FePt-TiO2 exchange coupled composite media

advertisement

FePt-TiO2 exchange coupled composite media with wellisolated columnar microstructure for high density

magnetic recording

C. J. Jiang1*, J. S. Chen1, J.F. Hu, 2 G. M. Chow1

1

Department of Materials Science and Engineering, National University of Singapore, 117574,

Republic of Singapore

2

Data Storage Institute, Singapore, 117608.

We reported the fabrication of (001) textured FePt-TiO2 exchange coupled composite

(ECC) media including hard/soft bilayer and multilayer with well isolated columnar

microstructures. The magnetic anisotropy of FePt-TiO2 was adjusted by applying various

substrate bias during film deposition. The cross-sectional TEM images showed isolated

granular microstructures in single hard layer, bilayer and multilayer media. For the

bilayer media, it was observed that both the coercivity and magnetization squareness of

composite media decreased with increasing thickness of the soft layer. A soft layer with

the thickness of 4 nm was more effective to significantly reduce the switching field and

maintain a higher thermal stability factor than that of others. Incoherent switching

behavior was observed as the soft layer thickness was increased to 6 nm. For multilayer

media, it was found that the out-of-plane coercivity decreased to 6.5 kOe, which was

close to half of that of the single hard layer. However, the thermal stability factor of the

multilayer media slightly decreased compared with the single hard layer and bilayer

media due to finite thickness. The results suggested a way to obtain the adjustable

anisotropy for ECC media in high density magnetic recording application.

*

Corresponding author: jiangchj03@126.com

I. INTRODUCTION

With the increase in demand for high recording areal density, L10 phase FePt with high

anisotropy (~7×107 ergs/cc) have received considerable attention in recent years due to its

potential application for ultrahigh density magnetic recording1-5. In order to realize its

practical application, it is a key challenge to obtain well isolated small grains of FePt with

the (001) texture. Due to the high anisotropy energy constant, FePt media is not writable

using the conventional recording head. Therefore the exchange spring and ECC media

comprising hard layer and soft layer have been proposed to reduce the switching field

(Hsw) of hard layer while maintaining similar thermal stability

6-9

. Micrcomagnetic

simulations indicated that a continuous variation in the anisotropy in the multilayer

recording media can reduce the coercive field more effectively than that of bilayer

media10-12. However, the preparations of ECC bilayer and multilayer media are

challenging. Experimentally, FePtC ECC media consisted of L10 FePt/fcc FePt has been

recently reported13. It was found that the coercivity reduced with the increase of

magnetically soft layer thickness. L10-FePt/FeAu graded media were also reported, in

which the graded anisotropy was controlled by interdiffusion at interface after

postannealing14. However, in order to decrease the lateral exchange coupling among the

grains, the ECC media with well isolated columnar microstructure is required. It is

difficult to meet this requirement by varying the deposition temperature or controlling the

post-deposition annealing. In this work, the anisotropy of L10 FePt-TiO2 media was

controlled by varying the substrate bias during film deposition without changing the

deposition temperature or employing post-deposition annealing. The magnetic properties

and microstructures of the ECC bilayer and multilayer media were investigated.

II. EXPERIMENTAL DETAILS

FePt-TiO2 thin films with a structure of glass/Cr90Ru10/MgO/ FePt-TiO2 (10 nm, 20

vol%) were prepared by AJA sputtering system (con-focal target sputtering) with a base

pressure better than 2×10-8 Torr. The CrRu and FePt-TiO2 targets were dc sputtered while

MgO target was rf sputtered in Ar. The film thickness of CrRu and MgO were fixed at 30

nm and 2 nm, respectively. The Ar working pressures were 1 and 10 mTorr for CrRu and

MgO layers, respectively. The deposition temperatures for CrRu and MgO layers were

fixed at 320 °C and 100 °C, respectively. The working pressure of depositing FePt-TiO2

layer was 15 mTorr. The sputtering power was 100 W and deposition temperature was

500°C. Different substrate bias power varying from 0 to 40 W was applied during

deposition. The crystallographic texture of the films was examined by x-ray diffraction

(XRD) using a Cu Kα radiation. The microstructures of the films were characterized using

transmission electron microscopy (TEM). The magnetic properties of FePt-TiO2 films

were measured using vibrating sample magnetometry (VSM) and alternating gradient

force magnetometry (AGFM).

