Project Components - Global Environment Facility

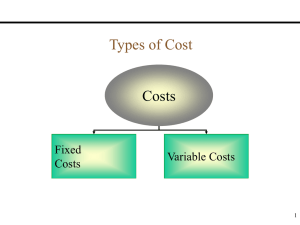

advertisement

PROJECT IDENTIFICATION FORM (PIF) PROJECT TYPE: FULL-SIZED PROJECT THE GEF TRUST FUND Submission Date: 1 August 2008 Re-submission Date: 22 October 2008 PART I: PROJECT IDENTIFICATION GEF PROJECT ID1: 3732 PROJECT DURATION: 4 YEARS GEF AGENCY PROJECT ID: GF/RAS/08/XXX COUNTRY(IES): Regional (Cambodia, Lao PDR, Mongolia, Philippines and Thailand*) * Indonesia is expected to ratify the Convention in March 2009 and therefore will join the project by CEO endorsement stage PROJECT TITLE: Demonstration of BAT and BEP in fossil fuel- INDICATIVE CALENDAR* Milestones Expected Dates Work Program (for FSP) November 2008 CEO Endorsement/Approval June 2009 Agency Approval Date July 2009 Implementation Start September 2009 Mid-term Evaluation June 2011 Project Closing Date June 2013 * See guidelines for definition of milestones. fired utility and industrial boilers in response to the Stockholm Convention on POPs GEF AGENCY(IES): UNIDO OTHER EXECUTING PARTNER(S): Ministry of Industry, Mines and Energy (Cambodia), Department of Environment (Lao PDR), Ministry of Environment (Indonesia), Ministry of Nature and Environment (Mongolia), Department of Environment and Natural Resources (Philippines) and Ministry of Natural Resources and Environment (Thailand) GEF FOCAL AREA (S)2: Persistent Organic Pollutants GEF-4 STRATEGIC PROGRAM(S): POPs-SPI, SP2 &-SP3 NAME OF PARENT PROGRAM/UMBRELLA PROJECT (if applicable): NA PROJECT PROMOTES SOUND CHEMICAL MANAGEMENT (if applicable): yes no A. PROJECT FRAMEWORK (Expand table as necessary) Project Objective: Overall objective: In accordance with the relevant resolutions of the third session of the Conference of the Parties (COP3) of the Stockholm Convention (SC), the project aims at reducing and eliminating unintentionally produced POPs (UP-POPs) releases by enhancing guidelines and guidance on BAT/BEP for fossil fuel-fired utility and industrial boilers through addressing specific features of industry, common practices in the region and related socio-economic considerations and thus formulating regional guidelines and guidance on BAT/BEP to be introduced in implementing the relevant requirements of SC. Immediate objective: The project aims at establishing UP-POPs baseline inventories in fossil fuel-fired utilities and industrial boilers source category achieved by specifically designed sectoral studies and targeted capacity building. The scope of this project also incorporates the promotion of technology transfer and investment by identification and implementation of innovative mechanisms for public-private partnership (PPP). The regional guidelines and guidance on BAT/BEP will fully incorporate the regional experience gained through pollution prevention/cleaner production (PP/CP) measures. Project Components Investment TA, or STA** 1. Formulation of regional guidelines and guidance on BAT/BEP for fossil fuel-fired utility and industrial boilers consistent with relevant requirements of Stockholm Convention 1 2 TA Expected Outcomes Expected Outputs Adopted guidelines and guidance on BAT/BEP addressing specific features of industry, common practices in the region and related socioeconomic considerations 1.1 Adopted regional guidelines and guidance on BAT/BEP on fossil fuel-fired utilities and industrial boilers in ESEA by adding, among others, two columns to Table 3: “Summary of recommended measures….” of UNEP/POPS/COP.3/INF/4 on health and economic benefits as well as wood and other biomass fuels that are widely used in ESEA region. Indicative Cofinancing* Total ($) ($) a % ($) b % c =a + b 1,000,000 30 2,400,000 70 3,400,000 1.2 Enhanced or strengthened specifications for different types of boilers (small/ medium / large) and fuels. 1.3 Adopted government policies including regulations, standards, incentives (energy, environment, industry, health, education) supporting reduction of UP-POPs releases from the fossil fuel-fired utilities and industrial boilers (Section VI.D) and from firing installations for wood and other biomass (Section VI.E). Project ID number will be assigned initially by GEFSEC. Select only those focal areas from which GEF financing is requested. UNIDO-PIF BAT/BEP-ESEA 22 October 2008rev Indicative GEF Financing* 1 2. Dissemination of pollution prevention/clea ner production (PP/CP) measures in fossil fuel-fired utilities and industrial boilers source category TA Pollution prevention measures (cleaner production) applied prior to introducing BAT/BEP (Annex C, Part V, A) 2.1 PP/CP methodology adopted and the corresponding technical capabilities in the fossil fuel-fired utility and industrial boilers sector for use in power generation and in industrial processes strengthened. 