MASAMI SHIMIZU* and KENJI TAKESHITA

advertisement

STUDIA UNIVERSITATIS BABEŞ-BOLYAI, PHYSICA, SPECIAL ISSUE, 2001

COMPARISON BETWEEN WATER DISTILLATION PROCESS AND

HYDROGEN ISOTOPE EXCHANGE PROCESS FOR DEPLETION

AND ENRICHMENT OF TRITIUM IN LIGHT WATER

MASAMI SHIMIZU* and KENJI TAKESHITA**

* Isotope Science Laboratory 1198 Issiki, Hayama, Kanagawa-ken 240-0111, Japan

** Dept. of Environmental Chemistry and Engineering, Tokyo Institute of Technology,

4259 Nagatsuda, Midori-ku, Yokohama 226-8502, Japan

ABSTRACT. The dimensions of typical tritium separation processes, water distillation

process and the hydrogen-isotope exchange process with hydrophobic Pt-catalyst, were

evaluated numerically for the recovery of tritium from wastewater generated by the

decommissioning of Magnox reactor. Both the column diameter and the column height

required for the hydrogen-isotope exchange process were much smaller than these for the

water distillation process. The application of hydrogen-isotope exchange process to the

treatment of the tritiated wastewater is effective for not only the reduction of process

dimensions but also the depression of energy consumption.

1. Introduction

When a 165-MWe Magnox reactor is decommissioned, a large amount of tritiated

wastewater is generated by cutting the concrete and the steel structure of reactor (1). Then,

the quantity of tritiated wastewater and the content of tritium in the wastewater are given

as 7600 m3 and 2.2×1011 Bq, respectively (1). If tritium is recovered by operating an

appropriate separation process for 5 yrs and then the operating time of separation process

per year is given as 8000 h/y, the waste water flow rate, F, and the tritium concentration

of the waste water, xF , are evaluated as

F

xF

7600 10 3 kg

1

10.56kmol / h

5y 8000h / y 18kg / kmol

(2.2 10 Bq)(3.12 10

11

10

3

m / Ci)

(7600 m )(3.7 10 Bq / Ci)

3

10

(1-1)

2.44 10 13 T atom fraction

(1-2)

respectively. In this study, typical separation processes, the water distillation process and

the hydrogen-isotope exchange process using Pt-catalyst, were applied for the recovery

of tritium in the wastewater. The dimensions of these processes were evaluated

numerically under the following same initial conditions,

COMPARISON BETWEEN WATER DISTILLATION PROCESS AND HYDROGEN ISOTOPE …

- tritium concentration of T-enriched waste water : xp = 104xF = 2.44×10-9 T-atom fraction

- tritium concentration of T-depleted waste water : xD ≤ 1×10-14 T-atom fraction.

Namely, the ratio of (xP / xF) = 104 and that of (xD / xF) ≤ ( 10-14 ) / ( 2.44×

-13

10 ) = 0.041. When tritium concentration of the waste water xD is less than 10-14

T-atom fraction, the wastewater is dischargeable directly to the atmosphere. When either

the water distillation process or the hydrogen isotope exchange process is applied for the

recovery of tritium from the wastewater, it is necessary to remove the impurities in the

wastewater as a pretreatment of the wastewater. In this study, the process dimensions

will be evaluated for the wastewater without impurities.

2. Isotope Separation factors

Two isotope exchange reactions between hydrogen and tritium,

H 2 O(g) HT(g) HTO(g) H 2 (g)

(2-1)

(2-2)

H2O(l) HTO(g) HTO(l) H2O(g)

have to be considered for the numerical evaluation of proposed processes. In the

previous papers (2),(3) , the isotope separation factor for Reaction (2-1), gH / T , is given as

gH / T

[HTO(g)][H 2 (g)]

336.5

exp{0.292 log( t 273)

1.055}

[H2O(g)][HT(g)]

t 273

(2-3)

and that for Reaction (2-2), lH / T , as

lH / T

[HTO(l)] [H2O(g)] PH 2O

47.98

23122

exp{0.00791

}

[H2O(l)] [HTO(g)] PHTO

t 273 (t 273)2

(2-4)

where t denotes Celsius temperature. From Eqs.(2-2) and (2-4), the separation factors of

gH / T and lH / T can be calculated as the function of temperature.

