Computer Assisted Orthpaedic Surgery in Adult Reconstructive

advertisement

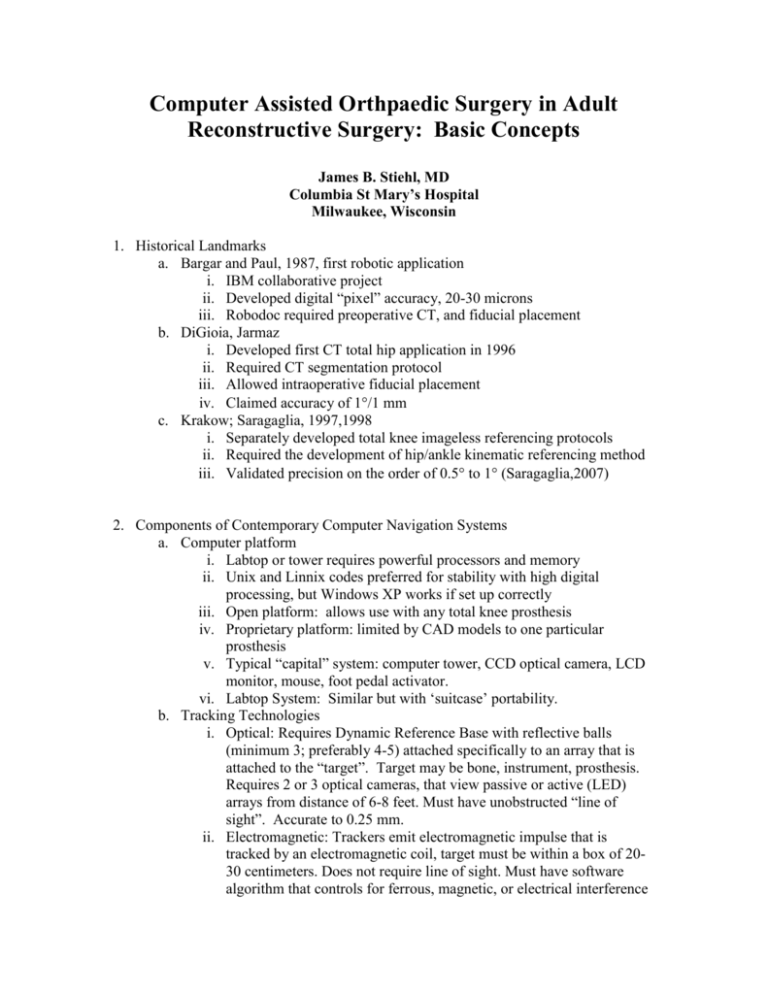

Computer Assisted Orthpaedic Surgery in Adult Reconstructive Surgery: Basic Concepts James B. Stiehl, MD Columbia St Mary’s Hospital Milwaukee, Wisconsin 1. Historical Landmarks a. Bargar and Paul, 1987, first robotic application i. IBM collaborative project ii. Developed digital “pixel” accuracy, 20-30 microns iii. Robodoc required preoperative CT, and fiducial placement b. DiGioia, Jarmaz i. Developed first CT total hip application in 1996 ii. Required CT segmentation protocol iii. Allowed intraoperative fiducial placement iv. Claimed accuracy of 1/1 mm c. Krakow; Saragaglia, 1997,1998 i. Separately developed total knee imageless referencing protocols ii. Required the development of hip/ankle kinematic referencing method iii. Validated precision on the order of 0.5 to 1 (Saragaglia,2007) 2. Components of Contemporary Computer Navigation Systems a. Computer platform i. Labtop or tower requires powerful processors and memory ii. Unix and Linnix codes preferred for stability with high digital processing, but Windows XP works if set up correctly iii. Open platform: allows use with any total knee prosthesis iv. Proprietary platform: limited by CAD models to one particular prosthesis v. Typical “capital” system: computer tower, CCD optical camera, LCD monitor, mouse, foot pedal activator. vi. Labtop System: Similar but with ‘suitcase’ portability. b. Tracking Technologies i. Optical: Requires Dynamic Reference Base with reflective balls (minimum 3; preferably 4-5) attached specifically to an array that is attached to the “target”. Target may be bone, instrument, prosthesis. Requires 2 or 3 optical cameras, that view passive or active (LED) arrays from distance of 6-8 feet. Must have unobstructed “line of sight”. Accurate to 0.25 mm. ii. Electromagnetic: Trackers emit electromagnetic impulse that is tracked by an electromagnetic coil, target must be within a box of 2030 centimeters. Does not require line of sight. Must have software algorithm that controls for ferrous, magnetic, or electrical interference to the electromagnetic impulse from the tracker. This is the current limiting factor for this technology! Accurate to 0.5 mm. iii. Ultrasound: Uses 2D, 2.5D or 3D probes to identify the position of a target landmark, bone, or object. Accurate to 0.25 mm. iv. Video Monitoring: Allows for realtime viewing of DRB movement. c. Referencing Methods: Means of Registering or Describing the “Target” i. Computed Tomography: Used initially for high 3D digital portrayal of the target object. First application was acetabular total hip placement. Requires segmentation of the image and standardization to a known reference frame, ie the anterior pelvic plane of the pelvis in THA. Highly reproducible and accurate to 1/1mm. Most systems utilize a ‘best fit’ validation scheme in the software. Currently requires a preop CT, but future systems with intraoperative CT may allow for ‘automatic’ registration. ii. Fluoroscopic Radiography: Two dimensional registration, that allows for biplanar images of the target object portrayed on screen, on which virtual movement of target objects such as drill or prosthesis may be observed by the surgeon. Requires registration of the images by direct ‘touch pointing’ of anatomical features that can be recognized on the images in real time. Similar accuracy as CT but relies on grid to correct for earth’s gravitational forces, and anatomical features that are specific enough to be precisely identified both on the patient and on the image. iii. Imageless: Requires direct ‘touch point’ matching of specifically predefined landmarks that