800,000 29 2,000,000 71 2,800,000 3. Establishment of regional UPPOPs baseline inventory in fossil fuel-fired utilities and industrial boilers source category TA UP-POPs baseline 3.1 Baseline studies on industrial boilers (through questionnaires completed in six participating countries). 1,200,000 44 1,500,000 56 2,700,000 500,000 33 1,000,000 67 1,500,000 250,000 32 525,000 68 775,000 250,000 40 375,000 60 625,000 inventories derived from representative industrial sources and projected at regional scale 3.2 Specific studies made on: (i) fish residues as fuel in seasonal use in Cambodia; (ii) use of spent/used oils as boiler fuel; and (iii) biomass fuel including wood, wood products, bagasse, charcoal, demolition wood; and (iv) low pressure furnaces and coal stoves in Mongolia, etc. 3.3 Identification and selection of industrial boilers and fossil fuel-fired utilities that would be representative for establishing regional UP- POPs baseline inventory by determining UP-POPs releases. 4. Regional coordination in developing human resources TA 5. Capacity building in sampling at industrial sources and analysis of UPPOPs 6. Project Management TA Established regional coordination of developing human resources 4.1 Adequate capacity in BAT and BEP built through training programs for government officials and through technical in-plant training for responsible persons for boiler operation of private and public sectors. Adequate capacity in sampling and analysis of UPPOP 5.1 Adequate regional capacity created by strengthening national and regional centers of excellence (national laboratories, private laboratories) in monitoring and assessment, specifically in sampling, analysis, and reporting of UP-POPs. 4.2 Awareness raising campaigns for specific target groups such as government policy makers, community leaders, managers of state owned industries and owners of private industries, schools, etc., and for the public at large. 5.2 Promotion of technology transfer and investment by identification and implementation of innovative mechanisms for PPPs. Established project management at the sector coordinator’s office, stakeholder partnerships, and relevant meetings 4,000,000 Total project costs 7,800,000 11,800,000 B. INDICATIVE FINANCING PLAN SUMMARY FOR THE PROJECT ($) Project Preparation (a) PDF-A/B GEF Co-financing Total PPG 400,000 300,000 700,000 Project (b) 4,000,000 7,800,000 11,800,000 Total C=a+b 4,400,000 8,100,000 12,500,000 Agency Fee 440,000 2 UNIDO-PIF BAT/BEP-ESEA 22 October 2008rev C. INDICATIVE CO-FINANCING FOR THE PROJECT PREPARATION AND FOR PROJECT BY SOURCE and BY NAME (in parenthesis) if available, ($) Sources of Co-financing Project Government Contribution GEF Agency(ies) (UNIDO) Private Sector Type of Co-financing Cash and in kind Cash and in-kind Cash and in-kind Total co-financing Project Preparation 200,000 Project Total 6,800,000 7,000,000 100,000 200,000 800,000 300,000 800,000 300, 000 7,800,000 8,100,000 D. GEF RESOURCES REQUESTED BY AGENCY (IES), FOCAL AREA(S) AND COUNTRY(IES)* GEF Agency Focal Area UNIDO OP14 (in $) Country Name/ Global Regional ASIA PPG** (a) 400,000 Project (b) 4,000,000 Agency Fee (c) 440,000 Total d=a+b+c 4,840,000 Total GEF Resources * No need to provide information for this table if it is a single focal area, single country and single GEF Agency project. ** Input only if PPG request submitted with PIF; if no PPG requested, leave the column blank. PART II: PROJECT JUSTIFICATION A. STATE THE ISSUE, HOW THE PROJECT SEEKS TO SOLVE IT, AND THE EXPECTED GLOBAL ENVIRONMENTAL BENEFITS TO BE DELIVERED: 1. According to Article 5 (a) of the Stockholm Convention, each Party shall develop an action plan or, where appropriate, a regional or subregional action plan to reduce the total releases of chemicals listed its Annex C, with the goal of their continuing minimization and, where feasible, ultimate elimination. The Conference of Parties in its first session (UNEP/POPS/COP.1/31/SC-1/20) stated that the incorporation of guidelines and guidance on BAT/BEP was a critical component of NIPs and that it need to be widely disseminated, demonstrated and understood by users, stakeholders and decision makers as well as promoted at regional, sub-regional and national levels. The third session of the Conference of the Parties (UNEP/POPS/COP.3/30/SC-3/5) adopted the revised draft guidelines on BAT and provisional guidance on BEP and requested the use of further contribution as appropriate to the document by all Parties. The introduction of BAT/BEP in the different source categories listed in Annex C of SC is the most important practical measure to continuing minimization of UP-POPs releases therefore it has of utmost importance. 