Basic Pump Operations

advertisement

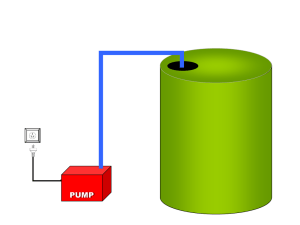

Welcome to Basic Pump Operations ! Basic Pump Operations Hardest class to teach and hardest class to learn WHY ?? Years of doing it one way and unwillingness to change Lack of training Not wanting to look like you don’t know what you’re doing Fear of math Basic Pump Operations Who is the most important firefighter on the fireground ? Pump operator, of course ! Chiefs can give orders, officers can direct, but without the pump operator delivering enough water, the fire wont go out and the situation will not get better Are you comfortable with whomever is the pump operator that day or moment ? Basic Pump Operations The Golden Truth There is a difference between simply being assigned as the pump operator and being a good pump operator Basic Pump Operations Learn From Experience What you should take away from every fire you go to Whether or not you were the pump operator, find out what the static and residual flow pressures were and how much total water was flowing per minute so next time you have a fire in that area, you have an idea of how much water you have to work with Take a practical look at how much fire you had on arrival. If you only end up using tank water for extinguishment, take a look at how much water is left in the tank after the fire is out. See how much water you needed to put out the amount if fire you had when you first arrived. Write down this information in a log of some sort so you remember it months down the line, otherwise you will forget. If you forget, you have lost this information forever. This is something I refer to as ‘negative experience gain’. Don’t let your past experience go to waste. Basic Pump Operations Learn From Experience What you should take away from every fire you go to If you weren’t the pump operator, talk to whomever was and find out if they had any problems and what they did to correct them, if they could. Experiment with your nozzles. Test them under different conditions. Can two of your firefighters hold onto a 1 ¾ line flowing 200 gpm ? Not sure ? You should be ! These are some of the key points to remember so you can be a GOOD pump operator, engine company chauffer, engineer, or what ever your department calls you. Basic Pump Operations What will be covered in this presentation Knowing your response area, equipment, and SOP’s How your pump works The basic steps to pump operations Vehicle positioning Engaging the pump Determining and establishing water supply Priming the pump Calculating total engine pressure Nozzles and flow rates Friction loss Troubleshooting Operating relief valves Practice problems Basic Pump Operations What will not be covered As I mentioned before, this is an introductory course, meant to give you beginning knowledge and add to your current knowledge. There are other topics you should be aware of and know. Some of them I will cover in my advanced class, some I won’t. The following topics will not be discussed in this PowerPoint, I am taking some of these topics out of the IFSTA Pumping Apparatus Driver/Operator handbook, which is an excellent book to purchase: Skills and Physical Abilities Maintenance Emergency Vehicle Driving High Rise/Standpipe & Sprinkler Operation Apparatus Testing Characteristics Of Water Water Shuttles Foam Basic Pump Operations KNOW YOUR…EQUIPMENT Pump and Tank Pump - Hale Tank size - 500 Gallons Pump Capacity - 1750 gpm Manufacturer ? Tank Size ? Pump Capacity ? Pump - Waterous Tank size - 750 Gallons Pump Capacity - 1250 gpm Pump - Hale Tank size - 2600 gallons Pump Capacity - 1250 gpm Basic Pump Operations KNOW YOUR…AREA Water Supply Hydrants Static Sources Water Flow Capabilities Building Construction Type I,II,III,IV,V Maps Single Family Homes Commercial Multifamily Basic Pump Operations KNOW YOUR…SOP’s Past practice may apply Who’s getting the hydrant ? Minimum flow rates ? Who’s taking the nozzle ? Who pumps into a standpipe ? LDH or smaller hose ? Forward or reverse lay ? Basic Pump Operations Basic Pump Operations How Your Pump Works There are several styles of pumps. Early fire department pumpers used what’s called a positive displacement pump. There are two types of positive displacement pumps, piston and rotary. However, centrifugal pumps are used as the main fire pump on today’s fire apparatus. Positive displacement pumps are still used today as part of the priming system. Their capability to pump air makes them ideal for that purpose. We will discuss the centrifugal pump in this presentation. Basic Pump Operations How Your Pump Works Every pump has a plate on it like this one that tells you what the maximum amount of water the pump can flow at 150 psi. All newer pumpers max out their flow at 15o psi. So does that mean that the pump this plate is referring to can only pump a maximum of 1510 gallons per minute ? Basic Pump Operations How Your Pump Works The answer is NO…because of a simple concept known as ‘net pump pressure’ or NPP. This is probably one of the most unknown concepts pump operators will face. Some operators would look at their discharge gauge and see that it was reading 150 psi and think the pump was maxed out, and its not. When pumps get their ratings, they are rated while drafting at about 6 - 8 feet. When receiving additional pressure from a hydrant or other source, the pump can exceed its rated flow. Even at draft it may be possible to exceed its rated flow if multiple intake lines are used. Basic Pump Operations How Your Pump Works NET PUMP PRESSURE (NPP) NPP is the pressure that the pump is creating on its own, without any additional pressure from hydrants, pumper relays, etc. It is the difference between intake and discharge pressure Discharge pressure - Intake pressure = NPP Example: If discharge gauge reads 175 psi and residual intake pressure reads 50 psi, the NPP is 125 psi. The pump is not maxed out, yet. Once the NPP hits 150 psi, the pump is not at its max flow Basic Pump Operations How Your Pump Works REMEMBER !!!! An increase in throttle does not always mean an increase in flow. At some point, as your net pump pressure increases past 150 psi, you will actually be flowing LESS water. So monitor your net pump pressure. If your net pump pressure goes above 150psi, you will be at your maximum pumping capacity. Take a look at the pump plate, and you will see how the flow drops as the pressure increases past 15o psi. Basic Pump Operations How Your Pump Works PTO Pump Basic Pump Operations How Your Pump Works Intakes How Your Pump Works Discharges Impeller Basic Pump Operations Single