CE 428-Lect4

advertisement

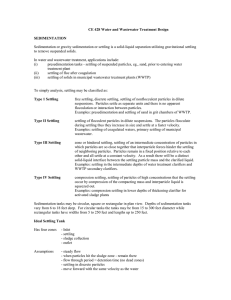

CE 428 Water and Wastewater Treatment Design SEDIMENTATION Sedimentation is a solid-liquid separation utilizing gravitational settling to remove suspended solids. In water and wastewater treatment, applications include: (i) presedimentation tanks - settling of suspended particles, eg., sand, prior to entering water treatment plant (ii) settling of floc after coagulation (iii) settling of solids in municipal wastewater treatment plants (WWTP) To simply analysis, settling may be classified as: Type 1 Settling free settling, settling of nonflocculent particles in dilute suspensions. Particles settle as separate units and there is no apparent flocculation or interaction between particles. Examples: presedimentation and settling of sand in grit chambers of WWTP. Type II Settling settling of flocculent particles in dilute suspensions. The particles flocculate during settling thus they increase in size and settle at a faster velocity. Examples: settling of coagulated waters, primary settling of municipal wastewater. Type III Settling zone or hindered settling, settling of an intermediate concentration of particles in which particles are so close together that interparticle forces hinder the settling of neighboring particles. Particles remain in a fixed position relative to each other and all settle at a constant velocity. As a result there will be a distinct solid-liquid interface between the settling particle mass and the clarified liquid. Examples: settling in the intermediate depths of water treatment clarifiers and WWTP secondary clarifiers. Type IV Settling compression settling, settling of particles of high concentrations that the settling occur by compression of the compacting mass and interparticle liquid is squeezed out. Examples: compression settling in lower depths of thickening clarifier for activated sludge plants Sedimentation tanks may be circular, square or rectangular in plan view. Depths of sedimentation tanks vary from 6 to 18 feet deep. For circular tanks the tanks may be from 15 to 300 feet diameter while rectangular tanks have widths from 5 to 250 feet and lengths up to 250 feet. Ideal Settling Tank Has four zones - Inlet - settling - sludge collection - outlet Assumptions - steady flow - when particles hot the sludge zone - remain there - flow through period = detention time (no dead zones) - settling in discrete particles - move forward with the same velocity as the water Design parameters - overflow rate or surface loading rate or clarification rate (m3/s/m2) - weir overflow rate (m3/d/m) Others - particle settling velocity Vs (m/s) - detention time (hr) (1) Overflow Rate/Surface Loading Rate Vo = flow rate/ surface area of sedimentation tank = Q/As (note independent of depth) If Vs > Vo particles will settle If Vs < Vo, particles will be carried over (Vo is usually set a < 80% of Vs) Notes there is a distribution of particle sizes therefore will have a range or distribution of V s the overflow rate is the average fluid velocity at about the mid section of the sedimentation tank. At the collection weir at the edge of the clarifier, the fluid velocity may be higher, resulting in a carry over of the particles. Therefore sufficient length must be provided to ensure that water will not rush over the weir. This lead to the second design parameter, (2) weir overflow rate given by: = flow rate/length of weir = Q/L (3) Detention Time - approximately 2 - 8 hours (4 - 6 hours common)- some lime softening system has a detention time of 2 hours. Application Alum Iron Salts Lime Overflow Rate (gal/d/ft2) 500 - 800 700 - 1000 700 - 1500 Weir Overflow Rate (gal/day/ft) 12,000 - 18,000 16,000 - 22,000 22,000 - 26,000 (4) Typical Depths - 2 to 6 m. Laboratory Approach in determining Removal Rates and Detention Time - use a column with the same depth as the clarifier. At various depths, sampling points are provided to remove samples to measure the suspended solids concentration - provide gentle mixing - start with uniform concentration throughout and at various times collect samples throughout the length of the column. - compute the mass fraction removed at each depth and time % removed P = ( 1 - Cij/Co) x 100 where Cij = concentration at depth I and time I Co = initial concentration - plot depth vs time, the percent removal at each time and depth - draw iso-removal rate lines - for a given retention and depth, compute the overall removal rate R = r o + ri where ri = (di/D)pi ro = fraction of solids removed at the given depth and retention time pi = differential removal rates di = depth of clarifier for ri (at the mid-point of differential removal rates) D = depth of clarifier Example Problem - Flocculation Analysis - Detention Time and Removal Rates Column analysis of a flocculating suspension is presented below. The initial average concentration throughout the column was 250 mg/L. What is the overall removal efficiency of a settling basin which 3 m deep with a retention time of 1 hour and 45 minutes Depth (m) 0.5 1.0 1.5 2.0 2.5 3.0 30 133 180 203 213 220 225 60 83 125 150 168 180 188 Time of Sampling (mins) 90 120 50 38 93 65 118 93 135 110 145 123 155 133 150 30 55 75 90 103 113 180 23 43 58 70 80 95 Time of Sampling (mins) 90 120 80 85 63 74 53 63 46 56 42 51 38 47 150 88 78 72 64 59 55 180 91 83 77 72 68 62 Solution Step 1 - Compute Removal Rates Depth (m) 0.5 1.0 1.5 2.0 2.5 3.0 30 60 67 50 40 33 28 25 28 19 15 12 10 Step 2 - Plot Iso-removal rate lines 0.0 0.5 47 67 80 85 88 91 1.0 28 50 63 74 78 83 1.5 19 40 53 63 72 77 2.0 15 33 46 56 64 72 2.5 12 28 42 51 59 68 3.0 10 25 38 47 55 62 30 60 90 120 150 180 Detention time = 105 mins, ro = 43% ri 0.07 0.1 0.1 0.1 0.1 0.1 di ri di = ri R = r o + ri Inclined (tube and plate settling) Principle: efficiency of discrete particle settling in horizontal liquid flow is dependent on the area available for settling and independent of the depth of the sedimentation tank V0 = Q/A Efficiency can be improved by increasing the area, i.e., by using multiple floors in sedimentation tanks. Another alternative is to use uniformly and closely spaced inclined surfaces called tube or plate or lamella settlers. Inclined settling systems are usually made of plastic. Angles of the plates may be as low as 5 o to as high as 70o. Flow in the channels must be laminar and in practice Reynolds number must be less than 800 in the channel. System comes in three flow arrangements: countercurrent, co-current and cross-flow. Most systems are counter current as shown in the diagram below. For each arrangement, conditions for removal of particles with a settling velocity Ut and greater are removed if: Countercurrent co-current cross-flow Ut where Uo L p cos sin Ut Uo L p cos sin Ut = settling velocity of particle Lp = length of surface needed Uo = liquid velocity between the surfaces = Q/Nb N = number of channels b = width of channel = perpendicular spacing between surfaces = angle of surface inclination Ut Uo L p cos