3. Water distillation process

Fig.3-1 shows the schematic description of water distillation process. Tritium is

enriched at the bottom of column. The separation performance of tritium in water

distillation column was described mathematically in the previous paper(4). The ratios of

tritium fraction between bottom and feed, (xP/xF) and that between top and feed, (xD/xF),

are given as

P

( P / V ) (1 1 )

(

P

/

V

) (1 1 )(1 / )M 1

F

D (1 / )1 (1 1/ ) (1 / ) N 1 (1 1 )

N

F (1 / ) 1 (1 1/ ) (1 / )(1 1 )

(3-1)

(3-2)

respectively.

71

MASAMI SHIMIZU and KENJI TAKESHITA

In the conditions that

the process is operated at

70°C, the separation factors

are calculated as

lH / T 1.062

and

Con d en s er

D(1 )

x

'

N 1

(R ’+1 )

( x D ) (Ls / D=R’)

y N 1

x 'N1

N

Ls

y 1

HP

1

s tr ip p in g

s ection

x1'

F

xF

x M +1

yM

xM

M

Le

V

x2

E n r ich in g

s ection

y1

x1

1

(R+1 )

(R=V / P)

Still

x0

P ?l ?

HB

x 0 (= x P )

Fig. 3 -1 Sch em a tic d es cr ip tion of wa ter d is tilla tion colu m n

1 1 / lH / T 1 / 1.062 0.942

As shown in Eq.(1-2), the

atom fraction of tritium in

the feed solution is estimated

as xF = 2.44x10-13. When

the overall separation factor

for the enrichment of tritium

is given as104, the atom

fraction of tritium in the

production and the fraction

ratio of (xD /xF) are given as

xP = 2.44×10-9 and 0.041,

respectively, from the mass

balance equations of tritium,

FxF=PxP+DxD and F=P+D.

Therefore, the molar flow

rates of product water and

stripped water are calculated

as

PF

(x F x D )

10.56 x(9.59 x105 ) 1.013x103

(x P x D )

kmol / h

D F P 10.56 1.013x10 3 10.559 kmol / h

The molar ratio of the production flow to the vapor flow, (P/V), is given as

(P / V )

P

D(1 R)

where R’ denotes the reflux ratio at the top of distillation column. The molar ratio of the

production flow to the depletion flow is described as

(P / D)

1 (x D / x F )

(x P / x F ) 1

from the overall mass balance equation of tritium. From (xD /xF)=0.041 and (xP/xF)=104,

(P / V)

72

1 0.041 1

1

(9.591 10 5 )

(10 4 1) (1 R )

(1 R )

COMPARISON BETWEEN WATER DISTILLATION PROCESS AND HYDROGEN ISOTOPE …

As shown in Appendix (A), the reflux ratio at the top of the distillation column,

R’, has to be given as more than 23.2. Table 3-1 shows the relations among the reflux

ratio (R’), the number of theoretical plates of the enriching section (M), the vapor flow

rate (V) and the measure of process dimension (M·V), which were calculated from

Eq.(3-1). The optimum reflux ratio, R’, and the optimum number of theoretical plates of

the enriching section, M, are evaluated as 24 and 170, respectively. Then, the number of

theoretical plates of the stripping section, N, is given as 111 from Eq.(3-2) substituting ’,

which was calculated by the relation of ’=Ls/V = (D·R’) / [D(R’+1)].

