Dao_Yang_Encapsualtion_of_AITC_2[1]

advertisement

![Dao_Yang_Encapsualtion_of_AITC_2[1]](http://s2.studylib.net/store/data/005790582_1-0f6eea1edf8e8a7d1b66758d2f8f6c2b-768x994.png)

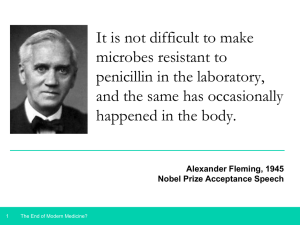

Antimicrobial Film: Encapsulation of Allyl-Isothiocyanate in β-Cyclodextrin Dao Yang, Joongmin Shin, Khanah Mokwena Manufacturing and Packaging Engineering Department, University of Wisconsin-Stout, Menomonie, WI 54751, Email: yangdao@my.uwstout.edu Abundance Abstract Antimicrobial film, including allyl-isothiocyanate (AITC), was performed by means of compression molding. In order to sustain the release of AITC, a pungent antimicrobial agent, it was encapsulated into β-cyclodextrin (β-CD) prior to compression with low density polyethylene (LPDE) resins. Several molar ratios of AITC-β-CD complex were prepared at (0.5:1.0, 1.0:1.0, 2.0:1.0, 3.0:1.0, and 1.0:2.0) respectively, and more than 90% of AITC was included at the molar ratio of (2.0:1.0). Various concentration levels of AITC-β-CD complex (0%, 1%, 2%, 4%, 6%, 8%, and 10%) were impregnated into LDPE resins. The release of AITC from these films was determined in different conditions (relative humidity and temperature). Results showed that the addition of the AITC-β-CD complex significantly changed the film’s mechanical properties (tensile strength and elongation), and optical property (light transmittance). However, the complexation of AITC and β-CD provided constant releasing rate and maintained consistent AITC concentration levels during the test period. AITC-β-CD impregnated with LPDE may be useful as potential antimicrobial packaging films. Introduction • • • 1.1e+07 1e+07 • • AITC reagents 9000000 8000000 7000000 6000000 5000000 4000000 noises e 3000000 2000000 1000000 0 4.00 5.00 6.00 7.00 8.00 9.00 10.00 11.00 12.00 13.00 14.00 15.00 16.00 Time--> 5. Impregnation of AITC-β-CD in LDPE 4. Gas Chromatography (GC) analysis 6. Prepare films for analyzing processes Elongation at break (in.) 0 1 7.6219a 7.6234a 13.2567a 2.5654b 2 7.5654a 2.0641b 4 6.6223b 1.4039c 6 6.5640b 1.1343d 8 6.4538c 0.6931e 10 5.2010d 0.3880f 7. GC analysis of released AITC in films 0% of AITC-β-CD 1% of AITC-β-CD 2% of AITC-β-CD 6% of AITC-β-CD 4% of AITC-β-CD * Encapsulation efficiency of β-CD (%) = (Recovered AITC/Initially input AITC)(100) Develop an effective antimicrobial packaging film that is composed of AITC and β-CD compounds. Evaluate the release of AITC from AITC-β-CD impregnated in LDPE film Compare its mechanical properties (tensile strength and elongation) and optical property (light transmittance) with control LDPE Table 2. Release of AITC in compression films, as function of time 1% 2% 4% 6% 8% 10% 6.00 Methodology 8% of AITC-β-CD Conclusion AITC Reagents (µl/l) 4.00 • 2.0 molar ratio AITC-β-CD complex is the most effective and the AITC encapsulation efficiency was up to 91.10%. • AITC-β-CD complex in LDPE maintained a consistent release rate during the 1st week of test period. • The impregnation of AITC-β-CD complex into LDPE causes significant changes in mechanical properties (Tensile strength and Elongation at break) • Significant changes in distribution were noticed in films above 4% of the applied AITCβ-CD complex • Immiscibility between films may be due to the hydrophilic and hydrophobic nature of agents and plastics, respectively. • Further studies, including barrier property changes on file and actual antimicrobial effectiveness, will be conducted in the future. 3.00 2.00 1.00 Chemical Structure of β-CD 0.00 Sample preparation & analyzing methods: 0 2 4 6 Day 1. Define molar ratio (AITC:β-CD) Table 3. Compressed films with concentration of (1%, 2%, 3%, 4%, 6%, 8% and 10%) Source of Variation 3. SPME absorption of AITC reagents 10% of AITC-β-CD * Actual size of image is 0.8in x 0.8in 5.00 Materials : • Low Density Polyethylene (LDPE) from Industrial Arts Supply • Allyl-isothiocyanate, ≥ 93%, FCC, Food Grade (SAFC) • β-Cyclodextrin (Sigma-Aldrich) 2. Encapsulate AITC in β-CD TS (Mpa) Figure 1. Distribution of antimicrobial film using compression molding method Antimicrobial packaging is an innovative concept that involves interactions between the packaging materials, antimicrobial agent, and surrounding environment to hinder spoilage and pathogenic microorganisms without damaging the integrity of the packaged food. AITC is a member of the Brassicaceae family and can be extracted from common everyday food staples such as mustard, horseradish, and wasabi. If 9. Evaluate optical property 8. Evaluate mechanical properties frequently consumed, studies have shown that AITC can provide essential benefits against deoxyribonucleic acid (DNA) damage and cancer due to its Results and Discussion high biological activities. Furthermore, this component is also known for its Table 1. Efficiency of encapsulated AITC-β-CD complex molar ratios high antioxidative, superoxide scavenging potency, and antimutagenic activity. Molar ratio of AITC/β-CD Efficiency (%)* However, AITC can easily become volatilized when exposed to any 0.5 63.84 nucleophilic agents or foods, thus shortening its effectiveness. 1.0 76.16 β-CD can be produced by means of extraction or obtained by degradation of starch. It is often used as an application for a control or subsidizing agent due 2.0 91.10 to its excellent polar hydrophilic outer shell and relatively hydrophobic cavity. 3.0 92.59 Chemical Structure of AITC % of AITC-β-CD Complex * The letters in each column indicate significantly different means (p<0.05) Objectives • Table 4. Mechanical properties as a function of AITC-β-CD complex contents in LDPE films SS df % of AITC-β-CD complex Days Interaction Within 182.721 12.235 4.063 65.703 5 2 10 144 Total 264.722 161 MS F 36.5442 80.0938 6.1177 13.4081 0.4063 0.8904 0.4563 P-value F crit 0.0000 0.0000 0.5438 2.2770 3.0589 1.8970 Acknowledgement Author would like to thank Dr. Brent Ristow in the chemistry department at UW-Stout for his assistance and facilities support (including GC-MS and Raman microscope). Additional thanks to Prof. John Schultz in the plastic engineering department at UWStout for his assistance and facilities support (including compression molder).