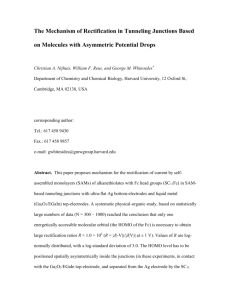

Experimental

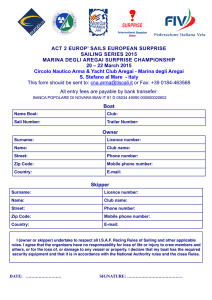

advertisement

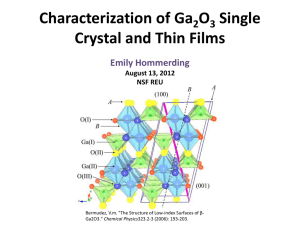

Large-scale synthesis of gallium oxide micro-whisker and nanowire structures via vapor phase growth Y. Wang, Y. W. Zhu, B. Xiang, J. Xu, D. P. Yu* School of Physics, State Key Laboratory for Mesoscopic Physics, and Electron Microscopy Laboratory, Peking University, Beijing 100871, China Abstract We report hereby the large-scale synthesis of Ga2O3 micro-fiber and nanowire structures through a simple evaporation of a mixture of Ga2O3 and SiO2 powder at 1100ºC. The whiskers have very peculiar morphology from very smooth fibers, fibers with branches, and composite complex. The growth mechanism of the fibers are discussed based on a VLS mechanism. Those Ga2O3 fibers are very useful in view point both from optoelectronics, and to composite reinforcement of the materials *To whom correspondence should be addressed: yudp@pku.edu.cn. Instruction The discovery of carbon nanotube[1] has drawn increasing attention regarding the fabrication of one-dimensional materials such as nanowires. Their nanoscale dimensions may allow novel structures that may find application in field-effect transistors, electronic and optoelectronic devices[2]. For instance, GaN nanorods have found applications for blue and ultraviolet optoelectronic devices.[3]. Array of ZnO nanowires were found to have interesting UV lasing action [4]. Thus it is important to synthesize such nanowires that can meet the demands of further applications. Monoclinic gallium oxide, β- Ga2O3 is a wide band gap compound (Eg = 4.9 eV), which has long been known to exhibit both conduction and luminescence properties[4]. β-Ga2O3 , a transparent conducting oxide, has potential applications in optoelectronic devices [5]. Ga2O3 thin films are considered as one of the most promising materials for stable high-temperature gas sensors [6]. As a part of a large program, we are trying to develop efficient synthesis approaches for gallium oxide. βGa2O3 nanowires have already been reported to form by the arc-discharge synthesis[7], but in their work, transition metals played an essential role. Zhang et al. produced a large scale Ga2O3 nanowires by the evaporation of powder Ga at 300°C under a pressure of 100 Torr [8]. In order to obtain pure gallium oxide nanowires without other metals, we explored a method similarly as H. Z .Zhang’s. In this letter we report the experiment in detail. Experimental The evaporation system is the same as what H. Z. Zhang used [8]. The experimental setup for Ga2O3 growth is described in details else where. In our approach, the gallium with a purity of 99.99% mixed with a minimal of SiO2 powders was placed on the quartz plate(10mm×6mm) in the center of the quartz boat. To find the optimal condition for the growth of the nanowires, we placed three quartz boats one by one from the front to the center of the alumina tube. During the experiment, the mixture was heated to 1100°C at the center of the tube for 2 h in a flow of Ar gas at 30 sccm. The system was evacuated in order to keep the ambient pressure inside the tube at 100 Torr. After cooling down, a white wool-like product was collected from both the inner and the outer wall of the second boat. And a white layer with large particles could be seen in the third one. While nothing new could be found in the first one. The products in the second boat were characterized and analyzed using x-ray diffraction (Philips X’Pert MRD), SEM in dual beam focused ion beam system (DB Strata 235-FIB). Results and Discussion Bulk quantity of the as-grown products was analyzed using the powder X-ray diffraction meter (XRD). The XRD pattern as shown in Figure 1 can be indexed in peak position to a monoclinic phase, which is consistent with a bulk Ga2O3. The lattice parameters of the crystalline phase are a = 1.223nm, b = 0.304nm, c = 0.580nm, and β = 103.7 o, and its space group is identified as C2/m(No.12). Very intensive peak 0 2 0 which may frequently happen for nano-sized structure is also observed. [020] [111] 700 [403] [420] [-313] [510] 200 [-112] 300 SiO2[332] 400 [202] SiO2[320] 500 [400] [002] Intensity(a.u.) 600 100 30 35 40 45 50 2 Theta 55 60 65 70 Fig. 1. X-ray diffraction spectrum of the gallium oxide products SEM observations reveal very rich morphology of the fiber-like structures in according to the position collected on the substrate. Fig. 2a show a SEM image of the samples collected far from the Ga source. The product formed at the different spots of the boat have different morphology, size, and orientation. At the front where gas flows in, numerous smooth micro-rods with the diameter of several hundreds nanometers and length up to a hundred micrometers highly aligned in the direction of the gas flow. Thus, it is possible to grow aligned Ga2O3 nanowires at a proper flow rate. (a) Fig.2. (b) SEM images of the products in the front of the boat. (a)At the low magnification (b) At a higher magnification At the center of the boat where was near to the source of the material(Ga), pantree-shaped rods with the same diameters and lengths were grown in a high yield (Figure 3.) On each rod grow many nanowires with the diameters of 60-100nm and legths up to 10 μm. (a) (b) Fig. 3. (a) SEM image of Ga2O3 nano-forest. (b) SEM image of Ga2O3 micro-pantrees.The needles of the micro-pantrees are tens of nanometers. At the back, a micro-forest was found. Numerous micro-pantrees across each other are randomly distributed as shown in Figure 6. (a) (b) Fig. 4. SEM image of microstructures at the back of the boat.(a) (a)At the low magnification (b) At a higher magnification In our experiment, the microstructures began to nucleate and grow directly on the boat surface. The reactions that may be involved in the formation of the microstructures are as follows: SiO2(s) + H2(g) H2O(g) + SiO(g) 4Ga(l) + 3SiO(g) + 3H2O(g) 2Ga2O3(s) + H2(g)+3Si(g) The first step involves melting and evaporation of the Ga and the formation of the gradient of the vapor in the boat. Then Ga2O3 formed and deposited inside the boat. The Ga is a metal element, so it can also get oxygen from the silicon oxide besides the equipment leakage. Fig. 5. SEM image of the tree-morphology of the Ga2O3 microstructures One cause of the different morphology of the products in the different areas may be the different densities of the material source and the gas flow. Gallium was in the center of the quartz boat. At the temperature of several hundreds degree, Ga vapor is continuously supplied at a steady rate from the melted gallium inside the boat and a (3) (4) density gradient was formed in the boat. We propose different models to account for the growth of the products in the different areas. The mixed vapor (Ga and Ga2O3) was cooled and crystaled. At the front where smooth, aligned micro-rods are produced in the direction of the gas flow, the product can be explained by the VS mechanism. Steady Ga vapor reacted with oxygen in the carrier gas and formed gallium oxide. Meantime there is air convection in the tube. In that circulation, the impinging atoms onto a whisker surface were temporarily adsorbed, and diffused along the lateral surface to a sink at the whisper tip [8]. In the center, where the density is bigger, more complicated structures (pantree-shaped structures) are formed, we propose an heterogeneous nucleation model. The clusters form on the substrate within the matrix of an adsorbed phase of the supersaturated vapor. We will treat the heterogeneous nucleation as a temporal sequence of two processes: (A) Formation of a adsorbed layer on the substrate from the vapor phase. (B) Formation of a critical nucleus from the adsorbed atoms and its growth to supercritical size [9]. We can obtain the equation