Ch4567PerfEval

advertisement

Chapter 4: DTMC

Exercice 1 : Stochastic process

Give a stochastic process to describe the evolution of the following variables as well as the nature of their time space

and state space :

a) The daily number of calls over a year

b) The number of calls arrived in interval [0, t]

c) Daily average time for handling a call over the week

d) Remaining waiting time of a customer given the time he has waited

Exercice 2 : Random walk

Let X , X , … be identical and independent random variables (i.i.d.). Consider the stochastic process{Y }

1

n n=0,1,2,…

2

Y0 = 0, and Yn = X1 + X2 + ... + Xn. {Y }

n n=0,1,2,…

is called a random walk.

a) Are the random variables Y independent ?

n

Let X be aBernoulli random variable with parameter p, i.e P[Xn = 1] = p and P[Xn = -1] = 1-p.

n

b) Propose a graphic representation of the random walk {Y }

c) Determine a relation between P[Y = i], i N and P[Y

n

n

n+1

= j], j N

Exercice 3 : Stochastic matrix

a) Let P be a stochastic matrix, show that Pn is also stochastic

b) Show that all stochastic matrix has an eigenvalue equal to 1.

c) Frobenius Theorem: let P be a stochastic matrix, show that all its eigenvalues are smaller or equal to 1.

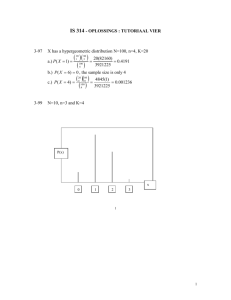

Exercice 4 : Graphic representation of DTMCs

Classify the states of the following DTMCs (absorbing, transient, recurrent). Are the DTMCs irreducible?

Exercice 5 : Canonical form

Consider a DTMC with the following graphic representation

a) Classify the states

b) Identify the sub-chains

c) Give the transition matrix of its canonical form

with

Problem 1 : It's your destinity !

Some sociologists range individuals of a society into 3 social classes: Bourgeois (B), Middle class (C) and Proletariat

(P). We are interested in this simplistic model on the social class reached by the end of lifetime by each individual.

Assume that this social class depends only on that of the father.

If the father belongs to B, his son belongs to B and C with proba 0.5 and 0.5.

If the father belongs to C, his son belongs to B, C and P with proba 0.2, 0.7 and 0.1.

If the father belongs to C, his son belongs to B, C and P with proba 0.1, 0.3 and 0.6.

a) Model this sociology behavior by a Markov chain.

b) Give its state-transition graph, its matrix

c) Determine the nature of each state. Is the chain irreducible? Periodic?

d) What is the long term average proportion of each class?

e) What is the stationary probability of being in a social class different from that of his grand father?

Problem 2 : Le contrat de confiance

The responsible of a supermarket observed that the daily demand of washing machines is a Bernoulli random variable.

More precisely, each day, a washing machine is sold with probability p and no machine is sold with probability 1-p.

When the last machine is sold, an order of m machines is issued and delivered the next day morning. The storage cost is

s per machine per day. The order cost is independent of order quantity and is b per order.

a) Determine the average daily cost with DTMC.

b) Which value of m minimizes this cost?

Problem 3 : French Roulette versus american roulette

You feel well, you buy i tokens and move to the nearest roulette table. Your strategy is simple: you put a token on each

game and only choose simple chances (even/odd, red/black, …). The probability of wining is p for each try and the

payout is 1 to 1. You decide to stop if you arrive at a tokens (or if you loose all and you are bankrupted).

Let Xn be your number of tokens after n games.

a) Show that {Xn}n=0,1,… is a Markov chain. Give its graphic representation and its transition matrix.

