Chapter 11 - Materials Science

advertisement

Lec 26

26/03/2014

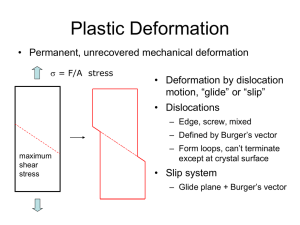

Plastic deformation

and

creep

in

crystalline materials

Chap. 11

Mechanical Properties of Materials

Stiffness

Resistance to elastic

deformation

Young’s

modulus

Strength

Resistance to plastic

deformation

Yield

stress

Toughness Resistance to fracture

Energy to

fracture

ductility

Strain to

fracture

Ability to deform

plastically

Uniaxial Tensile Test (Experiment 6)

Gauge

length

specimen

Result of a uniaxial tensile test

Ultimate

tensile

strength

(Engineering stress)

necking

UTS

Yield

strength

y

STRENGTH

Yield

point

break

Area = Toughness

STIFFNESS

Slope = Young’s

modulus (Y)

DUCTILITY

f (strain to fracture)

(engineering strain)

If there is a smooth

transition from elastic

to plastic region (no

distinct yield point)

then 0.2 % offset proof

stress is used

During uniaxial tensile test the length of the specimen is

continually increasing and the cross-sectional area is

decreasing.

True stress ≠ Engineering stress (=F/A0)

True strain ≠ Engineering strain (=L/L0)

True stress

P

T

Ai

True incremental strain

Ai = instantaneous area

Eqn. 11.3

dL

d T

L

L

True strain

dL

L

T

ln

L

L0

L0

Eqn. 11.4

T K

K

Strength coefficient

n

work hardening exponent

n

T

Eqn. 11.5

What happens

during plastic

deformation?

• Externally, permanent shape change

begins at y

• Internally, what happens?

What happens to crystal structure after

plastic deformation?

Plastic

Deformation

?

Some Possible answers

Remains the

Changes to

Becomes random

same

another

or

crystal

amorphous

structure

How Do We Decide?

X-ray diffraction

No change in crystal structure!

No change in internal crystal structure but

change in external shape!!

How does the microstructure of polycrystal

changes during plastic deformation?

EXPERIMENT 5

Comparison of undeformed Cu and deformed Cu

Slip Lines

Before Deformation

After Deformation

Callister

Slip lines in the

microstructure of

plastically deformed

Cu

Experiment 5

Slip

Slip Planes, Slip Directions, Slip

Systems

Slip Plane:

Crystallographic planes

Slip Direction: Crystallographic direction

Slip System:

A combination of a slip

plane and a slip direction

Lec 27

28/03/2014

Slip Systems in Metallic Crystals

Crystal

Slip

Plane

Slip

Direction

Slip

Systems

FCC

{111}

(4 planes)

<110>

4x3=12

(3 per plane)

BCC

{110}

(6 planes)

<111>

6x2=12

(2 per plane)

HCP

{001}

(1 plane)

<100>

3x1=3

(3 per plane)

Why slip planes are usually close packed

planes?

Why slip directions are close-packed

directions?

Slip Systems in FCC Crystal

(111)

z

y

x

Tensile vs Shear Stress

• Plastic deformation takes place by slip

• Slip requires shear stress

• Then, how does plastic deformation

take place during a tensile test?

: Applied tensile stress

N: Slip plane normal

N

D: Slip direction

1

2

D

F1: angle between and N

F2 =angle between and D

Is there any shear stress on the

slip plane in the slip direction

due to the applied tensile

stress?

