computational simulation of capillary forces acting between particles

advertisement

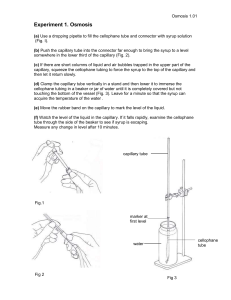

COMPUTATIONAL SIMULATION OF CAPILLARY FORCES ACTING BETWEEN PARTICLES CONNECTED WITH LIQUID “BRIDGE” Y. Tselischev, V. Valtsifer, V. Strelnikov Institute of Technical Chemistry of UB RAS, ac. Koroleva, 3, Perm, Russia tselishch@yandex.ru Abstract A method for computational simulation of capillary forces acting between dispersive components’ particles connected with liquid “bridge” has been developed. The method considers dimensions and shape of particles, distance between them, a type of their “contact”, volume and shape of liquid “bridge”, surface tension of liquid, and wetting angle. The offered method is based on good correlation between computational and experimental values of capillary forces. Investigations in capillary interaction between variously shaped particles–sphere, cone and plane – have been conducted. Computational simulation has resulted in ascertainment of basic parameters of particles and of liquid “bridge” exerting appreciable influence on capillary force and capillary pressure values. A conclusion has been drawn that the developed model enables to qualitatively appraise how humidity of air influences equilibrium moisture load in powders. Introduction Capillary forces are most significant forces acting between particles of dispersive components during their storage, processing, and use under natural conditions. These forces are generated in a liquid “bridge” which is formed within a narrow gap between particles due to absorption of moisture from both the environment and its capillary condensation. Values of these forces are dependent on various parameters characterizing particles of dispersive components, and on properties of liquid interlayer and of the environment. Immediate measurement of capillary forces and investigation in their variations caused by variable parameters of particles and of liquid “bridge” are difficult enough to perform due to small values of objects and forces under investigation. Among pioneer works theoretically describing capillary forces acting between model spherical particles of ideal soil 221 were works published by W.B. Haines and R.A. Fisher as early as in 1920s [1-3]. Later, results of more complete theoretical and experimental investigations in capillary forces acting between spherical particles were mentioned in a number of works by various authors [4-7]. Despite undisputed achievements, results obtained in this field of investigations as from these years are often either different or contradicting; this phenomenon may be explained by considerable complexity of records, of descriptions and, in a number of cases, of necessary simulation of various parameters in dispersive systems. This work aims at design of a computational model describing capillary forces between particles of dispersive components, and at determination of basic parameters of particles and of liquid interlayer which exert appreciable influence on these forces. Various dependences and methods for determination of capillary forces between particles regarded, as a rule, as uniform spheres, are known [1-7]. Capillary interaction between variously shaped and sized particles, as is usually the case with real powders, had been investigated much more rarely [8, 9]. Such status of research works is one of reasons why a method for calculation of capillary forces which would consider combined influence of various parameters of powders and could be experimentally confirmed is currently not available. Calculation part This work presents a computational method for determination of capillary forces between variously sized particles. This method considers various parameters of a powder and of liquid ‘bridge”. Due to interaction of liquid’s molecules between both themselves and dispersive particles, surface of “bridge” is bent. Microscopic investigations have shown the shape of liquid “bridge” between two model particles (Fig.1) to be adequately described by circumferences (O1 and O2) with radii r1 and r2, respectively [10]. Hence, investigation results enable approximating meniscus of “bridge” as a circular arc. This approximation was used to ascertain dependences needed to determine a capillary force value and a quantity of capillary liquid. 222 (а) (б) Fig.1. Liquid “bridges” between model particles (a), and shapes of their menisci (b). In the first stage of investigations, two spherically-shaped particles with liquid “bridge” between them were regarded as a computational cell (Fig. 2). At this point, the liquid “bridge” is assumed to be formed from (a) moisture from the environment and, (b) liquid components from dispersive compositions. Fig.2. Calculation cell for determination of capillary force acting between spherically-shaped particles The obtained dependences describing capillary interaction between particles of computational cell are mentioned further [10]. 