III. RESULTS AND DISCUSSIONS

A. Effect of substrate bias power

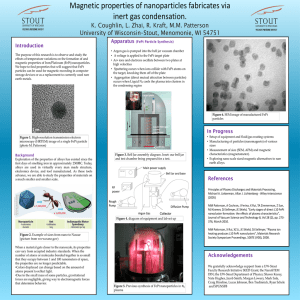

Figure 1(a) shows the XRD patterns of FePt-TiO2 nanocomposite thin films with

different substrate bias power. All the peaks were attributed to the CrRu and the FePt.

Note that the amorphous glass substrate rendered the differentiation of amorphous TiO2

matrix difficult in XRD spectra. Without applying substrate bias power, the FePt shows a

(001) preferred orientation. With increasing the substrate bias power, the integrated

intensity of the FePt (001) peak decreased, whereas FePt (002) / (200) peaks shifted

toward lower angles. This indicated that the chemical ordering of FePt films decreased

with increasing substrate bias power. Increased substrate bias power to 30 and 40 W, the

supperlattice (001) peak of FePt film almost disappeared and the (002)/(200) peaks

shifted to lower angle further, suggesting the transformation of FePt film to the

undesirable fcc phase. The inset of Fig. 1 (a) shows the rocking curve of fct FePt (001)

peak in different substrate bias power, respectively. It indicated that the full width halfmaximum of the rocking curves were increased with increasing substrate bias power. The

chemical ordering parameter (S) is defined according to relation I

(001)/I (002)

=1.87S2,

where I (001) and I (002) are the intergrated peak intensities of the superlattice (001) peak

and fundamental (002) peak 8, 15. The variation of S with the substrate bias power is

shown in Fig. 1 (b). The chemical ordering decreased monotonically with increasing

substrate bias power. This can be interpreted as follows: With increasing the substrate

bias power the bombardment energy of Ar ions on the film surface increased

16

. The

energy of Ar ions was transferred to surface atoms that could cause either re-sputtering of

the already deposited film and/or an increase of atomic mobility along both the film plane

and film normal. The deposition rates for different substrate biases remained constant,

indicating the re-sputtering effect was small as there was no loss of deposited film mass.

The atomic mobility along the film plane would promote the formation of chemical

ordered FePt film. The atomic mobility along the film normal however would deteriorate

the crystal structure and promoted the formation of fcc FePt. The experimental results

indicated that the substrate bias caused the enhancement of atomic mobility along the

film normal. This behavior was similar to the effect of implantation.

Figures 2(a) and (b) show the typical out-of-plane and in-plane hysteresis loops of

FePt-TiO2 films deposited at substrate bias power of 0 and 40 W, respectively. It was

observed that FePt-TiO2 films without substrate bias showed the perpendicular anisotropy.

At the substrate bias powers of 40 W, the film was magnetically soft with in-plane

magnetic anisotropy. These results were consistent with the XRD results. Figure 2(c)

shows the out-of-plane coercivity Hc and magnetocrystalline anisotropy, Ku, as a function

of the substrate bias power. For FePt films with perpendicular anisotropy, taking

demagnetizing field into account, the anisotropy of films can be roughly estimated by

Ku= MsHk/2+2πMs2, where Hk was the magnetic anisotropy field that can be estimated by

extrapolating the hard axis loop; while Ku= MsHk/2 can be obtained for FePt films with

in-plane anisotropy. The out-of-plane coercivity monotonically decreased from 11 kOe to

0.5 kOe with increasing substrate bias power from 0 to 30 W. Further increase of

substrate bias power, the coercivity remained almost the same as the film deposited with

30 W substrate bias power. Without applying substrate bias, Ku was as large as 1.7×107

erg/cc., Ku decreased linearly with the increase of the substrate bias power up to 20 W.

The FePt films still retained the perpendicular anisotropy. With further increase of the

substrate bias power to 30 and 40 W, the FePt films showed in-plane anisotropy with Ku

as low as 1-2×106 erg/cc. Comparing with the chemical ordering of FePt films at different

substrate bias power, the change of FePt films in coercivity and Ku were mainly attributed

to the decrease of the chemical ordering of FePt film caused by the bombardment of high

energy Ar ions under the substrate bias.

