Costing & Variance Analysis Formulas & Problems

Cost acc 2

Standard Costing and Variance Analysis Formulas:

This is a collection of variance formulas / equations which can help you calculate variances for direct materials, direct labor, and factory overhead.

Direct materials variances formulas

Direct labor variances formulas

Factory overhead variances formulas

Direct Materials Variances:

Materials purchase price variance Formula:

Materials purchase price variance = (Actual quantity purchased × Actual price) –

(Actual quantity purchased × Standard price)

Materials price usage variance formula

Materials price usage variance = (Actual quantity used × Actual price) – (Actual quantity used × Standard price) materials quantity / usage variance formula

Materials price usage variance = (Actual quantity used × Standard price) – (Standard quantity allowed × Standard price)

Materials mix variance formula

(Actual quantities at individual standard materials costs) – (Actual quantities at weighted average of standard materials costs)

Materials yield variance formula

(Actual quantities at weighted average of standard materials costs) – (Actual output quantity at standard materials cost)

Direct Labor Variances:

Direct labor rate / price variance formula:

(Actual hours worked × Actual rate) – (Actual hours worked × Standard rate)

Direct labor efficiency / usage / quantity formula:

(Actual hours worked × Standard rate) – (Standard hours allowed × Standard rate)

Direct labor yield variance formula:

(Standard hours allowed for expected output × Standard labor rate) – (Standard hours allowed for actual output × Standard labor rate)

Factory Overhead Variances:

Factory overhead controllable variance formula: www.jakartaprofessional.wordpress.com 1

(Actual factory overhead) – (Budgeted allowance based on standard hours allowed*)

Factory overhead volume variance:

(Budgeted allowance based on standard hours allowed*) – (Factory overhead applied or charged to production**)

Factory overhead spending variance:

(Actual factory overhead) – (Budgeted allowance based on actual hours worked***)

Factory overhead idle capacity variance formula:

(Budgeted allowance based on actual hours worked***) – (Actual hours worked ×

Standard overhead rate)

Factory overhead efficiency variance formula:

(Actual hours worked × Standard overhead rate) – (Standard hours allowed for expected output × Standard overhead rate)

Variable overhead efficiency variance formula:

(Actual hours worked × Standard variable overhead rate) – (Standard hours allowed ×

Standard variable overhead rate)

Variable overhead efficiency variance formula:

(Actual hours worked × Fixed overhead rate) – (Standard hours allowed × Fixed overhead rate)

Factory overhead yield variance formula:

(Standard hours allowed for expected output × Standard overhead rate) – (Standard hours allowed for actual output × Standard overhead rate)

Problem 1:

Materials Variance Analysis:

The Schlosser Lawn Furniture Company uses 12 meters of aluminum pipe at $0.80 per meter as standard for the production of its Type A lawn chair. During one month's operations, 100,000 meters of the pipe were purchased at $0.78 a meter, and 7,200 chairs were produced using 87,300 meters of pipe. The materials price variance is recognized when materials are purchased.

Required: Materials price and quantity variances.

Solution:

Actual quantity purchased actual quantity purchased

Materials purchase price variance

Actual quantity used

Meters of pipe

100,000

100,000

-----------

100,000

=======

87,300

Unit Cost

$0.78 actual

$0.80 standard

-----------

$(0.02)

=======

0.80 standard

Amount

$78,000

$80,000

-----------

$(2,000) fav.

=======

$69,840 www.jakartaprofessional.wordpress.com 2

Standard quantity allowed

Materials quantity variance

86,400

-------------

900

=======

0.80 standard

-------------

0.80

=======

$69120

-------------

$720 Unfav

=======

Problem 2:

Materials Variance Analysis:

The standard price for material 3-291 is $3.65 per liter. During November, 2,000 liters were purchased at $3.60 per liter. The quantity of material 3-291 issued during the month was 1775 liters and the quantity allowed for November production was 1,825 liters. Calculate materials price variance, assuming that:

Required: Materials price variance, assuming that:

It is recorded at the time of purchase (Materials purchase price variance).

