biological sulfate reduction in alkaline waters for the reprocessing of

advertisement

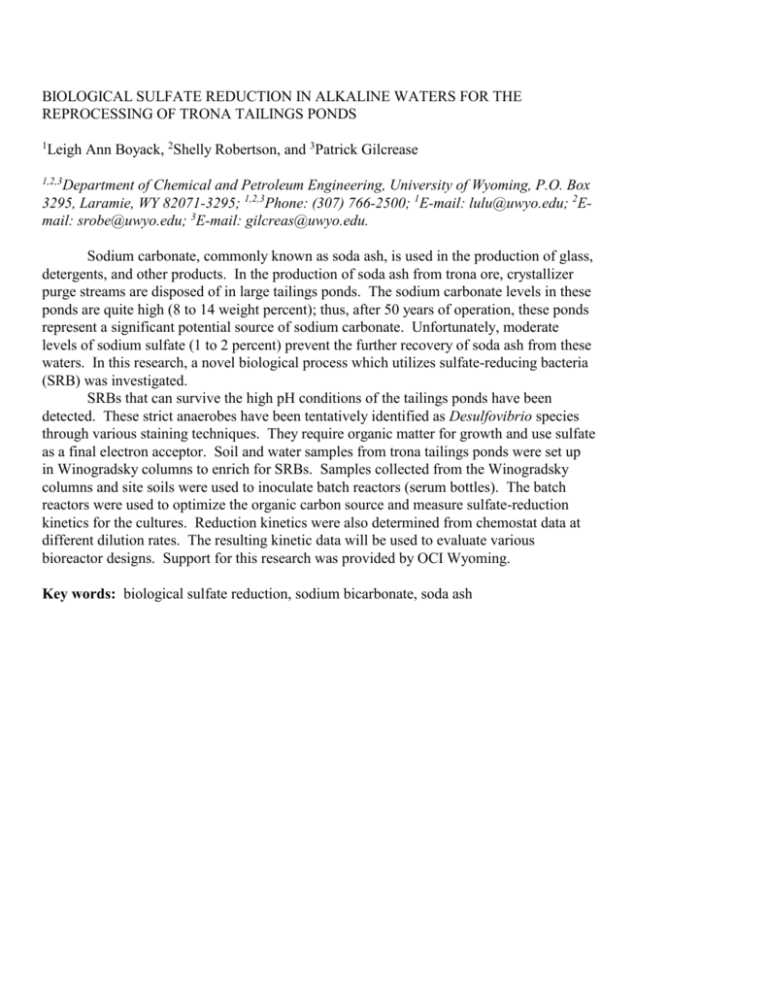

BIOLOGICAL SULFATE REDUCTION IN ALKALINE WATERS FOR THE REPROCESSING OF TRONA TAILINGS PONDS 1 Leigh Ann Boyack, 2Shelly Robertson, and 3Patrick Gilcrease 1,2,3 Department of Chemical and Petroleum Engineering, University of Wyoming, P.O. Box 3295, Laramie, WY 82071-3295; 1,2,3Phone: (307) 766-2500; 1E-mail: lulu@uwyo.edu; 2Email: srobe@uwyo.edu; 3E-mail: gilcreas@uwyo.edu. Sodium carbonate, commonly known as soda ash, is used in the production of glass, detergents, and other products. In the production of soda ash from trona ore, crystallizer purge streams are disposed of in large tailings ponds. The sodium carbonate levels in these ponds are quite high (8 to 14 weight percent); thus, after 50 years of operation, these ponds represent a significant potential source of sodium carbonate. Unfortunately, moderate levels of sodium sulfate (1 to 2 percent) prevent the further recovery of soda ash from these waters. In this research, a novel biological process which utilizes sulfate-reducing bacteria (SRB) was investigated. SRBs that can survive the high pH conditions of the tailings ponds have been detected. These strict anaerobes have been tentatively identified as Desulfovibrio species through various staining techniques. They require organic matter for growth and use sulfate as a final electron acceptor. Soil and water samples from trona tailings ponds were set up in Winogradsky columns to enrich for SRBs. Samples collected from the Winogradsky columns and site soils were used to inoculate batch reactors (serum bottles). The batch reactors were used to optimize the organic carbon source and measure sulfate-reduction kinetics for the cultures. Reduction kinetics were also determined from chemostat data at different dilution rates. The resulting kinetic data will be used to evaluate various bioreactor designs. Support for this research was provided by OCI Wyoming. Key words: biological sulfate reduction, sodium bicarbonate, soda ash