ppt-file

advertisement

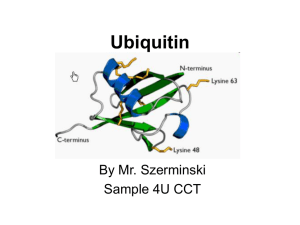

Elementary-Modes Analysis of Lysine Production in Corynebacterium glutamicum and Escherichia coli Stefan Schuster and Axel von Kamp Friedrich Schiller University Jena, Dept. of Bioinformatics Ernst-Abbe-Pl. 2, 07743 Jena email: (schuster, kamp)@minet.uni-jena.de Introduction Elementary (flux) modes serve as a mathematical formalization of metabolic pathways and describe potential simple flux distributions in metabolic networks at steady state [1]. Here, we apply this method to finding the potential pathways and associated molar yields in lysine production in C. glutamicum and E. coli. The essential amino acid, lysine is of great technological interest. Chemical structure of lysine First reaction scheme Pathway with the best yield Second reaction scheme Lysine production in C. glutamicum, based on [3]. Here, enzymes belonging to the same enzyme subset have been lumped. In addition to E. coli, the malic enzyme and the carboxylating and decarboxylating enzymes linking Pyr with OAA are included. External metabolites: lysine, acetate, glucose, NAD/NADH, O2, CO2 and NH3. By contrast, the cofactors ATP/ADP, and NADP/NADPH are here internal. This scheme gives rise to 36 elem. modes producing lysine [4]. 2 modes only use glucose as a substrate (yield: ¾), five modes only use acetate, and 29 use both. The optimal lysine over glucose yield of ¾ coincides with earlier results obtained by metabolite balancing in [3]. It is understandable that the yield is lower than when ATP and ADP are external (cf. first reaction scheme) because part of the glucose is needed for synthesizing ATP. The optimal lysine over acetate yield is ¼. References First, the TCA cycle, glyoxylate shunt and some adjacent reactions of amino acid metabolism in E. coli are considered. The carbon source 2-phosphoglycerate (PG), CO2, NH3, the produced amino acids and all cofactors such as ATP, ADP etc. are considered “external”. For this scheme, we computed, by the program METATOOL, 14 elementary modes, four of them producing lysine [2]. Molar lysine over glucose yields: 1, 2/3, 2/3 and ½. [1] S. Schuster, T. Dandekar, D.A. Fell (1999) Trends Biotechnol. 17 53-60. [2] S. Schuster (2004) In: Metabolic Engineering in the Post Genomic Era (B.N. Kholodenko and H.V. Westerhoff, eds) Horizon Scientific, Wymondham, pp. 181-208. [3] A.A. de Graaf (2000) In Bioreaction Engineering, Modelling and Control (ed. K.B. Schügerl, K. H.), pp. 506-555. Springer, New York. [4] S. Schuster, A. von Kamp, M. Pachkov (2005) In: Metabolomics, Methods and Protocols (W. Weckwerth, ed.) Humana Press, Totowa (NJ), in press.