1 1 Fc R1 sin 1 2 sin 1 R1 sin 1 , r l 223 (1) r R1 1 cos 1 R2 1 cos 2 h , cos 1 cos 2 l R1 sin 1 r 1 sin 1 , (2) (3) here, Fc – capillary force; r, l – curvature radii of liquid “bridge”; R1, R2 – radii of particles; 1, 2 – angles of liquid’s half-infilling in “bridge” for a “contact” of particles with radii R1, R2 , respectively (particles “1” and “2”); θ – wetting angle; h – gap between surfaces of particles. A capillary force value, as in the case with uniformly-sized particles [4], is dependent on two constituents. The first constituent (F) is determined by surface tension of liquid acting along perimeter of wetting area. The second constituent (Fp) is due to availability of either depression or pressure caused by curvature of “bridge” surface; this phenomenon is described by the Laplace equation. During investigation in interaction of uniformly-sized spherical particles mimicked by spherical segments with large radii of curvature, computational values of capillary forces were in good accord with experimental data. This circumstance had enabled using an approach based on the above mentioned dependence of forces on two constituents, also for investigation in capillary forces between variously-sized spherical particles. At this point, “contacted” particles are to be implied not only as particles with immediately contiguous surfaces, but also as particles spaced some distance apart, this distance, however, not leading to disruption of liquid “bridge”. To investigate in capillary forces as influenced upon by particles’ parameters, it is necessary to determine volume of liquid “bridge” exerting appreciable influence on values of these parameters. Taking into account a possibility to describe meniscus of “bridge” as a circular arc, the Vc (volume of capillary liquid) value is determined as volume of a figure formed by a circular arc with radius r turning around vertical Y axis (Fig.3) minus volumes of particles submerged into liquid (Vs): 224 Vс y2 F y 2 dy Vs , (4) y1 Here, F(y) is the equation of the curve forming a revolution surface around the Y axis; y1, y2 are integration limits determined as ordinates of upper and lower points of perimeters along which particles are wetted with liquid. The equation F(y) looks as follows: F ( y) r l r 2 y 2 , (5) The Vs value is to be determined from the following dependence: Vs 4 3 3 4 1 2 1 3 4 2 2 2 R1 sin 2 3 2 sin 2 R2 sin 2 3 2 sin 2 (6) The volume of liquid “bridge” can be obtained after calculation of upper and lower integration limits and of the Vs value, after substitution of these values into Eq. (4, 5), after its integration and transformation. Results and discussion The obtained dependence of capillary force vs. quantity of liquid within “bridge” during interaction of variously-sized spherical particles (Dp1, Dp2) is presented in Fig.3. Water was considered as capillary liquid wetting particles. Particles were spaced 0.01 μm apart; this distance did not exceed 0.1% of particles’ dimension. Results of more complete investigation in how the h value exerts influence on values of capillary forces and of capillary pressure in liquid “bridge” are presented below. To investigate in maximally possible values of forces, a status of complete wetting of particles with liquid (θ=0) was considered. As is apparent, augmentation of liquid’s quantity is in all cases accompanied by maximal capillary forces. This regularity was observed by several authors [4, 9, 11] during investigation in interaction of not contacting uniform spherically-shaped particles (h≠0). Capillary force values increase also, as dimensions of particles increase (Fig. 3). 225 Fig.3. Patterns of capillary force vs. volume of liquid “bridge” dependence during interaction of variously-sized spherical particles. Radius R1 of one particle equals 5 μm. The R2/R1 ratios of particles are: 1–100; 2–10; 3–5; 4–2.5; 5–1. However, as the R2/R1 ratio augments, it influences on capillary forces to a lesser extent, especially with large volumes of liquid “bridge”, when values of forces differ slightly. The obtained findings had permitted not only a qualitative conclusion, as for example in [8, 9], but also a quantitative demonstration of how differences in particles’ dimensions influence on values of capillary forces acting between them. Patterns reflecting capillary force vs. volume of liquid “bridge” φl (φl – ratio of volume of liquid in “bridge” to volume of particles) dependence at variable wetting angle were plotted for interaction between uniform spherically-shaped particles (Fig. 4). As is apparent from Fig. 4, either worsening of wetting, or an increase in wetting angle from 0 (pattern 1) to 80 (pattern 3) is accompanied by a lesser value of Fc. Variations of F and of Fp constituents as influenced upon by volume of liquid “bridge” and by surface tension were appraised (Fig. 5). The obtained dependences show that, as volume of liquid “bridge” augments, values of capillary force (Fc) and of its constituent (Fp) decrease, whereas value of the Fσ constituent increases. It is quite noticeable that, subject to small- and mid-sized “bridges”, total value of 226 capillary force (Fc) (pattern 1) is determined by either the Fp constituent, or capillary pressure in liquid “bridge”. 