synthetic cordierite - Інститут Проблем Матеріалознавства ім.І.М

National Academy of Science of Ukraine

Frantsevich Institute for Problems of Materials Science

SYNTHETIC CORDIERITE AND PRODUCTS BASED ON IT

Manufacturing of the cordierite ceramics as a single-phase product is among enough difficult physicochemical and technological processes.

Complexity of a cordierite (2MgO

2Al

2

O

3

5SiO

2

) synthesis with the high (95-98 vol. %) contents of a main phase determines by that cordierite forming oxides like magnesia, alumina, silicon oxide have high melting points - 2800, 2030 and 1700 о С accordingly, and sintering at

1600 оС. In the same a time the low temperature of incongruous melting cordierite - 1460 оС does not allow to elevate the temperature of its synthesis above 1400 о С.

Thermal resistant ceramic material (synthetic cordierite)

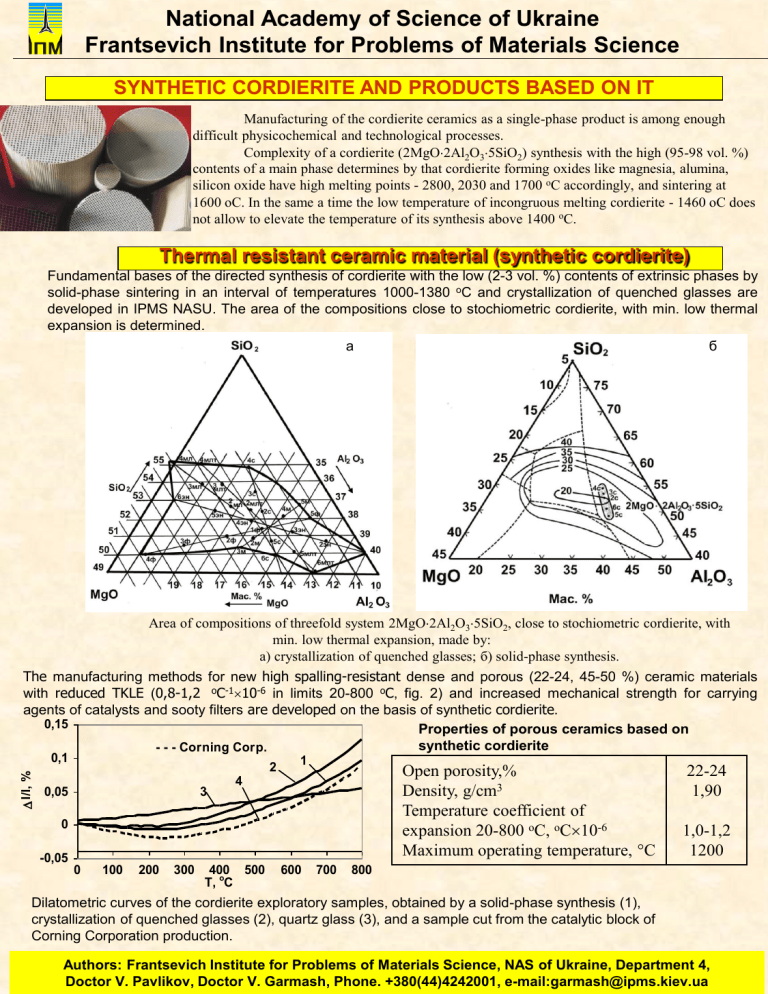

Fundamental bases of the directed synthesis of cordierite with the low (2-3 vol. %) contents of extrinsic phases by solid-phase sintering in an interval of temperatures 1000-1380 о С and crystallization of quenched glasses are developed in IPMS NASU. The area of the compositions close to stochiometric cordierite, with min. low thermal expansion is determined.

а б

Area of compositions of threefold system 2MgO

2Al

2

O

3

5SiO

2

, close to stochiometric cordierite, with min. low thermal expansion, made by: а) crystallization of quenched glasses; б) solid-phase synthesis.

The manufacturing methods for new high spalling-resistant dense and porous (22-24, 45-50 %) ceramic materials with reduced TKLE

(

0,8-1,2 -1 agents of catalysts and sooty filters are developed on the basis of synthetic cordierite .

0,15 о С 10 -6 in limits 20-800 о С

, fig. 2) and increased mechanical strength for carrying

Properties of porous ceramics based on

0,1

0,05

- - - Corning Corp.

3

4

2

1 synthetic cordierite

Open porosity,%

Density, g/cm 3

22-24

1,90

0

Temperature coefficient of expansion 20-800 о С, о С

10 -6

Maximum operating temperature, °C

-0,05

0 100 200 300 400 500 600 700 800

T, o C

1,0-1,2

1200

Dilatometric curves of the cordierite exploratory samples, obtained by a solid-phase synthesis (1), crystallization of quenched glasses (2), quartz glass (3), and a sample cut from the catalytic block of

Сornіng Corporatіon production.

Аuthors: Frantsevich Institute for Problems of Materials Science, NAS of Ukraine, Department 4,

Doctor V. Pavlikov, Doctor V. Garmash, Phone. +380(44)4242001, e-mail:garmash@ipms.kiev.ua

National Academy of Science of Ukraine

Frantsevich Institute for Problems of Materials Science

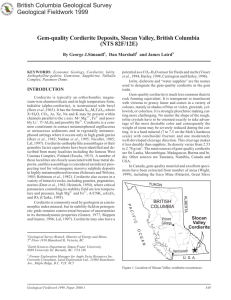

CATALYTIC NEUTRALIZERS FOR AUTOMOBILES WITH GASOLINE ENGINE

The catalytic converter intended for complex сleaning from CO, NOx, CxHy of exhaust gases of the automobiles using not ethylated variety of benzine.