Determine the nature of each state. Is the chain irreducible?

b) Determine the probability f of bankruptcy by starting with i tokens (you can try to find a recursive relation

i0

of f )

i0

c) Determine the expectation of gain E[G]

d) Calculate the average time ei of the game starting with i tokens

e) Numerical application: determine ei and fi0 for French roulette (p = 18/37) and american roulette (p = 18/38)

with i=50 and a=100

Problem 4 : Reliability

A company uses a machine with the following state of wear : new, slightly degraded, degraded, and unusable. Each day

of use in each of the four states brings a gain of respectively 1000 $, 1000$, 800$ and 0$. The degrading process is

modeled as a DTMC with day as time unit with the following transition probabilities:

new

slight degraded

degraded

unusable

new

0,6

0

0

0

slightly degraded

0,2

0,7

0

0

degraded

0,1

0,2

0,8

0

unusable

0,1

0,1

0,2

1

a) Determine the average lifetime of a new machine

b) Assume that the replacement of the machine by a new one cost K = 2000$ and takes one day for installation. Which

of the following two policies maximize the long term gain:

(P ) Replace the machine when it becomes unusable

1

(P ) Replace the machine when it is degraded or unusable

2

Chapter 5: CTMC

Exercise 1 : Exponential distribution

a) A memoryless random variable is a random variable T such that:

P{T t+ x | T t} = P{T x}, t, x

Show that the only memoryless continuous probability distribution is exponential distribution

b) Prove that the sojourn time in a state i of a CTMC is exponentially distributed.

c) Let X1, X2, … , Xn, be n independent random variables with exponential distribution of parameter λ , λ , … , λ and

1

Y= min{X ,X

1

2, …,

2

n

X }. Show that:

n

- Y is exponentially distributed with parameter λ + λ + …+ λ

1

2

n

- P[X = Y]= λ /(λ +λ + … +λ )

i

i

1

2

n

d) Let X1, X2, … , Xn be n independent random variables with the same exponential distribution of parameter λ. Show

that Z = X + X + ... + X has the following probability distribution :

n

1

2

n

fn x

x

n 1 x

e

n 1!

Remark : Zn is said to follow a n-stage Erlang distribution with parameter .

Exercise 2 : Poisson process

Let N(t) be a Poisson process with parameter λ .

a) Show the following probability distribution:

P N t k

t k e t

k!

b) Show that the superposition of n Poisson process with respectively rates λi (i=1,…,n) is a Poisson process with

parameter Σ λ .

i

c) Show that the split of N(t) with probabilities pi gives n Poisson processes of parameter λ p .

i

Problem 1 : Reliability

A factory has two identical machines, each with an exponential reliability of rate λ (which implies that the time between

two consecutive failures is exponentially distributed with parameter λ). Machines work permanently when they are not

failed. When a machine fails, the repair requires two repairmen R1 and R2 consecutively (always in the order R1 then

R2). The factory has only one repairman R1 and one repairman R2. As a result, if a machine fails while R2 is repairing

another machine, then the second machine has to wait of the end of the on-going repair (same wait for R2). The repair

time of R1 and R2 are exponentially distributed with rates μ and μ .

1

2

a) Show that the system can be modeled by a CTMC of 6 states. Give the associated graph.

b) Write the probability flow balance equation (also called equilibrium equation) for μ = μ = μ;

1

2

c) Compute the steady state probabilities.

d) Assume that, on average, a machine fails every 4 hours of operation and that each repairman takes 1 hour to

do his repair. What is the availability of the factory, i.e. the proportion of time during which at least one

machine is UP.

Problem 2 : Production

Consider a 3-machine production system

raw parts

1

1

1

2

finished

parts

The system is fed by an unlimited stock of raw parts. Each part has to visit all three machines in the same order for its

production. The machining time of each machine is exponentially distributed with rate μ on machine i. There is no

i

buffer space between the machines. When a part arrives on a machine, it starts the operation. At the end of the

operation, two scenarios are possible. If the next machine is available, then the part immediately moves forward and

continues its production. If the next machine is not available, the part remains on the machine and the machine is

blocked. The blocking situation ends when the next machine becomes available again. We assume that the last machine

is never blocked.

a) Model the behavior of the system by a CTMC and explain the meaning of each state.