Resolved Shear stress

F

= F/ A

Area=A

FD = F cos 2

N

1

2

D

As = A cos 1

RSS

Area = As

FD

AS

F cos2

A

cos1

F

cos1 cos2

A

F

RSS cos1 cos2

F

F

No resolved

shear stress

on planes

parallel or

perpendicular

to the stress

axis

F

cos 2 = 0

F

cos 1 = 0

Plastic deformation recap

No change in crystal structure:

slip

twinning

Slip takes place on slip systems (plane + direction)

Slip planes usually close-packed planes

Slip directions usually close-packed direction

Slip requires shear stress

In uniaxial tension there is a shear component

of tensile stress on the slip plane in the slip

direction:

RESOLVED SHEAR STRESS

CRITICAL RESOVED SHEAR STRESS

RSS

RSS cos1 cos2

CRSS

N

1

2

D

cos1 cos2

y

CRSS y cos1 cos2

Lec 28

01.04.2014

CRSS y cos1 cos2

If we change the direction of stress with respect to the

slip plane and the slip direction cos 1 cos 2 will change.

To maintain the equality which of the following

changes takes place?

1. CRSS changes.

2. y changes

Schmid’s Law:

CRSS is a material constant.

Anisotropy of Yield Stress

crss

y

cos1cos2

Yield stress of a single crystal depends upon the

direction of application of load

cos 1 cos 2 is called the Schmid factor

Active slip system

RSS

cos1a cos 2a

CRSS

cos1b cos 2b

y

CRSS y cos1 cos2

Slip system with

highest Schmid

factor is the

active slip system

Magnitude

of

Critical Resolved Shear Stress

Theory (Frenkel 1926)

Experiment

Potential

energy

Shear stress

CRSS

b/2

b

d

b

Critical Resolved Shear Stress

Theory Experiment

Ratio

(GPa)

(MPa)

Theory/Exp

Fe (BCC)

12

15

800

Cu (FCC)

7

0.5

14,000

Zn (HCP)

5

0.3

17,000

?

Solution

1934

E. Orowan

Michael Polanyi

Geoffrey Ingram Taylor

Solution

• Not a rigid body slip

• Part slip/ part unslipped

Slip

Not-yet-slipped

Boundary between slipped and unslipped parts

on the slip plane

Dislocation Line (One-Dimensional Defect)

Movement of an Edge Dislocation

From

W.D. Callister

Materials

Science

and Engineering

Plastic Deformation Summary

• Plastic deformation

•

Slip

slip

dislocations

• Plastic deformation requires movement of

dislocations on the slip plane

Recipe for strength?

Remove the dislocation

Stress,

MPa

Fig. 11.6

700

50

strain

Cu Whiskers tested in tension

Lec 29

02.04.2014

crystal structure changes?

No

Mechanism of deformation

slip

Nature of stress required for slip

Is there shear during tension?

Resolved shear stress

required for initiating slip

Shear stress

Resolved shear stress

Critical resolved shear stress

CRSS is independent of the direction of application of

tensile stress

Lec 29

02.04.2014

Effect of temperature on dislocation motion

Higher temperature makes the dislocation motion easier

Yield stress

F

e

W

Al2

O3

S

i

18-8 ss

Eqn. 11.14

Ni

11.15

Fig. 11.8

Cu

11.16

11.17

0

T/Tm

0.7

11.18

Recipe for strength

Remove the dislocation:

Possible but Impractical

Alternative:

Make the dislocation motion

DIFFICULT

Strengthening Mechanisms

• Strain hardening

• Grain refinement

• Solid solution hardening

• Precipitation hardening

Movement of an Edge Dislocation

A unit slip takes

place only when

the dislocation

comes out of the

crystal

During plastic deformation dislocation

density

of a crystal should go down

Experimental Result

Dislocation Density of a crystal actually goes up

Well-annealed crystal: 1010 m-2

Lightly cold-worked: 1012 m-2

Heavily cold-worked: 1016 m-2

?

Dislocation Sources

F.C. Frank and W.T. Read

Symposium

on

Plastic Deformation of Crystalline Solids

Pittsburgh, 1950

P

b

A

b

B

b

Q

b

http://zig.onera.fr/~douin/index.html

b

b

Fig. 11.9

http://zig.onera.fr/~douin/index.html

Problem 11.11

Strain Hardening or Work

hardening

y

y

Strain,

During plastic deformation dislocation density increases.

Dislocations are the cause of weakness of real crystals

Thus as a result of plastic deformation the crystal should

weaken.