2. The fossil fuel-fired utilities and industrial boilers source category is among the priority sources and therefore priority actions in the respective NIPs of the six participating countries in the East and Southeast Asia namely Cambodia, Indonesia, Lao PDR, Mongolia, the Philippines and Thailand. The fossil fuel-fired utilities and industrial boilers source category in the six participating countries has about 167 g TEQ/year total UP-POPs releases. This preliminary inventory figure that is based on estimations by the methodology of UNEP Toolkit seems to be underestimated. 3. Seeking a practical approach to overview this very diverse source category, the need for preparing questionnaires to collect data on industrial boilers emerged in the Regional Workshop held in Vientiane, 12-14 December 2007 on “BAT/BEP in fossil fuel-fired utilities and industrial boilers in response to the SC on POPs”. The questionnaires will be used to collect the data on boiler population on each of the six participating countries in order to have better understanding of the sector and start analyzing in more detail the process technologies used and the efficiency of pollutant abatement systems for UP-POPs emissions. During the Regional Workshop, it became apparent that to obtain a good response and turnover to the questionnaires, particularly from the owners of the small and medium size fossil fuel-fired utilities and industrial boilers some quite detailed explanatory notes should be provided. 4. In addition to the traditional fossil fuels, there are some special types that are used in some of the participating countries, such as (i) fish residues as fuel in seasonal use in Cambodia, (ii) spent/used oils as boiler fuel, (iii) biomass fuel including wood, wood products, bagasse, charcoal, demolition wood, and (iv) charcoal used for low pressure furnaces and stoves in Mongolia. The issue of these fuels, some of which might even be categorized as hazardous wastes, has to be addressed. In this context, coordination with the Basel Convention regional centres will be established. 5. The need for common rules for PCDD/PCDF inventories of the fossil fuel-fired utilities and industrial boilers emerged in the UNIDO ESEA regional workshop held in Vientiane in December 2007 and substantially agreed among the participating countries. Common rules for calculating PCDD/PCDF releases is required due to the inherent shortcomings and consequently the actual methodologies used by the countries for the inventories were different and therefore it was difficult to compare the results presented. 3 UNIDO-PIF BAT/BEP-ESEA 22 October 2008rev 6. 7. B. The project will facilitate the preparation of the baseline inventory of UP-POPs releases in the fossil fuel-fired utilities and industrial boilers source category in each of the six participating countries. From the updated national baseline inventories, a sub-regional and baseline will be projected. Based on the regional/sub-regional projections on the baseline inventories, the implementation of the corresponding regional action plan will deliver the global environmental benefits of the project. The project will strengthen the overall management and dissemination of BAT/BEP in the fossil fuel-fired utilities and industrial boilers and reduce the risk of POPs to human health and the environment at national, regional and global levels. Methodologies introduced in this project will positively contribute to similar projects in the same source category. The project will also contribute with valuable data to the further enhancement of UNEP Toolkit. In the project implementation, particular attention will be made on the cost-effectiveness and sustainability of the proposed measures. The expected global environmental benefits to be delivered include the continuing minimization of UP-POPs releases by introducing BAT/BEP in the fossil fuel-fired utilities and industrial boilers source category in the participating countries. DESCRIBE THE CONSISTENCY OF THE PROJECT WITH NATIONAL PRIORITIES/PLANS (Is the proposal consistent with country priorities? How does it build on ongoing programs, policies and political commitments?) 