Assume that the stationary probabilities are known.

b) What is the proportion of time P during which at least one machine is blocked?

c) What is the average number X of parts produced per unit of time?

d) What is the average number of parts present in the system?

e) What is the average number M of machines working on a part?

f) What is the average time R needed to produce a part (also called the production leadtime)?

Problem 3 : Packet switching

Consider a packet switching networking communication system composed of 3 nodes and 2 links:

The arrival process to node 1 is supposed to be Poisson with rate . All packets are transmitted through links 1-2 and 23. When node 3 receives a packet, it handles instantaneously the packet. All nodes have a limited capacity of one

packet. It implies:

- when a packet arrives at node 1 while node 1 is busy with another packet, the new packet is lost;

- if there is a packet on node 1 and another packet on node 2, then node 1 cannot start its emission till node 2 becomes

empty. It is assumed that node 1 is informed in real time of the availability of node 2.

The emission time of node i is assumed to be exponentially distributed with rate μi, i = 1, 2. The propagation on each

link is small enough to be neglected. While a packet is emitted, it occupies a place on the node.

a) Model the behavior of this network as a CTMC by indicating the meaning of each state;

b) Determine the stationary probabilities after the justification of their existence.

c) What is the probability of loss of a packet upon its arrival?

d) Give the average time a packet takes to traverse the network.

Chapter 6: Queueing systems

Problem 1 : Telephone switch

Consider a telephone switch system able to handle simultaneously C calls. A new call arriving while C calls are in

progress is lost. Assume that the arrival process of calls is a Poisson process with rate λ and the service is exponential

with rate μ.

a) Model the system by a queueing system and give its Kendall notation

b) Give the CTMC model of the system

c) Determine the stationary probabilities and give the stability condition

d) Give the expression of throughput rate of successful calls, of the average number of on-going calls and the

average response time.

Problem 2 : A finite population system

Consider a system with m potential customers. Each customer, when he is not in the system, arrives according to a

Poisson process of rate . The service time of a customer is exponentially distributed with rate . The system has

unlimited number of servers.

a) Model the system by a queueing system and give its Kendall notation

b) Give the CTMC model of the system

c) Determine the stationary probabilities and give the stability condition

d) Give the average number of customers in the system.

Problem 3 : Computer network

The computer network of a pharmaceutical company composed of 10 terminals. These 10 terminals (assumed to be

always busy) are connected to a processor (CPU). Each terminal can send a request at a time to the CPU and wait for

the answer of the processor before sending another request. After the answer of the CPU to a user, the latter should wait

on average 40 seconds before sending a new request. It is called think time. The processor treats the requests one after

another in FIFO order and it takes on average 4 seconds to treat a request.

The think time and the treatment time are exponentially distributed.

a) Model the computer network

b) Formulate the network as a queueing system and give its Kendall notation

c) Enumerate and classify all possible states of the associated Markov chain, give its graphic representation and

its infinitesimal generator

d) Assume that the stationary distribution is known. Compute the average number of requests in the processor,

the average response time and the utilization rate of the processor.

Problem 4 : Switch with priority

Consider a telephone switch able to handle simultaneously C calls. Three classes of calls arrive at the switch. It is

assumed that calls of type r arrive according to a Poisson process of rate λ , r = 1, 2 or 3. When a call arrives and there

r

are less than C calls in the switch, the call is treated immediately. The call time is assumed to be independent of the call

type and is exponentially distributed with rate m. When a call cannot be served immediately, depending on its type, it is

put in a FIFO queue of limited capacity or rejected.

