusty or greasy rubbish, a fabric work glove can be more suitable than a rubber glove. 3) Is it for protection against heat, cold, abrasion or cuts? “general purpose” rubber gloves are not suitable for these situations – specialised gloves are needed. Select from a good safety supplies catalogue. 4) Is it for protection against chemicals? a) Protection against incidental contact (i.e. against small splashes) – a disposable glove may suffice, nitrile being a good choice for most applications. b) Protection against sustained contact or immersion – thin disposable gloves are not suitable. Consult a manufacturer’s chemical resistance chart to select the correct glove material – see “Chemical resistance” below. 5) Is it for protection against blood-borne viruses? For handling blood and body fluids, a latex or nitrile glove will be suitable. 6) Is it for protection against laboratory animal allergens? For handling live animals or normal animal tissues, latex or nitrile gloves will be suitable For handling animals when administering compounds use gloves appropriate for the chemical (see next section, and the list on page 6.) 1 Chemical resistance DEFINITIONS Permeation rate is the rate at which the chemical will move through the material. It is measured in a laboratory and is expressed in units such as milligrams per square meter per second, or some other [weight of chemical] per [unit area of material] per [unit of time]. The higher the permeation rate, the faster the chemical will move through the material. The process of permeation continues even when the glove is no longer in contact with the chemical. Users should be aware that when a glove has been in contact with a chemical, the glove will to some extent be infiltrated with the chemical due to permeation. Permeation is different from penetration. Penetration occurs when the chemical leaks through seams, pinholes and other imperfections in the material: permeation occurs when the chemical diffuses or travels through intact material. Breakthrough time is the time it takes a chemical to permeate completely through the material. It is determined by applying the chemical on the glove exterior and measuring the time it takes to detect the chemical on the inside surface. The sensitivity of the analytical instruments used in these measurements influence when a chemical is first detected. The breakthrough time gives some indication of how long a glove can be used before the chemical will permeate through the material. Breakthrough time is the key parameter recognised by the current European standard for protective gloves (BSEN 374-1: 1994.) American standard tests use permeation rate test data, but European standards do not. The European standard defines the following protection classes for gloves: Measured breakthrough time (minutes) Protection Index >10 >30 >60 >120 >240 >480 Class 1 Class 2 Class 3 Class 4 Class 5 Class 6 Degradation is a measurement of the physical deterioration of the material due to contact with a chemical. The material may get harder, stiffer, more brittle, softer, weaker or may swell. The worst example is that the material may actually dissolve in the chemical. 2 GLOVE MATERIALS Selection of glove materials should be based on quantitative information such as permeation rate, breakthrough time, penetration and degradation, and the other considerations mentioned above. Various factors like the thickness of the material, manufacturing methods, and product quality control can have a significant effect on these properties. For a few specific situations when it is impossible to predict the variety of hazards, multi-laminate gloves made of layers of several different materials are available. Some of the more common glove materials are: butyl - a synthetic rubber with good resistance to weathering and a wide variety of chemicals. latex (natural rubber) - a highly flexible and conforming material made from a liquid tapped from rubber plants. Also referred to as NRL. neoprene - a synthetic rubber having chemical and wear-resistance properties superior to those of natural rubber. nitrile - a copolymer available in a wide range of acrylonitrile (propane nitrile) content; chemical resistance and stiffness increase with higher acrylonitrile content. Also called NBR or HNBR. polyethylene - a fairly chemical-resistant material used as a freestanding film or a fabric coating. polyvinyl alcohol - a water-soluble polymer that exhibits exceptional resistance to many organic solvents that rapidly permeate most rubbers. Not to be used with aqueous solutions. polyvinyl chloride - a stiff polymer that is made softer and more suitable for protective clothing applications by the addition of plasticizers. Also called vinyl or PVC. polyurethane - an abrasion-resistant rubber that is either coated onto fabrics or formed into gloves or boots. Viton® - a registered trademark of DuPont, it is a highly chemical-resistant but expensive synthetic elastomer. For a given thickness, the type of polymer selected has the greatest influence on the level