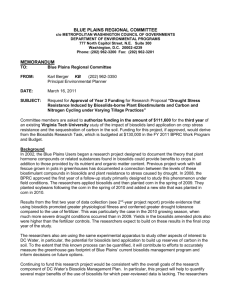

BIOSOLIDS

advertisement

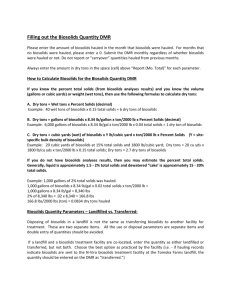

BIOSOLIDS Biosolids are regulated under the 1993 EPA Law “Standard for Use or Disposal of Sewage Sludge”, which is more commonly known as the “Part 503 Rule”. What are biosolids? Biosolids are the final treated product from domestic wastewater treatment sludge. They are NOT raw sewage solids. The material has undergone substantial treatment to be safe for humans and the environment. Some other terms to know: primary sludge: settled solids from raw sewage; contain most viruses secondary sludge: settled bacteria that degraded the wastewater organics (these bacteria are generally NOT human pathogens) Treatment processes destroy pathogens and stabilize the material. The treatment process will also reduce the “vector attraction” of the material. Vectors are disease transmitting organisms such as flies and mosquitoes. Biosolids can be useful as a soil conditioner. They provide a benefit when applied to crops, gardens, or lawns. Under the regulations there are different “classes” of biosolids, that are classified on the basis of the amount of treatment which has resulted in specified levels of environmental compatibility and safety. Class AA (some states): unrestricted use Class A: low levels of pathogens and metals; use allowed on public access areas but not for cultivation of tobacco or leafy vegetables Class B: use not allowed on unrestricted public access areas and not for cultivation of tobacco or leafy vegetables; time limits on certain activites after application BACTERIA PATHOGENS generally die quickly in hot, dry soil - within a few weeks poliovirus 0.01% survival in biosolids after 100 days in winter after application poliovirus 0.01% survival in biosolids after 7-10 days after soil application HUMAN ENTERIC VIRUSES IN BIOSOLIDS: (based on information presented at WEFTEC ‘98 by Mark Sobsey & S Meschke) viruses: very small 0.02-0.3 µm diameter; most hydrophilic & negatively charged at neutral pH most have some hydrophobic areas on the surface too important viruses: hepatitis A & E, adenoviruses, rotaviruses, poliovirus, enterovirus enteric viruses not normally present in healthy humans, most people get about 1 illness/yr but infection rate 2 to 100 times illness rate in raw sewage, 100 to 10,000 viruses per L; 1000-10,000 per L in sludge viruses are smaller & more resistant to treatment than bacteria Class A treatment should reduce viruses >99.99% Class B treatment may give >99.99% reduction of some viruses, but not most resistant like hepatitis A thermophilic aerobic treatment gives > 4 log reductions mesophilic typically gives 1-2 log reductions (not good enough for Class A) aerobic better than anaerobic at virus reduction heat drying at 80°C with <10% moisture gives >99.99% virus reduction Heptatis A more resistant to temperature & dessication inactivation than most other viruses hard to measure viruses in biosolids! may survive months or years in soils; tend to sorb to clay but can also move through soil since small also the potential for air-borne virus dispersal from activated sludge tanks, land application, etc. PARASITES: PROTOZOAN Most >2 µm to 2 mm, unicellular hardy cyst forms of most concern; but cysts bouyant so not usually with biosolids Giardia 10µm, Cryptosporidia 5µm Toxiplasma gondii : in cat feces, causes fetal deformations when ingested by pregnant women may survive months or years in soils PARASITES: HELMINTHS (aka worms) multicellular animals, eggs 25-100 µm so can pose risk via wastewater & biosolids eggs very resistant to inactivation processes Ascaris lumbricoides : a good indicator organism since it can survive anaerobic digestion: found in nearly 100% of wastewater plants Class A: only “alternative 3” requires parasite monitoring (“other processes”) Class B: no monitoring, assume that biosolids contain >1 egg/4 g TS; assume that land application restrictions prevent infections found that >50% of final treated biosolids contained detectable levels of eggs average concentration in the treated biosolids was 24 eggs / 4 g if biosolids were not tilled into the soil, eggs gone within 10 months if biosolids were tilled into the soil, >3 yrs required to reduce to <10% of initial concs HUMAN PATHOGENIC BACTERIA Class A: fecal coliforms <1000 MPN per gram total solids OR Salmonelle sp. <3 MPN/4 grams total solids Class B: fecal coliforms average <2 million MPNs or CFUs per gram total solids **** Note that in many cases, treatment conforming to specified levels will reduce the necessity to test for all pathogens. For example, four treatment regimes of time and temperature have been defined which have been shown to produce Class A biosolids in terms of pathogen reduction. For example, >7% solids, must maintain temperature of biosolids for 50°C or more for >20 min OR <7% solids at 50°C or more for >30 min. VECTOR ATTRACTION REDUCTION There are 12 options for reducing the attractiveness of the biosolids to disease-transmitting organisms such as flies, mosquitoes, rodents, and birds. These include: 1. 38% reduction in volatile solids content 2. anaerobic digestion 3. aerobic digestion or composting: >40°C for >14 days 4. stabilized solids at >75% solids content (<25% water) 5. unstabilized solids at >90% solids content (<10% water) 6. inject biosolids below the ground surface 7. hold at pH >12 for >2 hrs AND >11.5 for an additional 22 hrs METALS Municipal solids may contain metals from treating industrial wastewater effluents or other sources. Metals tend to associate with the biosolids during the treatment processes. The are maximum allowable concentrations of a variety of metals in biosolids applied to land (arsenic, cadmium, chromium, copper, lead, mercury, nickel, selenium, zinc). There are also cumulative and annual limits on the amounts of these metals that can be applied to a given land area. TREATMENT METHODS A variety of treatment methods are used to transform primary and secondary sludge from municipal wastewater treatment plants into biosolids. These include: anaerobic digestion – most common; variety of methods including heating, batch versus continuous treatment; methane is generated aerobic digestion – (ATAD, others) composting conditioning – adding chemicals dissolved air flotation (DAFT) – to thicken the sludge increasing the solids content belt press – to reduce liquid content centrifuge – to reduce liquid content