Response_Surfaces - The Morbidelli Group

advertisement

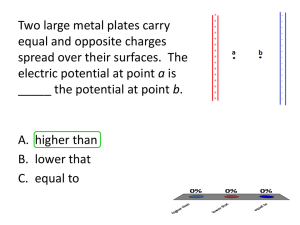

Response Surfaces max(S(b)) Marco Lattuada Swiss Federal Institute of Technology - ETH Institut für Chemie und Bioingenieurwissenschaften ETH Hönggerberg/ HCI F135 – Zürich (Switzerland) E-mail: lattuada@chem.ethz.ch http://www.morbidelli-group.ethz.ch/education/index Response Surfaces Object: Response surface method is a tool to: 1. investigate the response of a variable to the changes in a set of design or explanatory variables 2. find the optimal conditions for the response Example Consider a chemical process whose yield is a function of temperature and pressure: Y = Y(T,P) Suppose you do not know the function Y(T,P) but you want to achieve the maximum yield Y. Marco Lattuada– Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 2 "COVT" Approach "Change One Variable per Time" approach Preliminary remark Experimentation is often started in a region of the parameter values which is far from the optimal. Example Suppose a chemist wants to maximize the yield (Y) of his reaction by varying temperature (T) and pressure (P). He does not know the true response surface, that is Y = Y(T,P), and he starts investigating first the effect of temperature and then the effect of pressure. Alessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 3 "COVT" Approach T 50 60 Contour curves for the yield (Y) 70 Design of experiments 80 Optimum ??? Starting point Optimum !!! Alessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 4 COVT approach assumes the effect of changing one parameter per time is independent of the effect in changes of the others. ThisP is usually NOT true. 2k Factorial Design T 50 60 Contour curves for the yield (Y) Design of experiments 70 80 +1 -1 T Y -1 -1 40 -1 +1 78 +1 -1 59 +1 +1 58 Initial investigation starts with a first order approximation of the response surface +1 Optimum -1 P Alessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 5 P Example: Plastic Wrap Description An engineer attempts to gain insight into the influence of the sealing temperature (T) and the percentage of a polyethylene additive (P) on the seal strength (Y) of a certain plastic wrap. Response function (unknown to the engineer...) Y 20 0.85 T 1.5 P 0.0025 T 0.375 P 0.025 T P 2 2 Objective Maximize the strength of the plastic wrap Suggested starting conditions: Optimal conditions: T = 140°C T = 216°C Alessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 6 P = 4.0% P = 9.2% True Response Surface 300 60 20 280 70 50 30 260 75 40 70 70 60 75 220 75 78 50 78 70 200 180 60 o Temperature ( C) 240 Optimum 70 75 60 160 70 140 60 120 100 0 50 50 Starting point 60 40 30 50 5 10 PE Additive (%) Alessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 7 15 22 Factorial Design t T 140 p P4 20 T 2 P Coded t p 120 2 -1 -1 120 6 -1 +1 160 2 +1 -1 160 6 Initial regression model: +1 +1 Y b0 b1 p b2 t Alessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 8 +1 -1 +1 -1 22 Factorial Design True Response Surface 75 Contour Curves of Y 70 Y 65 60 55 50 45 1 1 0 t 0 -1 Alessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 9 -1 p 22 Factorial Design Experimental Responses 75 70 Y 65 60 55 50 45 1 1.5 1 0.5 0 0 t -0.5 -1 -1 -1.5 Alessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 10 p First Order Regression Regressed Response 80 Y 70 60 50 40 1 t 0 -1 -1.5 Alessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 11 -1 -0.5 0.5 0 p 1 1.5 22 Factorial Design with Center Point t T 140 p P4 20 2 T P 120 2 Coded +1 t p -1 -1 -1 120 6 -1 +1 160 2 +1 -1 160 6 +1 +1 140 4 0 0 Initial regression model: Y b0 b1 p b2 t Alessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 12 +1 -1 Central point does not influence the regression of the slope 22 Factorial Design with Center Point True Response Surface 80 Contour Curves of Y Y 70 Experimental Responses 60 50 40 1.5 1 1.5 1 0.5 0.5 0 t 0 -0.5 -0.5 -1 -1 -1.5 -1.5 Alessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 13 p First Order Regression Regressed Response 80 Y 70 60 50 40 1.5 1 1.5 1 0.5 0.5 0 t 0 -0.5 -0.5 -1 -1 -1.5 -1.5 Alessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 14 p Curvature Center points can give us an indication