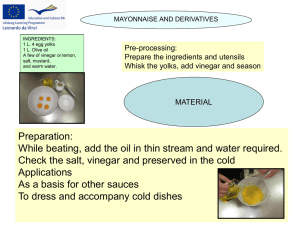

Mayonnaise & Margarine

advertisement

Mayonnaise & Margarine Presented by: Kar-Chan Choong Joseph Dorsheimer Barry McLaughlin Anthony Zientek Introduction • General definitions of mayonnaise and margarine • Food Chemistry – Regular and low-fat mayonnaise – Margarine • Surface Phenomena of mayonnaise and margarine – Basic emulsion theory Introduction (continued) – Regular and low-fat mayonnaise formulation – Margarine formulation • Processing Considerations – Regular and low-fat mayonnaise – Margarine • Conclusions – Product cost and sales History Margarine 1813 Mayonnaise 1756 General Definitions • Mayonnaise is an emulsified semisolid food prepared from: – – – – Vegetable Oil(s) 1 or both Acidifying Ingredients 1 or more Egg Yolk Containing Ingredients 1 or more of the Optional Ingredients • Contains not less than 65% by weight of vegetable oil General Definitions • Margarine is the food in the plastic form or liquid emulsion containing: – 1 or more edible fats and/or oils or mixtures of these – 1 or more aqueous phase ingredients • 1 or more of the optional ingredients can be added to the aqueous phase ingredients – Vitamin A in an amount not less than 15000 international units per pound • Contains not less than 80% fat as prescribed by the “official methods of analytical chemists” Suppliers • Mayonnaise – Kraft – Unilever • Hellmann’s, Best Foods – Better Brands • Allen, Nugget – Shurfine • Shurfine, Shurfresh, Ultimate Choice, Price Saver – Private Label Companies Suppliers • Margarine – ConAgra Foods • Nabisco Tablespreads Company – Fleischmann’s, Parkay, Blue Bonnet, Touch of Butter, Chiffon, Move Over Butter – Unilever Foods • I Can’t Believe It’s Not Butter, Shedd’s Spread Country Crock – ADM • Gold’N Flavor – Ventura • Saffola – Private Label Companies Food Chemistry of Regular Mayonnaise CH3(CH2)xCOOH Whole Eggs Egg Yolks H2O CH3COOH NaCl C12H22O11 Lemon Juice (C10H16O8N2)-Ca-Na2 Food Chemistry of Low/Reduced-Fat Mayonnaise H2O x-O-C6H8O2-O-C6H8O2-O-x Egg Whites NaCl Mustard C6H5COONa CH3(CH2)xCOOH C12H22O11 CH3COOH (C6H10O5)x (C35H49O29)x (C10H16O8N2)-Ca-Na2 Food Chemistry of Margarine CH3(CH2)xCOOH P. H. Soy Oil Whey NaCl (CH2)2CH(OH)2(COOR) (CH2)2CH(OH)1(COOR)2 C3H5(COOR)2POOOC5H14N CH3(CH)3COOK C6H5COONa H3PO4 C36H60O2 C40H56 Analytical Methods for Determining Composition Mayonnaise Total: solids, fats, nitrogen, phosphorous, acidity Egg content, Emulsion stability, Specific Wt., Gums by Copper Reduction Margarine Moisture, Fat, Salt Basic Emulsion Theory • Homogenous mixture of oil and water stabilized by an emulsifier • Two classifications – Macroemulsionsthermodynamically unstable – Microemulsionsthermodynamically stable • Interfacial tension • Net interaction between dispersed phase – Addition of van der Waals and electrostatic forces Emulsion Theory • Emulsifiers – Functionality direct result of chemistry – Consists of 2 parts • Hydrocarbon chain – lipophilic • Polar group – hydrophilic • Three types of emulsions – Temporary • Example: oil mixed with vinegar – Semi-Permanent • Example: pourable salad dressing – Permanent • Example: Mayonnaise Regular Mayonnaise Formulation • Addition pathway – – – – – Vinegar mixed with emulsifiers Oil added slowly Stabilizers and Preservatives Spices and flavor agents Results in closely packed foam of oil droplets • Emulsifiers used – Lecithin, lipovitellin, livetin (all found in egg yolk) – Lecithin also in soybean oil • Major emulsifier: Lecithin – Functional component: phospholipids – Phospholipids • Hydrophilic polar head • Lipophilic portion consists of 2 lipophilic tails Regular Mayonnaise Formulation • Adsorption of lipoprotiens to O/W interface – Diffusion of native protein molecules to interface – Penetration of interface by these molecules – Rearrangement of adsorbed molecules to state of lowest free energy • Ideal Emulsions – Dispersed droplets account for maximum of 74% volume • Mayonnaise – Dispersed phase accounts for 75% or more volume Low-Fat Mayonnaise Formulation • Same basic addition pathway • Other ingredients used to achieve low-fat – Example: egg whites • Interfacial chemistry problem – Emulsifiers found in egg yolk not as abundant in whites • Emulsifiers – Lecithin • Added through addition of more soybean oil – Fine mustard particles Margarine Formulation • Thermodynamically unstable – hydrophobic effects. Continuously change toward equilibrium. • Flocculation causes increase of viscosity. • Emulsifiers applied: monoglycerides, lecithin. • Emulsifiers prevent crystallization, improve plasticity and creaming texture and increase water holding ability. Analytical Methods for Determining Colloidal Properties • Rheology provides valuable information for quality control, storage ability, sensory assessment of consistency, knowledge for design of texture and unit operation, • Mayonnaise and margarine show viscoelastic properties. • Model developed to describe the transient flow. • Rheometrical studies of mayonnaise has been shown to be shearing thinning, viscoelastic and thixotropic. Mayonnaise Processing Equipment Suppliers • Waukesha Cherry Burrell • Bran Luebbe Packaging “Glass or PET?” QC/QA • Salt, T.A. Viscosity, pH, Density, Micro Margarine Process Flow Chart Operational Concerns GMPs SOPs Safety Apparel • Boots • Eyewear • Lab coats Equipment Necessary for Processing • • • • • • • • • • • Mixing and Storage Tanks Centrifugal Pumps Plate or Tubular Heat Exchangers Hot Water Sets Holding Tube Scraped Surface Heat Exchanger Agitated Worker Unit Quiescent Holding Unit Extrusion Valves Control System CIP System Conclusions • Product chemistry and colloid properties are important in reducing production cost and to meet the market demands. • Total sale in 2000 : $1,292.8 million (margarine), $747.45 million (mayonnaise) • Regular mayonnaise ~$0.88/lb, low-fat mayonnaise ~$1.42lb. • Regular margarine ~ $1.30/lb, low fat/cholesterol margarine ~ $2.00/lb. • Flavor plays the biggest role despite healthiness.