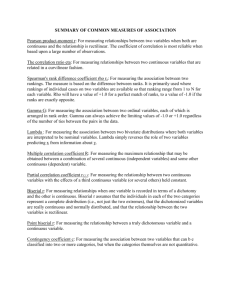

Theory:

advertisement