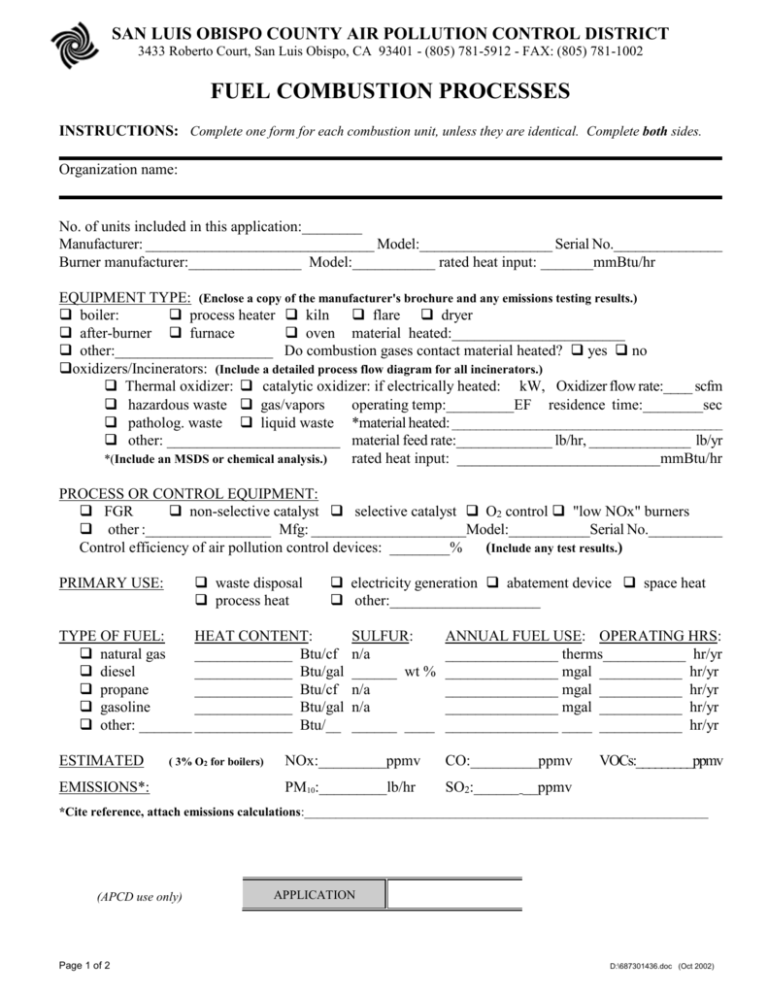

Fuel Combustion Processes - Air Pollution Control District

advertisement

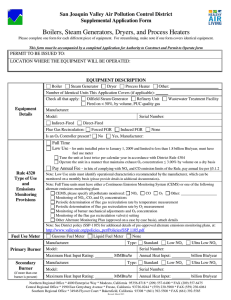

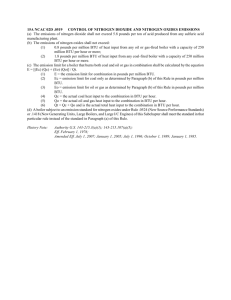

SAN LUIS OBISPO COUNTY AIR POLLUTION CONTROL DISTRICT 3433 Roberto Court, San Luis Obispo, CA 93401 - (805) 781-5912 - FAX: (805) 781-1002 FUEL COMBUSTION PROCESSES INSTRUCTIONS: Complete one form for each combustion unit, unless they are identical. Complete both sides. Organization name: No. of units included in this application:________ Manufacturer: _______________________________ Model:__________________ Serial No._______________ Burner manufacturer:_______________ Model:___________ rated heat input: _______mmBtu/hr EQUIPMENT TYPE: (Enclose a copy of the manufacturer's brochure and any emissions testing results.) boiler: process heater kiln flare dryer after-burner furnace oven material heated:_______________________ other:_____________________ Do combustion gases contact material heated? yes no oxidizers/Incinerators: (Include a detailed process flow diagram for all incinerators.) Thermal oxidizer: catalytic oxidizer: if electrically heated: kW, Oxidizer flow rate:____ scfm hazardous waste gas/vapors operating temp:_________F residence time:________sec patholog. waste liquid waste *material heated: _____________________________________________ other: _______________________ material feed rate:_____________ lb/hr, ______________ lb/yr *(Include an MSDS or chemical analysis.) rated heat input: ___________________________mmBtu/hr PROCESS OR CONTROL EQUIPMENT: FGR non-selective catalyst selective catalyst O2 control "low NOx" burners other :_________________ Mfg: _____________________Model:___________Serial No.__________ Control efficiency of air pollution control devices: ________% (Include any test results.) PRIMARY USE: waste disposal process heat electricity generation abatement device space heat other:____________________ TYPE OF FUEL: HEAT CONTENT: natural gas _____________ Btu/cf diesel _____________ Btu/gal propane _____________ Btu/cf gasoline _____________ Btu/gal other: _______ _____________ Btu/__ ESTIMATED ( 3% O2 for boilers) EMISSIONS*: SULFUR: n/a ______ wt % n/a n/a ______ ____ ANNUAL FUEL USE: OPERATING HRS: _______________ therms___________ hr/yr _______________ mgal ___________ hr/yr _______________ mgal ___________ hr/yr _______________ mgal ___________ hr/yr _______________ ____ ___________ hr/yr NOx:_________ppmv CO:_________ppmv PM10:_________lb/hr SO2:______ __ppmv VOCs:_________ppmv *Cite reference, attach emissions calculations:________________________________________________________________ (APCD use only) Page 1 of 2 APPLICATION D:\687301436.doc (Oct 2002) Provide the following information, as applicable: EXHAUST STACK: yes no stack diameter:____________inches flow capacity: cfm stack height above ground: feet exhaust temperature:_____F draft fan or blower rating (hp): _____________ rain cap or other stack restricter yes no stack tip direction: up down horizontal REMEDIATION PROJECT: Duration: ________days yes no If no, provide additional comments below. _________weeks _________years Est. amount of material to be remediated: ____________ tons cubic yards other:___________ Type of contamination: (Include a copy of the chemical analysis.) diesel/oil gasoline other:_____ ________________________________ Est. amount to be recovered or destroyed: ______________________lbs Material process rate (other than standard fuels):______________units/day ______________units/project Stockpiles, excavation, and handling of fugitives (include calculations): PM10: _________lbs/day VOCs: _________lbs/day COMMENTS: (Provide any additional information that would be useful to the District in estimating emissions from your process or equipment. Failure to provide complete information may result in delays in permit processing or in the assignment of your application as "incomplete".) ________________________________________________________________________________________________________ ________________________________________________________________________________________________________ ________________________________________________________________________________________________________ ________________________________________________________________________________________________________ ________________________________________________________________________________________________________ ________________________________________________________________________________________________________ ________________________________________________________________________________________________________ ________________________________________________________________________________________________________ ________________________________________________________________________________________________________ ________________________________________________________________________________________________________ ________________________________________________________________________________________________________ Page 2 of 2 D:\687301436.doc (Oct 2002)