The buffer is divided into three zones of size k , r = 1,2,3, each accepting calls of type r or of higher priority.

r

a) Represent the CTMC of the system

b) Explain while there is no problem of stability. To simplify the computation, assume C = 2, k = k = k = 1, λ

1

2

3

1

= λ = λ = 1/3 and μ = ½

2

3

c) Determine the stationary probabilities

d) What is the proportion of type r calls that are rejected?

e) Determine the average number of calls satisfied per time unit for each type and for the whole system

Problem 5 : M/G/1 Consider an M/G/1 queue. Its arrival process is a Poisson process of rate λ and its service time X

has a probability density function f . Its stationary distribution p(n) satisfies the following equilibrium equation where

X

i is the number of arrivals during a customer service and p(n) the probability of n customers in the system after a

departure:

Consider the following transform (z-transform) of p(n) and α :

i

a) Show P( z )

P(0)V ( z )(1 z )

V ( z) z

b) Prove P(0) = 1-

c) Determine the server utilization ratio U

Consider the Laplace transform of f : B(s) 0 e st f X (t )dt

X

d) Show E[Xn] = (-1)n B(n)(0)

(1 ) B( z )(1 z )

e) Show P( z )

B ( z ) z

f) Prove that the average number of customers in the system is Q = P'(1)

g) Establish the Pollaczeck-Kinchin (P-K) formula : Q

2 1 cv 2

2 1

h) Derive the average system time R

Reminder : cv 2

VAR( X )

2

E X

and Var(X) = E[X2] – E[X]2

Problem 6 : G/M/1

Following the approach of M/G/1 queue, determine an embedded Markov chain, determine transition probabilities and

the graphical representation.

Problem 7 : M/Ek/1

Consider a M/E /1 queue with service time of k-stage Erlang distribution of parameter (i.e. the sum of k exponential

k

distributed r.v.).

a) Model the system by a CTMC with state variable indicating the total number of remaining stages for all customers in

the system.

b) Give the graphic representation.

Problem 8 : Machining station Parts arrive at a machining station at the average rate of one part every 30 seconds.

Waiting parts are stacked in front of the machine with the last part on top of the others. The machining operation takes

on average 25 seconds.

a) Assume that parts arrive according to a Poisson process and machining times are iid random variables of

exponential distribution.

• Give the Kendall notation of the queueing system

• Precise the arrival rate and the service rate

• Check the stability of the queue

• Determine the average waiting time of the parts

b) A more detailed analysis shows that the machining process is composed of two phases: a first phase of

constant time of 5 seconds and second phase of uniformly distributed time between 10 to 30 seconds. What

is the average waiting time of parts?

c) How do you explain the difference of waiting times between these two models?

9 (Staffing : number of nurses) A hospital is exploring the level of staffing needed for a booth in the local mall, where

they would test and provide information on the diabetes. Previous experience has shown that, on average, every 6.67

minutes a new person approaches the booth. A nurse can complete testing and answering questions, on average, in

twelve minutes.

Assuming s = 2, 3, 4 nurses, a hourly cost of 40€ per nurse and a customer waiting cost of 75€ per hour.

Determine the following: patient arrival rate, service rate, overall system utilization, nb of patients in the system (Ls),

the average queue length (Lq), average time spent in the system (Ws), average waiting time (Wq), probability of no

patient (P0), probability of waiting (Pw), total system costs.

10. (Dimensioning the number of beds : Target occupancy level) Consider obstetrics units in hospitals. Obstetrics is

generally operated independently of other services, so its capacity needs can be determined without regard to other

services. It is also one for which the use of a standard M/M/s queueing model is quite good. Most obstetrics patients are

unscheduled and the assumption of Poisson arrivals has been shown to be a good one in studies of unscheduled hospital

admissions. In addition, the coefficient of variation (CV) of the length of stay (LOS), which is defined as the ratio of the

standard deviation to the mean, is typically very close to 1 satisfying the service time assumption of the M/M/s model.