of the free energy easily: ΔG=16/3×πσc-v×f(θ)/ (ΔGv)2 [10] ΔG is the Gibbs free energy of the system, ΔGv is the supersaturation free energy available per unit volume of the condensed phase, f(θ) is a function of the contact angle θ, and σ is the surface energy. From the equation we can see the shape of the substrate will have effect on the nucleation. Thus it is obvious that on different areas the phenomena is different. At the end of the boat, the circumfluence of the carrier gas made the reaction more complex and micro-pantree forests are formed. As H. Z. Zhang proposed in his letter [8], the structural defects such as the triple, quadruple, and quintuplet junction points of the micro twin variants play an important role in the nucleation. We also found dislocations, stacking faults, and other planar defects, which can serve as the center of the nucleation in some microstructures in the back area. As the first huge rods grow, Ga will continue to sink to the position of plane faults and particles on it and the second layer grow out. Then the third layer may grow on the second one. So many strange and complicated structures grow out from the sub-micro particles on the large rod. The temperature around the quartz boat is about 700-900°C . In H.Z.Zhang’s experiment, the temperature around the boat is 300°C [8] due to the role of H2. However, his experiment has never been reproduced. In our experiments, we found the temperature played an essential role. No nanowires have grown under a lower temperature with other parameters unchanged. We have shown that the growth of the microstructures was sensible to the temperature. We found some interesting structures on our substrate. A huge micro-rod with smaller sheets and belts are like the branches of the micro-tree. These structures may find applications in micro-materials for ribbons. Because the thorns can enhance the friction with other objects, we can use it in some paints as ribbons. The products also have a large surface area; thus, they may have good absorption ability and could have application in gas sensors. Conclusion Large scale microstructures with various morphologies were synthesized using Ga and SiO2 mixture via physical evaporation. Unlike any previously achieved results, the Ga2O3 growth exhibits many interesting new growth phenomena. This method avoids introducing transition metals and other catalysts and is important for the measurement of the electronic properties of Ga2O3 microstructures. The formation of the microstructures is significant because they would be ideal for understanding dimensionally confined transport phenomena in functional oxides and for building functional devices along individual microrods. Thus, it is a promising task to explore an optimum approach and is very important for further research. Acknowledgements This project was financially supported by national Natural Science Foundation of China (NSFC, No. 50025206, 19834080), the Research Fund for the Doctoral Program of Higher Education (RFDP), China,and by the Hui-Chun Chin and Tsung-Dao Lee Chinese Undergraduate Research Endowment(CURE). Reference: [1] S. Iijima, Nature(London)354,56(1999). [2] D. D. Edwards, T. O. Mason, F. Goutenoir, K. R. Poeppelmeier, Appl. Phys. Lett, 70(1997) 1706. [3] Weiqiang Han, Shoushan Fan, Qunqing Li, Yongdan Hu, Science, 277(1997) 1287. [4] L. Binet, D. Gourier, J. Phys. Chem. Solids 59 (1998) 1241. [5] D.D. Edwards, T.O. Mason, F. Goutenoir, K.R. Poeppelmeier, Appl. Phys. Lett. 70 (1997) 1706. [6] M.Ogita, N.Saika, Y.Nakanishi, Y.Hatanaka, Appl.Surf.Sci.142(1999) 188. [7]Young Chul Choi et al. Advanced Materials.2000,12,No.10. [8] H. Z. Zhang, Y. C. Kong, Y. Z. Wang, X. Du, Z. G. Bai, J. J. Wang, D. P. Yu, Y. Ding, Q. L. Hang, S. Q. Feng, Solid State Communications.109 (1999) 677 [9] P.Hartman, Crystal Growth: An Introduction, 51 [10] P. Hartman, Crystal Growth: An Introduction, 62