are recognized by the computer software protocol. Example is the femoral center point in total knee application. One system defines this point as the center of the roof of the intercondylar notch which also is on Whiteside’s line, and the transepicondylar axis. Total knee is one of the applications that allows ready access to landmarks than can be referenced under direct vision. This method is accurate to 0.25 mm. iv. Kinematic: Novel method described for total knee where the femur is marked with a DRB, and then passed in a circular motion to define a cone shaped movement whose center is the center of the femoral head. The computer then identifies the finite projection of the cone which is the center of the femoral head. Similar method defines the transmalleolar axis of the ankle joint. v. Ultrasound: Uses 2D, 2.5D, 3D imaging of ultrasound to define points in space, to a submillimeter accuracy. Problem to date has been the inability to accurately describe broad anatomical surfaces such as the ASIS which lead to errors of 2-5 mm. vi. Bone Morphing: Secondary referencing method where surfaces of the target bone are described and overlayed onto a ‘baseline’ structure such as the distal femur. 3. Validation of Computer Systems: a. Descriptive terms of Standard Metrology i. Unit of Measurement: Value of measurable quantity ii. True Value: Value determined by perfect measurement, considered infinite, as infinite number of measurements needed to determine iii. Conventional True Value: Best guess measure, also ‘ground truth’ or reference value iv. Measurand: Quantity subject to measurement v. Influence Quantity: Sum of slight variance that may occur in measurement, such as identifying the exact edge of acetabular component vi. Accuracy of Measurement: Qualitative assessment of measured value in relation to the true value vii. Precision of Measurement: Closeness of agreement of independent test results obtained under stipulated conditions, such as repeatability or reproducibility, and usually defined as standard deviation. viii. Repeatability: Measurement under identical prescribed conditions ix. Reproducibility: Measurement when one condition is altered in measurement, such as having different observers. x. Error of Measurement: Result of measured value minus the true value of the measurand. xi. Random Error: Measurement of measurand minus the mean after infinite number of measurements. xii. Systematic Error: Mean measurement of measurand minus the true value after an infinite number of measurements. xiii. Random Error equals Error minus Systematic Error xiv. Systematic Error equals Error minus Random Error xv. Correction: Amount added to measured value to correct for systematic error. xvi. Type A Error: Deals with errors created by uncertainty xvii. Type B Error: Error other than statistical error. b. Descriptive Statistics: i. Mean ii. Standard Deviation iii. Experimental Standard Deviation 4. Process Capability Analysis a. After manufacturing process is brought under control assessment of precision or process capbability is done by following formula: Cp Cp (USL - LSL ) 6 b. Where USL and USL is upper and lower specification limits beyond which an outlier is determined. is standard deviation. c. Typical Cp for process capable function is 1.3 d. Where there is offset of measurand from true value, offset capability index is determined: Cpk (USL - x ) ( x - LSL ) Cpk min , 3 3 e. For this measurement, the minimum of either the first or second value is determined, with a goal of at least 2.0 f. This analysis basically determines the 6 or the bell shaped curve for a process, and defines outliers as anything below or above the bell shaped curve. General Electric states