8. Cambodia The NIP for the SC on POPs in Cambodia prepared by the Ministry of Environment was endorsed by the Council of Ministers on 2 June 2006. Cambodia became a party on 25 August 2006. The most important factors influencing UP-POPs releases in the country were attributed to the growth of the industrial sector, poverty, lack of waste management facilities combined with increased waste generation and low public awareness. The main source categories of PCDD/PCDF releases were power generation and heating (11.967 g TEQ/year) and uncontrolled combustion (548.031 g TEQ/year). It is explicitly mentioned in the NIP that related data for fossil fuel consumptions provided by concerned institutions is insufficient proving the necessity of undertaking proper inventory of the UP-POPs releases in the country (NIP Chapter 1 Section 3.4, page 39.) Likewise, one of the key problems identified on UP-POPs centered on the absence of control measures for the reduction of UP-POPs releases from all sources (Chapter 2, page 45). Chapter 3 Section 3 of the NIP detailed the country’s priority projects relative to UP-POPs which include the introduction and promotion of BAT and BEP in existing industrial plants that are using wood as the main fuel and high calorific value waste for co-incineration (Project profile No.7: Introduce BAT and BEP for POPs releases). 9. Indonesia In 2000, the total PCDD/PCDF releases in the country was estimated as 20,977 g TEQ/year, out of which power plants represented 66.5% (13,949.705 g) and uncontrolled burning 7.8 % (1,636.206 g). By reviewing the reported inventory, the issue of wood residues versus waste wood and the use of appropriate emission factors for the different types of wood and biomass emerged. Recalculation and use of appropriate emission factors led to the correction of the emissions from power generation from the reported 13,000 g TEQ per year to about 84 g TEQ per year. This instance led to the discussion on the inadequacies of the UNEP toolkit in the provision of appropriate emission factors for various types of fuels and the necessity to come up with a common guidance and guideline document for the region. In the NIP one of the country priorities is BAT/BEP processing in power plants (Chapter III: National Strategies and Action Plans: Apply BAT/BEP for source categories in Part II and III of Annex C; 3.3.7: Measures to reduce releases from unintentional production, Page III-33). This priority is also substantiated in the timetable of NIP implementation: one of the performance indicators is BAT/BEP to be practiced in industry in 2008-2011. 10. Lao PDR Lao PDR became a party on 28 June 2006. The NIP was prepared by the Environmental Research Institute of the Science, Technology and Environment Agency (ERI/STEA). Based on 2002 production data and calculated by UNEP Toolkit methodology, the total PCDD/PCDF releases was estimated as 102.199 g TEQ/year, out of which power generation and heating represented 5% (5.492 g) and uncontrolled combustion processes 90% (90.742 g). 11. Mongolia The NIP was approved by the Government of Mongolia on 3 May 2006 after Mongolia became a party on 30 April 2004. In the NIP, the total PCDD/PCDF releases was estimated as 750.713 g TEQ/year, out of which power generation and heating/cooking represented 39.258 g (5.23%) and uncontrolled combustion processes 52.408 g (6.98%). One of the country priority projects is to identify sources of dioxins and furans and reduce their emissions. NIP states that “sources of dioxins and furans and their emission level will be identified and introduce BAT/BEP in emission reductions.” The expected commencement date of the project is 2009 (page 112 of NIP; Chapter 3.4: Development and capacity-building proposals and priorities). 12. The Philippines The Philippines became a party on 27 February 2004. The Industrial Technology Development Institute of the Department of Science and Technology (ITDI/DOST) prepared the Second National Inventory of Dioxins and Furans using UNEP Toolkit methodology. The total PCDD/PCDF releases was estimated as 457.731 g TEQ/year, out of which heat and power generation represented 77.275 g and open burning 203.492 g. As reported, however, in the Environmental Management Bureau 2001 Source Emission Inventory there are 2,821 fuel burning facilities in the country whose releases may not be wholly represented by the figure given. Thus, an updated inventory is appropriate. Based on the country`s NIP, the promotion and application of BAT/BEP is among the country priorities for UP-POPs in compliance with the requirements of the SC. Table 3-3 on page 3-16 of the NIP specifies the action plans addressing unintentional POPs. Objectives 1 and 2 target an updated inventory of UP-POPs releases for all significant sources and the development and implementation BAT/BEP promotion, adoption and monitoring programs within 3 years across the most significant dioxin and furan source categories (Chapter 3.0 Strategy and Action Plan Elements of the NIP, pages 3-20). 