size and shape

advertisement

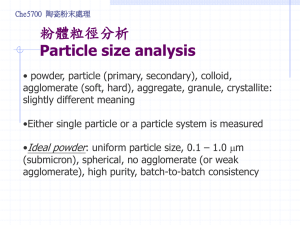

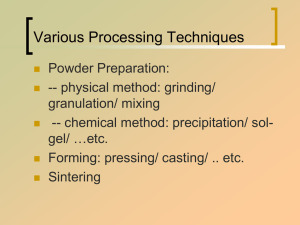

Che5700 陶瓷粉末處理 粉體粒徑分析 Particle size analysis • powder, particle (primary, secondary), colloid, agglomerate (soft, hard), aggregate, granule, crystallite: slightly different meaning •Either single particle or a particle system •Ideal powder: uniform particle size, 0.1 – 1.0 m (submicron), spherical, no agglomerate (or weak agglomerate), high purity, batch-to-batch consistency • Many possible particle shapes: rod, fiber, flake, tube (CNT), flower-like, etc. • If not spherical: need more than one parameter to describe the particle Che5700 陶瓷粉末處 理 Sampling • Be representative!! Need theories from statistical theory • different particles (shape, size, density etc.) – different motion, should be considered during sampling. •Golden Rules of Sampling: (a) samples should be in motion; (b) The whole stream of powder should be taken for many short increments of time in preference to part of the stream being taken for the whole time. • Results highly dependent on sampling techniques!! Grab sample; cone & quarter; Riffling (three experimental methods) From JS Reed, 2nd ed. Che5700 陶瓷粉末處理 Sampling Accuracy •Maximum sampling error: E = 2i/P where i = standard deviation from this sampling; P = weight fraction of material greater than 44μm (40 ppm here) •t = (i 2 + n 2) ½ where n = standard deviation from measurement (total error: substitute i with t); i.e. sampling error + measurement error •example: source: 10,000Kg; sample: 10g for analysis, after classification, particle >44m, Fe impurity (color problem) 40ppm (others = silica particle, 0.5m), estimate sampling error i = [P(1-P)/Ws . (P w1 + (1-P) w2) . (1- Ws/Wb)] ½ Ws =sample weight; Wb = total weight; w1 = impurity particle weight; w2 = main component particle weight result: i = 2.37x10-7; experimental error from sampling E = 1.19%; yet n = 4.0x10-6 (10%) main source of error: measurement, not sampling total error: 20% error size From JS Reed Two-Component Sampling Accuracy If we count particles (instead of measuring weight), then sampling error σi = [p (1-p)/Ns (1- Ns/Nb)] ½ where p = fraction of particles above a certain size Ns = number of particles counted Nb = number of particles in the bulk This equation can also be used in estimating error from public opinion poles; Che5700 陶瓷粉末處理 Different definitions of particle size •Principal concept: equivalent diameter to a sphere; •Equivalent items: e.g. volume, surface area, sedimentation velocity, projected area, (many kinds). • dv volume diameter V = /6 dv3 need particle volume • ds surface diameter S = ds2 .need particle surface • dvs surface volume diameter dsv = dv3/ds2 ..measure specific surface area of particle (per unit volume or unit weight) • Stoke’s diameter dStk same sedimentation velocity as a sphere Che5700 陶瓷粉末處理 Different definitions of particle size(2) • projected area A = /4 da2 • Sieve diameter: passing opening of a sieve (width of square opening) • Martin diameter: mean chord length of projected outline of particle • Feret’s diameter: mean value of distance between pairs of parallel tangents to the projected outline of particles • We often use software to help with analysis of projected images (from SEM, TEM) •Martin diameter: in reality, we can choose several different directions and average the data •Feret diameter: distance between parallel tangents •Statistical diameter From TA Ring, 1996. Coulter counter: Principle when each particle passing through the aperture, it will displace same volume of conducting liquid, resistance then rise the frequency and extent of rise particle size and distribution Problem: two particles passing at the same time, or continuous passing of two particles, particle too large or too heavy, electrolysis, aperture blockage etc. Che5700 陶瓷粉末處理 Microscopic Method • The basis of all techniques, (seeing is believing)!! OM, SEM, TEM •Need standard particles for calibration (e.g. PS polystyrene monodispersed particle from emulsion polymerization) • in association with image analysis software: can handle large number of images, good statistical