of chemical protection. For a given polymer an increase in thickness will result in a higher level of protection. A rule of thumb is that double the thickness will quadruple the breakthrough time. The manufacturing process of glove making may result in slight variations in performance. The user is warned to exercise care and to check the glove regularly for breakthrough and diminished physical performance. The selection of the proper chemical-resistant glove begins with an evaluation of the task to be undertaken. Factors that influence this selection are: the type of chemicals to be handled; frequency and duration of chemical contact – longer exposure time will shorten the breakthrough time; nature of contact (total immersion or splash only); concentration of chemicals; 3 temperature of chemicals – higher temperature will shorten the breakthrough time; abrasion-resistance requirements; puncture-, snag-, tear-, and cut-resistance requirements; length of hand and arm to be protected (hand only, forearm etc.); dexterity requirements - this need may significantly limit the thickness of glove material that can be used; grip requirements (dry grip, wet grip, oily) - the requirement for textured or non-slip surfaces to improve grip must be considered; cuff edge (plain, knit wrist, gauntlet); colour requirements (to show contamination); thermal protection; size and comfort requirements; price. Combination Hazard For mixtures and formulated products, the glove should be selected for maximum protection against the chemical component with the shortest breakthrough time (unless specific test data are available). Care should be taken to select a glove material that is compatible with all the components. Do not wear latex gloves if you have or think you are susceptible to a latex allergy. Any indication of possible latex allergy must be reported to the Head of Department and the Safety Services Office (see ref. 16.) GLOVE SELECTION CHARTS Gloves of various types are available from many different manufacturers and distributors. For non-incidental contact, start with selection charts provided by glove manufacturers. However, note that: Different manufacturers use different formulations and manufacturing processes, and a glove from one company may not have the same chemical resistance as a similar glove from another company. Glove selection based on the manufacturers' glove selection charts is often impossible, as only a limited range of chemicals have been tested for use with a specific manufacturer's glove. In particular, many research grade chemicals have not been tested by the various glove manufacturers. If in doubt contact the manufacturers of the chemical and the glove for advice. Physical performance may be a more critical factor in some cases than chemical resistance. If a job application involves handling heavy, rough, or sharp objects then the glove must have high resistance to abrasion, cuts, snags, etc. A hole in a glove can provide much greater chemical exposure potential than molecular permeation. The thicker the glove material the greater the chemical resistance. But thick gloves can impair grip, dexterity, and safety. Consider sensitivity and the ability to grip as very important factors. The proper glove design and fit contribute to comfort, productivity, and safety. Curved-finger glove design fits the natural hand contour for working comfort. Gloves that are too small bind and cause undue hand fatigue. However, gloves that are too 4 large are uncomfortable, hard to work in and can be dangerous if they get caught up in work equipment. The phrase sometimes found on Material Safety Data Sheets (MSDS) “Wear impervious (or impermeable) gloves” is technically inaccurate. No glove material remains impervious to a specific chemical indefinitely and no one glove material is resistant to all chemicals. Some chemicals will travel through or permeate the glove in a few seconds, while other chemicals may take days or weeks. Information specifying the best type of chemical protective material should be on the MSDS (e.g. neoprene, butyl rubber). If this information is missing, contact the supplier or manufacturer of the product. Contact the glove manufacturer if you have specific questions about their gloves. A professor in the USA died in 1997 from exposure to dimethylmercury, which penetrated her latex gloves. A researcher at Darmouth died in June of 1997 from acute mercury poisoning. Her exposure was the result of approximately one-half of a milliliter of dimethyl mercury falling on her hand during an experiment. Although she was wearing latex gloves and replaced them soon after the exposure, within several months she had developed mercury poisoning. The reason for her exposure was that dimethyl mercury easily permeates latex gloves. She and many of her colleagues around the world were totally unaware of this property of dimethyl mercury although they frequently use it. (quoted from http://www.ehs.washington.edu/updates/tipsGloves.htm) The type of chemical used is the most important