4 UNIDO-PIF BAT/BEP-ESEA 22 October 2008rev 13. Thailand Thailand became a party on 31 January 2005. In the NIP, the total PCDD/PCDF releases was estimated as 1,075.88 g TEQ/year, out of which power generation and heating represented 47.61 g and uncontrolled combustion processes 386.98 g. BAT/BEP is given priority as Goal 6: BAT/BEP is applied by Thai industries by 2012. Activity 2 of this goal focuses on a crucial element of the success: Development and implementation of tax incentives and honor awards granted for enterprises that use BAT/BEP to reduce or eliminate PCDDs/PCDFs emission. 14. The proposed project will play a vital role in supporting the participating six countries in fulfilling the project objectives. At the project preparation phase, the countries stated that fossil fuel-fired utility and industrial boilers source category was a priority category* in their countries. The total releases in power generation, heat industry and domestic heating and cooking sectors in the six countries were about 265.5 g TEQ/year. However, it was a strong consensus that the inventories should be revisited/re-calculated based on the countrywide energy/fossil fuel consumptions. The following table shows the number/capacity of thermal power plants and the number of boilers in the region. Country Thermal Power Plants Cambodia No. of Boilers 435 units (257 generator and compressor units) Indonesia Suralaya power plant with capacity of 25B KWh per year (27,000 tons of coal per day) 4,655 units Mongolia 3 large power plants with coal consumption of 4.6M tons of coal per year 400 low-pressure boilers and 600,000 stoves 1 power plant with a capacity of 540 MW Philippines 4 large power plants with capacity of 135, 308 TJ/year with consumption of over 5M tons of coal per year Thailand 35 power plants Lao PDR 8 boiler units in the power plant 6,673 industrial boilers and 217 power plant boilers 24,742 registered factories with boiler installations * Priority ranking among sectors in each participating country: Cambodia(3), Indonesia (1), Lao PDR(2), Mongolia(3), Philippines(2), Thailand(4) C. DESCRIBE THE CONSISTENCY OF THE PROJECT WITH GEF STRATEGIES AND FIT WITH STRATEGIC PROGRAMS: 15. The project is consistent with Strategic Program 1, 2 and 3 of persistent organic pollutants focal area strategy and strategic programming for GEF-4 respectively: D. Strengthening Capacities for NIP Implementation, with the objective to strengthen and/or build the capacity required in eligible countries to implement their Stockholm Convention NIPs in a sustainable, effective and comprehensive manner, while building upon and contributing to strengthening a country’s foundational capacities for sound management of chemicals more generally. Partnering in investments needed for NIP implementation to achieve impacts in the reduction of POPs production, use and releases, and reduce the stress on human health and the environment caused by POPs, including through promoting the use of substitute products or alternative techniques and practices that prevent or reduce the generation and/or release of POPs. Meeting the future challenges that lay ahead in the implementation of the Stockholm Convention, the GEF will support projects that demonstrate and promote the replication of environmentally sound, alternative products to POPs, or the substitution of materials and processes to prevent POPs formation, more specifically projects that demonstrate the use of a particular technique to help enhance the infrastructure of a country to manage POPs or the demonstration of BAT/BEP for reduction of releases of UP-POPs. OUTLINE THE COORDINATION WITH OTHER RELATED INITIATIVES (Coordination with other GEF agencies, organizations, and stakeholders involved in related initiatives; if similar projects exist in the same country/region, including GEF projects, report on synergies/complementarities with this proposal and demonstrate that there is no duplication). 