Evaluation of Betaine as Foam Booster

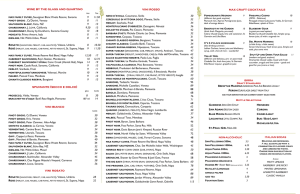

advertisement

Evaluation of Betaine as Foam Booster Leyu Cui Presentation in Consortium Meeting, April 26th 2011 Outline • Characterization: Cocamidopropyl-betaine (CAB) and Lauryl-betaine (LB) • Foam Evaluation: AOS, CAB and their blend • Thermal Stability: CAB and LB Outline • Characterization: Cocamidopropyl-betaine (CAB) and Lauryl-betaine (LB) • Foam Evaluation: AOS, CAB and their blend • Thermal Stability: CAB and LB Surfactants Structure • AOS 16-18: Sodium alpha-olefin sulfonate, from Stepan Co. CnH2n-1-SO3Na (n=16-18) • Cocamidopropyl-betaine (CAB): from Rhodia Co. R-CONH(CH2)3-N+(CH3)2CH2COO-, (R=CnH2n+1, n=12-14) • Lauryl-betaine (LB): from Rhodia Co. R-N+(CH3)2CH2COO-, (R=CnH2n+1, n=12) Viscosities of Surfactant Solution Viscosity / cp 12 10 AOS:CAB=1:1 Crude Oil AOS:LB=4:1 CAB AOS 16-18 Lauryl Betaine 8 API: 41˚ 6 4 2 0 0 100 200 300 Shear rate / 1/s 400 Figure 1: The viscosities of Surfactant Solution. Total surfactant concentration is 0.2(wt)%, NaCl 3.5%, Na2CO3 1.0% Outline • Characterization: Cocamidopropyl-betaine (CAB) and Lauryl-betaine (LB) • Foam Evaluation: AOS, CAB and their blend • Thermal Stability: CAB and LB 1-D Foam Evaluation Setup Surfactant Alternating Gas (SAG) injection method, gas fraction fg = 2/3, surfactant slug size=0.1 PV, u=20 ft/day Darcy’s Law: u Figure 2: The schematic of 1-D setup k Apparent viscosity/ cp CAB: Foam Booster rather than Foamer AOS-CAB blend AOS only CAB only 1000 100 10 1 0 0.5 1 1.5 2 2.5 3 TPV Figure 3: AOS, CAB and blend (0.2% total activity, ratio=1:1) foam evaluation in clean 20/40 mesh silica sandpack AOS Foam Collapse with Oil Apparent Viscosity / cp 1000 AOS in the absence of oil AOS in the presence of oil 100 10 1 0 1 2 TPV 3 4 Figure 4: AOS 16-18 (0.2% activity) foam evaluation in the presence of crude oil. AOS lost its mobility control in the presence of oil AOS Foam Flooding – Poor Sweep 0.1 TPV 1.0 TPV 2.1 TPV 3.0 TPV Figure 5: the pictures of the AOS 16-18 foam flooding sandpack, which shows there is still lots of residual oil in the sandpack. AOS foam doesn’t have good mobility control in the presence of oil. AOS/CAB Blend Foam Works with Oil Apparent Viscosity / cp 1000 100 10 AOS-CAB in the absence of oil AOS-CAB in the presence of oil 1 0 1 2 TPV 3 4 5 6 Figure 6: AOS-CAB blend(0.2% activity) foam evaluation in the presence of crude oil. Blend still has good foaming ability in the presence of oil, but not as good as in oilfree case. AOS/CAB blend Foam Flooding Figure 7: the pictures of AOS-CAB blend foam flooding sandpack, which shows the blend has a good oil-sweeping ability even in the presence of oil Possible Mechanisms for Good Sweep Efficiency of AOS/CAB blend • Foam Stability: The Pseudoemulsion film between oil drop and water-gas interface is stabilized by betaine. (Basheva, 2000) (Lobo1 1993) Viscosity / cp • The viscosity of the blend (8.33 cp) is much higher than crude oil (3.89 cp). So, a favorable mobility ratio can be reached. 15 AOS:CAB=1:1 Crude Oil 10 5 0 0 200 400 Outline • Characterization: Cocamidopropyl-betaine (CAB) and Lauryl-betaine (LB) • Foam Evaluation: AOS, CAB and their blend • Thermal Stability: CAB and LB HPLC-ELSD Setup to analyze surfactant HPLC Column: surfactant column Figure 8: HPLC-ELSD (evaporative light scattering detector) System CAB was aged for 10 days at 125 °C in DI water Figure 9: the comparison of HPLC signal for unaged and aged CAB in DI water. They are exactly the same at characteristic peak. So, CAB is stable at 125 C in DI water for 10 days. CAB aged for 40 hours and 8 days at 125 °C in 1% Na2CO3 brine Figure 10: The comparison of aged and unaged CAB in 1.0% Na2CO3 brine in Full Scale. The salinity peaks are too large compared to the surfactant peaks. Zoom in the Surfactant Peaks (1% Na2CO3) Figure 11: The comparison of aged and unaged CAB in 1.0% Na2CO3 brine in Zoom Scale. The characteristic peak (at 16.5 min) for aged sample is much smaller than unaged sample. So, the CAB is not stable at 125 C in 1.0% Na2CO3 brine CAB aged for 3 & 8 days at 125 °C in pH=3.19 buffer Figure 12: The comparison of aged and unaged CAB in pH=3.19 buffer (ammonium acetate – acetic acid ) in full scale. The characteristic peak is at 16.5 min. Zoom in Surfactant Peaks (pH=3.19) Figure 13: The comparison of aged and unaged CAB in pH=3.19 buffer (ammonium acetate – acetic acid ) in zoom scale. The characteristic peak is at 16.5 min. The peaks of aged samples are much lower than unaged one, which means CAB is not stable in pH=3.19 buffer at 125C LB was aged for 24 days at 125 °C in 1.0% Na2CO3 Figure 14: The comparison of aged and unaged LB in 1.0% Na2CO3 brine in Full Scale. The salinity peaks are too