results and analysis

advertisement

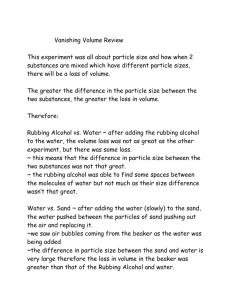

CHAPTER 4 RESULTS AND A N A L Y S I S 4.1 Introduction The analysis was done in order to find out the relationship between standard sand and river sand for determining the in-situ density of soil of natural or compacted fine- and medium-grained soils. The tests determine bulk density, the moisture content of the sample which is weighed has to be representative. By conducting this test it is possible to determine the field density of the soil. The moisture content is likely to vary from time to time and hence the field density also. So it is required to report the test result in terms of dry density. Other tests also being carried out, such as laboratory compaction test, liquid limit and plastic limit test, particle density test and particle distribution test including hydrometer analysis. These supplement tests were done to analyze the soil that was used to fill as the sudgrade material at the selected site of study. When the field density tests conducted using river sand, the dry density obtained from the selected site is higher compared to the silica sand. For all the tests have been done, the results of the dry density are higher than when silica sand is used for the test. 44 4.2 The Soil Classification Tests BS 1377: Part 2: 1990 specified methods of test for the classification of soil and for the determination of basic physical properties. 4.2.1 The Moisture Content Test The moisture content of soils, that is the amount of water in soils can influence their behavior. Measurement of moisture content, both in the natural state and under certain defined test conditions, can provide an extremely useful method of classifying cohesive soils and of assessing their engineering properties. The moisture content of a soil is the characteristic in which is most frequently determined, and applies to all types of soil. The types of test that involves determination of moisture content are liquid limit, plastic limit, laboratory compaction test and the sand replacement test. There are four tests carried out to determine the moisture content before the samples being used to conduct field density test. Table below shows the summary of the moisture content test for silica sand and river sand. Table 4.1: Moisture Content Test Result Silica Sand River Sand 0.14% 0.11% 0.10% 0.09% 0.12% 0.11% 0.11% 0.08% Average = 0.12% Average = 0.10% 45 From the result of moisture content test, the silica sand and river sand is considered almost totally dry. The sands are used to proceed with the testing. 4.2.2 The Particle Density Test Particle density is defined as the ratio mass of the soil particles to the mass of the same volume of water. The value of particle density may vary among the mineral constituents of the soil and from size fraction to size fraction. Clean sands generally have a particle density close to 2.65 Mg/m3 and clays a somewhat higher value around 2.72 Mg/m3 or more. Low values in natural soils would suggest the presence of organic matter. There are four tests carried out to determine the particle density to the silica sand, river sand and the soil to be used for filling at the selected site. The results were summarized in the table below. Table 4.2: Particle Density Test Result Particle Density Silica Sand for Particle Density for River Sand Particle Density use as “filled material” at site 2.646 Mg/m3 4.2.3 2.637 Mg/m3 Liquid Limit, Plastic Limit and Plasticity Index 2.715 Mg/m3 46 When a soil contains an appreciable quantity, say 20 percent or more by weight, of material finer than 0.063 mm size a description based on size distribution alone is insufficient. The size distribution of clays and silts is of interest, the behavior of clay is related to its mineralogical composition, water content and the micro- and macro-fabric of its particles. The change in the state of clay as the water content is changed has been found to be a useful and simple way of distinguishing one clay from another and this is the basis of soil classification applied to clays. The coarser soils may contain just sufficient fine material that when moist a cohesive mass of the soil can be formed. With a greater content of fines or more clay sizes among them the soil may show plasticity. The fine fraction of a coarse soil can thus usually be distinguished as either non-plastic or plastic. The result of liquid limit and plastic limit test of the “filled material” is as below: Liquid limit = 63% Plastic Limit = 41% Plasticity Index = 63% -41% = 22% Soil Type = MH The result of the soil test shows that it is classified as Silt High. 4.2.4 The particle Size Distribution Test Including Hydrometer Analysis The most common particle size distribution