16. The project will ensure close cooperation and coordination with the related GEF projects and other initiatives on BAT/BEP in the region. Thus, the project will use the experience gained and capacities built by the GEF-funded UNIDO project “Introduction of BAT and BEP methodology to demonstrate reduction or elimination of unintentionally produced persistent organic pollutants (UP-POPs) releases from the industry in Vietnam”. Cambodia, Indonesia, Lao PDR, Mongolia, the Philippines and Thailand are members to the Regional BAT/BEP Forum for East and South East Asia (ESEA) countries, which was adopted in Bangkok in October 2007. In order to share information and exchange experiences gained during the implementation with other Forum member countries, the Project Steering Committee and UNIDO will closely cooperate with and reports the results of this project to the Chair of the Regional ESEA Forum on BAT/BEP. 17. The project will contribute to the implementation of COP3 resolution SC-3/5: “Guidelines on BAT and provisional guidance on BEP” that invited Parties and others to provide to the Secretariat comments on their experience in implementing the revised draft guidelines on BAT and provisional guidance on BEP; requested to compile and to collect information (e.g., make use of a questionnaire) on experiences 5 UNIDO-PIF BAT/BEP-ESEA 22 October 2008rev gained in using the revised guidelines and guidance through field tests and other means by 31 December 2008; encouraged Parties and observers to exchange information on their experiences in implementing the guidelines and guidance by electronic means such as electronic discussion groups facilitated; and invited Parties and others in a position to do so to fund awareness-raising and training workshops on the guidelines on BAT and BEP. E. DESCRIBE THE INCREMENTAL REASONING OF THE PROJECT (What would happen without GEF support and what would be the expected change in global environmental benefits): 18. Without GEF support, the six (6) participating countries would not be able to successfully introduce BAT/BEP measures for reducing or eliminating unintentional PCDD/PCDF releases in a very diverse source category such as the fossil-fuel fired utility and industrial boilers (power generation and heating) and will continue to use unsustainable industrial technologies and common practices with possible negative impact on the global environment. With GEF support and technical assistance of UNIDO, the six participating countries will be able to develop and implement different economic incentives and honor awards to promote and introduce BAT/BEP measures in particular in the small and medium sized fossil-fuel fired utility and industrial boilers industry. GEF support will also be used for targeted awareness raising campaigns by which a large segment of the population will be reached for advocating environmentally sound common practices in this source category. The GEF support will maximize opportunities for private sector to venture capital, through joint venture with local companies, into solving POPs priority problems with a global dimension and large socio-economic scope. The scale and complexity of this project will require a multi-faceted response and draw on the combined resources of the public and private sectors. F. INDICATE RISKS, INCLUDING CLIMATE CHANGE RISKS, THAT MIGHT PREVENT THE PROJECT OBJECTIVE(S) FROM BEING ACHIEVED. OUTLINE THE RISK MANAGEMENT MEASURES, INCLUDING IMPROVING RESILIENCE TO CLIMATE CHANGE, THAT THE PROJECT PROPOSES TO UNDERTAKE: 19. The project is based on about 265.5 g TEQ/year that is the total UP-POPs releases in power generation and heat industry in the six participating countries in their NIPs. However, there is a strong consensus that this inventory figure is underestimated and the inventories should be revisited/re-calculated based on the countrywide energy/ fossil fuel consumptions and such to establish a baseline inventory for effectiveness evaluation of the implementation of SC. 20. The capital costs of power generation are up to US$5,000/kW. Such very high costs would make very unlikely that any modification of the plant would be made after it has been put into operation. A modification would be difficult to implement as the manufacturers rely on standardized models, the size and geometry of the boiler would determine the residence time, turbulence etc. Hence, BEP has to be implemented at users’ level that consists of boiler purchase (technical specifications), operation and maintenance (efficiency) and BAT/BEP implementation takes place at fuel supply and equipment design level. The fuel supply strategy has of very high importance as a large power plant consumes millions of tons