Stage Pump Intakes Basic Pump Operations How Your Pump Works Dual Stage Pump Basic Pump Operations How Your Pump Works Video from Waterous Company Basic Pump Operations How Your Pump Works Video from Waterous Company The General Pump Operator Steps To Follow 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Position Vehicle - Chock Wheels, When Possible Engage Pump Determine & Establish Water Supply Determine Total Engine Pressure (FL+NP+EL+DL) Open Appropriate Discharge Valve Throttle Up Or Down As Needed To Set Pressure Adjust Pressure Monitor Vacuum Side Of Pump We will follow Monitor Tank Water Level these steps Monitor Pump Temperature throughout the Basic Pump Operations presentation 1. VEHICLE POSITIONING Forward Lay What type of lay you use is largely dependent on what and where your water source is. If you’re using a hydrant for supply, and you are going to pass the hydrant en route to the building on fire, a firefighter will wrap the hydrant and either re-board the engine or stay at the hydrant to turn it on. Check your local SOP on how to handle that situation. Supply Line Attack Line Direction Of Travel Basic Pump Operations 1. VEHICLE POSITIONING Forward Lay A major benefit of a forward lay is that the engine will be parked directly in front of or close to the building on fire, allowing for quick and easy access to your equipment. The downside of the forward lay is that you either have to leave a firefighter at the hydrant or wait for a second in company to complete the connection. The firefighter at the hydrant wont be available for attack or any other operation until their return to the scene. Supply Line Attack Line Direction Of Travel Basic Pump Operations 1. VEHICLE POSITIONING Reverse Lay A reverse lay would be a situation where the engine goes directly to the fire building, drops off firefighters and necessary equipment along with a stretch of the attack line, and then proceeds to the supply source. Supply Line Attack Line Direction Of Travel Basic Pump Operations 1. VEHICLE POSITIONING Reverse Lay The major advantage to the reverse lay is that the attack line stretch is expedited. The major disadvantage is that the all of the equipment is still on the vehicle away from the scene. Supply Line Attack Line Direction Of Travel Basic Pump Operations 1. VEHICLE POSITIONING Communications Regardless of what type of lay you use, its vital that the pump operator has good communication with whomever is either making hose connections to the hydrant (as in a forward lay) or when the attack team is ready for water as in a reverse lay. If your department has a standard hand signal, or radio communication code, to acknowledge that everyone is ready, learn what those are. Supply Line Attack Line Direction Of Travel Basic Pump Operations 1. VEHICLE POSITIONING Some additional vehicle positioning pointers Try to stay out of the potential building collapse zone. Especially on commercial fires where you are pulling into a parking lot. Eyeball the size of the walls and try to keep at least 1.5 times the distance away. Have an idea of how long your supply lines are, specifically the lines you use to make direct hydrant connections when the hydrant is close to where you will be operating. You want enough room to make sure the hose plays out without any kinks. Don’t be nervous about pulling past a building and being ‘too far away’ from the fire because you left the front of the building open for ladder companies to operate. The best thing about hose is that its plenty long and plenty flexible. Its easier to add hose to a stretch than to move fire vehicles around. Basic Pump Operations 2. ENGAGING THE PUMP 1. Position the truck for the best hydrant hookup and discharge hose layout. 2. Bring the truck to a complete stop before you attempt to shift from road to pump. 3. Apply the truck parking brake. 4. Shift the truck transmission to the NEUTRAL position. Wait for the RPM gauge to drop to zero. 5. Move the in-cab pump shift control valve from the ROAD position to the PUMP position. The shift warning lights should come on in a second or two, indicating a complete shift. Basic Pump Operations 2. ENGAGING THE PUMP cont. If the truck manufacturer has used another in-cab valve to achieve pump shift or has an electric switch, follow the instructions supplied with that valve. 6. After pump shift is completed, put the truck transmission in the proper pump operating range or gear. 7. The speedometer should read 5 to 15 MPH after the shift has been completed. If the shift does not seem to be completed, shift truck transmission to “N” and repeat the entire procedure. Basic Pump Operations 2. ENGAGING THE PUMP cont. 8. Exit the driving compartment only after all the above steps are completed and you are sure that the shift completed lights in the cab and panel are on. 9. Chock the wheels DO NOT OPEN THROTTLE UNLESS ALL GREEN PUMP INDICATOR LIGHTS ARE ON. Basic Pump Operations 3. DETERMINE AND ESTABLISH WATER SUPPLY Determine where your water supply is coming from. Either one of the following: 1. Tank 2. Hydrant 3. Tanker Shuttle 4. Relay 5. Pond or Other Static Source Basic Pump Operations 3. DETERMINE AND ESTABLISH WATER SUPPLY Tank Water 1. Typically the initial choice at the scene of a working fire 2. Available until a more steady source is secured 3. Does not last long. A 500 gallon tank flowing 150 gpm will only last a little over 3 minutes. Flowing 250 gpm, you have 2 minutes. 4. Activated by use of tank to pump valve 5. Tanks allow the ability to have foams placed in them and create a pre-mixed solution in order to save time 6. Need to continuously monitor tank water level. 7. Re-fill off hydrant asap to use as backup Basic Pump Operations 3. DETERMINE AND ESTABLISH WATER SUPPLY If operating from tank…. 1. Open tank to pump. Allow 30 seconds for the pump to fill. 2. Priming the pump may be necessary because of trapped air 3. Open appropriate discharge valve 4. Increase throttle to desired pressure 5. Set relief valves if necessary Basic Pump Operations 3. DETERMINE AND ESTABLISH WATER SUPPLY Hydrants 1. Hydrants are usually the source of choice for constant water supply. 