The converter represents the synthetic cordierite ceramic block with cellular structure of the cylindrical form with volume from 1 litre. On a surface of internal channels the shallow layer of the secondary carrying agent from adamant is put, which improves in dozens of times (up to 15-16 m 2 /g) specific surface and ternary platinum-paladium-ruthenic catalyst.

The contents of active components - platinum metals is 3,5 g on kg of the ceramic carrying agent. Complex catalyst with replacement of a part of platinum with oxide of rare-earth metal is developed and passes test.

Ceramic block Catalytic afterburner Advantages

Material Dimensions of the block, mm

Number of channels in a crosssection on1sm 2

Dimensions of the channel,mm

Thickness of a wall, mm

Starting СО, NOx,

CxHy oxidizing reaction temperature, o C

Temperature of 100 %

СО,NOx,

CxHy, conversion, о С

1. Reduced starting oxidizing reaction temperature

2. Reduced temperature of 100

%transformation

3. Economy of platinum metals - up to

30 %

Synthetic cordierite d=95-100 h=100-

49 1х1 0,2

200

100

80

60

40

20

0

IPMS

СО removal

Walker

Linda Gobex

100 175 220 250 280 350 425 t ex. gases

100

С х Н у removal

80

60

IPMS

40

20

Walker

Linda Gobex

0

100 175 220 t

250 ex.gases

280 350 425

230,

50 % conversion

Results of the test performance catalytic converter at

50

40

30

20

10

0

100

90

80

70

60

170 different temperatures

230

400

280

T, o C

370

CO NO CxHy

420 450

Аuthors: Frantsevich Institute for Problems of Materials Science, NAS of Ukraine, Department 4,

Doctor V. Pavlikov, Doctor V. Garmash, Phone. +380(44)4242001, e-mail:garmash@ipms.kiev.ua

National Academy of Science of Ukraine

Frantsevich Institute for Problems of Materials Science

CERAMIC PARTICULATE FILTER WITH CATALYTIC COATING

The filter represents the ceramic cylindrical monolyte with cellular structure and volume up to 3 litres. Material of the block is synthetic cordierite. On a surface of internal channels and pores the shallow layer of the secondary carrying agent and the catalyst on the basis of oxides of transition metals is put.

Ceramic material - synthetic cordierite

100

94 98

90

Open porosity , % 55-60

80

74

76

Average pore size, micron 10-15

65

60 C

60

Density, g / sm 3 1,5

40

Coefficient of thermal expansion in the temperature range 20-800 о С, о С -1

10 -6 0,6-0,9

20

Limiting operating temperature, о С

1200

0

Specific surface, m

General surface, m

2

2

/ m 3 700-1000

5

D

D

D

CO

D

NOx

Test results efficiency particulate filter with catalytic coating at different temperatures

Ceramic sooty filter with a catalytic coat

1.

2.

Cylindrical monolite dimensions, mm

Commercial advantages

Temperature of soot oxidizing is comparable to temperature of EIC’s exhausts – automatic filter regeneration

3.

Dimensions of the channel, mm

Wall thickness of the channel, mm d=120 mm; h=150 mm

4

4

1

4.

5.

Catalytic coat on the basis of oxides of the transition metals

Trapping of particles depending on their size, %

Oxidizing of soot at 380-400 о С

95, starting with 10 nm Trapping of soot nano particles

6.

7.

Hydraulic resistance at air consumption 300 kg/h, sm of water column

Temperature of 100 % СО,NOx, CxHy, conversion, о С

40-60

420

Developed sooty filters can be used for making two-stage system of catalytic neutralization of exhaust gases, starting from low temperatures (start and warming-up of the drive) when traditional catalytic neutralizers are insufficiently effective (so-called problem of

"cool start”).

Аuthors: Frantsevich Institute for Problems of Materials Science, NAS of Ukraine, Department 4,

Doctor V. Pavlikov, Doctor V. Garmash, Phone. +380(44)4242001, e-mail:garmash@ipms.kiev.ua

National Academy of Science of Ukraine

Frantsevich Institute for Problems of Materials Science

CERAMIC FILTERS FOR MELTS OF METALS

Filters with honeycomb and cellular structure for refining (filtration) metal melts at a temperature operation up to 1650 ° C are based on synthetic mullite and mulite-zircon using domestic raw materials (kaolin, zircon, alumina). In combination with low temperature synthesis of mullite

(1500-1550

° C) ceramic filters based on mullite and mulite-zircon can be competitive in the CIS markets.

Key performance of ceramic filters

Material

Channel sizes, mm

Channels of 1 cm 2

Thickness of the channel wall, mm

Maximum operating temperature, ° C mullite, mulite-zircon

0,5-4

8-47

1

1650

50-70

>4х10 4

Porosity,%

Specific surface, cm 2 / g

Compressive strength, MPa

Coefficient of thermal expansion о in the temperature range 20-800

С -1

10 -6 о С,

>10

5,8

Number of cycles (initial-maximum operating temperature)

5

Аuthors: Frantsevich Institute for Problems of Materials Science, NAS of Ukraine, Department 4,

Doctor V. Pavlikov, Doctor V. Garmash, Phone. +380(44)4242001, e-mail:garmash@ipms.kiev.ua