LM-MHD Simulation Development and Recent Results

advertisement

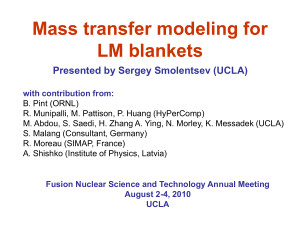

LM-MHD Simulation Development and Recent Results Presented by Sergey Smolentsev (UCLA) with contribution from: R. Munipalli, P. Huang (HyPerComp) M. Abdou, N. Morley, K. Messadek, N. Vetcha, D. Sutevski (UCLA) R. Moreau (SIMAP, France) Z. Xu (SWIP, China) MHD and heat/mass transfer considerations are primary drivers of any liquid metal blanket design • The motion of electrically conducting breeder/coolant in strong, plasmaconfining, magnetic field induces electric currents, which in turn interact with the magnetic field, resulting in Lorentz forces that modify the original flow in many ways. This is a subject of magnetohydrodynamics (MHD). • For decades, blankets were designed using simplified MHD flow models (slug flow, core flow approximation, etc.). The main focus was on MHD pressure drop. • Recent blanket studies have shown that the MHD phenomena in blankets are much richer and very complex (e.g., turbulence, coupling with heat and mass transfer, etc.) and need much more sophisticated analyses. MHD Thermofluid issues of LM blankets MHD related issue / phenomena S-C DCLL HCLL 1. MHD pressure drop *** ** ** 2. Electrical insulation *** ** * 3. Flow in a non-uniform magnetic field *** *** ** 4. Buoyant flows ** *** *** 5. MHD instabilities and turbulence *** *** * 6. Complex geometry flow and flow balancing *** *** *** 7. Electromagnetic coupling *** ** *** * *** * *** *** * 8. Thermal insulation 9. Interfacial phenomena *- not applicable or low importance; ** - important; *** - very important Where we are on MHD modeling for fusion? • No commercial MHD CFD codes • Modification of existing CFD codes (Fluent, Flow3D, OpenFoam) – no significant progress yet, results are often obviously wrong • Many 2D, Q2D and 3D research codes – still limited to simple geometries; other restrictions • Development of specialized MHD codes for blanket applications (e.g. HIMAG) – good progress but there is a need for further improvement to achieve blanket relevant conditions: Ha~104, Gr~1012 MHD modeling and code development at UCLA/HyPerComp • HIMAG (along with HYPERCOMP) – ongoing work on development of 3D MHD parallel MHD software for LM blanket applications • 2D, Q2D and 3D research codes to address particular MHD flows under blanket relevant conditions In this presentation: • New modeling results for “mixed convection” in poloidal flows • Study of hydrodynamic instabilities and transitions in MHD flows with “M-shaped” velocity profile • 3D modeling of Flow Channel Insert (FCI) experiment in China OTHER RELATED PRESENTATIONS at THIS MEETING TITLE Presenter Oral/Poster 3D HIMAG development progress R. Munipalli HyPerComp oral Study of MHD mixed convection in poloidal flows of DCLL blanket N. Vetcha UCLA poster D. Sutevski UCLA poster K. Messadek UCLA oral Modeling China FCI experiment LM-MHD experiments and PbLi loop progress Mixed Convection (MC) • In poloidal ducts, volumetric heating causes strong Archimedes forces in PbLi, resulting in buoyant flows • Forced flow ~ 10 cm/s Buoyant flow ~ 30 cm/s • MC affects the temperature field in the FCI, interfacial temperature, heat losses and tritium transport – all IMPORTANT! In the DCLL blanket conditions, the poloidal flows are expected to be hydrodynamically unstable and eventually turbulent How we attack the MC problem • Full 3D computations using HIMAG: limited to Ha~1000, Re~10,000, Gr~10^7; the code does not reproduce turbulence • Spectral Q2D MHD code (UCLA, Smolentsev): captures MHD turbulence but limited to simplified geometry and periodic BC • 1D analytical solution for undisturbed flow • Linear stability analysis to predict transitions in the flow – see poster presentation by N. Vetcha • Experiment – see presentation by K. Messadek 3D modeling of MC flows Ha=700 Ha=400 Ha=100 Ha=1000 Re=10,000 Gr=107 a/b=1 g g g Tendency to quasi-two-dimensional state as Ha number is increased has been demonstrated for both velocity and temperature field 3D modeling of MC flows Velocity Ha=400 Ha=700 Temperature Ha=400 Ha=700 • Pronounced entry/exit effects Ha=1000 • Reverse flow bubble at the entry • Accelerated flow zone at the entry • “Hot” spot in the left-top corner • Reduction of entry/exit effects with B Ha=1000 • Near fully developed flow in the middle MC: comparison between 3D and 1D Full solution Ha=400 Wall functions BC Ha=700 Wall functions BC Ha=1000 Fully developed 1D analytical solution -Flow is Q2D -Flow is fully developed Major assumptions of the 1D theory have been verified with 3D modeling. 