(Dimensioning the number of beds) Since obstetrics patients are considered emergent, the American College of

Obstetrics and Gynecology (ACOG) recommends that occupancy levels of obstetrics units not exceeding 75%. Many

hospitals have obsterics units operating below this level. However, some have eliminated beds to reduce « excess »

capacity and costs and 20% of NY hospitals had obstetrics units that would be considered over-utilized by this standard.

Assuming the target occupancy level of 75%, what is the probability of delay for lack of beds for a hospital with s = 10,

20, 40, 60, 80, 100, 150, 200 beds.

Lesson: For the same occupancy level, the probability of delay decreases with the size of the service.

11 (Dimensioning the number of beds) Evaluation of capacity based on a delay target leads to very important

conclusion. Though there is no standard delay target, it has been suggested that the probability of delay for an obstetrics

bed should not exceed 1%.

What is the size of an obstetrics unit (nb of beds) necessary to achieve a probability of delay not exceeding 1% while

keeping the target occupancy level of 60%, 70%, 75%, 80%, 85%?

Lessons :

Achieving high occupancy level while having small probability of delay is only possible for obsterics unit of large

hospitals.

Capacity cut should be made with clear understanding of the impact. Simple and naive analysis based on average could

lead to bad decisions.

12. (Dimensioning the number of beds: Impact of seasonality) Consider an obstetrics unit with 56 beds which

experiences a significant degree of seasonality with occupancy level varying from a low of 68% in January to about

88% in July.

What is the probability of delay in January and in July?

If, as is likely, there are several days when actual arrivals exceed the month average by 10%, what is the probability of

delay for these days in July?

Lesson :

Capacity planning should not be based only on the yearly average. Extra bed capacity should be planned for

predictable demand increase during peak times.

13 (Dimensioning the number of beds : Impact of clinical organization) Consider the possibility of combining

cardiac and thoracic surgery patients as thoracic patients are relatively few and require similar nursing skills as cardiac

patients.

The average arrival rate of cardiac patients is 1.91 bed requests per day and that of thoracic patients is 0.42. No

additional information is available on the arrival pattern and we assume Poisson arrivals. The average LOS (Length Of

Stay) is 7.7 days for cardiac patients and 3.8 days for thoracic patients.

What is the number of beds for cardiac patients and thoracic patients in order to have average patient waiting time for a

bed E(D) not exceeding 0.5, 1, 2, 3 days? What is the number of beds if all patients are treated in the same nursing unit?

Delay in this case measures the time a patient coming out of surgery spends waiting in a recovery unit or ICU until a

bed in the nursing unit is available. Long delays cause backups in operating rooms/emergency rooms, surgery

cancellation and ambulance diversion.

Lesson :

Personal and equipment flexibility and service pooling can achieve higher occupancy level and reduction of beds.

However, priority given to one patient group could significantly degrade the waiting time of other patients if all treated

in the same nursing unit.

Production-Inventory queues

Problem 1 : Optimization of a base stock policy with backlogged demand

Consider a machine with a production rate μ parts per time unit. A finished part is immediately put in a stock. If the

stock is not empty, an incoming customer order is satisfied immediately from stock. If there is no more stock, customer

orders are backlogged and will be satisfied with future productions. Customer orders arrive at rate λ.

The inventory control policy is as follows: the machine produces as long as the stock level is below a given

threshold S. When there are S parts in stock, the machine stops producing.

Let X(t) be the number of parts in stock at time t. X(t)<0 implies -X(t) customer orders are waiting.

The goal is to determine the optimal value S* which minimize the total cost.

Only two costs are considered:

• h : unit inventory holding cost (cost per product per time unit)

• b : unit demand backlogging cost.

1. Show that X(t) is a CTMC under some assumptions that you precise;

2. Give the graphic representation of the CTMC;

3. Determine the steady state distribution n = limt P[X(t) = n] after having justified their existence;

4. Let C(S) be the average total cost per time unit for threshold S. Express C(S) as a function of h, b, ρ, S and

n;

S 1

h S

5. Assume that C(S) = (h b)

. Show that S* = min{S | C(S+1) – C(S) > 0};

1

1

h

h b

6. Prove S* = log

h

, show that the optimal cost C* = (h+b)S* and draw on Excel C* by varying for h =

hb

7. With S* = log

1 and b = 10.