However, plastic deformation increases the yield strength

of the crystal: strain hardening or work hardening

?

Strain Hardening

Dislocation against Dislocation

A dislocation in the path of other

dislocation can act as an

obstacle to the motion

of the latter

Sessile dislocation in an FCC crystal

1

[10 1 ]

2

a2 a2 a2

2

2

2

1

[1 1 0]

2

Energetically

favourable reaction

1

[0 1 1]

2

(001) not a favourable slip plane

(CRSS is high).

1

[0 1 1]

2

( 1 11)

1

[1 1 0]

2

Eqn. 11.20

(001)

Fig. 11.10

The dislocation

immobile or sessile.

1

[10 1 ]

2

[110]

(1 1 1)

Sessile dislocation a barrier to other

dislocations creating a dislocation pile-up

Sessile dislocation (barrier)

(1 1 1)

( 1 11)

Fig. 11.10

Piled up dislocations

Lec 30 04.04.2014

Empirical relation for strain hardening or

work hardening

0 A

Eq. 11.21

Is the shear stress to move a dislocation in a

crystal with dislocation density

o and A : empirical constants

Fig. 11.11

Dislocation Motion

Easy Dislocation Motion

Plastic Deformation

Easy Plastic Deformation

Weak Crystal

Difficult

Difficult

Dislocation Motion

Plastic Deformation

Strong Crystal

Grain Boundary

Grain 2

Grain1

Grain boundary

2-D Defect: Grain Boundaries

Single Crystal

No Grain Boundaries

Polycrystal

Grains of different orientations

separated by grain boundaries

Discontinuity of a slip plane

across a grain boundary

Slip plane

Dislocation

Grain Boundary

Grain Boundary Strengthening

• Slip plane discontinuity at grain

boundary

• A dislocation cannot glide across a grain

boundary

• Higher stresses required for deformation

• Finer the grains, greater the strength

Coarse Grains

Fine Grains

Grain Size

Strengthening

Hall-Petch Relation

k

y 0

D

y: yield strength

D: average grain diameter

0, k: constants

Some recent developments

The hardness of coarse-grained materials is inversely

proportional to the square root of the grain size. But as

Van Swygenhoven explains in her Perspective, at

nanometer scale grain sizes this relation no longer

holds. Atomistic simulations are providing key insights

into the structural and mechanical properties of

nanocrystalline metals, shedding light on the distinct

mechanism by which these materials deform.

Science 5 April 2002:

Vol. 296 no. 5565 pp. 66-67

POLYCRYSTALLINE MATERIALS

Grain Boundaries and Dislocations

Solid Solutions

• Mixture of two or more metals

• Solute atoms: a zero dimensional defect or

a point defect

• Two types:

– 1. Interstitial solid solution

– 2. Substitutional solid solution

Interstitial Solid Solution

Perfect Crystal

Distortion caused by a

large interstitial atom

Substitutional Solid Solution

Small solute atom

Large solute atom

Solute atom: a zero-dimensional point defect

Solid Solution

Strengthening

Solute

atoms

Strong

crystal

Strains in the

surrounding crystal

Obstacle to dislocation

motion

Alloys stronger than pure metals

200 Sn (1.51)

Be (1.12)

Matrix = Cu (r = 1.28 Å)

150

(Values in parenthesis are

atomic radius values in Å)

100

Zn (1.31)

50

0

40

20

10

30

Solute Concentration (Atom %) →

Figure: Anandh

Subramaniam

Fig 11.13

Airbus A380 to be launched on October 2007

A shop inside Airbus A380

Alfred Wilm’s Laboratory

1906-1909

Steels harden by quenching

Why not harden Al alloys also

by quenching?

Wilm’s Plan for

hardening Al4%Cu alloy

T

550ºC

Hold

Check

hardness

One of the greatest

technological

achievements of 20th

century

Sorry! No

increase in

hardness.

time

Eureka !

Hardness

has

Increased !!

Hardness increases as a function of time: AGE

HARDENING

Property = f (microstructure)

Wilm checked the microstructure of

his age-hardened alloys.