results •ASTM counting requirements: modal size class at least 25 particles, best 10 in each class, total no less than 100 particles; (another suggestion: 700 particles least) Some Terminology Rayleigh scattering: particle size much smaller than wavelength d<<λ Rθ = Iθ r2/Io = 8 π4α2/λ4 (1+ cos2θ), where α = polarisability = (no/2π)(dn/dc)(M/L); λ = wavelength of incident light; no = refractive index of solvent, dn/dc = change of RI due to concentration, M = molecular weight (measured value), L = Avogadro No. particle size much greater than wavelength: opaque, only scattering, Fraunhofer diffraction Mie scattering: interaction between particle and light (in general 10λ – λ/10) Che5700 陶瓷粉末處理 Optical Methods (Optical counters) •Laser diffraction technique: each particle producing Fraunhofer diffraction effect when passing parallel laser light, intensity of diffracted light ~ (size)2; diffracted angle ~ size. Handles gas (aerosol) or liquid samples. • Sensing volume can be very small such that only one particle counted at a time. 取自粉粒體粒徑量測 技術, 高立圖書1998 Forward scatter, side scatter, back scatter Dynamic Light Scattering (DLS) • Also termed as Photon Correlation Spectroscopy (PCS); or Quasi-elastic Light Scattering QELS) •Electric-filed time correlation function obtained from the scattered light due to motion of particles was analyzed to evaluate the average decay rate: Γ= D q2 • D = diffusion coefficient of particles; •Stokes-Einstein equation: R = kBT/(6πηD) to get particle size (R) • q = (4πno/λo) sin(θ/2); no refractive index of solvent; λo = wavelength of light PCS or DLS 基本上是量測粒子散射光的相對強度, 運動前 後的差別, 利用correlator來分析數據, complex mathematics Uncertainty analysis by dynamic light scattering •source: 機械工業, No 288, 94-100, 2007 • factors of uncertainty: Boltzman constant, wavelength of laser, scattering angle, diffraction coefficient, viscosity of solution, etc. • Based on the experiences of the authors: (以PS standard particles) for 20nm, 100nm & 1000 nm; their uncertainty 3.2 nm, 6.2 nm & 48 nm respectively. Che5700 陶瓷粉末處理 Hydrodynamic Chromatography •Same as other chromatography technique, particles of different size will move at different speed through the column, to become separated and then detected; smaller particles affected more by wall, move at slower rate. disadvantage: low sample recovery (may be trapped), possible interaction between particle and packing material, excessive sample dispersion, relative low resolution etc. Rf = (time of passage of marker)/ (time of passage of colloid) versus colloid size calibration Fluid flow + centrifuge produce separation X-ray Line Broadening •From full width at half maximum of XRD peaks, estimate of crystallite size (an average number); need complex mathematical treatment to get size distribution. •Scherrer equation: d hkl = k /(o cos); k = constant (mostly taken as 0.9 or 1.0; o = width at half height; = x ray wavelength; = diffraction angle (notice 2 ) [in theory: βo2=βm2-βi2, βm = measured breadth, βi = instrument breadth] •Reasons for broadening: small grain size, strain (or disorder) inside, instrumental error - use single crystal (Si) for calibration From JS Reed, 2nd ed. Good instrument and practice should obtain similar results, not easy for one method to dominate. Che5700 陶瓷粉末處理 Shape Factor •Surface or volume shape factor: V = v d3; or S = s d2; = shape factor, dependent on size measurement; αv =π/6; αs = π • shpericity 球形度: = (surface area of a sphere having same volume)/(actual surface area of particle) = (d NV/d 2 NS) • similar definition: circularity = (perimeter of a circle having same area)/(actual perimeter) • aspect ratio (長軸比): for fibers, = (length/ diameter) or (longest to shortest dimension) All particles are hydrous zinc oxide (from different precipitation conditions): Shapes are different Different name for different shapes ψA/ψV index of angularity (shape factor based on area/shape factor based on volume) Acicular: slender and pointed, needle-like 常用於 描述葉子的形狀 * 取自TA Ring, 1996; S/V = St/V . Dav ; 其中St/V = surface area/unit volume (specific surface area, similar to based on unit weight), an easy to measure item (BET data) More