about the curvature of the surface and its statistical significance Hypothesis: it there is no curvature and the linear model is an appropriate description of the response surface over the region of interest, then the average of the experimental responses in the center point and in the corner points is roughly equal (within the standard deviation) s curv t , n center 2 1 1 var Ycenter 2 n center 2 C E Y center E Y corner s curv CAlessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 15 C+ Tukey-Ancombe Plot 3 2 Residuals 1 0 -1 -2 -3 -4 50 55 60 65 Y Regressed Alessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 16 70 75 Steepest Ascent Direction Experimental Points 1.5 Contour Lines of the Regressed 1st order Surface 1 0.5 Steepest Ascent Direction t 0 Steepest Ascent Direction -0.5 -1 -1.5 -1.5 -1 -0.5 0 0.5 p Alessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 17 1 1.5 Steepest Ascent Direction 80 75 70 Y 65 60 55 50 45 1 0 t -1 -1.5 Alessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 18 -1 -0.5 0.5 0 p 1 1.5 Monodimensional Search 300 280 60 50 20 40 30 70 70 260 75 60 75 78 Monodimensional search 200 75 70 60 T 220 78 240 50 70 70 180 Steepest Ascent Direction 75 60 160 70 140 50 60 60 120 100 0 50 40 50 5 10 P Alessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 19 30 20 15 Monodimensional Search 80 78 76 Y 74 72 Experimental points 70 68 True Response along the steepest ascent direction 66 64 0 1 2 3 4 5 Step Number Alessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 20 6 7 8 9 22 Factorial Design with Center Points 1.5 Maximum of response surface (unknown) 1 Maximum from the monodimensional search t 0.5 0 New 2k Factorial Design -0.5 -1 -1.5 -1.5 -1 -0.5 0 p Alessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 21 0.5 1 1.5 22 Factorial Design with Center Points True response surface 80 Experimental Points 78 76 74 72 70 1.5 1 0.5 0 t -0.5 -1 -1.5 -1.5 -1 Alessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 22 -0.5 0.5 0 p 1 1.5 First Order Regression Regressed Response 80 78 76 74 72 70 1.5 1 0.5 0 t -0.5 -1 -1.5 Alessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 23 -1.5 -1 -0.5 0.5 0 p 1 1.5 Central Composite Design 2k Factorial Design 1.5 Central Composite Design 1 t 0.5 At least three different levels are needed to estimate a second order function 0 -0.5 -1 -1.5 -1.5 -1 -0.5 0 p Alessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 24 0.5 1 1.5 Central Composite Design Y b 0 b 1 p b 2 t b 3 p b 4 t b 5 pt 2 2 80 78 Y 76 74 72 70 1 0 t -1 -1.5 -1 -0.5 0 0.5 1 1.5 p Check Jacobian of the regression to verify the nature of the stationary point Alessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 25 Central Composite Design Tukey-Ancombe Plot 2.5 2 1.5 Residuals 1 0.5 0 -0.5 -1 -1.5 -2 -2.5 73 74 76 75 Regressed Y Alessandro Butté – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 26 77 78 79 Principal Component Analysis (PCA) Consider a large sets of data (e.g., many spectra (n) of a chemical reaction as a function of the wavelength (p)) Objective: Data reduction: find a smaller set of (k) derived (composite) variables that retain as much information as possible p n A Marco Lattuada – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 27 k n X PCA PCA takes a data matrix of n objects by p variables, which may be correlated, and summarizes it by uncorrelated axes (principal components or principal axes) that are linear combinations of the original p variables New axes= new coordinate system. Construct the Covariance Matrix of the data (which need to be first centered), and find its eigenvalues and eigenvectors Marco Lattuada – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 28 PCA with Matlab There are two possibilities to perform PCA with Matlab: 1) Use Singular Value Decomposition: [U,S,V]=svd(data); where U contains the scores, V the eigenvectors of the covariance matrix, or loading vectors. SVD does not require the statistics toolbox. 2) Command [COEFF,Scores]=princomp(data), is a specialized command to perform principal value decomposition. It requires the statistics toolbox. Marco Lattuada – Statistical and Numerical Methods for Chemical Engineers Response Surfaces – Page # 29