Lecture 28

advertisement

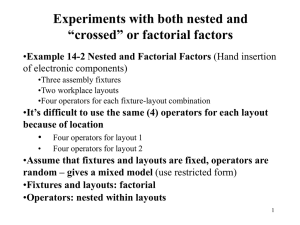

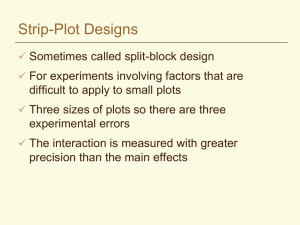

Robust Parameter Design and Process Robustness Studies •Robust parameter design (RPD): an approach to product realization activities that emphasizes choosing the levels of controllable factors (parameters) in a process or product to achieve two objectives: •To ensure that the mean of the output response is at a desired level or target •To ensure that the variability around this target value is as small as possible •When an RPD study is conducted on a process, it is usually called a process robustness study • Four operators for layout 1 • Four operators for layout 2 •Developed by Genichi Taguchi (1980s) 1 Robust Parameter Design and Process Robustness Studies •Before Taguchi, (RPD was often done by overdesign – expensive • Controversy about experimental procedures and data analysis methods (Taguchi’s methods are usually inefficient or ineffective) • Response surface methodology (RSM) was developed as an approach to the RPD problem •Certain types of variables cause variability in the important system response variables (noise variables or uncontrollable variables) 2 Robust Parameter Design and Process Robustness Studies •A robust design problem usually focuses on one or more of the following • Designing systems that are insensitive to environmental factors that can affect performance once the system is deployed in the field • Designing products so that they are insensitive to variability transmitted by the components of the system •Designing processes so that the manufactured product will be as close as possible to the desired target specifications, even though some process variables are impossible to control precisely •Determining the operating conditions for a process so that the critical process characteristics are as close as possible to the desired target values and the variability around this target is minimized 3 Example 14-2 – Minitab Analysis Table 14-12 Minitab Balanced ANOVA Analysis of Example 14-2 Using the Restricted Model 4 The Split-Plot Design 5 The Split-Plot Design • Pulp preparation methods is a hard-to-change factor • Consider an alternate experimental design: – In replicate 1, select a pulp preparation method, prepare a batch – Divide the batch into four sections or samples, and assign one of the temperature levels to each – Repeat for each pulp preparation method – Conduct replicates 2 and 3 similarly 6 The Split-Plot Design • Each replicate (sometimes called blocks) has been divided into three parts, called the whole plots • Pulp preparation methods is the whole plot treatment • Each whole plot has been divided into four subplots or split-plots • Temperature is the subplot treatment • Generally, the hard-to-change factor is assigned to the whole plots • This design requires only 9 batches of pulp (assuming three replicates) 7 The Split-Plot Design Model and Statistical Analysis yijk i j ( )ij k ( )ik ( ) jk ( )ijk ijk i 1, 2,..., r j 1, 2,..., a k 1, 2,..., b Table 14-15 Expected Mean Square Derivation for Split-Plot Design 8 Split-Plot ANOVA Table 14-14 9 Split-Plot ANOVA Table 14-16 Analysis of Variance for the Split-Plot Design Using Tensile Strength Data from Table 14-14 Calculations follow a three-factor ANOVA with one replicate Note the two different error structures; whole plot and subplot 10 Alternate Model for the Split-Plot yijk i j ( )ij k ( ) jk ijk i 1, 2,..., r j 1, 2,..., a k 1, 2,..., b 11 The Agriculture Heritage of Split-Plot Design • Whole plots: large areas of land • Subplots: smaller areas of land within large areas • Example: Effects of variety, field, and fertilizer on the growth of a crop • One variety is planted in a field (a whole plot) • Each field is divided into subplots with each subplot is treated with one type of fertilizer • Crop varieties: main treatments • Fertilizers: subtreatments 12