2. Flow rates vary, from several hundred gallons to nearly 2000 gpm. 3. Usually located every 300 feet 4. Will determine whether you have a reverse or forward lay 5. Can connect to either front, side or rear of vehicles 6. Must not let residual pressure drop below 20 psi Basic Pump Operations 3. DETERMINE AND ESTABLISH WATER SUPPLY Transitioning From Tank Water To Hydrant At some point, your tank will run empty and you will need to switch over to your alternative water supply. This is a delicate procedure that needs to be practiced routinely. Of course, you should make the switch BEFORE you run out of water. Pressures from the hydrant will most likely vary from what your current total engine pressure. Usually the hydrant will be higher. It will be important to know if your vehicle’s tank to pump (TTP) valve has a check valve that will not allow hydrant pressure to back fill the tank. This was an NFPA requirement dating back to the early 90’s. If this is the case, you may be allowed to leave the TTP valve open when making the switch. Keeping the valve open will allow there to be an unimpeded flow of water if the hydrant were to fail. It would also give the engineer, OIC, and interior teams time to come up with an alternative option or retreating time. Check your local protocol and pump set up. Basic Pump Operations 3. DETERMINE AND ESTABLISH WATER SUPPLY Transitioning From Tank Water To Hydrant Procedure This procedure assumes you are already in pump gear and that you have been flowing water at the appropriate pressure and now notice that your tank water is low enough to begin the switch 1. 2. 3. 4. 5. Open the bleeder valve of the supply line to allow air to escape and not enter the pump Once water is flowing out of the bleeder, close the bleeder Remove the cap off the intake you are using and connect the hose. If you are using a piston intake valve, connect the hose Make sure the hydrant you are using has been flushed and the proper fittings attached according to your SOP Set relief valves Basic Pump Operations 3. DETERMINE AND ESTABLISH WATER SUPPLY Transitioning From Tank Water To Hydrant Procedure 6. Open the hydrant slowly to make the switch. As you are opening the hydrant, you can close the tank to pump, if necessary. You may need to make throttle adjustments. 7. Close tank fill and re-circulating valves after tank has reached full. If tank fill was not open, crack the tank fill until your tank is full, so you have the back-up water if you need it. 8. If discharge lines are shut down at any point after this, re-open tank to pump and tank fill to re-circulate water. Basic Pump Operations 3. DETERMINE AND ESTABLISH WATER SUPPLY If operating from hydrant…. 1. Communicate to firefighter making hydrant connection that you are ready for water 2. Open bleeder valves for the suction line to bleed out air. 3. Open intake valve and read the static pressure, if possible 4. Open appropriate discharge valve 5. Increase throttle to desired pressure 6. Set relief valves if necessary Basic Pump Operations 3. DETERMINE AND ESTABLISH WATER SUPPLY REMEMBER !!!! There is friction loss in supply lines when connected to hydrants, relays, etc. Know how much total water you are discharging and be sure you are not discharging more water than you know is possible as supply from the hydrant. Basic Pump Operations 3. DETERMINE AND ESTABLISH WATER SUPPLY Priming the pump Sometimes air can get trapped in the pump and cause you to ‘lose prime’. Fire pumps are good at pumping water, not so good at pumping air ! Priming is not always necessary If pump is kept wet, priming should normally not be needed Head pressure created by onboard tank and hydrant pressure are usually enough to prime the pump. You must have an open discharge or tank fill open in order for this to work Make sure bleeder valves are open on intake valves to bleed off air. Basic Pump Operations 3. DETERMINE AND ESTABLISH WATER SUPPLY Priming the pump If you need to use the primer valve This would be most necessary if you are drafting from a static water source. 1. 2. 3. 4. 5. 6. 7. Engage the pump Connect hydrant supply hose to truck Open hydrant supply bleeder Close all discharges Engage primer Check for prime - when discharge changes from oil and air to oil and water, you have prime. There may also be a sound change You should a positive change in discharge pressure Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL So how do we determine our required operating pressures ? There are four pieces of information that are listed below that you will need in order to find out what your operating or, total engine pressure needs to be so that you are delivering the appropriate amount of water out of your nozzles The Total Engine Pressure Pie Nozzle Pressure Friction Loss Elevation Loss Device Loss Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL As much as the 4 parts of the total engine pressure (TEP) pie as listed above and on the previous slide are important, the biggest question to ask yourself as you are determining what your TEP will be, is… “What is my flow rate ?” In other words, how much total water will I be flowing out of nozzles, master streams, etc. ? Remember that question because that will always be your starting point in determining TEP. Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL When we talk about total engine pressure what exactly are we talking about ? We are trying to figure out what this gauge on the right should be reading. This is the main discharge gauge usually found on the right side of the pump panel. It usually says ‘PRESSURE’ as opposed to ‘VACUUM’ for the intake gauge. The formula above will give you that answer. Don’t get caught up in friction loss only. Friction loss is only one piece of the pie Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL Nozzles & Nozzle Pressure Nozzles help us determine our flow rate or how much water we are flowing out of the nozzle. ‘Nozzle pressure’ or NP in the formula refers to the amount of pressure required at the nozzle in order for the nozzle to operate properly. Depending on the nozzle, the pressures vary. If a nozzle were to say operate at 100 psi, for example, that means if we put a gauge at the end of the line before the nozzle, it would need to read 100 psi Basic Pump Operations for the nozzle to work right. 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL The smooth bore, fog nozzle debate This is an ongoing debate that will never end. Each side has good points and bad points My own personal suggestions: Heavy, advanced fire and a direct attack = smooth bore nozzle Indirect attack, fog nozzle Foam applications, fog nozzle Standpipe operations, smooth bore Exposure protection, fog nozzle Let your own personal experience dictate which one you choose Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL Smooth Bore Nozzle (Flow rates depend on tip size) 30-300 gpm @ min. 50 psi Basic Pump Operations The smooth bore nozzles resurgence in recent years has led to many firefighters believing this is a do all end all nozzle. As good as this nozzle is, remember the previous slide, which suggests choosing the right nozzle for the right job. The smooth bore offers easy tip adjustment if needed (Stacked tips). Low operating pressures are also ideal for low pressure areas and high rise operations. The reach of the nozzles is also excellent. The resistance to become clogged with small rocks and other debris is an added safety feature. One important point to note is that they operate at 50 psi. It should be noted they operate at a minimum of 50 psi, but they will pump more at higher psi’s. You will get more flow, but higher nozzle reaction, so be careful. 