B. Bilayer media

According to the above experimental results, Ku decreased with increasing substrate

bias power and approached 2×106 erg/cc at 40 W substrate bias. Therefore the bilayer

media comprising 10 nm hardest layer of FePt-TiO2 (no substrate bias) and different

thickness (2, 4, 6, and 8 nm) of softest layer deposited at substrate bias of 40 W were

fabricated. Figure 3 shows the XRD spectra of the bilayer media with different thickness

of the soft layer. The intensity of superlattice FePt (001) peaks remained almost

unchanged with different soft layer thicknesses. With increasing soft layer thickness,

combined FePt (200) and (002) peaks broadened, which suggested an increase in the fcc

FePt (200) component of the films. These results can be explained as follows: the

deposition parameters of the hard layer in all samples were kept constant, which

maintained the chemical ordering of the bottom L10 FePt layer. The grains in the

overlayer deposited at the substrate bias 40 W were formed with fcc (200) texture which

grew epitaxially on FePt (001) of hard layer.

Figure 4 (a) shows the out-of-plane hysteresis loops of the bilayer media with different

soft layer thickness. The coercivity and magnetization squareness Mr/Ms, (ratio of

remanent magnetization to saturation magnetization) with various thickness of soft layer

are summarized in Fig. 4b. With increasing thickness of the soft layer, the coercivity

decreased monotonically, while Mr/Ms decreased slightly with the soft layer thickness

less than 4 nm, and then decreased hugely at 6 nm. With the soft layer thickness less than

4 nm, the magnetization of soft layer was almost parallel with that of hard layer due to

strong exchange coupling between them, which resulted in slight decrease of the

squareness. The reduced squareness with increasing soft layer thickness to 6 nm was

attributed to the canting of magnetization direction in the soft layer. Due to the high Msoft

~900 emu/cc of the soft FePt layer, the demagnetization energy was as large as ~5×106

erg/ cc. Such large demagnetization energy forced the magnetization of the soft FePt

layer to be in the film plane direction. In order to identify the mechanism of the

coercivity reduction, we calculated the domain wall width of the soft layer by the

following formula 17:

soft

ldw

2 Asoft

H appl M soft

,

(1)

where Happl was the applied field, Asoft and Msoft were stiffness constant and saturation

magnetization of the soft layer, respectively. For our samples with the soft thickness of 2,

4, 6, and 8 nm and having respective switching fields of 9.0, 8.2, 7.1, and 6.1 kOe, the

domain wall width were calculated as 5.0, 5.2, 5.6, and 5.9 nm, respectively. Initially for

soft layer thickness 4 nm less than domain wall width, the switch mechanism would be

coherent rotation due to strong exchange coupling between hard and soft layer, which

was testified by following recoil loop. In this case, the effective anisotropy of the bilayer

can be described by Keff = (KhardVhard +KsoftVsoft)/(Vhard+Vsoft) due to almost same

magnetization of two layers. Khard, Ksoft were the anisotropies of the hard and soft layers,

Vhard and Vsoft were the volume of hard and soft grain. Due to Ksoft<<Khard, Keff of bilayer

media was less than Khard, which resulted in the reduction of coercivity after coupling

with a soft layer. When the thickness of soft layer exceeded 6 nm, more than domain wall

width, it was enough to form a full domain wall. Therefore, the switching mechanism

could become incoherent switching18. The magnetic reversal process with applied

magnetic field could be described in the following: the domain wall nucleated in the soft

layer, and propagated to soft/hard interface where it was pinned. Therefore, the coercivity

was dependent on the pinning field of the domain wall at the interface between soft and

hard layer. In order to confirm the switching mechanism with the soft layer thickness

around domain wall width, the recoil loops of bilayer media with 4 and 6 nm soft layers

were measured. The recoil loops were obtained from removal and reapplication of a

demagnetization field to a magnetically saturated material, which can provide

information about the reversible and irreversible components of the magnetization, as

shown in Fig. 5. In the case of 4 nm soft layer, the magnetization was slightly increased

after removing the applied field. This indicated that the switching mechanism was

dominated by coherent rotation. However, with increasing thickness of soft layer to 6 nm,

the magnetization after removing the applied field increased. This was due to the increase

of reversible magnetization switching, which resulted from incoherent rotation.

