5.Amino acids

advertisement

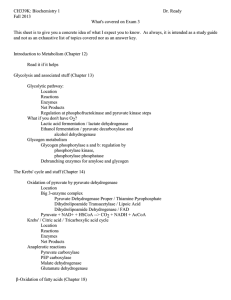

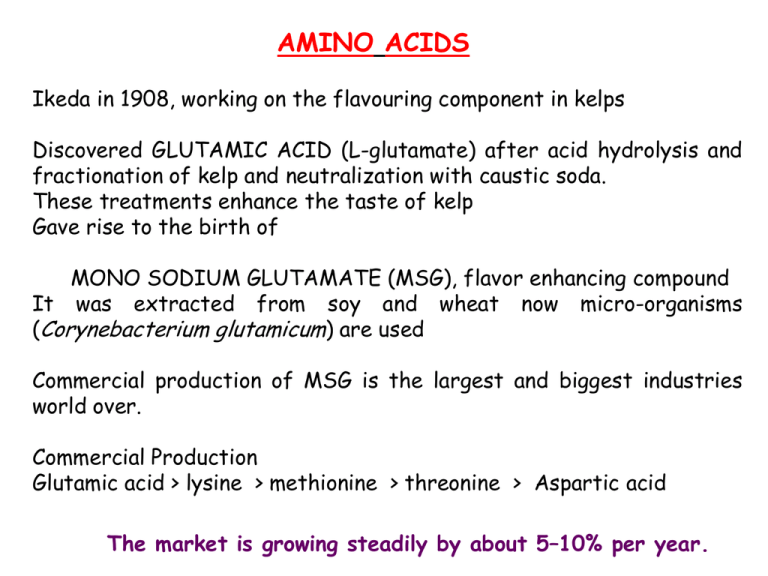

AMINO ACIDS Ikeda in 1908, working on the flavouring component in kelps Discovered GLUTAMIC ACID (L-glutamate) after acid hydrolysis and fractionation of kelp and neutralization with caustic soda. These treatments enhance the taste of kelp Gave rise to the birth of MONO SODIUM GLUTAMATE (MSG), flavor enhancing compound It was extracted from soy and wheat now micro-organisms (Corynebacterium glutamicum) are used Commercial production of MSG is the largest and biggest industries world over. Commercial Production Glutamic acid > lysine > methionine > threonine > Aspartic acid The market is growing steadily by about 5–10% per year. USES OF AMINO ACIDS IN INDUSTRIAL APPLICATIONS Food industry: 65% Feed Additives: 30% Pharmaceutical: 5% FOOD INDUSTRY • Flavor enhancers, MSG, glycine, alanine. Tryptophan and histidine act as antioxidants to preserve milk powder. For fruit juices cysteine is used as an antioxidant. • Aspartame, dipeptide (aspartyl-phenylalanine-methyl ester) produced by combination of asp and Phe is 200 sweeter than sucrose. Used as low calorie artificial sweetener in soft drink industry • Essential amino acidsor those deficient in plant based foods like lys, met, thr, Trp improves nutritional quality of food and feed additives (animal). Bread: lysine, soy products or soyabean meal (pigs/animals): methionine PHARMACEUTICAL INDUSTRY Used as medicines, infusions to patients with post operative treatment CHEMICAL INDUSTRY • • • • • Used as a precursor for production of several cpds Glycine used to manufacture GLYPHOSATE (a herbicide) Threonine used for AZTHREONAM (herbicide) Poly methyl glutamate: manufac. Of synthetic leather N-acyl derivatives of amino acids used for making cosmetics METHODS FOR PRODUCTION OF AMINO ACIDS 1. EXTRACTION: hydrolysis of proteins to isolate amino acids like cys, tyr, leu 2. CHEMICAL SYNTHESIS: can result in racemic mixture (D and L amino acids), most applications are for L-form sometime DL or D maybe required. 3. MICROBIOLOGICAL SYNTHESIS a. Direct fermentation: MO use carbon sources and produce aa. Carbon like glu, fructose, alkanes, ethanol, glycerol, molasses, starch, methanol etc. b. Conversion of metabolic intermediates to amino acids: c. Use of enzymes (microbial) or immobilized cells: resting cells, crude cell extracts, immobilized cells can be used. STRAIN IMPROVEMENT METHODS FOR AA PRODUCTION Because of regulatory control of metabolic reactions natural over production is rare Regulatory control has to be removed Mutagenesis and screening for mutants are done 1. Auxotrophic mutants: lack of formation of regulatory end product (repressor or effector molecule). Intermediates accumulate and get excreted. 2. Genetic recombination: for overproduction (recombinant molecules created) or protoplast fusion to develop hybrids 3. Recombinant DNA Technology: gene cloning, gene engineering 4. Functional genomics: whole chromosome sequencing data L-GLUTAMIC ACID Corynebacterium glutamicum, is a short, aerobic, Gram-positive rod capable of growing on a simple mineral salt medium with glucose, provided that biotin is also added. Production of L-glutamic acid by C. glutamicum is maximal at a critical biotin concentration of 0.5 mg g-1 of dry cells, which is suboptimal for growth Detergents like Tween-40, addition of penicillin, use of Glucose, Glucose-6P, CO2, fatty acid auxotrophic strains, or addition of ethambutol- inhibiting synthesis. arabinogalactan L-GLUTAMIC ACID Metabolic pathway C.glutamicum used glycolysis, PPP and Citric acid cycle Krebs cycle is replenished produced is high in amount the Glu biotin biotin Phosphoenol pyruvate carboxylase Glutamic acid bacteria have high activity of Glutamate dehydrogenase and low activity of a-ketoglutarate dehydrogenase Microbacterium Brevibacterium Arthrobacter PDH Isocitrate dehydrogenase L-GLUTAMIC ACID Regulatory control: Good supply of glucose and efficient conversion of phosphoenol pyruvate to oxaloacetate Phosphoenol pyruvate carboxylase and pyruvate carboxylase, pyruvate dehydrogenase a-ketoglutarate dehydrogenase (low activity by adding penicillin, surfactants) Glutamate dehydrogenase (high activity) 1 mole of glucose should produce 1 mole of glu In practice, efficiency is 70% • Glu is synthesized intracellularly • Carrier mediated processess • Biotin is essential co factor (for Acetyl CoA carboxylase), deficiency of biotin affects fatty acid biosynthesis, membrane formation falters, permeability is affected and intracellular export of glu is altered FACTORS INFLUENCING PRODUCTION 1. 2. 3. 4. Carbon sources Nitrogen source: ammonia for carbon to glu pH control Growth factors :biotin O2 supply: high conc inhibits growth and low O2 leads to lactic acid production and succinic acid, Afftects Glu production in both cases Nutrients Glucose (12%) Dissolving tank 38oC 30-35h Sterlizer Buffer tank Inoculum Sterile air FERMENTER Cell separator Ammonia, pH control (7.8) (ammonium acetate 0.5%) Eluted in NaOH Anion exchanger Evaporation Crystallization 100g/L