respectively constant

advertisement

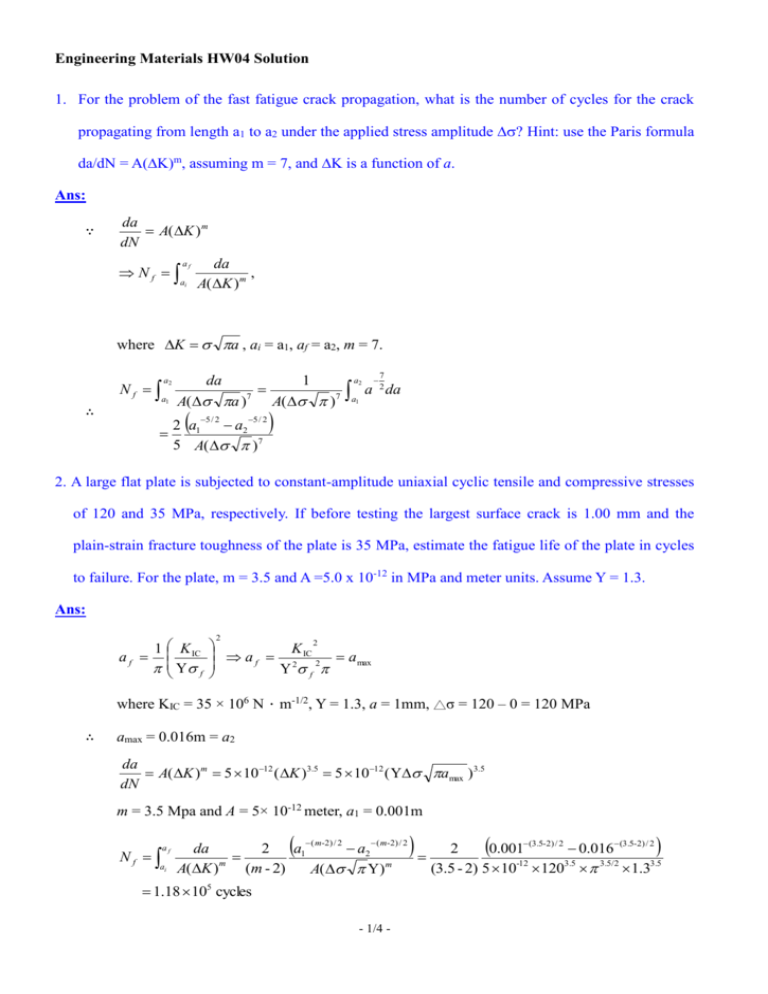

Engineering Materials HW04 Solution 1. For the problem of the fast fatigue crack propagation, what is the number of cycles for the crack propagating from length a1 to a2 under the applied stress amplitude ? Hint: use the Paris formula da/dN = A(K)m, assuming m = 7, and K is a function of a. Ans: ∵ da A(K ) m dN Nf af ai da , A( K )m where K a , ai = a1, af = a2, m = 7. a2 da a1 A( a )7 Nf ∴ 5 / 2 5 / 2 2 a1 a2 5 A( )7 1 A( )7 a2 a1 7 a 2 da 2. A large flat plate is subjected to constant-amplitude uniaxial cyclic tensile and compressive stresses of 120 and 35 MPa, respectively. If before testing the largest surface crack is 1.00 mm and the plain-strain fracture toughness of the plate is 35 MPa, estimate the fatigue life of the plate in cycles to failure. For the plate, m = 3.5 and A =5.0 x 10-12 in MPa and meter units. Assume Y = 1.3. Ans: 1 K a f IC Y f 2 2 a f K IC 2 a max Y 2 f where KIC = 35 × 106 N.m-1/2, Y = 1.3, a = 1mm, △σ = 120 – 0 = 120 MPa ∴ amax = 0.016m = a2 da A( K )m 5 1012 ( K )3.5 5 1012 ( Y amax )3.5 dN m = 3.5 Mpa and A = 5× 10-12 meter, a1 = 0.001m Nf af ai ( m-2) / 2 ( m-2) / 2 da 2 a1 a2 m A( K ) (m - 2) A( Y)m 1.18 105 cycles - 1/4 - 0.001(3.5-2) / 2 0.016(3.5-2) / 2 2 (3.5 - 2) 5 10-12 1203.5 3.5/2 1.33.5 Engineering Materials HW04 Solution 3. The S-N curve of a material is described by the relationship S log N 10 1 0 Here N is the number of cycles to failure, S is the amplitude of the applied cyclic stress, and s 0 is the monotonic fracture strength. A component made of this material is subjected to 10 4 cycles at S=0.5 0. If the cyclic load is now increased to S=0.75 0, how many more cycles will the component withstand? Ans: log N f 10 (1 s 0 ) s = 0.5σ0 log N f 10 (1 0.5) 5 N f 105 s = 0.75σ0 log N f ' 10 (1 0.75) 2.5 N f ' 102.5 n N N1 N 