Bachelor of Science in Information Systems Department of

advertisement

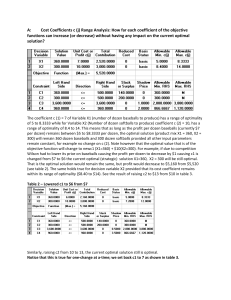

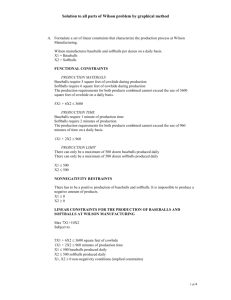

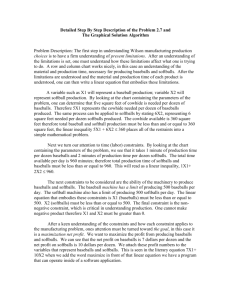

Bachelor of Science in Information Systems Department of Information Systems College of Computer & Information Sciences Imam Mohammad Bin Saud University Course Title: Quantitative methods Instructor: Mjdah Al Shehri Problem 1 Reddy Mikks Company produces both interior and exterior paints from two raw materials. M1 and M2. The following table provides the basic data of the problem Tons of raw material per ton of Exterior paint Interior pints Raw material, M1 Raw material, M2 Profit per tons ($1000) 6 1 5 4 2 4 The complete Reddy Mikks model is Maximize z = 5 X1 + 4 X2 Subject to 6 X1 + 4X2 <= 24 X1 + 2 X2 <=6 -X1 + X2 <=1 X2<= 2 X1, X2 >= 0 1 Maximum daily availability (tons) 24 6 1. Construct each the following constraints and express them with constant right-hand side: a. The daily demand for interior paint exceeds that of exterior paint by at least 1 ton b. The daily usage of raw material M2 is at most 6 tons and at least 3 tons c. The demand for interior paint cannot be less than the demand for exterior paint d. The minimum quantity that should be produced of both the interior and the exterior paint is 3 tons e. The proportion of interior paint to the total production of both interior and exterior paints must not exceed 0.5 2. Determine the best/ feasible solution among the following ( feasible and infeasible) solution of the Reddy Mikks model a. X1= 1, X2= 4 b. X1= 2 , X2= 2 c. X1= 3, X2=1.5 d. X1=2, X2=1 e. X1=2, X2=-1 3. for thefeasible solution x1=2, x2=2 of theroddy mikks model, determine a. the unused amount of raw material M1 b. the unused amount of raw material M2 4. suppose that Roddy Mikks sells its exterior paint to a who;esler at quantity discount. The profit per ton is $ 5000 if the contractor buys no more than 2 tons daily and $4500 otherwise. Can this situation be modeled as an LP model? 2 1. The solution: a. b. c. d. e. X2 – x1 >= 1 X1 + 2X2 >= 3 X2 >= X1 X1 + X2 >= 3 X2 / (X1+ X2) <= 0.5 OR and OR –X1 + X2 >=1 X1 + 2X2<= 6 X1 – X2 <=0 OR 0.5X1 – 0.5X2 >=0 2. THE SOULTION: a. (X1,X2)= (1,4) (X1,X2)>=0 6(1) + 4(4) = 22 <24 1(1) + 2(4) = 9 ≤ 6 IT IS INFEASIBLE b. (X1,X2)= (2,2) (X1,X2) >= 0 6(2)+ 4(2) = 20 <=24 1(2) + 2(2) =6 <=6 -1(2) +1(2) =0 <=1 1(2) =2<=2 IT IS FEASIBLE Z= 5( 2) + 4(2) = $18 3 c. (X1,X2) = ( 3,1.5) (X1,X2)>=0 6(3) = 4(1.5)= 24 <=24 1(3) + 2(1.5) = 6 <=6 -1(3) + 1(1.5)= -1.5<=1 1(1.5) = 1.5<=2 IT IS FEASIBLE Z= 5 (3) + 4 (1.5) = $21 d. (X1,X2) = (2,1) 6(2)+ 4(1) = 16 <= 24 1(2) + 2(1) =4 <=6 -1(2) + 1(1) =-1 <=1 1(1) =1 <=2 IT IS FEASIBLE Z= 5(2) + 4(1) = $14 e. (X1,X2) = (2,-1) X1>=0, X2<0 IT IS INFEASIBLE CONCLUSION ( C ) IS BEST SOULTION. 4 Problem 2: Wilson manufacturing produces both baseballs and softballs, which it wholesales to vendors around the country. Its facilities permit the manufacture of a maximum of 500 dozen baseballs and maximum of 500 dozen softballs each day. The cowhide covers for each ball are cut from the same processed cowhide sheet. Each dozen baseballs require five square feet of cowhide, including waste, whereas each dozen softballs require six square feet. Wilson has 3600 square feet of cowhide sheets available each day. Production of baseball and softballs includes making the inside core, cutting and sewing the cover, and packaging. It takes about one minute to manufacture a dozen baseballs and two minutes to manufacture a dozen softballs. A total of 960 minutes is available for production daily. a. Formulate a set of linear constraints that characterize the production process at Wilson manufacturing. b. Graph the feasible region for this problem. c. Wilson is considering manufacturing either 300 dozen baseballs and 300 dozen softballs or 350 dozen baseballs and 350 dozen softballs. Characterize each of these solutions. d. If Wilson estimates that its profit is $7 per dozen baseballs and $10 per dozen softballs, determine the objective function. 