8. With the same approximation, express the service rate (i.e. percentage of customers served immediately) as a

function of h and b in the case S = S*. What can you conclude?

Problem 2 : Optimization of base stock policy with lost demand

The system is similar to that of the last problem except that it is not possible to make customers wait. Un demand

that cannot be satisfied immediately from stock is definitely lost. Each lost demand incurs a lost demand cost c. The

other parameters are the same as in the last problem.

1. Express the average total cost C(S) as a function of h, c, ρ, λ, S and n ;

2. It can be shown that the average inventory is I

S S 1

1 S 1

1

. Use Excel to determine the optimal base stock S*

and the optimal cost C* for λ=0.9, μ=1 , h=1, c=10.

Problem 3 (Queueing network)

Consider a production system composed of three machines M1, M2, M3. Two types of products P1 and P2

are produced. The manufacturing processes are as follows. Products arrive from outside system randomly.

Each product P1 is first treated by machine M1 and then by machine M3. Each product P2 is first treated by

machine M2 and then by machine M3. Machine M3 is then shared by both products.

a) Assume that products P1 arrive according to a Poisson process of rate = 3 parts/hour and products

P2 arrive according to an independent Poisson process of rate = 2 parts/hour. What are the

average inter-arrival times of P1 and P2?

b) Assume that the processing times at the machines are random variables of exponential distribution

with mean equal to 15 min on M1, 20 min on M2 and 10 min on M3 (independent of the product

type). What are the service rates of the machines?

c) What are the arrival rates of products at each machine?

d) Determine the average inventory level at each machine, the total WIP, and the production lead time

of each product.

e) Assume that the ratios of the two types of products are fixed with 3/5 of P1 and 2/5 of P2. What is

the maximal capacity of the system, i.e. the maximal production rate? What happens if the arrival

rates approach this maximal capacity?

M1

S1

P1

S3

M3

P2

M2

S2

Problem 4 (a tandem queueing network)

Consider a tandem production line composed of 3 workstations (M1, M2, M3). Each workstation is

composed of a machine and an upstream buffer. The maximal production rate is 1 = 5 parts/hour on M1,

2= 6 parts/hour on M2 and 3=5 parts/hour on M3. What are the average buffer level and the average

production lead time for arrival rate = 3, 4, 4.5?

S1

M1

S2

M2

S3

M3

Chapter 7. Failure-prone production lines

Problem 1 Failure prone production lines

Consider a production line composed of 2 machines M1 and M2 separated by a buffer B. The processing times are

on average 10 minutes on M1 and 12 minutes on M2. Machines are subject to failures and the reliability model

ODF (Operation-Dependent Failure) is used. The mean time between failures is 9 hours for M1 and 14 hours for

M2. The repair time is the same for the two machines and is on average 1 hour. All the times are assumed

exponentially distributed.

a) Explain the meaning of ODF failures.

b) Determine the isolated productivity of each machine, i.e. the productivity if it is never starved nor

blocked.

c) Determine the productivity if the line was without buffers. In this case, which machine to improve first in

order to improve the performance of the line? Why?

d) Determine the productivity of the line if there were an unlimited buffer. Would be the stock limited?

Why? In this case, which machine to improve first in order to improve the performance of the line? Why?

e) Consider the continuous flow model with a buffer B of limited capacity h = 5 and assume that machine

M1 is slowed down to a rate of 12 minutes per product (i.e. it waits 2 minutes after each operation).

Determine the effective failure rate of M1. Determine the probability of starvation of M2, the probability

of blockage of M1 and the productivity of the line. In this case, which machine to improve first in order

to improve the performance of the line? Why?