curves are plotted in the cumulative diagram displaying the percentage by weight of the material finer than 47 any given size. It is being presented on a logarithmic scale. When the particles are matched against sieves of known aperture sizes a satisfactory estimate of the amounts of material finer than each size is easily obtained. The lower limit of size analyzed by sieving is usually fine sand at 0.063 mm. The particle size distribution of the silty fractions of soil is of interest and these sizes lie below 0.063 mm. The size distribution over the silt range is in-directly assessed from determinations of the velocities of sedimentation of the particles in water. The silts reach their terminal velocity almost immediately and thereafter fall in water at a constant velocity, which, for the silt sizes, is proportional to the square of the particle diameter. Soils with similar size distribution curves would in a general sense be expected to show similar engineering characteristics. Predictions of behavior are made cautiously because the size distribution alone does not convey the arrangement and density of packing of the particles and other factors which influence the behavior of the soil. The fine grains in a soil exercise the largest influence on its behavior. The effective size or ten percent size (D 10) is used in describing soils. The steepness of the curve is given a numerical value in the uniformity coefficient Cu. If the range of sizes present in a soil is small it is described as a uniform soil or uniformly graded. Such poorly graded soils will have Cu values of 2 or less. Some poorly graded soils may have a deficiency of intermediate sizes and are described as gap graded. A well-graded soil is one which can give a dense, rather strong soil. It will have a wide range of particle sizes and the distribution curve will be smooth and concave upwards, with no deficiencies or excesses of sizes in any size range. A well-graded soil has a Cu value of 5 or more. From the result of sieving analysis carried out, both the silica sand and river sand is 100 percent felt within the range of passing 0.600 mm test sieve and retained on 0.063 mm test sieve. Therefore it is permitted to use for field density test. 48 From the result of sieving analysis test including hydrometer test of the soil sample, the clay contains about 22 percent, silt is around 5 percent and sand is about 20 percent. Thus, the soil can be classified as reddish sandy silty Clay. Table 4.3: River sand And Silica Sand Coefficiency River Sand Silica Sand Cu = 1.58 Cu =1.43 Cc =1.16 Cc =1.03 % Of Passing Silica Sand Sieve Analysis 100 90 80 70 60 50 40 30 20 10 0 0.001 0.01 0.1 1 10 Particle Size Figure 4.1: Silica Sand Grading Curve Result River Sand Sieve Analysis 100 90 % Of Passing 80 70 60 50 40 30 20 10 0 0.001 0.01 0.1 Particle Size 1 10 49 Figure 4.2: River Sand Grading Curve Result Reddish silty CLAY Sieve Analysis 100 90 % Of Passing 80 70 60 50 40 30 20 10 0 0.0001 0.001 0.01 0.1 1 10 Particle Size Figure 4.3: Filled Material Grading Curve Result 4.3 Laboratory Compaction Test The process of mechanically pressing together the particles of a soil to increase the density is extensively employed in the construction of embankments and in strengthening the subgrade of roads and runways. Compaction is the packing together of soil particles by the expulsion of air. The densities achieved by compaction are invariably expressed as dry densities, generally in Mg/m3. 50 The procedure forms the basis of the British Standard compaction and used a compact effort in which roughly corresponded to that available in the field at the time. Laboratory tests are useful for the classification and the selection of fill materials for earthworks, but it is not usually possible to apply results from these tests to work in the field due to the difference in the compactness efforts. For large earth full scale tests should be carried out, compacting a test section with the actual plant that will ultimately be employed on the project. In this way it is possible to determine the number of passes of the machine required in achieving the desired dry density. The maximum dry density depends upon the type of soil compacted. The soil being used for filling at the selected site is classified as reddish silty clay. There was one laboratory compaction test carried out to the filled material to determine the maximum dry density and the optimum moisture content. After the laboratory compaction test, the maximum dry density is 1.400 Mg/m3 as obtained from the moisture content against dry density relation curve. The optimum moisture content is about 27 percent. This is meant that the soil that is used for site filling will be able to achieve in-situ field density of 1.400 Mg/m3 provided that the number of passes of the selected machine is determined. From the field density tests result collected, the compactive efforts were about 75 percent to 98 percent. However, there is a possibility of over-compaction in the field if the compact effort does not take the soil into the range beyond optimum moisture content. 