5 The Solution Decision Variables X1= number of dozen baseballs produced daily X2= number of dozen softballs produced daily a. The constraints : 5X1 + 6X2 3600 (Cowhide) X1 + 2X2 960 (Production time) X1 500 (Production limit of baseballs) X2 500 (Production limit of softballs) X1, X2 0 (Non-negativity) b. 6 c. - Wilson is considering manufacturing 300 dozen baseballs and 300 dozen softballs. Applying the constraints: C1; X1 =< 500; 300 =< 500. Constraint is satisfied. C2: X2 =< 500; 300 =< 500. Constraint is satisfied. C3; 5X1 + 6X2 =< 3600; 5(300) + 6(300) =3300=<3600. Constraint is satisfied. C4; X1 + 2X2 =< 960; 300 +2(300) = 900 =< 960. Constraint is satisfied. Since the constraints are satisfied, the solution of 300 dozen each is an interior point located within the feasible area. - Wilson considers manufacturing 350 dozen baseballs and 350 dozen softballs. Again, Applying the constraints: C1; X1 500; 350= < 500. Constraint is satisfied. C2; X2 500; 350 =< 500. Constraint is satisfied. C3; 5X1 + 6X2 3600; 5(350) +6(350) = 3850 >= 3600. Constraint is not satisfied. C4; X1 + 2X2 960; 350 + 2(350) = 1050 > =960. Constraint is not satisfied. Wilson does not have enough materials or the time necessary to manufacture according to this objective. Constraints C3 and C4 are infeasible points. d. Wilson estimates that its profit is $7.00 per dozen baseballs and $10.00 per dozen softballs, the production schedule that maximizes their daily profit is found at the extreme point, (360, and 300). Max 7X1 + 10X2 7(360) + 10(300) = 5,520. 7 Problem 3: Panasonic electronics manufactures several products, including 45-inch GE45 and 60inch GE60 televisions. It makes a profit of $50 on each GE45 and $75 on each GE60 television produced. During each shift, Panasonic allocates up to 300 man-hours in its production area and 240 man-hours in its assembly area to manufacture the television. Each GE45 require two man-hors in production area and one man-hour in the assembly area, whereas each GE60 require two man-hours in the production are and three manhours in the assembly area. Solve this problem by formulate the objective function and constraints. 8 The solution X1 = Number of GE45 televisions produced per shift X2 = Number of GE60 televisions produced per shift MAX 50X1 + 75X2 S.T. 2X1 + 2X2 300 (Production hours) X1 + 3X2 240 (Assembly hours) X1, X2 0 9 Problem 4 Palmgard International makes two products: inner glove and STS batting glove. Profit is $5 for the inner glove and $7 for the STS batting glove. The inner glove requires 1.5 sq. ft. of leather and 6 inches of foam while the STS batting glove requires 1 sq. ft of leather and 4 inches of foam. Palmgard receives 500 sq.ft of leather and 175 ft. of foam each day for production. It takes 6 minutes to construct an inner glove and 4 minutes to construct an STS batting glove and there are 80 hours available each day. Palmgard requires that at least 275 inner gloves are made daily. Solve this problem by formulate the objective function and constraints. Required information: 1 feet= 12 inches 10 The solution Decision Variables are: X1 = Number of inner glove made daily X2 = Number of STS batting gloves made daily Maximize daily profit 5X1 + 7X2 s.t. 1.5X1 + X2 500 (leather) 6X1 + 4X2 2100 (foam) 6X1 + 4X2 4800 (labor) X1 275 (production) X1, X2 0. 11 Problem 5: Joe's Garage specializes in oil changes and tune-ups. Profit per oil change is $7 and $15 per tune-up. Joe's has a fleet account customer, which guarantees 30 oil changes per week. Each oil change requires 20 minutes labor and $8 in supplies. A tune-up takes one hour and costs Joe's $15 in supplies. Mechanics are paid $10 per hour and Joe's currently employs two mechanics working 40 hours each per week. Every week Joe's orders $1,750 in supplies, and Joe's wishes to maximize profit. a. Formulate the problem. b. Solve the problem graphically. What is Joe's maximum profit per week? 12 The Solution a. This is a linear programming question. A portion of an oil change or tune-up is not feasible. X1 = Oil changes X2 = Tune-ups Maximize: 7X1 + 15X2 Subject to: X1 30 Fleet Account 20X1 + 60X2 4800 Labor time 8X1 + 15X2 1750 Materials X1, X2 0, b. 13 The labor cost of $10 per hour is not required to format the problem since the profit per oil change and tune-up takes into consideration the labor cost. The optimal solution is (183.33, 18.89), which could be rounded to (183, 19) which can be shown by using your QSB package that is indeed optimal integer solution. Maximum profit per week is $1,566.00. So, Joe should perform 183 oil changes and 19 tune-ups. 14