Result:

NO CHANGE in the

microstructure !!

Lec 31

Creep

09/04/2014

Lec 32

11/01.2014

Peak hardness

Hardness

As- quenched

hardness

time

Hardness initially increases: age hardening

Attains a peak value

Decreases subsequently: Overaging

Tsolvus

: solid

solution of

Cu in FCC Al

+

: intermetallic

compound CuAl2

4

supersaturated

saturated

FCC

FCC

Tetragonal

4 wt%Cu

0.5 wt%Cu

54 wt%Cu

+

Precipitation

of in

Stable

Tsolvus

TTT diagram of precipitation of in

unstable

+

Asquench

ed

Aging

A fine distribution of precipitates in matrix causes

hardening

Completion of precipitation corresponds to peak

hardness

As quenched

Aged

Peak

aged

-grains

-grains +

Dense

distribution

of fine

overaged

Driving force for

coarsening

/ interfacial energy

Sparse

distribution

of coarse

hardness

Aging temperature

100ºC

20ºC

180ºC

Fig. 9.15

Aging time

0.1

1

10

100

(days)

Peak hardness is less at higher aging temperature

Peak hardness is obtained in shorter time at higher

aging temperature

Stable

T

U

Tsolvus

unstable

+

180 ºC

Asquenched

100 ºC

Aging

I

100ºC

hardness

180ºC

1

20ºC

Hardness increases as as a function of time

hardness

As-quenched

hardness

time

No change in microstructure - Wilm!

Numerous fine precipitates form with time

Not visible in optical micrograph

X-Ray Diffraction (XRD)

Transmission Electron Microscopy (TEM)

Guinier-Preston Zones, 1938

“It seems justifiable at the moment to

conclude that the process of age

hardening in this alloys is associated

with the segregation of copper atoms on

the (100) planes of the crystal as

suggested by C.H. Desch in The

Chemistry of Solids, 1934”

Preston, 1938, “The Diffraction of X-rays

by Age-Hardening Aluminium Copper Alloys

Precipitation Hardening

Precipitates are obstacles to the motion of dislocation

Solute atoms

Pebbles

Precipitates

boulders

Cake with nuts

Age-hardening = Precipitation hardening

Dislocation-precipitate interaction

Dislocation can

1. Either cut through the precipitate

particles (small precipitate)

2. Or they can bypass the

precipitates

Precipitate cutting

before

after

Fig 11.14 a, c

Dislocation bypassing the

precipitate

b

L

Fig. 11.14 b and d

Movement of onedimensional defects called

dislocations causes plastic

deformation

Obstacles to the movement

of dislocations cause

strengthening

Strengthening Mechanisms

Name

Obstacle Type

Solid solution hardening

Solute atoms (0-D)

Strain hardening

Dislocations (1-D)

Grain refinement

Grain boundaries (2-D)

Precipitation hardening

Precipitates (3-D)

: How do glaciers move?

102

http://rmkilc.wordpress.com/

2. Electric Bulb

“Genius is one

percent

inspiration and

ninety-nine

percent

perspiration”

-T.A. Edison

Q2: How do bulbs fuse?

105

Rolls-Royce Plc

Q3: What does the Rolls-Royce plc make?

106

107

Q: What is common to all the three?

Ans: CREEP

1. Glaciers move due to creep of snow.

2. Bulbs fuse due to creep of W filament.

3. Life of jet engine depends of creep of the turbine

blades.

108

Creep

Creep is time dependent plastic deformation at

constant load or stress

Difference between normal plastic deformation

and creep ?

It is a “high temperature” deformation

T 0.4 Tm

Tm is the m.p. in K.

