Biomass Pyrolysis By Dr. Titiladunayo: Part 2

advertisement

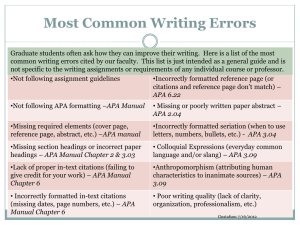

DEVELOPMENT OF A BIOMASS PYROLYSIS REACTOR AND CHARACTERISATION OF ITS PRODUCTS FOR INDUSTRIAL APPLICATIONS Department of Mechanical Engineering The Federal University of Technology Akure. Ondo State. Nigeria JANUARY, 2012 Introduction It comprises:- aggregate of all biologically produced matter inform of: wood and wood wastes; agricultural crops and their waste by-products; municipal solid wastes; animal wastes; wastes from food processing; and aquatic plants including sea weeds and algae (Agarwal and Agarwal, 1999; U.S Dept of Energy, 2003). Biomass is cheap, available, affordable and reliable It’s a regular source of rural energy in Nigeria, fuel wood is cheap, easily accessed by both rural & urban dwellers. 2 – renewable, available, and abundant on earth. It is a versatile energy and chemical resource It could be converted into renewable products that could significantly supplement the energy needs of society Biomass 3 Selected Feedstock Species (A) M. excelsa (B) A. africana (C) E. guineensis Fig. 17: Sizing of Selected Feedstock for Pyrolysis Experiments 4 Experimentation and Documentation 5 Carbonisation experiments were carried out at various elevated temperatures for all samples in the developed electrically fired ‘Fixed-Bed Reactor’ at pre-determined temps., ranging from 400°C to 800°C and at 100°C intervals. Fifteen batches (0.5 kg net weight per batch) each of the selected materials of constant moisture content were used as feedstock in 3 replicated experiments Experimentation & Documentation Cont… By-products of pyrolysis: charcoal (solid fuel), oils (liquid fuel), and pyrogas (non-condensable gaseous products). 6 Experiments were conducted under a quiescent environment (insufficient or complete absence of air). Feedstock residence time, furnace temp. and pyrolysis (reaction) temp. were recorded as displayed on the controllers and recorded every 5 min. Experimental Set-up Fig. 18: Pyrolysis Experimental set-up 7 Assembling the Fixed-Bed Reactor 8 Fig.19 Assembling the reactor for an Experiment Fig. 20: Fully Assembled Fixed-Bed Reactor with an Ongoing Experiment 9 10 Fig. 21:Dismantling the Reactor after an Experiment The appearance of the Fixed-Bed Reactor and Furnace at 600 °C and 700 °C respectively Fig. 22: Appearance of the Fixed-Bed Reactor and Furnace at 6000C & 7000C respectively (During the Day) 11 The appearance of the Fixed-Bed Reactor and Furnace at 800 °C Day Appearance Night Appearance Fig. 23: Fixed Bed Reactor after an Experiment 12 Result and Discussion 13 The relationship between Carbonisation and reaction temperatures for the three species were positive but not linear (Fig. 4A). The temperature interactions within species and between species were significant (p<0.05) as shown Fig.4B The mass of the char fractions vary from one species to the other but a general mass reduction across higher temperature profile is generally noticed. Pyrolysis oil yield also varies with temperature The sygas fraction varies with temperature. Result and Discussion 14 The mass of the char fractions vary from one species to the other but a general mass reduction across higher temperature profile is generally noticed. Pyrolysis oil yield also varies with temperature The sygas fraction varies with temperature. Pyroligneous oil is used as solvent and insecticide Table 6A: Mean and Standard Deviation of Reaction Temperature for all samples React. Temp. S/No Species 1 Apa 2 Iroko 3 PKS Carbonisation Temperature (°C) 400 500 334.67±5.03 3 363.00±8.88 8 366.00±2.00 0 380.33±29.7 04 412.00±5.29 2 390.67±19.3 99 600 700 439.33±2 512.33±15.3 708.67±4. 