When a commercial

packing, Sulzer Pack- Table3-1 The relations between the reflux ratio (R’), the number

ing, was used in the of theoretical plates of the enriching section (M), the vapor flow

distillation column, the

rate (V) and the measure of process dimension (M·V)

HETP of distilltion

column was reported to

R’[-]

24

25

26

be 0.1m at the operatM[-]

170

169

168

ing conditions that the

V[kmol/h]

264

275

285

column temperature is

4

4

4

M·V[kmol/h

4.49x10

4.65x10

4.79x10

70°C and the linear

]

velocity of vapor is 1.0

m/s (op.c) (5). ThereTable 3-2 Summary of water distillation process

fore, the heights of the

enriching section and

Operating

70

Remarks

the stripping section are

temperature

evaluated as 17m and

Vapor pressure

233.7 mm Hg

11.1m, respectively. As

1.062

H/T

shown in Appendix (B), No. of theor. Plates

M

170

the cross-sectional area

N

111

of the distillaion column,

(M+N)

281

A, is calculated as 2.06

H=(0.1)(M+N) [m]

28.1

HETP=0.1 m(4)

m2 in the conditions of

u [m/s (op.c)]

1.0

=233.7 mmHg and

F [kmol/h]

10.56

V=264 kmol/h, as

V/F

25.0

shown in Ref. (5). Thus,

V [kmol/h]

264

the column diameter, Di, A [m2]

2.06

Appendix(B)

is given as 1.62 m.. As

Di [m]

1.62

Appendix(B)

the latent heat of

CEV[kw]

3062

Appendix(B)

evaporation, L, is given

as 1.0x104 kcal/kmol at 70°C, the energy consumption for the phase conversion between

liquid and vapor, CEV, is calculated as 3062 kW from the relation of CEV= VL/860

(1kw=860 kcal/h). The operating conditions and the calculation results were

summarized in Table3-2.

73

MASAMI SHIMIZU and KENJI TAKESHITA

4. Hydrogen isotope exchange process

4-1 Separation system

zA

NA

zW

N1

xR

NR

z nW 2

yW

N

y nW1

x Hn 1

scrubbing bed

NW

L

N GW

NH

G

catalyst bed

Scrubbing bed

(n+1)th

unit

x nW1

z1W

zF N

F

z nW1

yW

0

W

H

W

z N1

Catalyst bed

x0

yM

y nW

H

x Hn

xM

Scrubbing bed

W

NL

W

z1

W

NG

W

y0

H

NG

nth

unit

x nW

Catalyst bed

H

z nW

x0

W

zB

zp N

P

electrolyser

σw

Fig.4-1 Schematic description of hydrogenisotope exchange process

y nW1

x Hn 1

σV

σH

Fig.4-2 Schematic description of

exchange column

Figures 4-1 and 4-2 show the hydrogen-isotope exchange process using Pt-catalyst,

which consists of an exchange column with Pt-catalyst and an electrolyser. It should be

noted that the process does not have a phase converter, H2/O2-recombiner at the top of

column. Natural water is fed to the top of the exchange column and the tritium-depleted

hydrogen gas is discharged to the atmosphere. The electrolyser plays a role as a phase

converter, in which H2O is decomposed electrochemically to H2 and O2. The hydrogen

gas obtained is transferred to the bottom of exchange column. The exchange column has

many units, which consists of a packed bed with a hydrophobic Pt catalyst and a

scrubbing bed with a commercial packing, Dixon packing. The hydrophobic Pt-catalyst

is a porous stylene-divinylbenzene copolymer impregnated with 0.5 wt% Pt (0.5wt%

Pt/SDBC) and is 4 mm in diameter. Tritium is transferred from H2(g) to H2O(l) in the

exchange column. The overall exchange reaction of hydrogen isotope can be described as

HT (g) H 2 O(l) H 2 (g) HTO (l)

74

(4-1)

COMPARISON BETWEEN WATER DISTILLATION PROCESS AND HYDROGEN ISOTOPE …

The hydrogen-isotope exchange reaction between H2(g) and H2O (v),

HT (g) H 2 O( v) H 2 (g) HTO ( v)

(4-2)

takes place in the Pt-catalyst bed and that between H2O (l) and H2O (v),

HTO ( v) H 2 O(l) H 2 O( v) HTO (l)

(4-3)

in the scrubbing bed. Tritium is enriched at the bottom of exchange column.

