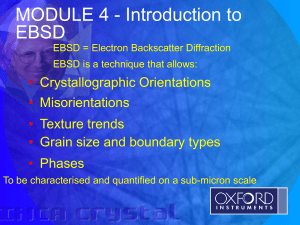

sem electron backscattered diffraction

advertisement

RMS Summer School 2010, Leeds

SEM ELECTRON BACKSCATTERED DIFFRACTION

Geoffrey E. Lloyd

School of Earth & Environment, Leeds University

http://www.see.leeds.ac.uk/research/igt/people/lloyd/rms/

Acknowledgements:

Niels-Henrik Schmidt, Austin Day, Pat Trimby (formerly HKL Software)

Obducat CamScan (Dick Paden)

Dave Prior (University of Liverpool)

Plan

•

•

•

•

•

•

•

•

•

Basic principals

EBSD pattern recognition

EBSD problems

Orientation contrast imaging

Automated EBSD analysis

Specimen requirements

EBSD applications

A few examples

Concluding remarks

Basic Principals

Electron:Sample Interaction

Single

nucleus

incident

electrons

Multiple scattering

emitted

electrons

‘focussed’

emitted

electrons

‘unfocussed’

‘lost’

electrons

‘lost’ electrons

Effects of Scattering

1. creates a ‘point’ source of

electrons, with all possible

trajectories, within the

material

2. crystalline materials:

electrons are diffracted by the

crystal lattice planes when the

Bragg condition is satisfied

note different

lattice spacing

Scattering from single lattice planes

Cone of

Intense Electrons

Electron Beam

Each lattice plane (hkl)

gives rise to 2 diffraction

‘cones’

Diffracting

Plane

Tilted

Specimen

Kikuchi

Lines

Phosphor

(after A. Day)

For SEM electron wavelengths, opening cone

angles are close to 180

Scattering from 3D lattice planes

• A 20keV electron beam

strikes a sample tilted at

65-75°

• The crystal structure at

the point of incidence

diffracts the electron

beam according to

Bragg’s law, nl = 2dsinq

• Each lattice plane (hkl)

gives rise to 2 diffraction

‘cones’

(after J. Hjeiling)

The image (EBSD pattern) is

unique for the crystal orientation

& composition at the point of

incidence on the

sample

(after

A. Day)

Typical SEM EBSD set-up

incident electron beam:

8-40kV, 0.01-50nA

EBSD detector - position

usually constrained by

chamber geometry

low-light sensitive (now

digital; originally analogue)

emitted

electrons

Specimen:

Surface normal

typically

inclined 60°-80°

to beam

EBSD detector distance

set to give ~90 °

angular range in EBSP

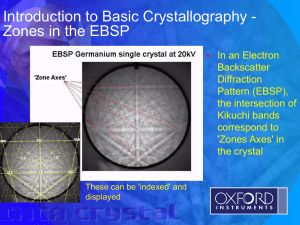

EBSD Pattern Recognition

EBSD pattern recognition

• EBSD patterns are unique for a specific crystal orientation

• The pattern is controlled by the crystal structure: space

group symmetry, lattice parameters, precise composition

• Within each pattern, specific ‘bands’ (i.e. pairs of ‘cones of

diffraction’) represent the spacing of specific lattice planes

(i.e. dhkl)

• EBSD pattern recognition compares the pattern of bands

with an ‘atlas’ of all possible patterns in order to index the

crystal orientation depicted

• This process WAS manual – it is NOW automated !

• Example - next slide

EBSD Patterns

diffraction from

specific lattice plane

pyrite

width = 1/d-spacing

FeS2

major crystal

‘pole’

HOLZ ring

1st order diffraction

• Unique for crystal orientation &

composition at the point of

beam incidence

• Can be >100° of total crystal

projection - easy to index as

symmetry decreases

• Spatial resolution (1m)

• Some pattern details:

2nd order diffraction

Example: pattern indexing

Original pattern

manual/auto-indexed bands

Computer indexed pattern

EBSD pattern ‘range’

Determined by crystal symmetry – defines the crystallographic

unit triangle that repeats the range of patterns over a sphere

Example: fcc (Cu)

Example: trigonal (quartz)

0001

001

rotate

101

unit

triangle

011

symmetrically

111

equivalent

unit triangle

-2110

11-20

-12-10

unit triangle

Indexing requirements

• SEM geometry:

beam energy, specimen & detector positions & orientations

usually fixed per SEM

• Crystallography:

sample lattice parameters & Laue/space group

input per phase (i.e. composition) as required

• Diffraction characteristics:

relative diffraction intensities from different (hkl) lattice planes

calculated per phase as required

Creating a crystal database

1. Select a crystal

e.g.

aluminium

2. Input lattice

parameters

e.g.

a = b = c = 0.405nm

a = b = c = 90

3. Input crystal

symmetry

e.g.

cubic

Laue group =

Space group =

or

m3m

225

Fm-3m

4. Input crystal

unit cell

e.g.