1.410 15% Air void Line 10 % Air Void Line 1.405 DRY DENSITY (Mg/m 3) 1.400 1.395 1.390 1.385 1.380 1.375 51 Figure 4.4: Filled Material Laboratory Compaction Curve Result 4.4 In-situ Field Density Test The analysis is done at the selected site. The site was compacted using a 5 ton roller. With different number of passes to the selected ground, sand replacement test was carried out. Each time there were five tests done within the selected location of approximately 1 square meter. Two tests were done using standard sand or ‘silica sand’ and three tests were using river sand. The average of the field density was taken for the two tests of silica sand and the same to the 3 tests of the river sand. The studied was done with about 12 different compactness of the ground. Therefore there were about 20 silica sand tests result of in-situ field density using sand replacement method and 30 tests result using river sand. Then the final result will be able to produce 12 points of different in degree of compaction for silica sand and river sand and the related density can be obtained. 4.4.1 Summary Of Field Density Test Result The table below shows the calculated average dry density of the silica sand and river sand conducted in-situ at different level of compaction at the selected site. 52 Table 4.4A: Summary In-situ Field Density Test Result Set 1 FD SILICA AVERAGE REFERENCE SAND SILICA 1 1.268 2 1.279 RIVER AVERAGE SAND RIVER SAND 1.274 3 1.289 4 1.298 5 1.297 Table 4.4B: Summary In-situ Field Density Test Result Set 2 FD SILICA AVERAGE REFERENCE SAND SILICA 8 1.276 9 1.270 RIVER AVERAGE SAND RIVER SAND 1.273 10 1.295 11 1.306 12 1.297 Table 4.4C: Summary In-situ Field Density Test Result Set 3 FD SILICA AVERAGE REFERENCE SAND SILICA 13 1.294 14 1.310 1.295 1.299 RIVER AVERAGE SAND RIVER SAND 1.302 15 1.331 16 1.330 17 1.328 1.330 53 Table 4.4D: Summary In-situ Field Density Test Result set 4 FD SILICA AVERAGE REFERENCE SAND SILICA 21 1.310 22 1.319 RIVER AVERAGE SAND RIVER SAND 1.315 18 1.335 19 1.353 20 1.343 Table 4.4E: Summary In-situ Field Density Test Result Set 5 FD SILICA AVERAGE REFERENCE SAND SILICA 26 1.295 27 1.295 RIVER AVERAGE SAND RIVER SAND 1.295 23 1.313 24 1.317 25 1.328 Table 4.4F: Summary In-situ Field Density Test Result Set 6 FD SILICA AVERAGE REFERENCE SAND SILICA 31 1.255 32 1.243 1.344 1.319 RIVER AVERAGE SAND RIVER SAND 1.249 28 1.280 29 1.266 30 1.273 1.273 54 Table 4.4G: Summary In-situ Field Density Test Result Set 7 FD SILICA AVERAGE REFERENCE SAND SILICA 36 1.098 37 1.092 RIVER AVERAGE SAND RIVER SAND 1.095 33 1.118 34 1.121 35 1.104 1.114 Table 4.4H: Summary In-situ Field Density Test Result Set 8 FD SILICA AVERAGE SILICA RIVER AVERAGE REFERENCE SAND SAND RIVER SAND 38 1.129 39 1.116 1.123 40 1.139 41 1.143 42 1.146 1.143 Table 4.4I: Summary In-situ Field Density Test Result Set 9 FD SILICA AVERAGE SILICA RIVER AVERAGE REFERENCE SAND SAND RIVER SAND 43 1.126 44 45 1.130 1.128 1.139 55 46 1.147 47 1.158 Table 4.4J: Summary In-situ Field Density Test Result Set 10 FD SILICA AVERAGE REFERENCE SAND SILICA 48 1.100 49 1.112 1.148 RIVER AVERAGE SAND RIVER SAND 1.106 50 1.130 51 1.127 52 1.118 1.125 Table 4.4K: Summary In-situ Field Density Test Result Set 11 FD SILICA AVERAGE SILICA RIVER AVERAGE REFERENCE SAND SAND RIVER SAND 53 1.209 54 1.208 1.209 55 1.236 56 1.232 57 1.235 Table 4.4L: Summary In-situ Field Density Test Result Set 12 FD SILICA AVERAGE REFERENCE SAND SILICA 58 1.251 1.234 RIVER AVERAGE SAND RIVER SAND 56 59 1.239 1.245 60 1.275 61 1.259 62 1.270 1.268 4.4.1.1 Tabulated Dry Density Table 4.5: Summary Result of the Field Density Test AVERAGE DRY DENSITY RIVER SAND(Mg/m3) AVERAGE DRY DENSITY SILICA SAND(Mg/m3) 1.295 1.274 1.299 1.273 1.330 1.302 1.344 1.315 1.319 1.295 1.273 1.249 1.114 1.095 1.143 1.123 57 1.148 1.128 1.125 1.106 1.234 1.209 1.268 1.245 4.4.1.2 Dry Density Relationship Between Silica Sand And River Sand Figure 4.4 below is the outcome of the analysis. The relationship between silica sand dry density and the river sand dry density is established. The correlation factor is 0.9813. 58 Silica Sand Dry Density Dry Density Correlation Between River Sand And Silica Sand 1.350 1.300 y = 0.9813x R2 = 0.9993 1.250 1.200 1.150 1.100 1.050 1.000 1.000 1.050 1.100 1.150 1.200 1.250 1.300 1.350 River Sand Dry Density Figure 4.5 : River Sand and Silica Sand Relationship Graph 1.400