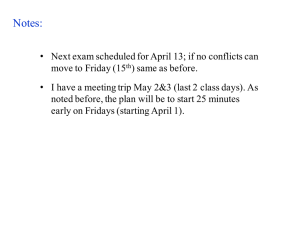

ME381R Homework #1:

advertisement

ME381R Homework #3 & Example final project (Due 10/23 before class):

Background

Metal oxides (e.g. SnO2) are being widely used for detecting flammable and toxic

gases, including organophosphosphorus compounds such as nerve agents, halogenated

hydrocarbons, CO, NO2, NH3, CH4, H2, H2S, alcohols, O2, and ozone. The sensing

mechanism of metal oxide sensors is based on a surface oxidation/reduction process that

changes the concentration of surface oxygen vacancies and thus alters the electrical

conductance of the metal oxide. Because only the ~10 nm thick surface region changes

the conductance due to the oxidation/reduction process, the sensitivity of a metal oxide

sensor increases for decreasing thickness. For this reason, thin film metal oxide gas

sensors have been actively developed using MEMS technologies [for a review, see

Kovacs, 1998]. A key component of the MEMS metal oxide sensors is a thermally

isolated membrane structure with an integrated thin film heater, as illustrated in Fig. 1.

On the membrane, a metal oxide film is deposited by sputtering, evaporation, or metalorganic deposition. The temperature of the thermally isolated membrane can be feedback

controlled to 200 oC -300oC by Joule heating the thin film heater that also serves as a

resistance thermometer. The high temperature enhances the surface oxidation/reduction

process and improves the sensitivity.

A careful thermal simulation is needed to assure a uniform temperature

distribution in the membrane structure. To do that, you will need to calculate the thermal

conductivity of various thin films, which can be very different from the bulk values. To

calculate the thermal conductivity of the SnO2 film that is only 100 nm thick, you can use

an expression derived from the Boltzmann Transport Equation (BTE), as following:

1

1

2 2 k BT 2

2 2

0 D

e

e

k BT

k BT

1

2

d

(1)

This expression is called the Callaway model, and is essentially the same as what we

derived in class using the BTE for the continuum case with an additional assumption of a

Debye-type linear phonon dispersion (as a result, the phonon group or sound velocity v is

independent of energy).

In eqn. 1, is the frequency-dependent relaxation time, which can be obtained

using Matthiessen’s rule as 1 U1 b1 i1 . Here, U1 , b1 , and i1 are the

Umklapp phonon-phonon, boundary, and impurity scattering rates, respectively. A

phenomenological expression for the Umklapp phonon scattering rate has been

used: U1 B e b / T 2T ,where B and b are two fitting parameters. The boundary and

impurity scattering rates can be written as b1 v L and i1 A 4 . Here, L is the

characteristic length of the system (grain size for a bulk crystal, or thickness for a thin

film), and A is a parameter arising from Rayleigh scattering of phonons by atomic scale

impurities. The Debye temperature and the sound velocity were TD = 570 K and v = 4.3 x

103 m/s, respectively, for SnO2. Türkes et al have measured the bulk thermal conductivity

in the (001) or C// direction of SnO2 and their measurement data are shown in Table 1.

Assignment

(1) Use eqn. 1 to calculate the thermal conductivity of bulk SnO2 in the (001)

direction as a function of temperature in the range of 10 K to 350 K. Adjust the

fitting parameters so that your calculation results fit with the measurement data.

(For your information, a Matlab code and the best fitting parameters that I have

obtained are attached below Fig. 2. In the code, I integrated eqn 1 over x

k BT

instead of )

(2) Discusses the effects of different fitting parameters on the calculated temperaturedependant thermal conductivity curve.

(3) Predict the thermal conductivity of a 100 nm thick SnO2 film as a function of

temperature. Assume: (i) the film is single crystalline in the (001) direction; (ii) its

phonon dispersion, Umklapp phonon scattering rate, impurity scattering rate is the

same as those for the bulk crystal.

Table 1: Thermal conductivity in the (001) direction of SnO2 bulk crystalline (from

P. Türkes, Ch. Pluntke, R. Helbig, J. Phys. C: Solid St. Phys. 13, 4941 (1980))

T(K)

k(W/m-K)

318.1600

83.4250

206.2700

137.6900

161.7900

174.0800

136.5800

224.8300

120.3500

239.6800

101.6100

299.8100

84.8790

391.3700

56.2040

632.3000

46.9340

879.9200

44.5110

968.5300

37.1690

1347.8000

32.7520

1452.2000

27.9530

1704.0000

20.4000

1548.2000

16.5430

1333.5000

Fig.1 Schematic diagrams of MEMS SnO2 sensors (from G. Kovas, Micromachined

Transducers Sourcebook)

Thermal conductivity (W/m-K)

2000

1500

1000

500

10

100

Temperature (K)

Fig. 2. Comparison of the measurement and my fitting results of the thermal

conductivity of SnO2 bulk crystal in the (001) direction. If I remembered correctly,

the fitting parameters were L = 6 x 10-4 m, A = 6.077 x 10-45 s3, B = 5.45 x 10-19 s/K, b

= 115.2 K.

Matlab code:

function y=conductivity()

global T L;

debye=570;

L=6e-4; % to be changed

n=1;

temperature=[2:1:350];

for T=2:1:350

temp(n)=quad(@for_integral,0,debye/T);

n=n+1;

end

temp,

temp_2=[temperature',temp'];

save('results','temp_2','-ASCII')

plot(2:1:350,temp,'+')

function y=for_integral(x)

global T L;

k_B=1.38062e-23;

h=1.05459e-34;

C=k_B/h;

v=4.3e3;

A=6.077e-45;

B=5.45e-19;

b=115.2;

y=k_B/2/pi^2/v*C^3*T^3*x.^4.*exp(x).*(exp(x)-1).^(2)./(v/L+A*C^4*x.^4*T^4+C^2*(B*exp(-1*b/T))*x.^2*T^3);