7.465 08 041 487.67±1 590.67±22.1 685.00±2. 5.373 21 000 520.33±1 617.00±1.73 729.33±1 3.429 2 5.044 Table 6B: Variance ratios (F-calculated) from various ANOVA tables for Reaction Temperature F - Value 15 Species Treatment (TR) Carbonisation Temp.(TC) Interaction (TR*.TC) * = significant (p<0.05), R2=0.991 800 40.388* 773.350* 7.947* Effect of Carbonisation Temperature on Reaction Temperature Reaction Temperature (TR) - ( C) 1000 TApa = 9E-06 Tc3 - 0.014 Tc2 + 7.765 Tc - 1080. R² = 0.998 900 T Iroko = - 0.188 Tc + 300.6 R² = 0.997 T PKS = 0.001 Tc2 - 0.267 Tc + 298.5 R² = 0.986 800 700 600 500 400 300 Apa React. Temp. (TApa)- (°C) Iroko React. Temp. (TIroko) - (°C) PKS React. Temp. (TPKS) - (°C) 200 100 0 300 400 500 600 700 800 900 Carbonisation Temperature (TC) - (ºC) Fig. 24: Increase of Reaction Temperature with increasing carbonisation Temperature for all samples 16 Table 7: Mean Reaction Temperature between Species Carbonisation Temp N 1 400 500 600 700 800 Sig. 9 9 9 9 9 Subset (Reaction Temperatures) 2 3 4 5 354.56 394.33 482.44 573.33 707.67 1.000 1.000 1.000 1.000 1.000 Alpha (α) = 0.5 17 Variance ratios (F-calculated) from various ANOVA Tables for Reaction Temperature Table 8: Variance ratios (F-calculated) from various ANOVA Tables for Reaction Temperature F - Value Species Treatment (TR) 40.388* Carbonisation Temp. (TC) 773.350* Interaction (TR*.TC) * = significant (p<0.05), R2=0.991 7.947* 18 Residence Time (t) -(min) 250 200 t Apa = -9E-08TC4 - 0.174TC2 + 65.51TC - 8983. R² = 1 t PKS = 2E-08TC4 - 4E-05TC3 + 0.033TC2 - 12.68TC + 1815 R² = 1 t I roko = 2E-06TC3 - 0.002TC2 + 0.897TC - 79.01 R² = 0.999 150 100 50 Apa Wood Residence Time (Tapa) Iroko Wood Residence Time (TIroko) PKS Residence Time (TPKS) 0 300 400 500 600 700 800 Carbonisation Temperature (T C) - ( C) 900 Fig. 19 25: Effect of Carbonisation Temperature on Residence Time Recovering Pyro-liquor through Phase change Fig.26: Pyrolysis Liquor Recovery 20 Recovered Pyrolysis Liquor at 400 °C, 500 °C, 600 °C, 700 °C, and 800 °C Pyro-oil from Palm Kernel Pyro-oil from Iroko Wood Pyro-oil from Apa Wood Fig. 27: Pyrolysis oil across selected samples 21 2.80 Mean pH - value across samples 2.60 2.40 2.20 2.00 1.80 1.60 Apa wood (pH-value) 1.40 Iroko wood (pH- value) PKS (pH-value) 1.20 1.00 300 22 400 500 600 700 Carbonisation Temperature ( C) 800 900 Fig. 28: Acidic - pH for all samples Mean Pyro-Oil Residual fraction (g) per 500g Batch Size across species 190 185 180 175 170 IROKO APA PKS 165 160 300 400 500 600 700 800 900 Carbonisation Temperature (TC) - ( C) Fig.29: Variation of Pyro-oil yield with Carbonisation Temperature 23 Mean Tar Residual fraction (g) per 500g Batch Size across species 60 55 50 45 40 35 30 IROKO APA PKS 25 20 300 400 500 600 700 800 Carbonisation Temperature (T C) - ( C) 900 Fig.30: Variation of Tar yield with Carbonisation Temperature 24 150 Syngas yield (g) per 500g Batch Size across species 140 130 120 110 100 Apa wood (NCG) Iroko wood (NCG) PKS (NCG) 90 80 70 60 300 400 500 600 700 800 900 Carbonisation Temperature (TC) - ( C) Fig. 31: Variation of Syngas yield with Carbonisation Temperature 25 Mean Char Residual fraction (g) per 500g Batch Size across Species (CR) 250 C R = -0.083TC + 205.7 R² = 0.979 C R = -0.143TC + 252.8 R² = 0.976 200 C R = -0.095TC + 228.6 R² = 0.957 150 100 IROKO APA PKS 50 0 300 400 500 600 700 800 900 