that an outlier, beyond the specification limits will occur in 3.4 of 1,000,000 trials. The advantage of this method is that it allows simple calculations that can be applied across a variety of technologies. g. The most difficult aspect of this method is to establish the upper or lower specification limits. For example, we would recommend that the specification limits for mechanical axis alignment in total knee arthroplasty would be 5. Our reasoning, normal knees have been shown to be up to 5 from the mechanical axis. Also Ritter,et.al. has shown that tibial components with 5 of varus will fail. Another biomechanical study has shown that 5 of variation from the mechanical axis creates unacceptable forces in the knee joint. Examples: Bibliography 1. Langlotz F, Nolte LP. Technical Appraoches to Computer-Assisted Orthopedic Surgery. Eur J Trauma 2004;30:1-11 2. Nolte LP, Visarius H, Arm E, Langlotz F, Schwarzenbach O, Zamorano L. Computer-aided fixation of spinal implants. J Imag Guid Surg 1995;1:88-93 3. Stulberg, SD, Picard FD, Saragaglia D: Computer-Assisted Total Knee Replacement Arthroplasty. Operative Techniques in Orthopaedics 2000;10(1):2539. 4. Bathis H, Perlick L, Tingart M, Luring C, Zurakowski D, Grifka J. Alignment in total knee arthroplasty. A comparison of computer-assisted surgery with the conventional technique. J Bone Joint Surg Br 2004;86(5):682-7. 5. Chauhan SK, Scott RG, Breidahl W, Beaver RJ. Computer-assisted knee arthroplasty versus a conventional jig-based technique. A randomised, prospective trial. J Bone Joint Surg Br 2004; 86(3):372-7. 6. Decking R, Markmann Y, Fuchs J, Puhl W, Scharf HP. Leg axis after computernavigated total knee arthroplasty: A prospective randomized trial comparing computer-navigated and manual implantation. J Arthroplasty 2005; 20: 282-8. 7. Stockl B, Nogler M, Rosiek R, Fischer M, Krismer M, Kessler O. Navigation improves accuracy of rotational alignment in total knee arthroplasty. Clin Orthop Relat Res 2004;(426):180-6. 8. Victor J, Hoste D. Image-based computer-assisted total knee arthroplasty leads to lower variability in coronal alignment. Clin Orthop Relat Res 2004;(428):131-9. 9. Sparmann M, Wolke B, Czupalla H, Banzer D, Zink A. Positioning of total knee arthroplasty with and without navigation support. A prospective, randomised study. J Bone Joint Surg Br 2003;85(6):830-5. 10. Kim, S. J., MacDonald, M., Hernandez, J., and Wixson, R. L.: Computer assisted navigation in total knee arthroplasty: improved coronal alignment. J. Arthroplasty 2005; 20:123-131. 11. Jenny JY, Clemens U, Kohler S, Kiefer H, Konermann W, Miehlke RK. Consistency of implantation of a total knee arthroplasty with a non-image-based navigation system: a case-control study of 235 cases compared with 235 conventionally implanted prostheses. J Arthroplasty. 2005 Oct; 20: 832-9 12. Zheng G, Marx A, Langlotz U, Widmer KH, Buttaro M, Nolte LP. A hybrid CTfree navigation system for total hip arthroplasty. Comp. Aid. Surg. 2002; 7:129145. 13. Saragaglia D, Picard F, Chaussard C, et al: Computer-assisted knee arthroplasty: Comparison with a conventional procedure. Results of 50 cases in a prospective, randomized study. Rev Chir Orthop Reparatrice Appar Mot 2001; 87: 18-28. 14. Leenders T, Vandevelde D, Mahieu G, Nuys R. Reduction in variability of Acetabular Cup Abduction using Computer Assisted Surgery: A Prospective and Randomized Study. J Computer Assisted Surgery 2002; 7: 99-106. 15. Bernsmann K, Langlotz U, Ansari B, Wiese M. Computerasistierte navigierte platziernung von verschiedenen pfannentypen in der Huftendorothetik- eine randomisierte kontrollierte studie (in German) Z Orthop Ihre Grenzgeb 139: 512- 16. Bolognesi M, Hofmann A. Computer navigation versus standard instrumentation for TKA: a single-surgeon experience. Clin Orthop 2005; 440: 162-169. 