The cross-sectional TEM images of single hard layer and bilayer media with 4 nm

thickness of soft layer are shown in Fig. 6. Both single hard layer and bilayer media

showed only one layer of well-isolated FePt grains, whereas the CrRu and MgO layers

showed the continuous microstructures. It is worth noting that there was no double layer

or multilayer structured FePt found in bilayer media, which had been observed in

previous report13. This indicated that the soft layer was epitaxially grown on the

underlying hard FePt layer. The epitaxial growths of soft layer on hard layer caused a

strong vertical exchange coupling between these two layers, which effectively decreased

the out-of-plane coercivity.

Thermal stability factor (TSF) at zero magnetic field were investigated by the Sharrock

equation19

H c (t ) H 0 {1 [

ft

k BT

ln( 0 )]1 / n } ,

E0

ln 2

(2)

Here, H0 is the intrinsic coercivity without thermal fluctuation; ∆E0 the energy barrier at

zero external field, f0 the attempt frequency for an individual switching event, typically

of the order of lattice vibrations (109-1010 Hz); kB the Boltzmann constant, and t the

duration of applied field. The effect of the exponent n on the thermal stability factor was

under investigation. According to the results of simulation 20, the exponent n=1.5 for the

single layer and bilayer media and n=1 for the multilayer was used. Figure 7 shows the

measured energy barrier versus soft layer thickness. It was found that the thermal stability

factor (KuV*/kBT) was 208 for the single hard layer media and increased to 259 for the

bilayer media with soft layer thickness increased to 4 nm. The increase of TSF for bilayer

media with the 4 nm soft layer may be attributed to an increased switching volume due to

the strong exchange interaction between the hard and soft layers. However, the TSF

decreased when the soft layer exceeded 4 nm. This was due to the presence of

demagnetization energy in the soft layer resulting in the reduction of energy barrier. The

thicker the soft layer, the larger the reduction in the energy barrier. The figure of merit, ξ,

which is the ratio of the energy barrier and the switching energy21, was also calculated

based on the experimental data, as shown in figure 7 (right y-axis). ξ reached its

maximum value of 1.3 when the soft layer thickness increased to 4 nm. Then, ξ decreased

slightly to 1.1 at the soft layer thickness of 8 nm.

C. Multilayer media

According to experimental results with various substrate bias powers, Ku decreased

gradually with increasing substrate bias power. The multilayer media was thus fabricated

by first depositing the 10 nm FePt-TiO2 hard layer without substrate bias, thereafter,

successive FePt-TiO2 layers of 2 nm each were deposited with substrate bias power 10,

20, 30 and 40 W, respectively. Figure 8(a) shows the XRD patterns of the multilayer

media. The FePt film showed a (001) preferred orientation and broad (002) + (200) peaks

comparing with single hard layer, which was attributed to the capping soft layer. The

inset of Fig. 8 (a) shows the rocking curve of fct FePt (001) peak in the single hard layer

and the multilayer media, respectively. Both the full width half-maximum of the rocking

curves were about 7°, indicating a good FePt fct (001) texture. The out-of-plane and inplane hysteresis loops of the multilayer media are shown in Fig. 8b. The out-of-plane

multilayer media reduced drastically to 6.5 kOe which was close to the half of that of the

hardest layer. However, it was slightly larger compared with that of the bilayer media

with the same thickness. This was due to that the thickness of each soft layer in the

multilayer media was only 2 nm and total thickness of graded soft layer was 8 nm. At the

saddle point, the nucleated domain wall sweep to interface of hard layer, it was difficult

to form a full 180° domain wall. In order to clarify the mechanism of the coercivity in the

single hard layer, bilayer and multilayer media, their recoil loops were measured, as

shown in Fig. 9. For the single hard layer, the magnetization remained almost unchanged

after removing the applied field, indicating coherent magnetization rotation behavior. For

bilayer and multilayer media, both showed increased magnetization upon removal of

applied field. Moreover, the slope of bilayer media was larger than that of multilayer

media, suggesting a more incoherent switching behavior in bilayer media.