4-2 Numerical calculation of hydrogen-isotope exchange process

In the n-th unit, the exchange efficiency c of Pt-catalyst bed and the scrubbing

efficiency b of scrubbing bed are defined as

b

nW ynW

nW ( ynW )e

C

nH1 nH

nH1 ( nH )e

and

(4-4)

respectively, where the suffix, e, denotes equilibrium. As seen in Figs.4-1 and 4-2, the

relationships among xH, yW and zW are obtained as follows,

x Hn Ax Hn 1 BynW1

x nW Cx Hn 1 DynW1

y nW Ez nW Fx nW

z nW1

Gz nW

(4-5)

Hx nW

where the coefficients of A to H are defined as follows,

g c

c

b

g g c

B

A 1 g c ,

, C ,

, D 1

, E

,

g g

g g

g g

1 1b

g g

F (1 b )

12b

1

, G

1 1b

1 1b

and H

11b

1 1b

Eqs.(4-5) are transformed to the following finite difference equation concerning xH.

x Hn 3 px Hn 2 qx Hn 1 r x Hn 0

(4-6)

where, the coeficients of p, q and r deonte as p = – ( A + DF + G ), q = (ADF – BDF +

AG + DFG + DEH ) and r = (BC – AD )(FG – EH ). The solution of Eq.(4-6) is given as

follows,

(4-7)

x Hn K1g1n K 2g n2 K3g3n (n=0)

where, g1, g2 and g3 denote the real roots of the following characteristic equation,

g3+pg2+qg+r=0

(4-8)

K1, K2 and K3 mean constants to determine the boundary conditions shown in the

Section 4-3. By Combining Eqs.(4-5) with Eq.(4-7), the atom fractions of tritium in

75

MASAMI SHIMIZU and KENJI TAKESHITA

hydrogen gas, water vapor and water are given as

x nW

3

Ki[C B (g

D

A)]g in 1

i

i 1

(n≥1)

(4-9)

3

Ki(

y nW

i 1

gi A n

)g i

B

(n≥0)

(4-10)

z nW

3

Ki

BE {(g

A)g i F[BC D(g i A)]}g ni 1

i

(n1)

i 1

(4-11)

The concentration profiles of tritium in hydrogen gas, water vapor and water of the

stripping section of the multiunit hydrogen isotope exchange column are calculated by

Eqs.(4-7) to (4-11). Similarly, these of the enriching section are calculated by the

following equations,

H

xn

3

K g

i

n

i

(n≥0)

i 1

W

xn

3

K [C B (g

n 1

D

i

i

A)]g i

(n≥1)

(4-13)

(n≥0)

(4-14)

i 1

3

W

yn

K (

i

gi A

B

i 1

W

3

Ki

i 1

BE

zn

(4-12)

n

)g i

n 1

{(g i A )g i F[ BC D(g i A )]}g i

(4-15)

where the bars on these symbols denote the enriching section.

4-3. Boundary conditions for calculation

The boundary conditions for the exchange column of Fig.4-1 were given as

W

H

H

(1) z B ( N A N F ) z P N P x 0 N G

(2)

z lW

(3)

l y 0W

(1

l ) l y 0W

x (1 / El )z P

H

0

(4-16)

(4-17)

(4-18)

for the enriching section and

(4)

(5)

76

x 0H x HM

y

W

0

y

W

M

(4-19)

(4-20)

COMPARISON BETWEEN WATER DISTILLATION PROCESS AND HYDROGEN ISOTOPE …

(6)

z lW N LW z F N F z MW1 ( N LW N F )

xF z

(7)

(8)

(4-21)

(4-22)

W

M 1

W

W

W

zW

N 1 N L z A N A y N N G

(4-23)

for the stripping section. Then, the separation factor of tritium in the water electrolysis,

El , is 5.6 at 30°C (7). The values of K1 , K 2 , K 3 , K 1 , K 2 and K 3 are calculated by

way of the above boundary conditions and Eqs.(4-4) to (4-15).

4-4 Summery of calculation conditions and results

The calculation conditions and results were summarized in Table 4-1. The flow

rate of natural water from the top of column, NA, was assumed as a half of feed rate.