Carbonisation Temperature (TC) - ( C) Fig. 32: Variation of char yield with carbonisation temperature 26 Recovered Carbon & Smokeless Burning Charcoal B A C D 27Fig. 33: Charring Residues & Smokeless combustion Residual yield per species (% wt) Percentage Residual fractions for Apa wood (wt%) 120 100 80 60 Syngas yield (NCG) Tar yield Pyro-oil yield Char yield 40 20 0 400 500 600 700 800 Carbonisation Temperature ( C) Fig. 34: Variation of Apa wood residual fractions with carbonisation temperature 28 Residual yield per species (% wt) Percentage Residual fractions for Iroko wood (wt%) 120 100 80 60 Syngas yield (NCG) Tar yield 40 Pyro-oil yield Char yield 20 0 400 500 600 700 800 Carbonisation Temperature (°C) Fig. 35: Variation of Iroko wood residual fractions with carbonisation temperature 29 Residual yield per species (% wt) Percentage Residual fractions for PKS (wt%) 120 100 80 60 Syngas yield (NCG) Tar yield Pyro-oil yield 40 Char yield 20 0 400 500 600 700 800 Carbonisation Temperature ( C) 30 Fig. 36: Variation of Iroko wood residual fractions with carbonisation temperature Table 9:Char yield / 1000 kg of feedstock as a function of temperature 31 Temperature ( °C) Iroko Derived charcoal Apa Wood Derived Charcoal PKS Derived Charcoal 400 500 600 700 800 341.46 334.54 309.06 295.20 278.00 393.66 356.00 332.66 315.86 270.40 388.46 354.46 337.80 321.06 309.34 Table. 10: Pyro-oil yield / 1000 kg of feedstock as a function of temperature Temperature Iroko Derived Apa Wood ( °C) Pyro-oil Derived Pyro-oil 400 500 600 700 800 32 339.80 342.74 353.06 359.60 365.06 329.86 334.80 334.14 329.06 350.54 PKS Derived Pyro-oil 341.00 350.46 365.40 365.46 373.86 Fig.11: Tar yield / 1000 kg of feedstock as a function of temperature Temperature Iroko Apa Wood PKS Derived ( °C) Derived Tar Derived Tar Tar 33 400 99.14 80.26 91.94 500 97.86 100.80 98.80 600 107.00 100.80 90.60 700 102.66 108.74 86.66 800 100.20 104.66 93.80 Fig.12: Syngas yield / 1000 kg of feedstock as a function of temperature Temperature ( °C) Iroko Derived Syngas Apa Wood Derived syngas PKS Derived syngas 400 500 600 700 800 219.60 224.86 230.06 242.60 254.74 196.20 208.46 227.34 245.86 274.40 178.60 196.86 206.20 226.80 223.00 34 Material & Products Characterization (1) (2) (4) (5) (6) FTIR and TGA – Analysis Determine: Proximate analysis of parent stock and fractions: M.C, V.M, F. C, & Ash content Determine: Ultimate analysis (Elemental analysis of Parent stock and fractions)- C, H, O, N, S, Ash Energy Content Analysis (HHV) Density Moisture Content Determination 36 The moisture content was determined by using METTLER TOLEDO HB 43-S Hologen, moisture Analyzer. The result is as shown in Table 3. Table 5: Moisture Content (%wt/wt) BIOMASS Moisture Content (%wt/wt) (i) Apa Wood (ii) Iroko (iii) PKS (iv) Coconut Shell (v) Gmelina Arborea (vi) Bamboo 37 REPLICATES (%) 1st 2nd 3rd 4.88 4.27 4.10 5.03 4.87 3.74 4.78 4.40 4.17 4.91 4.90 3.99 4.89 4.23 4.24 4.92 4.98 3.87 MEAN + STDV 4.85 ± 0.06 4.30 ± 0.09 4.17 ± 0.07 4.95 ± 0.07 4.92 ± 0.06 3.87 ± 0.13 Table. 6: BIOMASS Volatile Matter (%wt/wt) BIOMASS Volatile Matter (%wt/wt) 1st 2nd Mean ± STDV (i) Apa Wood A 75.35 82.09 78.72 ± 4.77 (ii) Iroko Wood B 82.06 81.962 82.01 ± 0.07 (iii) Palm Kernel Shell C (PKS) 77.01 77.23 77.12 ± 0.16 (iv) Coconut Shell D 82.3 87.30 84.80 ± 3.54 (v) Gmelina Arborea F 93.414 90.08 91.75 ± 2.36 (vi) Bamboo E 88.714 85.04 86.88 ± 2.60 Density Determination The materials were ground to pass through 2 mm filter Dried to constant weights in the muffle furnace at 103±2°C and later cooled in the desiccator. Three replicates (0.001kg) measured with high precision ‘METTLER Balance for compression Pelletized in the die at a pressure of 5000 Ib/in2 (34.5 MN/m2) for all samples. The diameter (D) and height (h) of all the pellets were measured with electronic Veneer Caliper. • Density of pellet (ρ) = 39 4m/(πD^2 h) Table. 