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL Automatic Nozzle Designed to maintain 100 psi (or close to it) at the nozzle and compensate for pressure and flow fluctuations 60-200 gpm @ 100-200 psi Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL Automatic Nozzle As the debates on nozzles go, the automatic nozzle is not far behind the smooth bore in its controversy. The original automatics were created to control water flow fluctuations during master stream operations. The nozzle has a spring loaded baffle that will adjust the stream as the pressure decreases or increases. When the pressure is low, the baffle retracts to ‘tighten’ the stream and increase reach. This had lead to the “good looking stream” with not enough gpm’s. This good looking stream used to be good until departments realized they were sacrificing flow for reach. Reach isn't going to be effective if the amount of water is not enough. Akron Brass actually stopped making this type of nozzle in early 2002. They are bulky and expensive as well. Pump operators and nozzle operators become dangerously unaware of flow changes because of the nozzles ability to automatically adjust. There can be sudden changes in flow that result in sudden changes in nozzle reaction force, which could injure firefighters. Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL Adjustable Gallonage Constant Flow 95-200 gpm @ 100 psi for 1 ¾” 95-250 gpm @ 100 psi for 2 ½” Basic Pump Operations This is one of our standard nozzles, and widely popular in the fire service for it’s ability to provide a fog stream and ‘straight stream’. Mind you that the straight stream on this nozzle is not the same as a stream from a smooth bore nozzle. The nozzle has a ring on it that allows the nozzle operator to adjust the flow as necessary. The pump operator must know what the nozzle is set at. Check your nozzles in the morning to see what they are set at so you can provide the right discharge pressures. Another problem with this nozzle is what I call “Control of the ring” that adjusts the flow. It can accidentally be changed and therefore suffer an unknown change in flow. The firefighters on the line must communicate with the pump operator so the P.O. can adjust the pressure when needed. 4. CALCULATING TOTAL ENGINE PRESSURE Combination Smooth Bore and Fog 1” tip Smooth Bore = 210 gpm Fog Pattern 135 gpm Basic Pump Operations This is a unique nozzle that combines the smooth bore concept and fog concept in one nozzle. It seems like a great idea, but this one falls a bit short. Our department has these nozzles on our engine, but we caution our firefighters NOT to use them on fog for a fire attack due to the low flow, we have other nozzles that are better for that use. We have one on our 2 ½ line and one on our 1 ¾ line, they both flow the same amount !! Bizarre. Can also be dangerous to other departments who may use them and be unfamiliar with them. They could open up in fog thinking they were in smooth bore. Very bulky as well, and do not automatically adjust when switched from smooth bore to fog. 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL What are the operating pressures of our nozzles ? Lets talk about the nozzles we have here first and how they work. Fixed Pressure Fixed Gallonage (AKA Low Pressure Fog) 150 gpm @ 75 psi Basic Pump Operations We have these on the volunteer department I work for. They are nice because of their simplicity. It is one pressure and one set gallonage. Very easy for pump operators to remember. But that can also be part of the problem. You are stuck with one set gallonage. If in the case of the nozzle pictured, you need more that 150 gpm, you are in trouble. There are other styles with higher GPM’s available if that’s what you need. 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL Greater than 300 gpm @ 80 psi Master Streams Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL Combination fog and smooth bore Fixed Gallonage Fixed Pressure 50 and 100 psi 50, 75 and 100 psi Smooth Bore REVIEW Min 50 psi Master Streams Adjustable Gallonage Constant Flow 100 psi 80 psi Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL Friction Loss How do we determine friction loss ? Friction loss is defined as the resistance to flow. In the fire service, friction loss is caused by water coming in contact with the hose, and the water coming in contact with itself. For a given size of hose, the more you try to ‘push’ through it, the more friction loss you get. We measure this loss in pounds per square inch, or psi. Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL How do we determine friction loss ? Friction Loss Formula FL =C*Q2*L C = coefficient Q = gpm/100 L = hose Length Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL How do we determine friction loss ? Friction Loss Formula Of all the methods available for determining friction loss, using the friction loss formula is the hardest for most firefighters to use. You can, however, with constant practice, use this method effectively. It is a great method for pre-determining your specific attack lines. The absolute most exact method to determine friction loss would be to attach in line gauges with flow meters and test your own hose yourself. That’s assuming you have all those items, many fire departments do not. Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE How do we determine TEP = NP + friction loss ? FL + EL + DL Friction Loss Formula Example You are the pump operator and are on the scene of a working fire. You need to determine the friction loss for a 200’ long 1 ¾” line flowing 200 gpm. FL =C*Q2*L The coefficient for 1 ¾” hose is 15.5 FL = 15.5*Q2*L Q is gpm/100 then squared FL = 15.5*(200/100)2*L L is length/ 1oo FL = 15.5*(200/100)2*200/100 So… FL = 15.5*4*2 Finally FL = 124 psi Basic Pump Operations FL =C*Q2*L C = coefficient (listed below) Q = gpm/100 L = hose Length Coefficients 1” hose is -150 1.5" -24.0 1.75"-15.5 2" - 8 2.5" -2 3" -0.8 4" -0.2 5" -0.08 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL How do Slide Calculator we determine slide calculator is a good way to determine friction friction The loss. The problem with the calculator is, is you have to buy one. I use the one pictured above, made by Akron Brass. loss ? They are about 20 dollars or so. Basic Pump Operations 4. CALCULATING TOTAL ENGINE How do we determine friction PRESSURE Slide Calculator loss ? So where do we start when determining friction loss using the slide calculator ? Same place we start with every other method, yes, you should know it by now, we start with the question “What is our flow rate ?” The calculator will help you determine what your flow rate is if you’re not sure, but only if you’re using a smooth bore nozzle. Otherwise you will need to find that information out. Basic Pump Operations 4. CALCULATING TOTAL ENGINE How do we determine friction loss ? PRESSURE Slide Calculator 1 2 3 4 5 If you want to know what you are flowing using a smooth bore nozzle, go to the side of the calculator shown above. On the top of the calculator, set your nozzle pressure (arrow 1), in this case it is set at 50 psi for a handline. Go to line 2 and locate the tip size listed just above the line that you are using. Lets say we are using a 7/8” tip. Locate 7/8” above line 2. The number below 7/8” will indicate your flow rate for a 7/8” tip smooth bore nozzle at 50 psi. Which in our example would be 160 gpm. I will explain lines 3,4, and 5 later. Basic Pump Operations 4. CALCULATING TOTAL ENGINE How do we determine PRESSURE Slide Calculator friction loss ? 1 2 3 All right, so we know what our flow rate is, what’s next ? Flip the calculator over to the side listed above with “U.S. GPM FLOW” on top. In line 1, slide the calculator over to the appropriate flow rate, in this example we are using the 160 gpm number from the previous slide. Go to line 2 and locate the hose size in the white section. The handline, for the example, is let’s say an 1 ¾” line. If you follow the 1 ¾” mark to the numbers above, you will see the number 40. So, 40 psi would be your friction loss PER 100 feet. If we were using a 200 foot line, our example would have an 80 psi total friction loss, 40 psi for each 100 foot section. Basic Pump Operations 4. CALCULATING TOTAL ENGINE How do we determine PRESSURE Slide Calculator friction loss ? 1 2 3 The list of black numbers just below line 2 would be the numbers you would use if you were using multiple lines to supply the given flow rate. For example, if you were using 2 lines to flow our 160 gpm, (we were using 1 ¾” lines) the friction loss would be 10 psi. You do have to use the same size lines to use this part of the slide calculator. Line 3 would be used for 3 or 4 lines to supply a given flow rate. Basic Pump Operations 4. CALCULATING TOTAL ENGINE How do we determine friction loss ? PRESSURE Slide Calculator 1 2 3 4 5 Getting back to lines 3,4, and 5 from the “NOZZLE PRESSURE” side of the calculator. This side of the calculator, if you remember, allows you to determine flow rates. Lines 3,4, and 5 let you know what your flow rates are for fog nozzles when you either over or under supply the tip. We know nozzles operate at different pressures, but if for some reason your supply pressures cant supply 100 psi at the nozzle (If that is the operating pressure of the nozzle), you can flow them at under that amount. Basic Pump Operations 4. CALCULATING TOTAL ENGINE How do we determine friction loss ? PRESSURE Slide Calculator 1 2 3 4 5 Using the above example, let’s say you are using a fog nozzle that operates at 100 psi. You don’t have enough pressure to maintain that 100 psi operating pressure, so you decide to operate it at 50 psi. Go to line 3. If the nozzle is set at 125 gpm on the collar (or whatever the flow rate), look at line 4 to see what you are actually flowing. In reality you would be flowing about only 90 gpm. If you had a nozzle that operates at 75 psi, go to line 5. A 75 psi nozzle operating at 50 psi with the collar set at 125 would only be flowing about 100 gpm. Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL How do we determine friction loss ? Pump Chart Flow charts are usually ‘home made’ items that someone in your department ends up making. You can put whatever information on your charts you would like. Coming up in the following slides, I will explain how to use the charts I created. Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL How do we determine friction loss ? Pump Chart The pump chart has, for me, become my method of choice for determining friction loss. I enclosed a copy of the pump chart we use here in my department. Keep in mind these are theoretical flows. For them to be perfect, you would need to flow test your own hose. However, I have used these numbers repeatedly for years and they are near exact, varying maybe by about 5 psi when used with our flow meters to confirm. Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL Pump Chart To use the pump chart I have provided, use the following steps: 1. There are two charts on the page. The chart on top is needed when using smooth bore tips. If you are using any other nozzle, go to chart 2. 2. Determine what your flow rate is, depending on the nozzle. If you are using a smooth bore, locate the psi you will be using on the left side, usually 50 psi for handlines and 80 psi for master streams. Then locate the tip size on the top. The point they intersect will be the flow rate. Take that number to chart 2. 3. Start by locating the closest flow rate in GPM on the left hand side. If the rate is not exact, you can move to the next highest number. Next, locate the hose size across the top. The point they intersect will be the friction loss per 100 ft. of hose. Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL Pump Chart To use the pump chart I have provided, use the following steps: 4. I listed information on the side I felt was helpful to me and my department. I included total engine pressures for some of our pre-connects. It seems like that would not be necessary since the charts you need to come up with those answers are right next to you. This was just something I did, if you want to do something else, please do so. Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL Elevation Loss What is the elevation loss for this building ? For every floor, add 5 psi to your calculation. If you're going downhill, for every 10 ft, subtract 5 psi Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL Device Loss As water passes through objects such as deck guns, portable monitors, gated wyes, gated manifolds, etc, there is pressure loss. This can be figured anywhere from 5 psi for a small gated wye to 25-35 psi for manifolds Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL Practice Problems Problem 1 You arrive on the scene of a working house fire and are ordered to stretch a 200 foot 2 ½” attack line. The line has a fixed pressure, fixed gallonage (FP/FG) nozzle. What is your discharge pressure ? Assume your nozzle is a 75 psi 250 gpm Problem 2 En route to a car fire on I-71, you are told by the OIC that you will be stretching the front bumper line to fight the fire. The line is a 150 foot long 1 ¾” line with an adjustable gallonage constant flow nozzle set at 150 gpm. What is the discharge pressure ? Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE TEP = NP + FL + EL + DL Problem 3 Practice Problems The ‘Smithville FD’ is requesting mutual aid to The Regal Park Apartment Building in their city for an apartment fire. You are the pump operator and arrive on scene to find fire blowing out of the 3rd floor window. Their captain has ordered your company to stretch a 250 foot 2 ½” attack line with a 1” tip smooth bore nozzle on it. What is your discharge pressure ? Problem 4 The tones go off at 3 a.m. for a large fire at the nearby lumber company. While en route, you are ordered by the chief already on scene to set up for master stream operations. What would be your discharge pressure ? Your master stream tip is 1 3/8”. Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE Practice Problems Answers Problem 1 You arrive on the scene of a working house fire and are ordered to stretch a 200 foot 2 ½” attack line. The line has a fixed pressure, fixed gallonage (FP/FG) nozzle. What is your total engine pressure ? Assume your nozzle is a 75 psi 250 gpm model. ANSWER : 101 psi (using the pump chart and friction loss calculator) Explanation of pump chart method below First question to ask yourself, “What is my flow rate ?” ..the answer is in this case 250 gpm. Using the chart, you can skip the first chart because this isnt a smooth bore nozzle so go to chart 2. Find 250 gpm on the left hand side. Follow it over to the 2 ½ “ hose, and you will see 13, for 13 psi loss per 100 feet. Since there is 200 feet here, you double the 13 psi to get 26 psi friction loss. 26 psi plus the 75 psi for the nozzle, with no elevation loss or gain and no device loss, puts you at a total discharge pressure of 101 or simply 100 psi. Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE Practice Problems Answers Problem 2 En route to a car fire on I-71, you are told by the OIC that you will be stretching the front bumper line to fight the fire. The line is a 150 foot long 1 ¾” line with an adjustable gallonage constant flow nozzle set at 150 gpm. What is the discharge pressure ? ANSWER : 145 psi (using the pump chart and 154 psi using the slide calculator) Slide rule explanation below On the side of the slide rule with the U.S. GPM FLOW on top, slide the calculator over to the 150 mark. Go to the middle white row section, the one just below the white U.S. GPM FLOW section. Find the 1 ¾” mark in the block. Locate the amount of friction loss on top of the block, denoting a single line flow. Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE Practice Problems Answers Problem 3 The ‘Smithville FD’ is requesting mutual aid to The Regal Park Apartment Building in their city for an apartment fire. You are the pump operator and arrive on scene to find fire blowing out of the 3rd floor window. Their captain has ordered your company to stretch a 250 foot 2 ½” attack line with a 1” tip smooth bore nozzle on it. What is your discharge pressure ? ANSWER : 85 psi (both the pump chart and slide calculator were nearly identical) Your flow rate here is 210 gpm. You figured that out by starting with chart 1, since you are using a smooth bore nozzle at 50 psi, the minimum pressure. Take your 210 gpm and go to chart 2. Find the closest match to 210 gpm. In this case you round up to 220. Follow that over to the 2 ½” block, and you will see 10 psi friction loss per 100 feet. For a 250 foot line, that would be 25 psi loss. There are 3 stories, but 2 above the ground floor. You can include or exclude the first floor, the 5 psi difference should not be too detrimental. Excluding it, you have 10 psi elevation loss. There is generally considered to be no friction loss in the standpipe, usually a 4” line. So add the 25 psi for friction loss, 10 psi for elevation, and 50 psi for the nozzle, and you get 85 psi. Basic Pump Operations 4. CALCULATING TOTAL ENGINE PRESSURE Practice Problems Answers Problem 4 The tones go off at 3 a.m. for a large fire at the nearby lumber company. While en route, you are ordered by the chief already on scene to set up for master stream operations. What would be your discharge pressure ? Your deluge/ deck gun master stream tip is 1 3/8”. ANSWER : It varies, but approximately 95 psi The reason this answer varies is because of the device loss. I have routinely used 15 psi friction loss as my deluge gun friction loss standard. Otherwise, this is a pretty easy one to figure out. Your nozzle is a 1 3/8” tip smooth bore. Go to chart one and find 1 3/8”. Remember, master streams operate at a minimum of 80 psi. In this case, there is no hose friction loss, just device loss. So 80 psi for the tip, and 15 psi for the device puts you at 95 psi. Keep in mind, if you have a master stream device with fog nozzles on them, it’s a distinct possibility they operate at 100 psi. Basic Pump Operations Operating The Relief Valve The main function of the relief valve is to divert excess pressure surges from the firefighters operating on the attack lines. Common Misconceptions Regarding The Relief Valve The valve does not dump water onto the ground. It sends the water back into the suction side of the pump The spring does not develop a memory. You can leave it preset. Some vehicles have a pressure governor that controls pressure surges by reducing the rpm’s of the engine. More on the pressure governor in later slides Basic Pump Operations There are actually two types of relief valves. Most are familiar with the DISCHARGE relief valve. There is also an INTAKE relief valve. Operating The Relief Valve Pilot Valve 4 Way Valve Often confused with the relief valve, the pilot valve controls the relief valve Basic Pump Operations Operating The Relief Valve The main function of the relief valve is to divert excess pressure surges from the firefighters operating on the attack lines. Pilot Valve Often confused with the relief valve, the pilot valve controls the relief valve Basic Pump Operations Operating The Relief Valve BEFORE YOU SET THE RELIEF VALVE… 1. There has to be a 50 psi differential between intake and discharge pressure 2. If your required discharge pressure is below 90 psi, the relief valve will not work 3. You must have multiple lines flowing in order for it to work. Tank fill can be one of the lines. Basic Pump Operations Operating The Relief Valve 1. After making sure the previous rules are checked, go back to your discharge gauge and make sure the pressure is correct. 