Namely, the molar flow ratio, (NA/NF), was given as 0.5 instead of the minimum flow

ratio, 0.183, which is required to

Table 4-1 Summery of calculation results

Item

Calculation

conditions&results

NF[kmol/h]

ZF[T atom-fraction]

NA[kmol/h]

ZA[T atom-fraction]

NR[kmol/h]

XR[T atom-fraction]

Np[kmol/h]

Zp/ZF

P[mmHg]

tC

Ug(H+V)[Nm/s]

c[-]

b[-]

Hg[m]

Hl[m]

nE

nS

10.56

2.4410-13

5.26

210-17

15.84

110-14

1.0310-3

1104

760

70

0.6

0.9

0.9

0.1

0.15

13.8

7.7

HE[m]

4.14

Hs[m]

2.31

Dex[m]

Vcat[m3]

CEL[kw]

0.55

0.57

1774

Remarks

2.895107 Bq/m3 water

Assumed as half of feed rate

Concentration of tritium in natural water

Dischargeable directly to the atmosphere

Enrichment factor of tritium

Operating preasure

Operating temperature

(H2+vap.) gas velocity

Ref.(8)

Ref.(8)

Height of catalyst bed

Height of scrubbing bed

No. of unit in enriching section

No. of unit in stripping section

Height of enriching section. Height of unit is

assumed as 0.3 m/unit.

Height of stripping section. Height of unit is

assumed as 0.3 m/unit

Eq.(4-24)

Eq.(4-25)

Eq.(4-26)

obtain the enrichment factor of 104. The column diameter (DEX), the total volume of

Pt-catalyst (Vcat) and the energy consumption of electrolyser (CEL) were evaluated as

77

MASAMI SHIMIZU and KENJI TAKESHITA

D EX

( N F N A N P )( 22.4)( p )

H 2O

3.14

3600 u g ( H V ) (

)

4

Vcat H g (n E n S )(D 2EX )(3.14 / 4)

[m]

(4-24)

[m3]

(4-25)

C EL N R 22.4 ( 5kwh / Nm H 2 ) [kW]

3

(4-26)

5. Conclusion

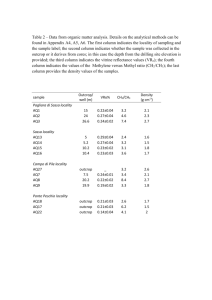

Table 5-1 shows the comparison of calculation results between the hydrogen-isotope

exchange process and the water distillation process. It is found that the diameter and

height of hydrogen-isotope exchange process are much smaller than those of water

distillation process and the energy consumption of elecrolyser is reduced to about 55%

of that of still of water distillation process. It is concluded that the hydrogen-isotope

exchange process is suitable for the treatment of tritiated wastewater generated by the

decommissioning of Magnox reactor.

Table 5-1. Comparison between hydrogen-isotope exchange process and water

distillation process

F or NF [kmol/h]

XF or ZF [T atom fraction]

R’ or A[-]

D or NR [kmol/h]

xD or xR [T-atom fraction]

NA [kmol/h]

zA [T-atom fraction]

10.56

2.4410-13

R’=LS/D=24

A =NA/NF=0.5

D=10.559

NR=15.839

xD 10-14

xR 10-14

5.28

2 10-17

P or NP [kmol/h]

xp/xF or zP/zF

(Operating conditions)

Pressure [mmHg]

Temperature (C)

uV or ug(H+V)

(Operating constants)

HETP [m]

c [-]

b [-]

Hg [m]

Hl [m]

(Results of calculation)

No of theor. plates

No of units

Height of Colum [m]

Diameter of Column [m]

Vcat [m3]

CEV or CEL [kw]

P=1.01 10-3

78

NP=1.03 10-3

1104

233.7

70

uV=1.0 m/s (op.c)

Feed flow

Tritium in feed

Reflux ratio

Depleted flow

Release to atmosphere

Tritium in Natural

water

Production

Enrichment factor

760

70

ug(H+V)=0.6 Nm/s

0.1

0.9

0.9

0.1

0.15

Sulzer packing (Ref.5)