CREEP

Fig. 11.15

Creep Mechanisms of crystalline materials

Cross-slip

Dislocation climb

Creep

Vacancy diffusion

Grain boundary sliding

Cross-slip

In the low temperature of creep → screw dislocations can cross-slip

(by thermal activation) and can give rise to plastic strain [as f(t)]

Slip

plane 1

b

1

2

3

Dislocation climb

Edge dislocations piled up against an obstacle can climb to another slip

plane and cause plastic deformation [as f(t), in response to stress]

Rate controlling step is the diffusion of vacancies

Nabarro-Herring creep → high T → lattice diffusion

Diffusional creep

Coble creep → low T → Due to GB diffusion

In response to the applied stress vacancies preferentially move from

surfaces/interfaces (GB) of specimen transverse to the stress axis to

surfaces/interfaces parallel to the stress axis→ causing elongation

This process like dislocation creep is controlled by the diffusion of

vacancies → but diffusional does not require dislocations to operate

Flow of vacancies

Grain boundary sliding

At low temperatures the grain boundaries are ‘stronger’ than the crystal

interior and impede the motion of dislocations

Being a higher energy region, the grain boundaries melt before the crystal

interior

Above the equicohesive temperature grain boundaries are weaker than

grain and slide past one another to cause plastic deformation

Single crystal turbine blade

Pigtail: a helical

channel which

gradually

eliminates most

columnar grains

Starter: initiates columnar

grains as in Directional

Solidification (DS)

Single crystal

blade: best

creep

resistance

117

Coarser grains

-> Less grain boundaries

-> Better for creep application

Single Crystal

-> No grain boundaries

-> Best for creep application

Nanocrystalline materials

-> not good for creep applications!

118

Improvements due to blade manufacturing technique:

Show turbine blades

119

Improvements due to engineering design: Blade

cooling

Engineering Materials 1: Ashby and Jones

120

Thermal Barrier Coating (TBC)

NiCrAlY or NiCoCrAlY

Ceramic top

coat:

Yittria stabilized

Zirconia

(YSZ)

1. Low thermal

conductivity

www.matsceng.ohio-state.edu

2. High thermal

expansion

3. High M.P

Reduction in surface temp 100-300 oC

Operating temp > M.P. (~1300 oC)

121

Creep Resistant Materials

Higher operating temperatures gives better efficiency for a heat engine

High melting point → E.g. Ceramics

Dispersion hardening → ThO2 dispersed Ni (~0.9 Tm)

Creep

resistance

Solid solution strengthening

Single crystal / aligned (oriented) grains

Cost, fabrication ease, density etc. are other factors which determine

the final choice of a material

Commonly used materials → Fe, Ni, Co base alloys

Precipitation hardening (instead of dispersion hardening) is not a good

method as particles coarsen (smaller particles dissolve and larger

particles grow interparticle separation ↑)

Ni-base superalloys have Ni3(Ti,Al) precipitates which form a low

energy interface with the matrix low driving force for coarsening

Cold work cannot be used for increasing creep resistance as

recrystallization can occur which will produced strain free crystals

Fine grain size is not desirable for creep resistance →

grain boundary sliding can cause creep elongation / cavitation

► Single crystals (single crystal Ti turbine blades in gas turbine

engine have been used)

► Aligned / oriented polycrystals

No Dislocations

Ultra Strong Crystals

Whiskers

Composite Materials

Various Crystal Defects

Substitutional

solute

Stacking

fault

G-P zone

Dislocations

Interstitial

solute

Vacancy

(Diffusion)

Grain Boundary

Moral of the Story

Strength depends upon defects

Microstructure

• Structural features observed under a

microscope

– Phases and their distribution

– Grains and grain boundaries

– Twin boundaries

– Stacking faults

– Dislocations

Hierarchy of Structures

nuclear structure

Physics and

chemistry

atomic structure

1A0

crystal structure

1nm

Metallurgy and

Materials Science

Engineering: Civil,

Mechanical, etc.

microstructure

1m

macrostructure

1mm

engineering structure

1m

Real Moral of the Story

Properties depend upon

microstructure

Structure Sensitive

vs

Structure Insensitive Properties

For true understanding comprehension

of detail is imperative. Since such

detail is well nigh infinite

our knowledge is always

superficial and

imperfect.

Duc Franccois de la Rochefoucald

(1613-1680)