Theory of Metal Forming

advertisement

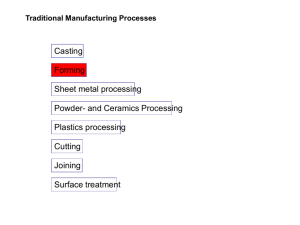

Course Specifications Relevant Programme B.Sc. in Engineering Department offers the programme Faculty of Engineering (Production Engineering and Mechanical Design) Department offers the course ٍ Department of Metallurgy-Faculty of Engineering- Cairo University* Production Engineering and Mechanical Design Scholar year Metal Forming 3rd Year Production Engineering and Mechanical Design / First Semester Date of specification approval 2006 *Instructor: Dr Mahmoud M. Tash e-mail: mahmoud_tash1@yahoo.com A- Basic Information Title: Theory Metal Forming Code: MPD3117 Credit Hours: Lecture: 3 Tutorial and Practical: 3 Total: 6 B- Professional Information 1 – Aims 1. Learn the basics of metal forming processes and the yielding criteria 2. Conduct simple mechanical analysis calculations on work piece and calculate the necessary loads, using the stress equations he learns from the course of "Theory of Elasticity and Plasticity". 3. Correlate the various metal working parameters (stress, temperature, and strain rate) to basic metallurgical and mechanical properties. 4. know the mechanical and metallurgical aspect in plasticity 5. Compare the cold and hot forming processes 6. Understand the role of friction and tribology in metal forming 7. Conduct simple mechanical analysis calculations on work piece and calculate the necessary loads by different theorem (Ideal work-Strip method or force equilibrium-upper bound theorem-slip line fields-FEM). 8. Conduct simple forging load calculations. 9. learn certain metal forming process (forging, extrusion, drawing and rolling) 2 – Intended Learning Outcomes (ILOs) a-Knowledge and Understanding: a.1Technology of metal forming processes. a.2 Mechanics of metal working. a.3 Metallurgy of metal working. a.4 Technology of rolling and sheet metal forming processes. a.5 Mechanics of rolling. b-Intellectual Skills b.1 Calculation of loads necessary for a certain metal forming process. b.2 Identifying suitable metal forming operation for some products. b.3 Calculation of loads necessary for rolling. c- Professional and Practical Skills c1- Learning how are parts manufactured. c2- Selection of proper metal working process for different parts. d- General and Transferable Skills d1- Working in a team. d2- Writing a technical report. d3- Presenting a report. 3- Contents Lecture Topic Outline No. of hours Week Topics Lect. Tutorial 1 Introduction: Classification of forming processes, Review on 3 some concepts related to metal forming: true stress-strain curve, yielding criteria., Solved examples on calculation of true and engineering strains 3 2 Mechanics of metalworking: slab method, uniform deformation energy method. Solved examples on calculation of true and engineering strains and application of yielding phenomena. 3 3 Friction and lubrication in metal working, the effect of friction on load calculations, sliding vs sticking friction. Deriving the equations describing load requirements taking friction into consideration. 3 4 Metallurgical aspect of metal working: Metallurgical effects in metal working: (static and dynamic) recovery and recrystallization. 3 5 Metallurgical aspect of metal working: hot and cold working. Temperature-pressure-strain rate effect on amount of deformation. 6 Mid-term Exam 3 3 7 Forging Process, calculation of forging load. 3 3 8 Extrusion Process, direct and indirect extrusion, problems. 3 3 9 Methods of solving problems in metal forming: forging, 3 3 3 3 3 3 3 extrusion and drawing 3 10 Conduct simple mechanical analysis calculations on work piece and calculate the necessary loads by Ideal work and Strip method or force equilibrium theorem. 11 Conduct simple mechanical analysis calculations on work piece and calculate the necessary loads by upper bound theorem. 3 12 Conduct simple mechanical analysis calculations on work piece and calculate the necessary loads by slip line field theory . 3 13 forging, extrusion, rolling and drawing: basics. 3 3 14 forging, extrusion, rolling and drawing: processes 3 3 3 3 3 4– Teaching and Learning Methods 4.1- Lectures: Blackboard, Overhead Transparencies 5- Student Assessment Homework to assess problem solving abilities. Mid-term to assess understanding and versatility. Oral Discussions to assess understanding and ability to present data. Final Exam to assess overall course assimilation. Year Work Item #Points% Attendance and Pop Quizzes Homework assignments One midterm exams Final Examination 1 15 10 35 60 90 Totals__ 150 6- List of References 6.1- Course Notes 6.2- Essential Books (Text Books) 1- Mechanical Metallurgy; G. E. Dieter, Mc. Graw-Hill Book Company, 1988. (Part 4, ch15-20). 2- Mechanical Working of Metals: Theory and Practice; Pergamon International Library. 6.3- Periodicals, Web Sites, … etc