1 2 Fc∙106, N 2 1 3 0 -7 -6 -5 -4 -3 -2 -1 lg jl Fig.4. Patterns of capillary force vs. volume of liquid “bridge” dependence at variable wetting angle (deg.): 1 – 0; 2 – 50; 3 – 80; h= 2 nm, D1=D2=10 μm 1 Fc, Fσ, Fp,[·106], N 2 2 1 3 4 6 0 5 -1 -7 -6 -5 -4 lg jl -3 -2 -1 Fig. 5. Patterns of Fc, F, Fp vs. volume of liquid “bridge” dependence: 1, 4 – Fc, 2, 5 – Fp, 3, 6 – F; 1-3 – σ=72.8 mN/m; 4-6 – σ=22.8 mN/m; D1[2] =10 μm; h=2 nm; θ=0 As volume of “bridge” augments, proportion of the Fσ constituent increases as well (pattern 3). A decrease in coefficient of surface tension from 72.8 mN/m (patterns 1-3) to 22.8 mN/m (patterns 4-6), which is 227 typical for “water-ethyl alcohol” mixtures, leads to diminution of all constituents of capillary force. Variable coefficient of surface tension of a liquid mixture exerting influence on structural formation of porous materials (incl. variations caused by variable capillary forces between particles) was considered by us during synthesis of silica-based mesoporous materials [12]. Investigation in capillary pressure within liquid “bridge” has led to ascertainment of the fact that volumes of “bridge” within which capillary pressure equals zero may exist. The P=0 condition has been ascertained to be determined by quantity of liquid in “bridge”, by wetting angle value, and by a gap between particles. The obtained dependence of “bridge” volume vs. wetting angle at variable distance (h) between uniform spherically-shaped particles is presented in Fig. 6. The P=0 condition has been ascertained to be attained at two values of liquid’s volume, namely at minimal (Pφ.g.min=0, dotted curves), and at maximal (Pφ.g.max=0, firm curves). As is apparent, the obtained patterns at P=0 form an area with capillary depression (P<0, Fc=f (Fσ , Fp)=”+”), characterized by combined action of both constituents of capillary force and, accordingly, by its maximal value. 0 P > 1; Fp = "-"; Fc=f(Fσ)="+" -2 4 Pφ l. max=0 3 -4 lg jl P < 1; Fp = "+"; Fc=f(Fσ, Fp)="+" 2 1 -6 Pφ l. min=0 -8 Fc=f(Fp)="-" -10 0 15 30 45 60 75 90 , o Fig. 6. Patterns of liquid “bridge” volume vs. wetting angle dependence at P=0 and at variable gap h (% D): 1 – 5 nm (0.05); 2 – 10 nm (0.1); 3 – 0.1 μm (1): 4 – 1 μm (10); σ=22.8 mN/m; D1[2] =10 μm Area above the pattern of Pφ.g.max=0 is determined by Fσ constituent, whereas area below the pattern Pφ.g.min=0 is determined by 228 Fp=”-“constituent. Should volume of liquid within “bridge” either exceed maximal value, or be below minimal value, capillary pressure P and the Fp constituent of capillary force promote repulsion of particles [13]. It has been ascertained that either separation of particles, or increased gap (h) between them (from 0.05% in pattern I to 10% in pattern 4) lead to appreciable diminution of this area. It is noticeable that worse wetting of particles’ surface is also accompanied by diminution of this area, albeit to a lesser extent. Results of computational investigations in the Fc vs. h dependence are presented in Fig. 7, 8. As is apparent, maximal values of capillary force are attained under condition of “contact” between particles (pattern I – h/D=410-5). With small- and mid-sized volumes of “bridges” (patterns 1-4 in Fig. 7), a slightly increased distance between particles leads to a considerable decrease in capillary force. As volume of interlayer augments, a horizontal section of patterns appears, where Fc is either not, or slightly dependent on separation of particles. As follows from the obtained dependence, a powdered material even with moderate content of liquid will ruin while slightly strained; augmentation of liquid’s volume will increase plasticity of powder. Hence, larger-sized “bridges” will exert determining influence on strength properties of powder, since they exist in a larger diapason of variable distances between particles. Fc·107, N 9 6 1 3 2 3 4 5 6 7 8 0 -10 -9 -8 -7 -6 lg (h, m) Fig. 7. Patterns of Fc vs. h dependence at variable φg: 1 – 110-8; 2 – 110-7; 3 – 110-6; 4 – 110-5; 5 – 110-4; 6 – 110-3; 7 – 110-2; 8 – 110-1; D=5 μm; σ=72.8 mN/m 229 As is apparent from Fig. 8, worse wetting of particles with liquid, alongside with the θ angle varying from 0 (patterns 1, 8) to 50 (patterns 1’, 8’), weakens their capillary cohesion forces; at this point, qualitative character of this dependence remains. 