of fuel per year. 21. The boiler purchase has different drivers depending on its size that have to be taken into due consideration during implementation. It should be noted that Cambodia and Lao PDR did not have large fossil fuel-fired power plants or large-size industrial boilers. Type of boiler Drivers governing purchase Decision of purchase Small Market and prices Personal Medium Market and design Personal Large Design Government or private 22. Other particular risks that maybe encountered in the implementation of the project as well as the measures that maybe carried out to mitigate, if not eliminate them, are given in the following table: RISKS RISK MITIGATION MEASURES Unavailability of national experts to formulate the The proposed project will facilitate the training of National Coordinators to regional guidelines and guidance on BAT/BEP for fossil prepare the guidelines and guidance. The risk is LOW in this area. fuel fired utility and industrial boilers No databases in countries where systematic data The project will establish the database in a systematic and coordinated manner collection is done over the years through harmonized data collection tools such as questionnaires, survey, etc. For this component, the level of risk is LOW. Lack of capacity in sampling UP-POPs The project will identify suitable laboratories in each country that could provide training/workshops on sampling and analysis based on international standards. The level of risk is LOW. G. DESCRIBE, IF POSSIBLE, THE EXPECTED COST-EFFECTIVENESS OF THE PROJECT (e.g. $/g of PCDD/PCDF abated). IF COST-EFFECTIVENESS IS NOT PRESENTED, OUTLINE THE STEPS THAT PROJECT PREPARATION WOULD UNDERTAKE TO PRESENT COST-EFFECTIVENESS AT CEO ENDORSEMENT: 23. Fossil fuel-fired utility and industrial boilers are facilities designed to burn fuel to heat water or to produce steam for use in electricity generation or in industrial processes. The need of common methodology for the inventory preparation emerged during the preparatory phase of the project. National data on energy supply and final energy demand as reference to determine the fuel consumptions by power and industrial boilers should be used by all countries in order to have a common data source. Official energy data, prepared by relevant 6 UNIDO-PIF BAT/BEP-ESEA 22 October 2008rev 24. 25. 26. 27. 28. H. offices of the ministries of Energy/Industry of the countries are usually available and published. The energy data are based on internationally followed common rules and are updated yearly. The consumption is given per year and only conversions among the used units are needed to calculate PCDD/PCDFs emissions per year (UNEP Toolkit unit conversion tables can be used). The volumetric concentrations of chemicals listed in Annex C in the Stockholm Convention in the emissions from fossil fuel-fired boilers are generally very low. However, the total mass emissions from the boiler sector may be significant because of the scale of fossil fuel combustion, in terms of both tonnage and distribution, for electricity generation and heat or steam production. Measures that can be taken to decrease the formation and release of the chemicals listed in Annex C include: maintenance of efficient combustion conditions within the boiler and ensuring sufficient time is available to allow complete combustion to occur; undertaking measures to ensure fuel is not contaminated with PCB, HCB or chlorine, and is low in other components known to act as catalysts in the formation of unintentional POPs; use of appropriate gas-cleaning methods to lower emissions that may contain entrained pollutants; and appropriate strategies for disposal, storage or ongoing use of collected ash. Internationally achievable performance levels are significantly lower than 0.1ng TEQ/Nm3. In order to reduce UP-POPs releases from fossil fuel-fired utilities and industrial boilers the generation of these chemical must be minimized in the design and operation of the process. This can be effectively achieved by primary measures addressing (i) fuel quality by sourcing, monitoring and specifications; and (ii) combustion conditions, such as temperature ( >900 0 C), time (2 seconds), turbulence (high) and excess of air (reference oxygen: 6% in excess for solid fuels and 3% in excess for liquid fuels). Cost-effectiveness analysis of BAT/BEP measures has two main aspects. In other words primary measures mean the introduction of such technologies that would efficiently destruct and avoid de novo generation of unintentionally produced POPs. Secondary