2. Increase your throttle to go about 5 psi above your operating pressure. This is done so that the relief valve doesn’t open for minor pressure surges. Lets pretend that our operating pressure is 15o psi. In this case we would set it to 155 psi. 3. For the Waterous relief valve, you would switch the on/off switch (4 way valve) to the on position. For the Hale, continue to step 4. 4. Make sure the light is not on to indicate that the valve is open. If it is, you will need to increase the pressure to get the light to turn off. 5. With the light off, rotate the control knob counter-clockwise until the light comes on. Basic Pump Operations Operating The Relief Valve 6. When the light comes on, stop and rotate the control knob clockwise until the light goes off. Once the light goes off, rotate the handle back about a half turn back counterclockwise. The relief valve is now set. Basic Pump Operations Operating The Relief Valve This is a diagram of the entire relief valve system. In this example, the diagram is showing the flow of water when the relief valve opens in a pressure surge situation. Basic Pump Operations Operating The Relief Valve I have a demonstration on the next slide of how to operate the relief valve. The demo will begin once you click the slide. As the demo starts, each step described along the right side will blink. After the blink is over, you will see the operation occur. There will be a 5 second delay inbetween steps. Basic Pump Operations Operating The Relief Valve 1. 2. 3. 4. 5. Increase your throttle to 155 psi, 5 psi above our example of 150 psi . Turn on/off switch to the on position Rotate pilot valve counterclockwise until open light comes on. When the open light comes on, rotate the pilot valve slowly clockwise until the open light turns off and the closed light comes on Once the closed light comes on, rotate the pilot valve counterclockwise ½ Basic or 1Pump full Operations turn 5-7. Open Appropriate Discharge 1. Check to see which line needs to be opened. SLOWLY open the line and adjust pressure. 2. If multiple lines need to be opened, you need to determine the operating pressure for all the lines. 3. Find the line that has the highest operating pressure and set the main discharge for that pressure. 4. Use the controls and gauges for the other lines and gate them down to the proper pressure. Always open and close all valves slowly ! Basic Pump Operations 8-10. Monitor 1. Monitor your vacuum pressure. Make sure your residual pressure pressure does not drop below 20 psi. 2. Monitor tank water level 3. Monitor pump temperature 1. Recirculate pump water to prevent overheating a. Use recirc valve b. crack tank to pump ½ way 2. Feel your intakes for heat build up BAD RANGE Basic Pump Operations Pressure Governors This Replaces This Today’s newer fire apparatus may contain what is called a pressure governor. The pressure governor is an electronically controlled device that does a number of functions. It’s primary function is to control the pressure of the pump. It does this by way of controlling the engine RPM’s. It also acts as a replacement for the discharge relief valve. When an attack line is shut down, the governor will react by decreasing the RPM’s. You set the discharge pressure by pressing an up or down button. There are many different types of governor’s, so you will have to acclimate yourself to the type of governor you have. The one I’m familiar with is the Class 1 Captain Pressure governor, which is picture above in the left hand corner. It takes time to get used to these, especially some if you’re used to the old style vernier throttles. We will review the Captain And This governor and its operation. Basic Pump Operations Pressure Governors 1. Follow all previous instructions and department SOP’s on getting your pump into gear and to the point you are out of the vehicle and now in front of the pump panel. 2. When initially powered on, the pressure governor will default to [MODE] on the display. If you are going to operate from the tank or a hydrant for your INITIAL water supply, you should start in pressure mode. 3. If drafting from a static water source such as pond or tanker shuttle, you should start in RPM mode. 4. Press the [MODE] button once to go into pressure mode. The display will read ‘pressure’. After you have figured out what your total engine pressure should be, you can either select your preset button or throttle up using the yellow ‘INC’ and ‘DEC’ buttons. You will have to determine what your factory set ‘preset’ pressure is. 5. Open appropriate discharge valves and the governor will automatically throttle up to adjust. 6. Gate back the controls as necessary on other attack lines to their appropriate pressure. Basic Pump Operations Pressure Governors Items To Be Aware Of When Using A Pressure Governor DO NOT fall victim to the belief that you can hit the preset button and walk away. The preset on the attack lines on our engine where I work is the incorrect pressure for all of the lines. Make sure that you are in PSI mode when attack lines are in use, or you will not have the protection of the governor for pressure spikes. If on hydrant pressure alone, you will NOT have pressure surge protection, regardless of what mode the governor is in. When making the transition from tank to hydrant, you need to switch to RPM mode and throttle down, the manufacturer does not feel the governor can react quickly enough to hydrant surges to offer the optimal protection It it also critical to rid your mind of the commonly heard phrase “Set it and walk away”. Despite the fact pressure governors help us out, you as the pump operator are still responsible for any problems, and problems can occur. Please take the time to look over the owners manual and know what to do when certain prompts appear on the display. Basic Pump Operations TROUBLESHOOTING Troubles with pumping can usually be traced back to one of four problem areas 1. Procedural 2. Supply 