8 Fc·107, N 6 8' 4 1 1' 2 0 -10 -9 -8 -7 -6 lg (h, m) Fig. 8. Patterns of Fc vs. h dependence at variable wetting angle θ (deg.): 1, 8 – 0; 1’, 8’ – 50; and volume φg: 1, 1’ – 110-8; 8, 8’ – 110-1; D=5 μm; σ=72.8 mN/m Numerous types of capillary interaction between particles of dispersive components may be described as “contacts” of particles shaped as sphere, plane, and cone. While applying the approach used in description of capillary interaction between spherically-shaped particles and equations (1-6) derived for this case to the offered types of “contacts”, we can use computational dependences to determine capillary forces and volumes of “bridge” [10]. The obtained dependences of capillary forces vs. volumes of “bridge” with various types of “contact” are presented in Fig. 9. 230 Fig. 9. Patterns of capillary forces vs. volumes of “bridge” dependence with various types of “contact” between particles: 1 – ‘plane-plane”; 2 – “sphere-plane”; 3 – “sphere-sphere”; 4 – “cone-cone” (=150); 5 – “cone-plane” (=90); 6 – “cone-cone” (=90); h=0.01 μm; 2, 3 – D=1 μm; θ=0. As is apparent from these patterns, a type of “contact” exerts appreciable influence on character of dependence and on value of capillary forces. With small quantity of liquid, value of capillary forces is slightly dependent on a type of “contact”. Its influence starts growing, as volume of “bridge” augments. For “plane-plane” contact, maximal value of capillary force is attained (pattern 1); at this point, dimension of flat particles appraised from diameter of their surface wetted with capillary liquid (d0.3 μm) is less than dimension of spherically-shaped particles (with wetting diameter up to 1 μm). Minimal value of force is observable for “cone-cone” contact (pattern 6) with lesser angles at their vertices. For “sphere-sphere” (pattern 3) and “sphere-plane” (pattern 2) contacts, dependences have extreme character with availability of maximums. While comparing patterns 3, 2 for “sphere-sphere” and “sphereplane” contacts, respectively, with patterns 4, 6 for “cone-cone” contacts, a distinction in principle between them is visible, namely: for the former, growth of capillary forces, as volume of liquid increases, is observable only in a certain interval of variable volume of liquid; 231 whereas for “cone-cone” contacts, increase in volume of liquid leads to growth of capillary forces in entire diapason of variable volume of liquid within “bridge”. The presented dependences have permitted a conclusion that variable type of “contact” may be accompanied by variable value of capillary force in a wide diapason of several hundreds percent. The offered method enables also determination of volume of liquid within capillary “bridges” between particles of dispersive components. As mentioned above, storage and processing of any powder under real conditions is accompanied by formation of liquid “bridge” within a narrow gap between “contacting” particles and by appearance of capillary forces within it. A value of these forces is dependent on volume of liquid which, in turn, is determined by moisture value of the environment. Investigations in how moisture of the environment influences volume of water within “bridge” and value of capillary forces were conducted with use of the offered dependences (1-6) and while taking into account: (a) the Kelvin equation (7) describing capillary condensation: M 1 1 p , (7) 1 exp p2 l RgT r1 r2 where - relative pressure of saturated vapor over bent surface of liquid; p1, p2 – pressure of saturated vapors of liquid over bent and flat surfaces; σ – surface energy (tension) of liquid on phase interface; M – molecular mass of liquid; ρ1 – density of liquid; Rg – universal gas constant; T – absolute temperature; r1, r2 – curvature radii of main mutually perpendicular normal sections of liquid’s surface; and (b) the Laplace equation (8) describing capillary pressure in liquid: 1 1 P pl p g , r1 r2 232 (8) where pl, pg – pressure in liquid and gaseous phases, and under condition of no mass exchange between medium and “bridge”. 