The cross-sectional TEM image of multilayer media is shown in Fig. 10. The image

showed that most of the FePt grains were isolated from each other. The cross-sectional

image also indicated only one layer of well-isolated columnar FePt grains, the same as

single hard layer as shown in Fig. 6a. This indicated that each layer was epitaxially

grown on the underlying layer and as a result it formed a columnar grain microstructure.

The epitaxial growth of each soft layer on hard layer and diffusion among these layers at

high temperature caused an increased anisotropy from top to bottom in the media.

Figure 11 shows the thermal stability factor (KuV*/kBT) of the single layer FePt-TiO2

film and the multilayer media obtained from the dynamic coercivity versus time

measurement. For comparison, the bilayer media comprising the 10 nm hardest layer of

FePt-TiO2 (no substrate bias) and 8 nm of softest layer (with 40 W substrate bias) is also

shown. For the single FePt-TiO2 hard layer, the thermal stability factor was 208 and

intrinsic coercivity is 15.5 kOe, while KuV*/kBT for multilayer media was 175 and 8.7

kOe, for bilayer media the values were 213 and 7.8 kOe. For the single hard layer, it was

assumed coherent magnetization rotation and energy barrier was KhardldF. Khard was the

anisotropy in the hard layer, ld the thickness of the hard layer, F the cross-section area of

the grain. For the multilayer and bilayer media, the magnetization reversal mechanism

was incoherent rotation, and the energy barrier was domain wall energy 4F (AKh)

1/2

. In

our system, Kh=1.7×107 erg/cc, and A= 10-6 erg/cm. The energy barrier for hard layer was

calculated as ~17F, while for multilayer media and bilayer media were ~16.5F. However,

experimentally, the energy barrier of multilayer media was smaller than that of single

hard layer and bilayer media due to finite thickness of each soft layer. In the multilayer

media, the switching field can be written as22, Hsw=4(AKhard) 1/2/ [(2L-ld)Msoft]. L was total

length; Msoft was saturated magnetization of soft layer. L=18 nm and Msoft= 900 emu/cc

in our sample. Therefore, Hsw was calculated to be 7.0 kOe, which was slightly smaller

compared with the experimental result due to the finite thickness of multilayer media. For

the bilayer media, the switching field was determined by the pinning field at hard/soft

layer interface15. It can be written as

Hp

1 2( K hard K soft )

,

4

M hard

(3)

Ksoft was anisotropy of soft layer. In our case, Ksoft = 2×106 erg/cc, Hp = 9.4 kOe, which

was larger than the experimental result. A possible reason was that the anisotropy at

hard/soft interface was not sharply changed due to the interlayer diffusion at high

temperature, which caused the decrease of the pinning field at the interface.

IV. CONCLUSION

In summary, (001) textured FePt-TiO2 bilayer and multilayer media with well isolated

columnar microstructures were fabricated. The graded anisotropy was obtained by

varying the substrate bias power during deposition. The potential merits of bilayer and

multilayer media were discussed compared to that of single hard layer. The results

indicated that Hc of the bilayer and multilayer media was reduced effectively but retained

a high thermal stability. However, the Hc of multilayer media was larger than that of

bilayer with same thickness, contrary to the simulation results. This is due to the finite

thickness of multilayer media in experiments instead of the infinite thickness used in the

simulations. The bilayer media was proposed with a soft layer with in-plane anisotropy.

As a consequence the magnetization of soft layer was oriented in the film plane, which

could lead to the decrease of demagnetizing field. Further reduction of the switching field

may be obtained by adjusting the magnetization of soft layer18.

ACKNOWLEDGEMENTS

This work was supported by the Ministry of Education (MOE) Fund (T207B1104-RS).

1

K. Kang, Z. G. Zhang, C. Papusoi, and T. Suzuki, Appl. Phys. Lett. 84, 404 (2004).

2

Y. C. Wu, L. W. Wang, C. H. Lai, Appl. Phys. Lett. 93, 242501 (2008).

3

Y. F. Ding, J. S. Chen, B. C. Lim, J. F. Hu, B. Liu, and G. Ju, Appl. Phys. Lett. 93, 032506 (2008).

4

J. S. Chen, B. C. Lim, J. F. Hu, B. Liu, G. M. Chow, and G. Ju, Appl. Phys. Lett. 91, 132506 (2007).

5

Y. K. Takahashi, T, Koyama, M. Ohnuma, T. Ohkubo, and K. Hono, J. Appl. Phys. 95, 2690 (2004).

6

J. P. Wang, W. K. Shen, J. M. Bai, R. H. Victora, J. H. Judy, and W. L. Song, Appl. Phys. Lett. 86,

142504 (2005).