factor for selecting gloves to protect against chemical exposure, especially for highly toxic chemicals. Select the glove with the highest chemical resistance rating and other glove properties that best address your application. For highly toxic chemicals, the use of an inner and outer glove may be necessary. For example, a highly resistant laminated glove should be worn under a pair of long-cuffed, unsupported neoprene, nitrile, or similar heavy-duty gloves when highly toxic chemicals are being handled. There are many resources available to assist in selecting the proper glove for your application (see references.) An example of a simple glove selection chart is reproduced below. Such tables should be used as a starting point for proper selection of glove material, but not used alone. These charts have their limitations: it is often not possible to tell what thickness of glove is being referred to it is often not possible to tell on what basis judgements such as “good” or “poor” are being made (breakthrough time, permeation rate?) conflicting advice will sometimes be found there is sometimes no indication of the quantitative data on which semiquantitative statements are based (what is the cut-off between “good” and “fair”?) unless specifically stated, charts giving breakthrough times or permeation rates do not refer to thin disposable gloves. Reliable information is best obtained by finding data for the specific glove in question – this information is usually only obtainable from the supplier or manufacturer. This is sometimes available on manufacturers’ Web sites, e.g. Ansell, and sometimes as 5 printed tables e.g. Marigold Industrial. (See References for both.) The type of information and level of detail given by manufacturers varies – Marigold Industrial, for example, provide a detailed table showing breakthrough time, permeation rate and degradation time. 6 EXAMPLE OF A GLOVE SELECTION (CHEMICAL RESISTANCE) CHART Source – Denison University, USA (E = Excellent. G = Good, F = Fair, P = Poor) Chemical Acetaldehyde Acetic Acid Acetone Acrylonitrile Ammonium hydroxide (conc.) Aniline Benzaldehyde Benzene Benzyl Chloride (a) Bromine Butane Butyraldehyde Calcium hypochlorite Carbon disulfide Carbon tetrachloride Chlorine Chloroacetone Chloroform (a) Chromic acid Cyclohexane Dibenzyl ether Dibutyl phthalate Diethanolamine Diethyl ether Dimethyl Sulfoxide (b) Ethyl acetate Ethylene dichloride (a) Ethylene glycol Ethylene trichloride (a) Fluorine Formaldehyde Formic acid Glycerol Hexane Hydrobromic acid (40%) Hydrochloric acid (conc.) Hydrofluoric acid (30%) Hydrogen peroxide Iodine Methylamine Methyl cellosolve Methyl chloride (a) Methylene chloride (a) Methyl ethyl ketone Monoethanolamine Morpholine Naphthalene (a) Nitric acid (conc.) Perchloric acid Phenol Phosphoric acid Potassium hydroxide (sat.) Propylene dichloride Sodium hydroxide Sodium hypochlorite Sulfuric acid (conc.) Toluene (a) Trichloroethylene (a) Tricresyl phosphate Triethanolamine Trinitrotoluene Natural Rubber Neoprene Nitrile Vinyl G E G P G F F P F G P P P P P G F P P F F F F F F P G P G G G G P G G G G G G F P F F F F G P F G G G P G G G P P P F P G E G G E G F F P G E G G P F G E F F E G G E G G F G P G E E G E E G G G G G E E F G E E G P G E E G F G P G F F F E E E E G E E E G G G G G G F E G G E E E E G G G E G G E P F G G F F G G E - G E F F E F G F P G P G G F F G P P E P P P E P F P E P G E E E P E E E E G E P P F P E E G G E E E E P E G G F F F E P 7 (a) Aromatic and halogenated hydrocarbons will attack all types of natural and synthetic glove material. Should swelling occur, the user should change to fresh gloves and allow the swollen gloves to dry and return to normal. (b) No data on the resistance to dimethyl sulfoxide of natural rubber, neoprene, nitrile rubber, or vinyl materials are available; the manufacturer of the substance recommends the use of butyl rubber gloves. The table was taken from Prudent Practices for Handling Chemicals in Laboratories, National Research Council, National Academy Press Washington, D.C., P. 159-160 (1981) Use of disposable gloves Disposable versus Re-usable Gloves The first task is to decide if single use, surgical or examination type gloves will provide adequate protection. Reusable gloves are necessary wherever there is heavy contact with chemicals, immersion in chemicals or potential for contact with extremely hazardous chemicals. Disposable gloves can provide protection only against splashes and incidental chemical contact. Disposable gloves do not provide the same degree of chemical protection as reusable gloves. Disposable latex and nitrile gloves are the most common gloves used in research laboratories. Standard latex examination gloves are cheap and do provide protection for biological and minor chemical hazards. However, they are not recommended for protection from chemicals and are generally not listed in chemical glove selection guides. While disposable nitrile gloves are slightly more expensive than latex, glove selection data can be found for some of