1D/3D comparison is fair MHD turbulence, instability and transitions M o lte n s a lt s e lf-c o o le d 105 D C L L , IT E R T B M 104 103 H C L L , IT E R T B M 10 2 L A M IN A R o r Q 2D TURBULENT FLO W 101 101 • The Q2D turbulent structures appear as large columnar-like vortices aligned with the field direction. This Q2D MHD turbulence is mostly foreseen in long poloidal ducts resulting in a strong modification of heat and mass transfer. • We do some analysis for MHD instability and laminar-turbulent transitions for flows with “Mshaped” velocity profiles, which are typical to blanket conditions P b L i s e lf-c o o le d L i s e lf-c o o le d 106 DCLL, DEM O OB R e y n o ld s n u m b e r 107 All liquid metal blankets fall on the sub-region below the line Re/Ha~200 associated with the turbulization of the Hartmann layer. Here, MHD turbulence exists in a very specific quasi-twodimensional (Q2D) form. TURBULENT FLOW D C L L , D E M O IB 108 • 102 103 104 H a rtm a n n n u m b e r 105 MHD turbulence, instability and transitions Direct Numerical Simulation of Q2D MHD turbulence Side layer Internal shear layers The next few movies will illustrate major findings, namely: Type I Type II •How the instability starts •Two types of instability •Primarily instability (Type I): inflectional instability •Secondary instability (Type II): bulk eddy/wall interaction •How MHD turbulence eventually evolves MHD turbulence, instability and transitions Type I (primarily) instability (Re=2500, Ha=200) Transition from Type I to Type II instability and evolvement of MHD turbulence Modeling FCI experiment in China M.S. TILLACK, S. MALANG, “High Performance PbLi Blanket,” Proc.17th IEE/NPSS Symposium on Fusion Engineering, Vol.2, 1000-1004, San Diego, California, Oct.6-10, 1997. Sic/SiC FCI is used inside the DCLL blanket and also in the feeding ducts as electrical and thermal insulator allowing for ΔP<2 MPa, T~700 C, >40% Possible thermal deformations and small FCI displacements are accommodated with a ~ 2-mm gap also filled with PbLi Tritium and corrosion products in the gap are removed with the slowly flowing PbLi There are pressure equalization openings in the FCI, either in the form of holes (PEH) or a single slot (PES), to equalize the pressure between the gap and the bulk flow The FCI surfaces are sealed with CVD-SiC to prevent “soaking” PbLi. The sealing layer can also serve as a tritium permeation barrier The FCI is subdivided into sections, each about 0.25-0.5 m long. Two FCI sections are loosely overlapped at the junction, similar to roof tiles The FCI is thought as a purely functional (not a structural) element experiencing only secondary stresses, which can be tolerated Poloidal duct of the DCLL blanket with FCI and helium channels Two overlapping FCI sections Modeling FCI experiment in China Flow of InGaSn in a SS rectangular duct with ideally insulating FCI made of epoxy subject to a strong (2 T) transverse magnetic field 1000 mm Picture of experimental MHD facilities in the Southerstern Institute of Physics (SWIP), China. Courtesy of Prof. Zengyu XU, SWIP Modeling FCI experiment in China Dimension Notation Value, m Half-width of the FCI box b 0.023 Half-height of the FCI box a 0.027 tFCI 0.002 Thickness of the gap tg 0.005 Thickness of the slot ts 0.003 Thickness of the Fe wall tw 0.002 FCI thickness •2 mm FCI made of epoxy provides ideal electrical insulation •Maximum magnetic field is 2 T (Ha=2400) •Uniform B-field: 740 mm (length) x 170 mm (width) x 80 mm (height) •Outer SS rectangular duct: 1500 mm long •FCI box: 1000 mm long •Pressure equalization openings: slot (PES) or holes (PES) •Measurements: pressure drop, velocity (LEVI) Modeling was performed under the experimental conditions using the fully developed flow model first (2009) and then in 3D (2010) using HIMAG Modeling FCI experiment in China S. SMOLENTSEV, Z.XU, C.PAN, M.ABDOU, Numerical and Experimental Studies of MHD flow in a Rectangular Duct with a Non-Conducting Flow Insert, Magnetohydrodynamics, 46, 99-111 (2010). Pressure drop coefficient Previous 2D computations show MHD pressure drop much smaller than that in the experiment Current 3D computations demonstrate good match with the experiment These suggest 3D axial currents 3D modeling, NEW ! 2D modeling, previous 1 2 In this figure jx (axial current) is plotted: 1 – axial current in the gap, just above the slot 2 – return current Concluding remarks • In the recent past, the main focus of MHD studies for fusion applications was placed mostly on MHD pressure drop. • Although MHD pressure drop still remains one of the most important issues, current studies are more focusing on the detailed structure of MHD flows in the blanket, including various 3D and unsteady effects. • These phenomena are not fully understood yet. For example, the mass transport (e.g. tritium permeation, corrosion) is closely coupled with MHD flows and heat transfer, requiring much better knowledge compared to relatively simple pressure drop predictions. • Therefore, the key to the development of advanced liquid metal blankets for future power plants lies in a better understanding of complex MHD flows, both laminar and turbulent, via developing validated numerical tools and physical experiments.