Atom

Al

Al

Al

Al

z

0

0.5

0.5

0

symmetry indicates

4 atomic positions

x

0

0

0.5

0.5

y

0

0.5

0

0.5

Occ

1

1

1

1

Create a diffraction database

• To index EBSD patterns, we must know the relative intensities of the

(Kikuchi) bands (reflectors) in the patterns

• Most approaches use the kinematic electron diffraction model

• This model calculates the structure factor (intensity) for each (hkl)

reflecting plane:

intensity of

(hkl) plane

number

of atoms

F (hkl )

lattice planes

F ( hkl ) f g exp 2ih xg k y g i z g

structure factor

for (hkl) plane

N

g 1

atomic

scattering

factor

atomic position

of atom g

Diffraction database

Conventional software packages automatically calculate

the diffraction (reflector) database of (relative) intensities

e.g. aluminium:

Reflectors

No.

{111}

4

2.338

100.0

{200}

3

2.025

69.4

{202}

6

1.432

27.6

{113}

12

1.221

18.2

{222}

4

1.169

16.2

etc.

d-spacing Å Intensity %

EBSD Problems

Pseudo-symmetry

Spatial resolution

Angular resolution

Specimen preparation - see later

Pseudo-symmetry

• Occurs where 2 orientations cannot easily be distinguished

due to an apparent n-fold rotation axis

• Especially common in lower symmetry crystal structures:

e.g. the orthorhombic structure with a b can appear to be tetragonal

when viewed down the c-axis

• Specific examples (minerals):

quartz

trigonal but can appear pseudo-hexagonal

olivine

orthorhombic but can appear pseudo-hexagonal

plagioclase triclinic but can appear pseudo-monoclinic &/or pseudohexagonal

Example

Quartz:

60° rotation about

the c-axis

Often results

in similar

EBSD patterns

Recognition

depends on the

identification of

‘minor’ bands

(black) - often

not selected

automatically

negative

rhomb

distinguishes

positive

rhomb

Spatial resolution

• Depends on the penetration &

deviation of electrons into a sample

(plus beam diameter)

• Typically ranges from ‘few’ m for

W-filament SEM to a few 100nm for

FEG SEM

Example:

P

R

R

• Penetration depends on:

sample atomic number

accelerating voltage

beam current

(plus, coating depth &

surface damage - see

later)

P

note ‘down slope’ effect of tilting – scan ‘uphill’

Several Monte Carlo based

simulation packages are

available via the Web

(e.g.

http://www.gel.usherbrooke.ca/casino/index.html)

Angular Resolution

• Angular resolution of an individual EBSD pattern is typically ~1

• Also important when determining the misorientation between two

(adjacent) crystal lattices (e.g. grains) – ‘misorientation analysis’ is

becoming a popular application of EBSD as it provides information

on sample properties & behaviour

• But, calculations of misorientation axes from 2 individual measurements

with misorientation of <15° contain increasingly large errors

• Angular resolution depends typically on basic EBSD set-up configuration,

EBSD pattern quality & hence indexing software (parameters,

composition, pseudo-symmetry, etc.)

• Examples (next slides)

Angular resolution 1:

sample-detector considerations

Small detector distance

Large detector distance

poor for indexing but good angular

resolution

good for indexing but

poor angular resolution

important for constraining

misorientation axes.

Angular resolution 2:

effect of angle imaged

large angular spread:

low angular resolution

low angular spread:

good angular resolution

Changes in high resolution EBSD patterns can be used to define better

rotation angles & more accurate misorientations

Orientation Contrast

Imaging

Control of crystal orientation

on emission signal

polycrystalline sample

note variation in image grey-scale level - depends on penetration &

emission, which depend on crystal orientation

EBSD microstructural images

• Electron beam is scanned over an area of a tilted sample, rather than

positioning the beam on a point for EBSD patterns

• Forescattered

electrons (FSE) with

intensities determined

by penetration (i.e.

crystal orientation) are

emitted towards the

EBSD detector

quartzite

• FSE signal detected

by silicon devices

attached to EBSD

detector

• FSE Orientation Contrast image of variation in crystal orientation contrast variations only qualitative (next slide)

Warnings

2 grains with the same

orientation can have

different OC signals

beam

2 grains with different

orientations can have the

same OC signal

beam

due to different

‘incident angles’

due to effectively

the same

‘incident angles’

OC images not quantitative !

• Grey-levels cannot be

inverted to give orientation

• Grains in different

orientations could have the

same grey shade

• One image may show only

60% of boundaries – so,

move the image slightly

Percentage of boundaries imaged

• Grains in the same

orientation but different

positions have different grey

shades

120

100

80

60

40

20

0

0

2

4

6

No of Images Used

(after D. J. Prior)

8

10

Automated EBSD Analysis

Automated EBSD analysis

• Computer controlled movement

of the electron beam across a

sample

• EBSD pattern ‘captured’ at each

point

• Indexing of EBSD patterns is via

pattern recognition software

• Software writes the crystal orientation

(3 Euler angles), & phase information

per pattern to a data-base for later

analysis

• BUT – important to run a manual visual

check of solutions before the

automated analysis!