2 i 1 N f1 N f 2 i 1 N f i ∵ Miner’s rule ∴ 10 4 x 2.5 1 x 285 cycles 5 10 10 4. From a stress controlled, high-cycle fatigue test, one finds statistically that the specimens fails at Nf = 106 cycles under = 300 MPa, and Nf = 3 x 106 cycles under = 270 MPa. (a) What is the Basquin’s exponent? (Hint: (Nf)a = constant, the symbol a is the Basquin’s exponent.) (b) Calculate the stress amplitude needed for the specimens failed at 108 cycles. Ans: 4.a Nf1 = 106 cycles, △σ1 = 300 MPa - 2/4 - Engineering Materials HW04 Solution Nf2 = 3 × 106 cycles, △σ1 = 270 MPa ∵ ( N f ) a constant ∴ 1 300 log log N 2 270 1 1 ( N f 1 )a 2 ( N f 2 )a f 2 a 2 Nf 2 3 106 Nf 1 log log 6 1 10 Nf 1 a a = 0.0959 4.b a N 106 1 f 1 300 106 8 10 Nf ∴ 0.0959 192.9 MPa σamplitude = Δσ/2 = 96.4 MPa 5. Steady state creep data for an alloy is taken at a stress level of 70 MPa. ss sec T (K) 1 x 10-5 977 2.5 x 10-3 1089 The value of stress exponent of this alloy n=7. (a) Suppose that a specimen 750 mm long of this alloy is subjected to a tensile stress of 70 MPa at 1000 K. What is the elongation due to steady state creep for 5hr? (b) What is the steady state creep rate at 1089K and a stress level of 50 MPa ? Ans: 5.a ss A e n Q RT ,n=7 For σ = 70 MPa, T = 977K, εss = 1 × 10-5 s-1 ss1 A(70 106 )7 e Q 1 R 977 1 10-5 (1) For σ = 70 MPa, T = 1089K, εss = 2.5 × 10-3 s-1 ss2 A(70 106 )7 e Q 1 R 1089 (2) - 3/4 - Engineering Materials HW04 Solution (1)/(2) e ∴ Q 1 1 ( ) R 977 1089 4 10-3 Q/R = 52451.6, substitute into Eq.(1) A = 2.51 × 10-37 When T = 1000K and tensile stress = 70 MPa ss 2.51 10-37 (70 106 ) 7 e 1 52451.6( ) 1000 3.438 10-5 s 1 If time is 5 hrs ε = 3.438 × 10-5 × (5 × 60 × 60) = 0.6188 Elongation △l = ε × l0 = 0.6188 × 750 = 464 mm 5.b ∵ ss A n e Q RT where A = 2.51 × 10-37, σ = 50 MPa, Q/R = 52451.6 ss = 2.51 × 10-37 × (50 × 106)7 × e-52451.6/1089 = 2.372 × 10-4 s-1 - 4/4 -