17. Mittelstadt B, Kazanzides P, Zuhars J, Wiliamson B, Cain P, Smith F, Bargar WL. The evolution of a surgical robot from prototype t human clinical use. In: Taylor RH, Lavallée S, Burdea GC, Mösges R, eds. Computer Integrated Surgery; Cambridge: The MIT Press, 1996; 397-407. 18. Honl M, Dierk O, Gauck C, Carrero V, Lampe F, Dries S, Quante M, Schwieger K, Hille E, Morlock MM. Comparison of robotic-assisted and manual implantation of a primary total hip replacement. A prospective study. J Bone Joint Surg (Am.) 2003;85A8:1470-8 19. Jakopec M, Harris SJ, Rodriguez y Baena F, Gomes P, Cobb J, Davies BL. The first clinical application of a "hands-on" robotic knee surgery system. Comput Aided Surg 2001;66:329-39 20. Paul A. Operationsroboter in der Endoprothetik: Wie CAOSPAR Hand an die Hüfte legt. MMW Fortschr Med 1999;141(33):18 21. Jarmaz B, DiGioa AM, Blackwell M, Nikou C. Computer assisted measurement of cup placement in total hip replacement. Clin. Orthop 1998; 354: 70-81. 22. Di Gioia AM, Jamaraz B, Nikou C, LaBarca RS, Moody JE, Colgan S. Surgical Navigation for total hip replacement with the use of HipNav. Operative Techniques in Orthopaedics 2000; 10: 3-8. 23. Anderson KC, Buehler KC, Markel DC. Computer assisted navigation in total knee arthroplasty. J of Arthroplasty 2005; 20: 132-138. 24. Bathis H, Perlick L, Tingart M, Luring C, Zurakowski D, Grifka J. Alignment in total knee arthroplasty. A comparison of computer-assisted surgery with the conventional technique. J Bone and Joint Surg 2004; 86B: 682-87. 25. Kim SJ, MacDonald M, Hernandez J, Wixson RL. Computer assisted navigation in total knee arthroplasty: Improved coronal alignment. J of Arthroplasty 2005; 20: 123-131. 26. Jolles BM, Genoud P, Hoffmeyer P. Computer-assisted cup placement techniques in total hip replacement improve accuracy of placement. Clin Orthop 2004; 426: 175-179. 27. Stiehl JB, Heck DA, Lazzeri MA. Accuacy of the Computer Navigation in Acebatular Component Placement. Computed Assisted Surgery 2005; 10: 321327. 28. Khadem et al. Comparative tracking error analysis of five different optical tracking systems. Comput Aided Surg 2000; 5:98-107. 29. Wiles AD, Thompson DG, Frantz DD. Accuracy assessment and interpretation for optical tracking sytems. Society of Photo Optical Instrumentation Engineers; Proceedings 5367, 2004, pp 1-12. 30. Lionberger R: The Attraction of Electromagnetic Computer-Assisted Navigation in Orthopaedic Surgery, In Stiehl JB, Konermann W, Hacker R (eds): Navigation and MIS in Orthopaedic Surgery, Heidelberg, Germany, Springer Verlag, 2007, pp 44-53. 31. Frantz et al. Accuracy assessment protocols for electromagnetic tracking systems. Phys Med Biol 2003; 48:2241-2251. 32. Milne et al. Accuracy of an electromagnetic tracking device: a study of the optimal operating range and metal interference. J Biomech 1996; 29:791-793. 33. Glossop et al. Accuracy evaluation of the Aurora magnetic tracking system. Comput Aided Surg 2001; 6:112. 34. Haaker RGA, Tiedgen K, Ottersbach A, Rubenthaler F, Stockheim M, Stiehl JB: Comparison of conventional versus computer-navigated component insertion. J of Arthroplasty: July, 2007. 35. Van Hellemondt G, Kleuver M, Kerckhaert A, Anderson P, Langlotz F, Nolte LP, Pavlov PW: Computer-assisted pelvic surgery: A Invitro study of two registration protocols. Clin Orthop 2002; 405: 287-293. 36. Foley KT, Simon DA, Rampersaud YR. Virtual fluoroscopy: computer-assisted fluoroscopic navigation. Spine 2001; 26:347-351. 37. Hinsche AF; Giannoudis PV; Smith RM. Fluoroscopy-based multiplanar image guidance for insertion of sacroiliac screws. Clin Orthop 2001; 395:135-144. 