measures are those that are applied to prevent PCDD/PCDF releases generated unintentionally through the process by installation of the most appropriate air pollution control devices (APCD). For example wet scrubbers are used in large boilers to remove in two stages (acid and basic) of acids and metals. However, PCDD/PCDF can be adsorbed on the plastic surface of wet scrubbers and at temperature higher than 900C, PCDD/PCDF would be released from the surfaces. Polypropylene embedded with carbon provides selective adsorption of PCDD/PCDF and mercury (60-70%). By adding spray injection of active carbon and Ca (OH) 2 in dry and semi-dry scrubbers would increase the efficiency to 99%. To remove particulate matter several devices can be used. They would also remove PCDD/PCDF. The removal efficiency of electrostatic precipitator is 96.5%, the removal efficiency of fabric filter is 99.6% and that of the wet scrubber is 98.5%. For large boilers continuous emissions monitoring systems (CEMS) have to be used. For small boilers manual sampling is applied with portable devices (5-10 kg). For PCDD/PCDF sampling several methods exist. In a large power plant, where PCDD/PCDF emissions are low, 10 Nm3 flue gas has to be collected that might take 8-10 hours. With continuous PCDD/PCDF monitoring device sampling might be extended from 1 day to 2-3 weeks to get a more representative sample. Then the sample processing can takes sometimes for 2-3 days before the analytical determination. The cost-effectiveness of the project in a widely diverse source category such as the fossil fuel-fired utility and industrial boilers can not easily be estimated. However, may draw some ideas from the results of the Italian Government financed pilot BAT/BEP project implemented in China. An intensive survey and pilot study was carried out in two Chinese medical waste incinerators with good APCS. During the pilot studies the process parameters were optimized and a few secondary measures were introduced without any major capital investment. The results showed that the cost of PCDD/PCDF release reduction was about US$ 150,000/g TEQ in 2006. It is clear from the above (see paragraph 20) that the very high investment costs of large power plant would not make feasible to make any modifications at the technology level, therefore only BEP measures could be introduced. However, in the small and medium size boiler sector, more opportunities could be found to disseminating BAT/BEP and as part of BEP measures introducing environmentally sound common practices in the small and microscale enterprises and informal sector. It seems to be feasible that in the latter sectors higher cost effectiveness could be achieved by avoiding the use of chlorine and heavy metal catalysts containing wastes as fuel. JUSTIFY THE COMPARATIVE ADVANTAGE OF GEF AGENCY: 29. The project focuses on technological solutions to environmental and health problems within Operational Program 14, where UNIDO has a clear comparative advantage. UNIDO is mandated to support developing countries and countries with economy in transition to achieve industrial development. UNIDO has also developed and implemented a large number of GF-funded NIPs and post-NIP projects and contributed to the efforts made in sound management of chemicals. This project will integrate both aspects of technology transfer and investment in introducing BAT/BEP in fossil fuel-fired utilities and industrial boilers source category, which are clearly falling in the comparative domain of UNIDO. 7 UNIDO-PIF BAT/BEP-ESEA 22 October 2008rev PART III: APPROVAL/ENDORSEMENT BY GEF OPERATIONAL FOCAL POINT(S) AND GEF AGENCY(IES) A. RECORD OF ENDORSEMENT OF GEF OPERATIONAL FOCAL POINT (S) ON BEHALF OF THE GOVERNMENT(S): (Please attach the country endorsement letter(s) or regional endorsement letter(s) with this template). CAMBODIA Lohn Heal Date: 1 July 2008 GEF Operational Focal Point Technical Director General Ministry of Environment Cambodia INDONESIA (to be submitted) Date: LAO PDR Khampadith Khammounheuang Date: 6 June 2008 GEF National Focal Point Lao PDR MONGOLIA A. Enkhbat Date: 4 June 2008 GEF Operational Focal Point Director for Sustainable Development and Strategic Planning Department Ministry of Nature and the Environment Mongolia PHILIPPINES Ms. Analiza R. Teh Date: 13 June 2008 GEF Operational Focal Point Assistant Secretary, FASPO Philippines THAILAND Mr. Saksit Tridech Date: 21 July 2008 Permanent Secretary Ministry of Natural Resources and Environment Bangkok, Thailand 8 UNIDO-PIF BAT/BEP-ESEA 22 October 2008rev