Shape Factors •Dynamic shape factor = (d NV/ d st)2 ; same motion resistance as a shpere; d NV & d st = volume equivalent diameter based on number & Stoke’s diameter respectively; •= -½ ( = sphericity) • Simple way to quantify shape and can be related to other properties or processing variables Che5700 陶瓷粉末處理 Fractal Shapes • texture like a broccoli or cauliflower, the particle is fractal; then use fractal shapes, C = circumference (週線) estimated with a ruler of size Cx ~ x 1-D , where D = fractal dimension of particle • In a particle microscopic picture: number of particles in a circle of radius r plot log-log figure (N vs r), slope fractal dimension • Fractal shapes traditionally produced by agglomeration from sol-gel, or flame, plasma synthesis of ceramic powders • particle property related to fractal dimension, e.g. ~ R D-3; A ~ (r )-1 R D; (r = radius, R agglomerate size) o o Taken from TA Ring, 1996 Che5700 陶瓷粉末處理 Size Distributions •expressions: (a) as a figure – (i) cumulative (oversize or undersize); or (ii) frequency – based on number, weight or volume, etc. (b) proper mathematical equations •CNPF: cumulative distribution based on number, percentage finer; CNPL (L = larger than this size) •CMPF: (M for weight) (based on weight) Size interval: linear or geometric (幾何級數or log scale), e.g. 2 ½ Che5700 陶瓷粉末處理 Mathematical Equations •Two most popular equations: •Normal distribution: f(x) = 1/(2) exp[-(x – x)2/22] (two adjustable parameters): x & (average and standard deviation) ∫f(x) dx [from -∞ to ∞] = 1; σ=x(84.13) – x(50) = x(50) – x(15.87) •Log-normal distribution: f(z) = 1/(z2) exp[-(z – z)2/ 2z2] ; z = ln d (similar two parameters) or as f(d) = 1/(lng 2) exp[- (ln(d/dg))2/ 2 (lng)2] dg g = geometric mean size & standard deviation; σg = d 84.13/d 50 = d 50/d 15.87 Che5700 陶瓷粉末處理 More Equations •Rosin – Rammler distribution: f(x) = n b x (n-1) exp( - b xn) ; n & b adjustable parameters, related to particle characteristics, after integration, we get: F(x) cumulative distribution = exp( - b xn) …a simple equation •Gaudin – Schulmann model: w(d) = a n d based on weight (n-1) ; w(d) • Most equations have two parameters, similar results in fitting the true distribution, important question = what is the meaning of the parameters, any physical meaning. From TA Ring, 1996; bimodal distribution Obtained from mixing of two particles with different size distributions, or one type particle from two different formation mechanisms Che5700 陶瓷粉末處理 Mean diameters •Can use “mean”, “modal” (most populous) or median (in the middle or50%) •Mean (or average): several different ways (equations) to calculate it fN(a): number distribution of size a; we can also have number mean diameter Number frequency distribution (n) will be very much different from mass frequency distribution (nd3) * From TA Ring, 1996; e.g. if expect 1% error, for a size interval having 20wt%, we need to count about 400 particles; total error = sampling error + sizing (analysis) error Determine Error of Size Distribution (previous table) • 16-22 μm size interval: Wj = 13%, Nj = 110; Ej = error = Wj/(√Nj)= 1.2% • largest error: 60-84 size interval, only 1 particle counted, Wj = 6.5%, (from figure) Ej = 5% (?) • total error = ET = ΣEj Wj ~ 2% for this case Che5700 陶瓷粉末處理 Characteristics of Agglomerates •Binding between particles: electrostatic, magnetic, van der Waals, capillary adhesion, hydrogen bonding, solid bridge (from atom diffusion) due to sintering, chemical reaction, dissolution-evaporation etc. • strength: may be estimated by methods such as compaction, ultrasonic vibration (indirect); size distribution before and after treatment get an estimation, in theory can be obtained from: primary particle size, coordination number, agglomerate porosity etc. In general: = o exp( - b ); /tho = 1 - From Am. Cer. Soc. Bull., 65, 1591, 1986. conclusion: weak agglomerate provides better sintered density Soft agglomerate vs strong agglomerate Che5700 陶瓷粉末處理 Some methods to break agglomerates • For example: • • • • 研磨 milling 超音波震盪: ultrasonic treatment 分散劑 dispersion agent (chemical method) 高的成型壓力 high forming pressure From Vantage Tech. Corp.