38. Hofstetter R, et.al. Fluoroscopy as an imaging means for computer assisted surgical navigation. Computer Aided Surgery 1999; 4: 65-76. 39. Grutzner PA, Zheng G, Langlotz U, von Recum J, Nolte LP, Wentzensen A, Widmer. C-arm based navigation in total hip arthroplasty-background and clinical experience. Injury. 2004;35 Suppl 1:S-A90-5 40. Tannast M, Langlotz F, Kubiak-Langer M, Langlotz U, Siebenrock K. Accuracy and potential pitfalls of fluorscopy-guided acetabular cup placement. Computer Aided Surgery 2005; 10: 329-336. 41. Suhm N. Intraoperative accuracy evaluation of virtual fluoroscopy – a method for application in computer-assisted distal locking. Comp Aid Surg 2001; 6: 221–224. 42. Richolt JA, Effenberg H, Rittmeister ME: How does soft tissue distribution affect anteversion accuracy of the palpation procedure in image-free acetabular cup navi gation? An ultrasonographic assessment. Comput Aided Surg 2005; 10(2):87-92T. 43. Yau WP, Leung A, Chiu KY, Tang WM and Ng TP: Intraobserver Errors in obtaining Visually Selected Anatomic Landmarks During Registration Process in Nonimage-Based Navigation-Assisted Total Knee Arthroplasty ¡V A Cadaveric Experiment. J Arthroplasty 2005; 20:591-601. 44. Fuiko R, Kotten B, Zettl R and Ritschl P: The accuracy of palpation from orientation points for the navigated implantation of knee prostheses. Orthopade 2004; 33:338-343. 45. Siston RA, Patel JJ, Goodman SB, Delp SL, Giori NJ. The variability of femoral rotational alignment in total knee arthroplasty. J Bone and Joint Surg 2005; 87A: 2276-2280. 46. Robinson M, Eckhoff DG, Reinig KD, Bagur MM, Bach JM. Variability of landmark identification in total knee arthroplasty. Clin Orthop 2006; 442: 57-62. 47. Pitto RP, Graydon AJ, Bradley L, Malak SF, Walker CG, Anderson IA. Accuracy of computer-assisted navigation system for total knee replacement. J Bone and Joint Surg 2006; 88: 601-605. 48. Nogler M, Kessler O, Prassl A, Donnelly B, Streicher R, Sledge JB, Krismer M. Reduced variability of acetabular cup positioning with use of an imageless navigation system.Clin Orthop Relat Res. 2004;(426):159-63. 49. Stindel E., Briard J.L., Merloz P., Plaweski S., Dubrana F., Lefevre C., and Troccaz J., Bone Morphing: 3D Morphological Data for Total Knee Arthroplasty. Computer Aided Surgery 2002; 7:156–168. 50. Stindel E, Perrin N, Briard JL, Lavallée S, Lefevre C, Troccaz J: Bone Morphing: 3D Reconstruction without Pre- or Intra-Operative Imaging: In Stiehl JB, Konermann W, Hacker R (eds): Navigation and MIS in Orthopaedic Surgery, Heidelberg, Germany, Springer Verlag, 2007, pp 36-43. 51. Huitema RB, Hof AL, Postema K. Ultrasonic motion analysis system-measurement of temporal and spatial gait parameters. J Biomech 2002;356:83752. Amin DV, Kanade T, GiDioia AM, Jaramaz B. Ultrasound registration of the bone surface for surgical navigation. Comp. Aid. Surg. 2003; 8: 1-16. 53. Chen K, Abolmaesumi P, Pichora DR, Ellis RE: A system for ultra sound-guided computer-assisted orthopaedic surgery. Comput Aided Surg 2005; 10(5): 281– 292. 54. Kowal J, Amstutz CA, Nolte LP. On B-mode ultrasound-based registration for computer assisted orthopeadic surgery. Computer Aided Surgery 2001; 6: 47. 55. Tobias, E. C. C. a. P.: Engineering Statistics Handbook. 2005. 56. ISO, Guide to the Expression of Uncertainty in Measurement (International Organization for Standardization, Geneva, Switzerland, 1993). 57. Taylor BN, Kuyatt CE. Guidelines for Evaluating and Expressing the Uncertainty of NIST Measurement Results. National Institute of Standards and Technology, Gaithersburg, MD. 58. Kotz S, Johnson NL: Process Capability Indices, Chapman and Hale/CRC; 1993; pp.