7

T. J. Zhou, B. C. Lim, and B. Liu, Appl. Phys. Lett. 94, 152505 (2009).

8

K. K. M. Pandey, J. S. Chen, G. M. Chow, and J. F. Hu, Appl. Phys. Lett. 94, 232502 (2009).

9

D. Suess, T. Schrefl, S. Fahler, M. Kirschner, G. Hrkac, F. Dorfbauer, and J. Fidler, Appl. Phys. Lett. 87,

012504 (2005).

10

11

D. Suess, Appl. Phys. Lett. 89, 113105 (2006).

A. Y. Dobin, and H. J. Richter, Appl. Phys. Lett. 89, 062512 (2006).

12

G. T. Zimanyi, J. Appl. Phys. 103, 07F543 (2008).

13

J. F. Hu, J. S. Chen, Y. F. Ding, B. C. Lim, W. L. Phyoe, and B. Liu, Appl. Phys. Lett. 93, 072504 (2008).

14

F. Wang, X. H. Xu, Y. Liang, J. Zhang, and H. S. Wu, Appl. Phys. Lett. 95, 022516 (2009).

15

K. Barmak, J. Kim, L. H. Lewis, K. R. Coffrey, M. F. Toney, A. J. Kellock, and J. U. Thiele, J. Appl.

Phys. 98, 033904 (2005).

16

D. E. Ruddell, B. R. Stoner, and J. Y. Thompson, J. Vac. Sci. Technol. A20, 1744 (2002).

17

E. Girt, A. Y. Dobin, B. Valcu, H. J. Richer, X. Wu, and T. P. Nolan, IEEE.Trans. Magn. 43, 2166

(2007).

18

D. Suess, J. Lee, J. Fidler, and T. Schrefl, J. Magn. Magn. Mater. 321, 545 (2009).

19

M. P. Sharrock, J. Appl. Phys. 76, 6413 (1994).

20

D. Suess, S. Eder, J. Lee, R. Dittrich, J. Fidler, J. W. Harrell, T. Schrefl, G. Hrkac, M. Schabes, N.

Supper, and A. Berger, Phys. Rev. B 75, 174430 (2007).

21

R. H. Victora and X. Shen, Proc. IEEE 96, 1799 (2008).

22

D. Suess, J. Fidler, G. Zimanyi, T. Schrefl, and P. Visscher, Appl. Phys. Lett. 92, 173111 (2008).

Figure captions

Figure 1. (a) XRD (the inset are the rocking curve of the (001) peak for each sample) and (b) long-range

order parameter S of FePt-TiO2 films deposited at various substrate bias power.

Figure 2. Out-of-plane and in-plane hysteresis loops of FePt-TiO2 for (a) 0 and (b) 40 W substrate bias

power. (c) Variation of out-of-plane coercivity with increasing substrate bias power.

Figure 3. XRD patterns for bilayer media with various soft thickness.

Figure 4. Out-of-plane hysteresis loops FePt-TiO2 (soft) x nm/ FePt-TiO2 (hard) 10 nm where x=0, 2, 4, 6

and 8.

Figure 5. Recoil loops for bilayer media with thickness (a) 4 nm and (b) 6 nm of soft layer

Figure 6.TEM cross-section images of FePt-TiO2 (a) single hard layer and (b) bilayer media with 4 nm

thickness of soft layer.

Figure 7. Energy barrier and figure of merit for bilayer media with various soft thickness.

Figure 8. (a) XRD of multilayer media. The inset are the rocking curve of the (001) peak for single hard

layer and multilayer media. (b) Out-of-plane and in-plane hysteresis loops of multilayer media.

Figure 9. Recoil loops for (a) single hard layer, (b) bilayer media, and (c) multilayer media.

Figure 10. The cross-section TEM images of FePt-TiO2 multilayer media.

Figure 11.Thermal stability factor (KuV*/kBT) of single hard layer, bilayer media and multilayer media. The

inset is the multilayer media.