Dental radiology

advertisement

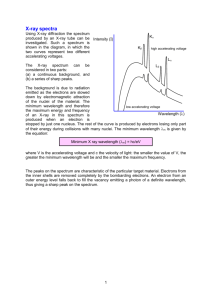

Lec. 2 Dental radiology Production of diagnostic X-ray Diagnostic radiation can be produced in two ways: 1. Use of radioactive isotopes for diagnostic purposes with exposure facilities to pump them in appropriate chamber to expose the radiographic film. 2. When high-speed electrons collide with a positively charged target. The kinetic energy of these electrons is partially converted into X-radiation. The X-ray machine The heart of an X-ray machine is the X-ray tube and its power supply. The X-ray tube is positioned within the tube head, along with some components of the power supply. The tube head is supported by an arm. A control panel allows the operator to adjust the time of exposure and often the energy and exposure rate of the x-ray beam. I X-ray tube The X-ray tube is made up of borosilicate glass vacuum tube. The component parts of the Xray tube are leaded-glass housing, a negative electrode as a cathode, and a positive electrode as an anode. Evacuation of the glass tube is done to prevent the loss of kinetic energy of the electrons by colliding with the gas molecules and also to prevent the oxidation burnout of the filament. The central area of the X-ray tube has an opening (window) that permits The X-ray beam to exit. Focusing cup II The cathode consists of: The filament: is the source of electrons within the X-ray tube, which is a coil of tungsten wire about 2mm in diameter and 1cm or less in length. It is mounted on two stiff wires that support it and carry the electric current. These two mounting wires lead through the glass envelope and connect to both high-and low-voltage electrical sources. The filament is heated to incandescence by the flow of current from the low-voltage source and emits electrons at a rate proportional to the temperature of the filament. The focusing cup: is a negatively charged concave reflector made of molybdenum which the filament lays in it. The focusing cup electrostically focuses the electrons emitted by the incandescent filament into a narrow beam directed a small rectangular area on the anode called the focal spot. The anode consists of a thin tungsten target plate embedded in a solid copper stem block. Tungsten is used as a target material because of its high atomic number (74) because it is most efficient in producing X-ray, high melting point (3370oC) because heat is generated at the anode, high thermal conductivity thus dissipating heat into the copper stem, and low vapor pressure of tungsten at high temperatures also helps maintain the vacuum in the tube at high operating temperature. The target converts the kinetic energy of the electrons into X-rays photons. The tungsten target is embedded in a large block of copper to dissipate heat. Copper is good thermal conductor, dissipates heat from the tungsten, thus reducing the risk of the target melting. The sharpness of the radiographic image improves if the focal spot in the target is small. The heat generated per unit target area, however, becomes greater as the focal spot decreases in size. The target is placed at an angle of 20o with respect to the central beam to achieve a small focal spot and to effectively distribute the striking electrons for better heat dissipation. The projection of the focal spot perpendicular to the electron beam called the effective focal spot is smaller than the actual size of the focal spot about 1*1mm as opposed to the actual focal spot, which is about 1*3mm. This principle is called as the line focus principle. Heel effect refers to the loss of intensity of X-ray beam in the peripheral region. The cathode side of the beam is more intense than anode side due to self-absorption of some of the bremsstrahlung photons by the target. III When the kinetic energy of the electrons is directed at the target, about 99% of it is converted into heat and only 1% is used for production of X-rays. The copper block is used to dissipate the excessive heat produced. The other methods of dissipating the heat are: I. Use of rotating anode usually used in tomographic or cephalometric unites. II. Insulating oil around the tube. III. Angulating the target. IV. Air-conditioning of the X-ray room. Power supply The primary functions of power supply of an X-ray machine are to: Provide a low-voltage current to heat the X-ray tube filament by use of a step-down transformer Generate a high potential difference between the anode and cathode by use of a highvoltage transformer. Electricity/electric current and circuits The milliamperage (mA) is the measurement of the number of electrons moving through the filament. The number of electrons passing through the cathode filament can be controlled by mA adjustment on the control panel of the X-ray machine. The voltage of the X-ray tube current, the current of electrons passing from the cathode to the anode is controlled by kilovoltage peak (kVp) adjustment on the control panel. IV The two circuits used in the production of X-rays are: A. The low-voltage filament circuit: The filament circuit uses 7 to 10 volts and is controlled by the milliamperage setting. B. The high-voltage circuit uses 65 to 70 kVp and provides high voltage required to accelerate the electrons and to generate X-rays in the X-ray tube and is controlled by the kilovoltage setting. Transformer A transformer either increases or decreases the voltage in an electrical circuit as following: A step-down transformer is used to decrease the voltage from the incoming 110or 220 line voltages to 7 to 10 volts. The step-down transformer has more wire coils in the primary coil or input coil than in the secondary coil or output coil. A step-up transformer is used to increase the voltage from the incoming 110 or 20 line voltages to 60 to 100 kVp. It has more wire coils in the secondary coil than in the primary coil. An autotransformer serves as a voltage compensator for correcting any minor fluctuation in the current. Because the line current is AC, which usually 60 cycles per second, the polarity of the X-ray tube alternates at the same frequency. When the polarity of the voltage applied across the tube causes the target anode to be positive and the filament to be negative, the electrons around the filament accelerate toward the positive target and current flows through the tube so the electrons strike the focal spot of the target; some of their energy convert to X-ray photons. Xrays are produced at the target with greatest efficiency when the voltage applied across the tube is high, therefore the intensity of X-ray pulses tend to be sharply peaked at the center of each cycle. During the following half of the cycle, the polarity of the AC reverses, and the V filament becomes positive and the target negative. At these times the electrons stay in the vicinity of the filament and do not flow across the gap between the two elements of the tube. This half of the cycle is called inverse voltage or reverse bias so that no X-rays are generated. Therefore when an X-ray tube is powered with 60-cycle AC, 60 pulses of X-rays are generated each second, each having duration of 1/120 second. This type of power supply circuitry, in which the alternating high voltage is applied directly across the X-ray tube, limits X-ray production to half the AC cycle and is called self-rectified or half-wave rectified. In full-wave rectification or full wave rectified circuit, even the negative half of the cycle is used for the production of X-ray. In these machines, X-rays are not produced in pulses but as a stream of X-rays. A full wave rectified X-ray machine produces 120 bursts of X-ray photons per second. VI Timer A timer is built into the high-voltage circuit to control the duration of the X-ray exposure. The timer controls the length of time that high voltage is applied to the tube and therefore the time during which tube current flows and X-rays are produced. Some X-ray machine timers are calibrated in fractions and whole numbers of seconds. The time intervals on other timers are expressed as numbers of impulse per exposure (e,g,, 3,6,9,15). Such numbers represent the number of impulses of radiation emitted during the exposure; thus the number of impulses divided by 60 the frequency of the power source gives the exposure time in seconds. Therefore a setting of 30 impulses means that there will be 30 impulses of radiation and is equivalent to a half-second exposure. VII