M1

B

M2

Problem 2 (Production line with two reliable machines).

Consider three 2-reliable-machine production lines defined as follows: (p1 = 10, p2 = 9, N = 0 to 50), (p1 = 9, p2 = 10,

N = 0 to 50), (p1 = 9.5, p2 = 9.5, N = 0 to 50).

Determining the throughput rate, the starvation and blockage probability, and the average WIP. Would do you observe?

Problem 3 CTMC model of failure-prone production lines.

Consider the CTMC model of a production line with two unreliable machines with production rate pi, failure rate i and

repair rate i. All times are exponentially distributed. Assume that there is no buffer but each machine can hold a part.

a) Give the graphic representation of the system;

b) Determine the throughput rate for the case pi = i = i = 1.

c) Compare b) with the result of production line without but buffer but with identical cycle time = 1. What do you

observe?

Problem 4. Numerical study of the continuous flow model of two-machine failure prone lines.

a) Consider the line (U = 1) where N is the buffer capacity. Determine the throughput

rate TH and the average buffer level WIP for N = 0 to 200 and = 0.06, 0.08, 0.1, 0.12, 0.14. What do you observe?

b) Consider the line L = (U = 1). Determine TH and WIP for N = 0 to 200 for L

and the cases 1 is improved to 0.12 and then 0.14. Repeat the exercice for improvement of 2 to 0.12 and then 0.14.

What do you observed?

c) Consider the line (U = 1). Assume that ) = 0.9. Determine the TH for m1

= 0.01 to 0.99. What do you observe?

Problem 5. Repeat problem 4 for slotted time model. When the difference between the two models significant?

Problem 6. (Progamming or Excel) Study of long continuous flow lines

a) Consider the continuous flow model of a line with 50 identical unreliable machines with parameters

(, U = 1, hi = 20). Determine the throughput rate TH and the buffer levels WIPi. How is the WIPi

distributed? How do you explain the phenomena?

b) Repeat a) for another line L' similar to L except = 0.0375.

c) Consider an 8-machine line with parameters ( = 0.75, U = 1.2, hi = 30) exept the buffer capacity h6.

Determine and represent graphically TH and WIPi for h6 = 0 to 50. What do you observe? How the increase of h6

impact on the WIP distribution? Why?

d) Consider a 9-machine line with parameters ( = 0.019, U = 1) and a total buffer capacity TC. Consider

two designs of the line L1 with TC equally shared among all 8 buffers and L2 with TC assigned equally to buffer 3

(after the 3rd machine) and buffer 6 (after the 6th machine). Determine TH with TC = 0 to 10000 and TC = 0 to 200.

What do you observe?

Problem 7 (Programming or Exel) Production line design

Consider three 20-machines production lines:

Case 1 : MTBF = 200 minutes and MTTR = 10.5 minutes for all machines (ei = 0.95 parts per minute)

Case 2 : Like Case 1 except Machine 5. For Machine 5, MTBF = 100 and MTTR = 10.5 minutes (ei = 0.905

parts per minute)

Case 3 : Like Case 1 except Machine 5. For Machine 5, MTBF = 200 and MTTR = 21 minutes (ei = 0.905

parts per minute)

Machines have identical cycle times of 1 minute per part.

The goal is to determine the smallest total amount of buffer capacities so that the line meets a production rate

target TH* = 0.88.

a) Determine the production rate if there is no buffer at all.

b) Determine the production rate if each buffer has a capacity hi = 10.

c) Improve iteratively the productivity of the line till obtaining TH* by adding each time units of buffer capacity to

the bottleneck buffer identified with the approach of Chapter 8 ( = 5 for example).

d) Compare you results with those of the ppt file of the course obtained for slotted time model with an optimization

based approach.

Problem 8. Translate the lines of problem 7 into Bernoulli lines and repeat the exercises. How good is the

transformation-based approach?