It is recorded at the time of issue (Materials price usage variance).

Problem 3:

Labor Variance Analysis:

The processing of a product requires a standard of 0.8 direct labor hours per unit for

Operation 4-802 at a standard wage rate of $6.75 per hour. The 2,000 units actually required 1,580 direct labor hours at a cost of $6.90 per hour.

Required: Calculate: labor rate variance or Labor price variance.

Labor efficiency or usage or quantity variance.

Two, three & four variance methods

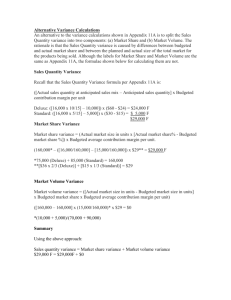

Factory Overhead Variance Analysis:

Example:

The Osage Company uses a standard cost system. The factory overhead standard rate per direct labor hour is:

Fixed:

Variable:

$4,500 / 5,000 hours = $0.90

$7,500 / 5,000 hours = $1.50

--------

$2.40

For October, actual factory overhead was $11,000 actual labor hours worked were

4,400 and the standard hours allowed for actual production were 4,500.

Required: Factory overhead variances using two, three and four variance methods. www.jakartaprofessional.wordpress.com 3

ANSWER:

Two Variance Method:

Actual factory overhead

Budgeted allowance based on standard hours allowed:

Fixed expenses budgeted

Variable expenses (4,500 standard hours allowed ×

$1.50 variable overhead rate)

Favorable controllable variance

Budgeted allowance based on standard hours allowed

Overhead charged to production (4,500 standard hours allowed × $2.40 standard rate)

Unfavorable volume variance

Three Variance Method:

Actual factory overhead

Budgeted allowance based on actual hours worked:

Fixed expenses budgeted

Variable expenses (4,400 actual hours worked ×

$1.50 variable overhead rate)

Favorable spending variance

Budgeted allowance based on actual hours worked

Actual hours worked × Standard overhead rate (4,400 hours × $2.40)

Unfavorable spending variance

Actual hours worked × Standard overhead rate (4,400 hours × $2.40)

Overhead charged to production (4,500 standard hours allowed × $2.40 standard rate)

Favorable efficiency variance

Four Variance Method:

Actual factory overhead

Budgeted allowance based on actual hours worked:

Fixed expense budgeted

Variable expenses (4,400 actual hours worked

× $1.50 variable overhead rate)

$4,500

$6,600

-----------

$4,500

$6,750

-----------

$4,500

$6,600

-----------

$11,000

$11,250

-----------

$ (250) fav.

======

$11,250

$10,800

------------

$450 unfav.

$11,000

$11,100

-----------

$ (100) fav.

======

$11,100

$10,560

------------

$540 unfav.

======

$10,560

$10,800

-----------

$ (240) fav.

$11,000

$11,100 www.jakartaprofessional.wordpress.com 4

Favorable spending variance

Budgeted allowance based on actual hours worked

Budgeted allowance based on standard hours allowed

Actual hours × fixed overhead rate (4,400 actual hours × $0.90 fixed overhead rate)

Standard hours allowed × fixed overhead rate

(4,500 actual hours × $0.90)

Favorable variable overhead efficiency variance

Favorable fixed overhead efficiency variance

Normal capacity hours (5000) × Fixed overhead rate ($0.90)

Actual hours worked (4,400) × Fixed overhead rate ($0.90)

Unfavorable Idle capacity variance (600 hours ×

$0.90)

-----------

$ (100) fav.

======

$11,100

$11,250

-----------

$ (150) fav.

======

$3,960

4,050

-----------

$ (90) fav.

======

$4,500

$3,960

------------

$540 unfav. www.jakartaprofessional.wordpress.com 5