Propellants

advertisement

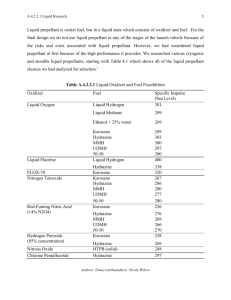

Propellants Dr. Andrew Ketsdever Propellants • Several Factors Must Be Addressed When Deciding on a Propellant – Performance • Chemical energy content, Achievable Isp – Economics • Availability, logistics of production and supply – Physical Hazards • Stability, corrosiveness, carcinogens Liquid Propellants • Desirable Properties – Low Freezing Point – High Specific Gravity – Good Stability – High Specific Heat – Low Vapor Pressure (better pumping) – Easy Ignition (hypergolic?) Liquid Propellants • Highest Potential Specific Impulse – Fluorine Oxidizer – Hydrogen Fuel with suspended Beryllium – Isp=480 sec at Po = 1000 psia (sea level) – Oxidizer highly corrosive (not storable) – Beryllium suspension can not be maintained uniformly Liquid Propellants • Oxidizers – Liquid Oxygen • • • • Boils at 90K Heat of Vaporization 213 kJ/kg High attainable performance Does not burn spontaneously with hydrocarbons at ambient pressures and temperatures • Noncorrosive and nontoxic • Cryogenic temperature poses handling issues Liquid Propellants – Liquid Fluorine • • • • • • • Boils at 53.7K Highest values of performance (typically) High specific gravity Extremely toxic and corrosive Poisonous exhaust gases Low commercial consumption Expensive Liquid Propellants – Hydrogen Peroxide (H2O2) • Requires high concentration (70-99%) • Storage concerns • Decomposition with certain metal catalysts – Nitric Acid (HNO3) • Highly corrosive • Certain stainless steels and gold containers required • Skin burns Liquid Propellants – Nitrogen Tetroxide (N2O4) • • • • • • • Most common storable oxidizer used in the US High density Relatively high freezing point Mildly corrosive Hypergolic with many fuels High vapor pressure Used with hydrazine (UDMH, MMH) propellants Liquid Propellants • Fuels – Hydrocarbon Fuels • RP-1 (Kerosene-like) – Easy to handle – Cost effective • Methane (CH4) – Cryogenic (denser than liquid hydrogen) Liquid Propellants – Liquid Hydrogen • Boils at 20K • Specific Gravity 0.07 • Bulky fuel tanks, large volumes – Increased drag • Feed system must be cryogenic compatable • Increased insulation • Nontoxic products (typically) Liquid Propellants – Hydrazine • Monomehtylhydrazine (MMH) • Unsymmetrical dimethylhydrazine (UDMH) – – – – – – – Toxic High freezing point 274.3K (MMH) / 216K (UDMH) Hypergolic with some oxidizers Spontaneous ignition with air can occur Positive heat of formation (good) Good monopropellants with the right catalyst Reasonable stability Solid Propellants • Classes – Double Base Propellant: forms a homogeneous propellant grain of a nitrocellulose and a solid ingredient dissolved in nitroglycerin plus minor additives – Composite Propellant: form a heterogeneous propellant grain with the oxidizer crystals and a powdered fuel held together in a matrix of synthetic rubber binders. • Less hazardous than double base Solid Propellants • Oxidizers – Ammonium Perchlorate (NH4ClO4) • Most widely used crystalline oxidizer • Good performance • Good availability – Potassium Perchlorate (KClO4) • Medium performance • Higher density than AP • Low burning rate Solid Propellants • Fuels – Powdered Aluminum • • • • 5-60 micron diameter 14-18% of propellant by weight (typical) Small particles can burn spontaneously in air Oxide particles can agglomerate and form larger particles (two phase issues) – Other metallic fuels • Boron, Beryllium Solid Propellants • Binders – Hydroxy Terminated Polybutadiene (HTPB) • Binder provides the structure or matrix in which solid ingredients are held together (composite propellant) • Polymer, synthetic rubber • Primary effect on motor reliability, storability and cost • Other Additives can be included – Improve burn rate, storability, curing Hybrid Propellants • Fuel and Oxidizer mixtures of liquid oxidizer and solid propellants (typically) – Combinations of propellants already discussed – Fuel: HTPB, PMMA, HS – Oxidizer: LOx, H2O2, N2O Nuclear Propellants • Fuels – Low molecular weights • Hydrogen, Water, Methane – No chemical reactions necessary