8385 Demonstrate knowledge of hide and skin faults

advertisement

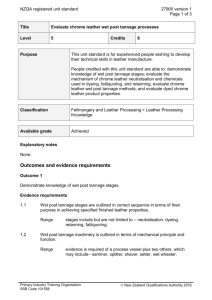

NZQA registered unit standard 8385 version 9 Page 1 of 3 Title Demonstrate knowledge of hide and skin faults Level 4 Credits Purpose 5 This theory-based unit standard is for experienced people in the fellmongery or leather industries or those wishing to develop their technical skills in leather manufacture. People credited with this unit standard are able to demonstrate knowledge of: hide and skin faults; eliminating or reducing hide and skin faults; and techniques used to eliminate or reduce the effect of faults on the finished product, in leather manufacture. Classification Fellmongery and Leather Processing > Leather Processing Knowledge Available grade Achieved Explanatory notes None. Outcomes and evidence requirements Outcome 1 Demonstrate knowledge of hide and skin faults in leather manufacture. Evidence requirements 1.1 Hide and skin faults are identified and described in terms of their cause and origin. Range 1.2 evidence is required of four faults from the following – farm, butcher, storage or transport. Hide and skin faults are identified and described in terms of appearance. Range evidence is required of four of the following – cockle, whitespot, shearing, scars, burrs, scratches, hide spot, grain strain, flay cuts, stunner burn, V butt, staling, red/purple heat, wool/hair slip. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA registered unit standard 8385 version 9 Page 2 of 3 Outcome 2 Demonstrate knowledge of eliminating or reducing hide and skin faults in leather manufacture. Evidence requirements 2.1 Process for eliminating or reducing hide and skin faults at origin are described in terms of controls or techniques used. evidence is required of two of the following – farm, butcher, storage or transport. Range Outcome 3 Demonstrate knowledge of techniques used to eliminate or reduce the effect of faults on the finished product in leather manufacture. Evidence requirements 3.1 Process for reducing or eliminating the effect of faults on finished leather is described in terms of techniques and their effectiveness on specific faults. Range evidence is required of three processes, which may include but are not limited to – reselecting, buffing, snuffing, shearing, pigmenting, laminating, embossing, trimming. Planned review date 31 December 2019 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 24 September 1996 31 December 2014 Revision 2 23 March 1999 31 December 2014 Review 3 27 April 2000 31 December 2014 Revision 4 20 February 2002 31 December 2014 Revision 5 14 October 2004 31 December 2104 Review 6 14 December 2007 31 December 2015 Review 7 21 February 2013 31 December 2017 Review 8 20 March 2014 31 December 2017 Review 9 19 February 2015 N/A Consent and Moderation Requirements (CMR) reference 0033 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA registered unit standard 8385 version 9 Page 3 of 3 Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the Primary Industry Training Organisation standards@primaryito.ac.nz if you wish to suggest changes to the content of this unit standard. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016