3. Pump 4. Discharge Procedural problems Somehow a problem or procedure specific with your fire engine during pump engagement such as switch, lever, was not properly done. Go back and check pump switches, make sure pump engaged and ok to pump lights are on Basic Pump Operations TROUBLESHOOTING 1. Procedural 2. Supply 3. Pump 4. Discharge Even though we discussed procedural problems first, the best way to troubleshoot pump problems is to back track the water flow from the point of the problem back to the source. The 3 final causes of trouble are best solved by using this method. Basic Pump Operations TROUBLESHOOTING 1. Procedural 2. Supply 3. Pump 4. Discharge Supply Problems How do you know you are having a supply problem to begin with ? Monitor your intake gauge. Make sure the residual pressure does not drop below 20psi. If it does, it’s supply troubleshooting time. If you allow the pressure to drop below zero, you will cavitate the pump. Cavitation is the grinding sound the pump will make when there is no or low water in it. This can cause irreversible damage to the pump and bring the operation to a complete stop. DO NOT ALLOW THIS TO HAPPEN ! Cavitation can occur while using any water source, not just a hydrant. In this powerpoint, we will address tank and hydrant supply problems When deciding how to solve your supply problem, remember, back track your supply until you reach the source Basic Pump Operations TROUBLESHOOTING 1. Procedural 2. Supply 3. Pump 4. Discharge Supply Problems How do you fix supply problems ? Start by determining what your water source is, which hopefully shouldn’t be hard! Either tank, hydrant, static source (drafting), pumper relay, or tanker shuttle. We will start with tank problems. Is the tank to pump valve completely open and did you lock it open ? Are there valves open that could be ‘stealing water’ and draining your supply quicker than you anticipated ? Check tank fill, main pump drain, and other discharges Did you check that the tank was full prior to starting the operation ? There may be air in the pump. Pull the primer for no more than 30 seconds until you see an increase in the discharge pressure. Basic Pump Operations TROUBLESHOOTING 1. Procedural 2. Supply 3. Pump 4. Discharge Supply Problems How do you fix supply problems ? On to hydrant problems. Many of the issues we discussed with tank problems can also be the cause of hydrant supply issues. Check the previous list. Firefighters making hydrant connections can get overexcited and not completely open the hydrant. Make sure the hydrant is open completely. I feel the biggest cause of supply problems are kinks in the line. This results from what I call an ‘improper supply stretch’. We practice stretching ATTACK lines, but rarely do we practice our supply stretch. I don’t specifically mean forward and reverse lays. The kinks tend to occur when the hydrant is close to the building on fire. The pump operator must get comfortable with however long the supply lines are and position the truck in such a way that the hose has enough room to fully play out. Basic Pump Operations TROUBLESHOOTING 1. Procedural 2. Supply 3. Pump 4. Discharge Supply Problems How do you fix supply problems ? Make sure the valve that allows water to enter the pump from the hydrant is fully open. One of the final items to check would be the strainer on the intake that protects the pump from debris from hydrants, drafts, etc. A piece or several pieces of something may be blocking the strainer. If you have checked everything else and nothing else seems to be wrong, you will have to check the strainer. This is an especially difficult event because if you have a piston intake valve like the one pictured above, its going to require a lot of work to remove. Basic Pump Operations TROUBLESHOOTING 1. Procedural 2. Supply 3. Pump 4. Discharge Pump Problems Pump problems usually focus on the pump not being in gear or somehow not engaged properly. Once you have determined that you do not have a supply problem, you can move to pump problems. Check your pump panel lights and make sure that they are all on and indicating that it is “OK to pump” Go back into the cab and check to see that the vehicle is in the appropriate drive range Was there an increase in MPH when you engaged the pump ? Is there one now ? Basic Pump Operations TROUBLESHOOTING 1. Procedural 2. Supply 3. Pump 4. Discharge Pump Problems If you are having problems engaging the pump, you may have to use the manual pump shift. This is a procedure that may require two people to correct. The procedures for this operation vary, so check with your owners manual’s and SOP’s. Look underneath the vehicle to see if the drive shaft is spinning. If its spinning very slowly, the pump is probably not engaged. Below is a picture of our 1990 Pierce Lance on the right and 1979 Sutphen Tower on the left. Basic Pump Operations TROUBLESHOOTING 1. Procedural 2. Supply 3. Pump 4. Discharge Discharge Problems Discharge problems begin from the time the water leaves the pump and exits the nozzle. If the previous 3 troubleshooting areas are ok, you may be having discharge problems. Most of the discharge problems will revolve around hose. If the attack team is asking for water, and you have opened the discharge, you could have the following problems Check to see that the proper valve is opened. Sometimes names used to identify specific lines can be confusing. Crosslays and speedlays are commonly mixed up. Know what your flow pressures are and always monitor them. If, for example, No. 1 discharge was supposed to flow say, 150 psi and its now its flowing at 50 psi and the master discharge is still at 150 along with the hose team asking for water and you don’t notice any significant increase in pressure with an increase of the throttle, you may have a burst line. Basic Pump Operations TROUBLESHOOTING 1. Procedural 2. Supply 3. Pump 4. Discharge Discharge Problems If the attack team is asking for water and the gauge, as in our example, on the No. 1 discharge is reading the same as the master discharge gauge, you have a blockage. The blockage could be in the form of a kink, a vehicle on the line, or an obstruction right at the nozzle, or the nozzle somehow has broke and or malfunctioned. Find and fix the kink if you can or have the attack team find the kink. If you don’t have pre-connected lines, its possible that someone connected a line to an intake. See the pictures below to help remember the difference. Both are intakes, as indicated by the female connection. The right picture has the cap off Basic Pump Operations