Doctorat doc

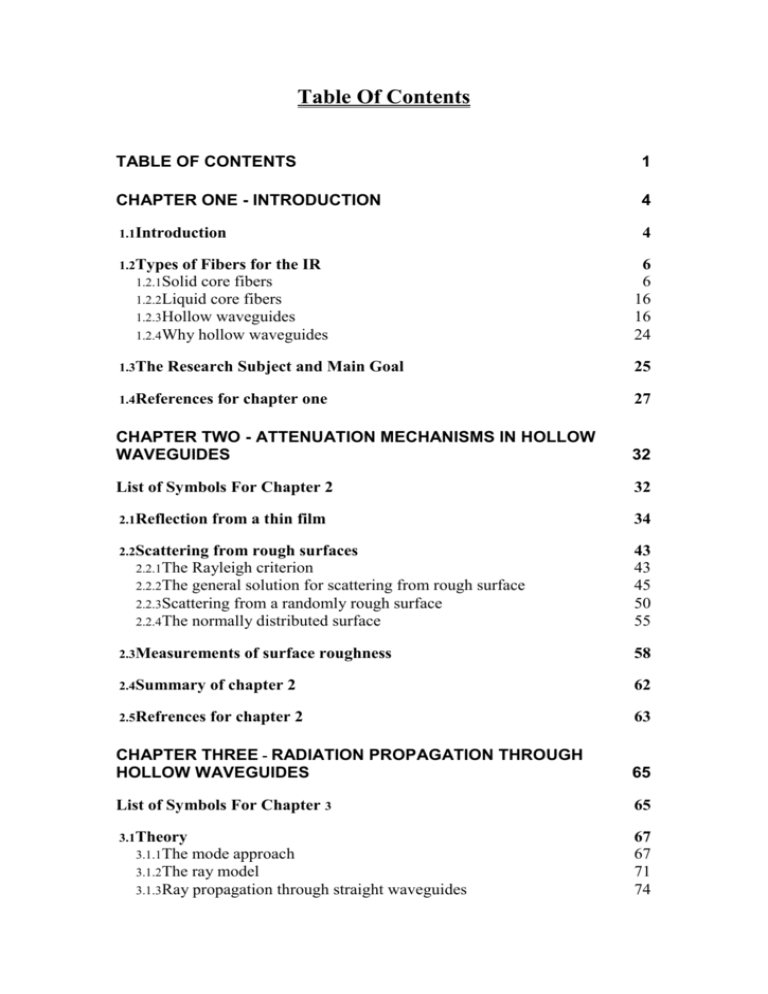

advertisement