0 3 lg jl -2 -4 2 -6 -8 3 -10 -3 -5 -7 -9 lg (R, m) Fig. 10. Patterns of relative volume of water in “bridge” vs. dimensions of particles at variable relative humidity of air (j, %): 1 – 50; 2 – 90; 3 – 99. Calculation results of relative volume of water in “bridge” vs. dimensions of particles at variable relative humidity of air ( j, %) and at zero wetting angle are presented in Fig. 10. As is apparent from Fig. 10, volume of condensed water is proportional to both humidity of air and dimensions of powder material’s particles. Humidity of air influences most appreciably at the j value exceeding 90%. With use of the obtained equations, volume of water in “bridge” and capillary force values between aluminium powder particles vs. relative humidity of air have been calculated. Basic data for calculations: (a) the powder is composed of spherically-shaped particles sized 20 μm; (b) ambient temperature 20C; (c) experimentally determined wetting angle 65. The obtained dependences are presented in Fig. 11. Comparison of computational values of water condensed in “bridges” (in accord with dependences 1-10) with experimental data for equilibrium moisture load of aluminium powder and of other components differing in nature has manifested their qualitative coincidence [14]. 233 lg (Fc, N), lg φl -4 -6 1 2 -8 -10 40 50 60 70 80 90 j, %ϕ, % Fig. 11. Computational patterns of capillary force (1) and of relative volume (2) of liquid “bridge” vs. relative humidity of air for particles with D=20 μm. As is apparent from Fig. 11, volume of liquid in “bridge” starts rapidly augmenting, as relative humidity of air exceeds 85% value. So, variation of relative humidity of air from 10% to 85% results in twoorder augmentation of volume of liquid; 85%-100% variation – to fourorder augmentation. Such augmentation of quantity of water leads to drastic growth of capillary forces acting between particles, as is reflected by pattern 1. The noted tendencies are confirmed by authors in a number of works [15, 16]. Conclusions Thus, method for computational simulation of capillary forces acting between dispersive components’ particles which considers dimensions and shape of particles, distance between them, a type of their “contact”, volume and shape of liquid “bridge”, surface tension of liquid, and wetting angle has been offered. Acknowledgements This work was financially supported by Russian Foundation for Basic Research (projects Nr. 14-03-00957_a and 14-0396009_p_ural_a). 234 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. References Haines W B. Studies on the physical properties of soils. A note on the cohesion developed by capillary forces in an ideal soil. J. Agric Sci, Vol.15, P. 529-535, 1925. Fisher R.A. On the capillary forces in an ideal soil; correction of formulae given by W. B. Heines. J. Agric. Sci., Vol. 16, P. 492-505, 1926. Haines W B. A Further contribution to the Theory of Capillary Phenomena in Soils. J. Agric Sci, Vol.17, P. 264-290, 1927. Pietsch W., Rumpf. H. Haftkraft, Kapillardruck, Flüssigkeitsvolumen und Grenz-winkel einer Flüssigkeitsbrücke zwischen zwei Kugeln. Chem. Ing. Tech., 1967, H. 15, S. 885. Picknett R.G. Letters to the editors. J. of Colloid and Interface Sci, 1969, Vol. 29, № 1, P. 173. Adams M.J., Perchard V. The cohesive forces between particles with interstitial liquid. Symp. Particle Technology, Birmingham, 57 March 1985, P. 147. Muguruma Y., Tanaka T., Kawatake S., Tsuji Y. Numerical simulation of particu-late flow with liquid bridge between particles (simulation of a centrifugal tumbling granulator). World Congress on Particle Technology 3, 6-9 July 1998, Brighton, UK, CD-ROM published, № 334. Smolej V., Pejovnik S. Some remarks on the driving force for liquid-phase sintering. Zeitschrift fur Metallkunde, 1976, Vol. 67, № 9, P. 603. Fairbrother R.J., Simons S.J.R. The Rupture Energy of Liquid Bridges between Spheres, the Effect of Contact Angle and Separation Distance on Liquid Bridge Geometries. World Congress on Particle Technology 3, 6-9 July 1998, Brighton, UK, CD-ROM published, № 110. Yu. G. Tselishchev, V. A. Val'tsifer. Influence of the Type of Contact between Particles Joined by a Liquid Bridge on the Capillary Cohesive Forces. Colloid Journal, 2003, Vol. 65, No. 3, pp. 385-389. Pietsch W.B. Tensile strength of granular materials. Nature, 1968, Vol. 217, P. 736. Kondrashova N., Saenko E., Lebedeva I., Valtsifer V., Strelnikov V. Effect of organic-silane additives on textural-structural 235 13. 14. 15. 16. properties of mesoporous silicate materials. Microporous and mesoporous materials, 2012, V. 153, P. 275-281. Yu. G. Tselishchev. Evaluation of the Capillary Pressure in a Liquid Interlayer between the Particles of a Dispersed Phase. Colloid Journal, 2007, Vol. 69, No. 4, pp. 537-539. Tselishchev Yu.G., Val'tsifer V.A., Vasil'eva O.G. Capillary Moisture Content of a Number of Powders of Varied Nature. Russian Journal of Applied Chemistry, 2006, Vol. 79, № 12, P. 1924-1929. Fuji M., Machida K., Watanabe T., Chikazawa M. Effect of phisisorbed water on the adhesional force of silicas. World Congress on Particle Technology 3, 6-9 July 1998, Brighton, UK, CD-ROM published, № 65. Visser J. Van der waals and other cohesive forces affecting powder fluidization. Powder Technology, 1989, Vol. 58, № 1, P. 1. 236