large compared to the surfactant peaks. Zoom in Small Peaks (1.0% Na2CO3) Figure 15: The comparison of aged and unaged LB in 1.0% Na2CO3 brine in Zoom Scale. The characteristic peaks (at 6.5 & 10.5 min) are the same. So, the LB is stable at 125 ˚C in 1.0% Na2CO3 brine for 24 days. LB aged at 125 ˚C in pH=3.36 buffer Figure 16: the comparison of HPLC signal for unaged and aged LB in pH=3.36 buffer. They are exactly the same at characteristic peak. So, LB is stable at 125 ˚C in pH=3.36 buffer solution for 24 days. Conclusion • The cocamidopropyl-betaine (CAB) is a very good foam booster, but not a good foamer. The blend of AOS 16-18 and CAB can tolerate crude oil and shows good mobility control in tertiary oil recovery process. • The thermal stability of CAB is a problem, especially in high and low pH solution (pH dependence) at high temperature (125 °C). But LB is relative stable at high temperature. Questions? Backup Slides Properties of SME Oil • Viscosity is 3.89 cp, API=41.1˚ • The Total Acid Number (TAN) is 0.127±0.015 mg KOH/ (g oil) • Soap Number is 0.0226±0.0022 mg KOH/ (g oil) with IPA and 0.0104±0.0018 mg KOH/ (g oil) without IPA; Viscosity of Blends AOS and CAB Foam in clean Sandpack AOS only Foam Apparent viscosity 1000 CAB only WAG 100 10 1 0 0.5 1 1.5 2 2.5 3 TPV Figure 3: AOS and CAB (0.2% activity) foam evaluation in clean 20/40 mesh silica sandpack. Foam Evaluation with crude oil Apparent Viscosity / cp 1000 100 10 AOS in the presence of oil AOS in the absence of oil WAG 1 0.1 0 1 TPV 2 3 4 Figure 8: AOS 16-18 (0.2% activity) foam evaluation in the presence of crude oil. AOS lost its foaming ability in the presence of oil Emulsion of AOS/LB Sample Bottles and Pressure Vessel (a) (b) Figure 9: (a) the sample bottle for surfactant aged at 125 °C (b) if the bottle was fully filled by liquid, the pressure inside and outside bottle can be balanced through the red rubber pad at the center of the lid. (c) high pressure vessel: the inside pressure is upto 50 psig to prevent the liquid boiling. (c) One CAB Sample was Tested Twice Figure 11: ELSD signals of 0.1% (activity) CAB in DI water. Both lines are for the same sample, the shift of the signal is due to the system error of HPLC. The characteristic peak is at 5.25 min. CAB Aged in 3.5% NaCl--full Scale CAB Aged in 3.5% NaCl--Zoom Scale Zoom in the Hydrophilic Components (1% Na2CO3) Figure 15: The comparison of aged and unaged samples in 1.0% Na2CO3 brine in Zoom Scale. Aged samples have more peaks around 3-4 mins, which means CAB can be degraded into very hydrophilic molecular at 125 C. CAB aged at 125 °C in pH=4.47 buffer Figure 16: The comparison of aged and unaged CAB in pH=4.47 buffer (ammonium acetic – acetic acid ) in full scale. The characteristic peak is at 16.5 min. Zoom in Surfactant Peaks (pH=4.47) Figure 17: The comparison of aged and unaged CAB in pH=4.47 buffer (ammonium acetate – acetic acid ) in zoom scale. The characteristic peak is at 16.5 min. The peaks decrease very slowly with the aging time. Zoom in Hydrophilic Components (pH=4.47) Figure 18: The comparison of aged and unaged CAB in pH=4.47 buffer (ammonium acetate – acetic acid ) in zoom scale. The salinity peaks of aged samples are little higher than unaged one, which means CAB is degrade into very hydrophilic molecular. CAB aged at 125 C in pH=4.47 buffer Red line: unaged sample Blue line: aged for 3days Green line: aged for 8days Figure 22 The comparison of aged and unaged CAB in pH=4.47 buffer (ammonium acetate – acetic acid ) in zoom scale. The salinity peaks of aged samples are little higher than unaged one, which means CAB is degrade into very hydrophilic molecular. Zoom in Hydrophilic Components (pH=3.19) Figure 21: The comparison of aged and unaged CAB in pH=3.19 buffer (ammonium acetate – acetic acid ) in zoom scale. The salinity peaks of aged samples are much higher than unaged one, which means CAB is degrade into very hydrophilic molecular. CAB aged at 125 C in pH=3.19 buffer Blue line: unaged sample Red line: aged for 3days Green line: aged for 8days Figure 25 The comparison of aged and unaged CAB in pH=3.19 buffer (ammonium acetate – acetic acid ) in zoom scale. The salinity peaks of aged samples are much higher than unaged one, which means CAB is degrade into very hydrophilic molecular. LB was aged for 24 days at 125 °C in DI water Figure 22: the comparison of HPLC signal for unaged and aged LB in DI water. They are exactly the same at characteristic peak. So, LB is stable at 125 C in DI water for 24 days. LB aged at 125 ˚C in pH=4.0 buffer Figure 25: the comparison of HPLC signal for unaged and aged LB in pH=4.0 buffer. They are exactly the same at characteristic peak. So, LB is stable at 125 C in pH=4.0 buffer solution for 24 days.