Ref.8

Ref.8

Ref.8

22

6.6

0.55

0.57

1774

M=170 N=111

ne=14 ns=8 units

Height of unit=0.3 m

App.(B), Eq(4-24)

Eq(4-25)

App(B), Eq(4-26)

281

28.1

1.62

3062

COMPARISON BETWEEN WATER DISTILLATION PROCESS AND HYDROGEN ISOTOPE …

Appendix ( A ) Reflux ratio, R’, at the top of the water distillation column

From Eq.(3-1), the following equation

1

M 1

P V1 x

P

1

1

x F

(A-1 )

x P 1

x

1

F

is obtained. As (1/)M+1 is positive, the numerator of Eq.(A-2 )

P x P

1 1 1 0

V x F

(A-2)

has to be positive. From the mass balance equation, (P/V) is expressed by

1 1 1

and (1-l) is

1

0.058

1.062

1 x D

P

xF 1

x

V

P 1 1 R '

xF

From these results, the limitation of reflux ratio, R’, is given as

(A-3)

R' 23.17

Appendix ( B )

Cross-sectional area of distillation column

The cross-sectional area of distillation column can be calculated by

V 22.4 PH 2O 273 t

A

[m2]

273

3600 u v

(B-1)

When uV = 1.0 m / s ( op.c )(5) for Sulzer Packing ( op.c ) ,

V PH O

A 2 273 t 2.27920 103

u

[m2]

(B-2)

The column diameter calculated from Eq.(B-1) was shown in Table B-1.

Table.B-1 Evaluation of column diameter, Di, by Eq.(B-1)

233.7

Remarks

Operating pressure [mmHg]

Operating Temperature t [°C]

70

Vapor flow rate V[kmol/h]

264

Vapor superficial velocity

1.0

Reference (4)

uV[m/s(op.c)]

Sectional area A[m2]

2.06

Eq (B-1)

Diameter of column

1.62

79

MASAMI SHIMIZU and KENJI TAKESHITA

SYMBOLS

P : T-enriched water flow rate [ kmol / h ]

V : Vapor flow rate [ kmol / h ]

: flow ratio = Le / V

’:flow ratio = Ls / V

Le, Ls : Flow rates of water in the enriching section and stripping one [kmol /h]

M, N : Numbers of theoretical plate in enriching section and stripping one [-]

x Hn , x nW , y Hn and z nW : T-atom fractions of hydrogen and water vapor leaving the nth

catalytic bed and those of water vapor and liquid leaving the nth scrubbing bed

respectively [-]

g H / V ( PH 2O ) / PH 2O l V / W

H/T

g gH / T l l

H, V and W : Hydrogen, water vapor and water liquid flow rate [kmol / m2h]

REFERENCES

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

80

Proposal of Fuji Electric Co.Ltd (1997)

J.F.Black : J.Chem.Phys , 11 , 395 ( 1943 )

M.M.Popov : Atom Energ. SSSR , 8 , 420 ( 1960 )

M.Shimizu and S.Hibino : Some Analyses on the Operation of Water Distillation Column ,

Nippon Genshiryoku Gakkaishi ( Japanese ) 4 , 313 ( 1962 )

M.Asahara : Hydrogen Isotope Separation by Water Distillation , “Separation of Deuterium

and Tritium “ ed.by Nakane , Isomura and Shimizu ( in Japanese ) , Gakujyutsu – Shuppan

Centre ( Japan ) , 1982.

M.Shimizu , T.Doi , A.Kitamoto , and Y. Takashima : Numerical Analysis on Heavy Water

Separation Characteristics for a pair of Dual Temperature Multistage-Type

H2/H2O-Exchange Columns , J. of Nucl. Sci. Technol. 17 , 448 ( 1980 )

K.Takeshita, Y.Wei, M.Shimizu, M.Kumagai and Y.Takashima: Application of

H2/HTO-Isotopic Exchange Method to Recovery of Tritium from Waste Water generated in

Spent Nuclear Fuel Reprocessing Plant , Fusion Technol. 28 , 1572 ( 1995 )

Private communications on the design data and the operating performance of the IPCR-PNC

type tritiated D2O upgrader in the Fugen site.