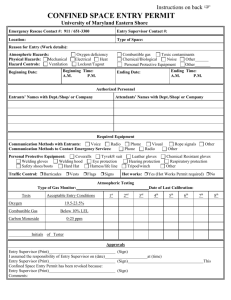

UCR CONFINED SPACE - Environmental Health & Safety

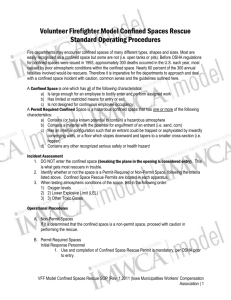

advertisement