7: Density of Selected Tropical Biomass (kg/m3)- Oven dry weight REPLICATES S/No (i) (ii) (iii) (iv) (v) (vi) 40 Selected Tropical Biomass Apa Wood Iroko Wood 1st MEAN + STDV 1029.25 1024.03 1009.09 1020.79 ± 10.46 878.13 874.17 895.60 882.63 ± 11.40 1028.47 1031.59 1038.37 1032.81 ± 5.06 1078.93 1066.51 1105.55 1083.67± 19.95 850.82 857.53 845.85 851.40 ± 5.86 914.82 914.91 930.95 920.23 ± 9.28 B C Coconut Shell D Bamboo 3rd A Palm Kernel Shell (PKS) Gmelina Arborea 2nd F E 1200 Density (kg/m3) 1000 800 600 400 200 0 Apa Wood Iroko Wood Palm Kernel Shell (PKS) 41 Coconut Shell Gmelina Arborea Fig. 27: Selected Woody Biomass Bamboo PROXIMATE ANALYSIS SAMPLE *P/Stk 400 500 APA 1.08 1.31±0.01e 1.59±0.02d ASH IROKO 600 1.94±0.01 2.21±0.01 c 0.82 4.89±0.02e 6.38±0.49d 2.23 4.07±0.02e 5.19±0.02d 21.06 56.38±0.23e IROKO 20.93 74.65±0.48e PKS 18.45 73.65±0.51e 77.86 42.31±0.22a IROKO 78.25 20.46±0.46a PKS 79.32 22.28±0.51a APA APA 42 FC VM 2.59±0.02a 8.20±0.01a b 6.17±0.01 6.26±0.01 c 800 b 7.45±0.01 8.03±0.02 c PKS 700 6.39±0.11a b 63.44±0.09 87.33±0.7 94.02±0.1 d 8c 9b 77.35±0.06 81.54±0.0 84.38±0.0 d 4c 2b 78.54±0.07 83.4±0.02 91.64±0.0 d c 5b 95.36±0.05a 34.97±0.10 10.73±0.7 3.77±0.19 b d 8c 16.49±0.08 11.01±0.0 7.58±0.01 b d 3c 16.27±0.06 10.43±0.0 2.09±0.05 b d 1c 2.05±0.04e 85.13±0.03a 92.3±0.09a 6.66±0.03a 1.29±0.11e Energy Content Determination 43 Samples were pulverized in Ball Mill, made to pass through 2 mm filter and dried to constant weight in an oven at 103±2°C. Parr 1341 Oxygen Bomb Calorimeter was standardized with using benzoic acid in three replicates. The standard energy was determined to be 2437.9 cal/°C (10.207 kJ/°C). Each biomass Pellets was fired in the Bomb Calorimeter and energy determined. Table 8: Biomass Energy Determination S/No Selected Tropical Biomass Energy Content (kJ/kg) (i) Apa Wood (ii) Iroko Wood (iii) Palm Kernel Shell (PKS) (iv) Coconut Shell (v) Gmelina Arborea (vi) Bamboo 44 REPLICATES 1st MEAN + STDV 2nd 3rd A 21.60 B 19.55 21.30 21.47 21.46 ± 0.15 20.42 19.25 19.74± 0.61 C 20.23 D 20.07 20.08 20.68 20.33 ± 0.32 20.12 19.92 20.04 ± 0.11 F 17.84 E 19.46 18.53 17.13 17.83 ± 0.70 17.91 18.88 18.75 ± 0.78 CONCLUSION: The electrically controlled thermal reactor plant for the conversion of biomass to charcoal was successfully developed. The performance of the reactor was evaluated over a temperature range of 4000C to 8000C and was found to be effective in degrading Palm Kernel (Elaesis Guineensis) Shells, Apa wood (Afzelium Africana) and Iroko wood to charcoal at pre-determined conditions. 45 Conclusion Cont…. Conversion efficiency is higher than reported in literature. Cycle time is much reduced than reported in literature Heat promotes the unzipping of biomass polymer chain in thermochemical reactions Biomass’ rate of mass disappearance is a function of temperature, degree of structural polymerization, thermal conductivity, material density, heating rate, thermal intensity, and residence time among others. Rapid evolution of volatiles is noticed from 275°C to 600°C. It reduces drastically to near zero between 700°C to 800°C for the selected biomass samples. 46 THANK YOU FOR LISTENING GOD BLESS YOU ALL 47