them, and they are more suitable for general lab use. Note that the performance levels defined by BSEN 374, as described above under “definitions, may not be assigned to some disposable gloves, which are classified as being “For minimal risks only”. Again it must be remembered that gloves are the last line of defence against chemicals and must therefore be used as “last resort” protection, after other control measures have been applied where possible. Gloves for incidental and extended contact "incidental contact" - none, or very little, actual contact with a chemical in use is anticipated. Disposable gloves can be used for incidental contact, as long as no very hazardous chemicals are being used. The gloves are there to prevent chemical contact with the skin when something goes wrong--a spill or splash to the hand, over spray from a dispensing device, etc. As soon as practicable after the chemical makes contact with the gloved hand the gloves must be removed and replaced. "extended contact" - the gloved hands come into substantial contact with or actually may become covered with or immersed in the chemical in use. 8 Generally, a glove specified for incidental contact is not suitable for extended contact and a more substantial glove will be required. Latex gloves Latex disposable gloves offer no worthwhile protection against many commonly used chemicals. They will severely degrade, often in a matter of seconds or minutes, when used with some chemicals (e.g. turpentine.) The use of disposable latex gloves is only appropriate for: Most biological materials including laboratory animal allergens Non-hazardous chemicals Very dilute, aqueous solutions of hazardous chemicals: Less than 1% for most hazardous chemicals or less than 0.1% if a known or suspect human carcinogen is in use in aqueous solution. Clean work area requirements Medical, veterinary and animal husbandry applications. An estimated 8-12% of the population are allergic to latex products. Staff required to wear latex gloves should receive training on the potential health effects related to latex. If latex is required, hypo-allergenic, non-powdered gloves should be used. Nitrile gloves In all cases single use, surgical or examination type nitrile gloves can be substituted for latex gloves. Nitrile gloves are more durable and provide a clearer indication when they tear or break. Nitrile gloves also offer a better set of chemical resistances and are less allergenic. Correct use of gloves INSPECTION: All gloves should be inspected before use for indications of degradation (swelling, cracking, shrinking, or discoloration) and any signs of cuts, splits or punctures. A damaged glove should be immediately disposed of. Change gloves frequently, especially thin disposable gloves that have been exposed to chemicals. 9 If chemicals are known or suspected to have reached the inside of a glove, either by penetration or permeation, the glove must be removed and discarded as soon as possible. CLEANING: Thicker reusable gloves should be rinsed after use to prolong their life and prevent the spread of chemical contamination from the dirty glove. Cleaning and re-use of disposable gloves is not recommended. REMOVAL: Remove gloves before leaving the immediate work site to prevent contamination of door knobs, light switches, telephones, etc. When removing gloves, pull the cuff over your hand and turn the glove inside-out. Wash your hands thoroughly with soap (or soapless hand cleanser) and water after wearing gloves. TRAINING: Staff training should include consideration of: what are the hazards of skin contact with the chemical? what are limitations of the gloves? what could happen and what to do if the gloves fail? when to dispose of or to decontaminate gloves. RE-USE OF GLOVES USED WITH HAZARDOUS CHEMICALS Glove decontamination and reuse are controversial and unresolved issues. Often, surface contamination can be removed by scrubbing with soap and water; at other times, as in the case of emulsifiable concentrates, it may be practically impossible. The solvents in many emulsifable concentrates prompt this concern. Volatile solvents such as toluene and xylene readily penetrate many polymers and the non-volatile solvents, such as alkylated napthalenes and petroleum oil, are very difficult to remove from the glove material. Once absorbed, some chemicals will continue to diffuse through the material toward the inside even after the surface has been decontaminated. For highly chemical resistant gloves, the amount reaching the inside may be insignificant, but for moderately performing materials, significant amounts of chemicals can reach the inside. This may not occur during use, but while the glove is stored overnight. The next morning, when the worker dons the glove, he may be putting his hand into direct contact with a hazardous chemical. In addition to the chemical resistance of the glove material, the amount of chemical reaching the inner surface can be affected by the duration of exposure, duration of storage, the surface area exposed and the temperature. The decision to reuse the gloves requires consideration of these factors as well as the toxicity of the chemical(s). Unless extreme care is exercised to ensure decontamination, the reuse of gloves that have been contaminated with a toxic chemical is not advisable. For this reason, the disposal of gloves on a regular and frequent basis is advisable. 10 Summary: General rules for hand protection 1. Protective gloves shall be worn where there is a likelihood of skin contact with irritant or corrosive chemicals, or with chemicals that can be absorbed through the skin. 2. Protective gloves that provide protection against cuts and abrasions shall be worn when handling sharp, rough or abrasive objects. 3. Gloves that provide thermal insulation shall be worn when hot or very cold objects must be handled. 4. Gloves should be selected on the basis of the materials being handled, the physical conditions that exist, and the requirements of the tasks to be performed. 5. Before each use, chemical resistant gloves shall be inspected for punctures, tears or other signs of degradation and new gloves used if these conditions are found. Disposable gloves must not be re-used if they have been in contact with hazardous chemicals. 6. Gloves, other than single use types, should be decontaminated by rinsing or washing before removal. 7. Special gloves are manufactured for use by electricians, welders and others. It is the responsibility of the supervisor to determine whether such specialised hand protection is needed and to make sure that it is readily available when needed. 8. Choose gloves of good quality – the cheapest gloves are unlikely to have undergone stringent quality control procedures during production. The gloves should be CE marked. 9. Do not use oil-based hand creams, such as barrier creams, when wearing rubber or plastic gloves. 10. Wash hands after removing gloves, and apply hand cream if desired. 11. Gloves should be removed when picking up a telephone or using equipment that other people touch bare-handed. Like all personal protective equipment gloves should be removed before leaving the hazard area. 12. Gloves should not be used where there is a danger of the glove becoming caught in moving machinery or materials. 13. Sleeves must be worn outside glove gauntlets when caustic substances are being poured. Note also: All glove materials are permeable to some extent. No one material serves as a barrier to all chemicals. A suitable glove is one that has an acceptably low 11 breakthrough time for the chemical being used under the circumstances of use. Breakthrough time is generally inversely related to glove thickness. Thin cotton gloves worn under rubber gloves improve comfort by absorbing perspiration during prolonged use. They also reduce chances for skin absorption by separating the glove surface and the skin. However, if the cotton lining contacts a hazardous material, it can act as a wick and soak up the hazardous material. References 1. Ansell Protective Products (manufacturer) – information on protective gloves, article on latex and chemical allergy, glove selection guidance http://www.ansell.be/ (from “Online Chemical Application & Recommendation Guide” from the menu on the left of the screen, click on “EN”.) 2. Marigold Industrial (manufacturer) http://www.marigoldindustrial.com/ 3. Kimberley-Clark Skin Wellness Institute http://www.kcskinhealth.com/ 4. Canadian Centre for Occupational Health & Safety: glove selection guidance http://www.ccohs.ca/oshanswers/prevention/ppe/gloves.html 5. EnviroDerm Services – articles and reports on skin protection http://www.enviroderm.co.uk/ 6. HSE leaflet on Personal Protective Equipment http://www.hse.gov.uk/pubns/ppe92a.htm 7. Edinburgh University Occupational Hygiene Unit’s glove guide http://www.safety.ed.ac.uk/resources/occ_hygiene/gnote_2.html Chemical resistance charts: 8. Florida State University: chemical resistance chart – a good basic chart http://www.safety.fsu.edu/chp.html - appendix6 9. University of Oxford glove guide – very useful information on selection by glove material and by chemical http://users.ox.ac.uk/~phar0036/biomedsafety/labsafety/ppe/gloves/ppegloves.html 10. US Department of Energy glove guide Glove Selection Material Chart (OSH-DOE) 11. Safeskin guide – chemical compatibility of latex and nitrile disposable gloves http://www.inform.umd.edu/CampusInfo/Departments/EnvirSafety/ls/safeskin.html 12 Available from the Safety Services Office: 12. Marigold Industrial chemical resistance chart and glove selection guide. 13. Video– Managing Latex Reactions and Sensitivities. 14. PowerPoint Presentation on CD-ROM: Managing Latex Reactions and Sensitivities. 15. Cost and Effectiveness of Chemical Protective Gloves for the Workplace (HSG 206). HSE, 2001 16. Policy and Code of Practice for the Prevention of Latex Allergy (University of Leicester). 17. Personal Protective Equipment (University of Leicester.) (in preparation) 18. Latex Allergy – information document (University of Leicester.) (in preparation) 13