Automated EBSD

analyses

crystal orientation variation

provides a variety of

information

orientation contrast

pattern quality - ‘strain’

P

T

crystal orientation ‘pole’ figures

many other parameters:

e.g. ‘misorientation’

(becoming very important in

microstructural analysis)

Specimen Requirements

Specimen Preparation

• Polished blocks, thin-sections, natural fractured or grown

surfaces

• Surface damage (m-mm) created by mechanical polishing

must be removed:

• chemical-mechanical (‘syton’) polish

• etching

• electro-polishing

• ion beam milling

• Insulating samples may require very thin carbon

coat, but uncoated samples may perform OK - next

Charging Problems

• Reduce charging by coating but only at expense of image

detail &/or resolution

Uncoated

3-5nm

C coat

K-feldspar. 20keV ~15nA (after D.J. Prior)

• Note: specimen damage can occur in absence of charging

Effect of coating on OC images

uncoated

~4nm C

200m

(after D.J. Prior)

~8nm C

Interim Summary

• Orientation contrast images:

variations in crystallographic orientation & sample microstructure

• EBSD patterns:

full crystallographic orientation of any point in OC image

• Spatial resolution:

~100nm (FEG, metals) to ~1m (W, rocks)

• Angular resolution:

~1 - 2° (misorientation >5 °)

• Materials:

most metals & ceramics; many minerals - depends on composition

• Automated analysis:

100’s of EBSD patterns/second (record ~800/sec via stage scanning)

but indexing accuracy may suffer (use of fast or sensitive EBSD

detectors increasing depending on requirements)

EBSD Applications

What can EBSD be used for?

• Measuring absolute (mis)orientation of known materials most popular/obvious usage

• Phase identification of known polymorphs - becoming

popular

• Calculating lattice parameters of unknown materials difficult, only possible for relatively simple structures?

• Measuring elastic strain

• Estimating plastic strain on the scale of the electron

beam activation volume

• Estimate aggregate elastic stiffness matrix (Cij) from grain

crystal texture – used to predict material properties (e.g.

thermal, electric, acoustic, magnetic, etc.)

Recommended applications

• Tremendous significance for many types of materials

research, including:

- deformation & recrystallisation

- understanding processing histories

- effects of pre-heating & heat treatments

- identifying phases in multi-component systems

- microstructural characterisation & calibration

(including boundary geometry, etc.)

- modelling microstructural processes

- constraining micro-chemical data

- estimating physical properties (e.g. elastic, thermal, sonic, electric,

magnetic)

- etc.

Example applications

Crystal orientation data from

SEM/EBSD

• Individual orientation measurements related to

microstructure:

crystal lattice preferred orientations/texture analysis (i.e. inverse/pole

figures, orientation distribution functions

misorientation data (similar types of plots)

• Non destructive

data be collected from representative samples

• Automated

statistically large/viable data sets acquired

• BUT! Samples must be oriented:

Materials - RD, ND, TD

Rocks – X, Y, Z or NSEW

CPO/texture analysis

• SEM/EBSD:

faster than optical & gives full crystallographic information

faster than X-ray goniometry & applicable to all crystals

faster & simpler than neutron diffraction & applicable to all crystals

does not suffer from problems associated with ODF calculations

• BUT! only surficial analysis:

restricted to electron beam penetration depths

not 3D (unless incorporate serial &/or three orthogonal sections)

Example: quartz

colour-coded

pole figures

misorientation

angle profile

subgrains

Dauphine

twins

Automated phase identification

100m

Crystal

orientation

(Euler) image

100m

Phase 1:

quartz

100m

Phase 2:

feldspar

Phase 3:

mica

In Situ Experiments

“Crystal-probe” HT (1200C) FEGSEM

(D.J. Prior, University of Liverpool)

Note: column tilted to 70° - allows horizontal sample movement

& greater access to sample chamber (i.e. various other electronspecimen signal detectors)

Publication rate - EBSD papers

projected 2010

(~3500)

3500

3000

April

2010

No. publications

2500

2000

1500

1000

500

0

1990

y = 0.6714x3 - 4013.4x2 + 8E+06x - 5E+09

R² = 0.9992

1992

1994

1996

1998

2000

Date (yrs)

2002

2004

2006

2008

2010

Selected bibliography

•

As of April 2010, searching for EBSD in Web of Knowledge results in ~3000 hits! So, here are

some ‘early’ papers.

•

Lloyd, G.E. 1987. Atomic number and crystallographic contrast images with the SEM: a review of

backscattered electron techniques. Mineralogical Magazine 51, 3-19.

•

Schmidt, N.-H. & Olesen, N.O. 1989. Computer-aided determination of crystal lattice orientation from

electron channelling patterns in the SEM. Canadian Mineralogist 27, 15-22.

•

Randle, V. 1992.Microtexture Determination and its Application. The Institute of Materials, London

174pp.

•

Randle, V. 1993. The Measurement of Grain Boundary Geometry. Institute of Physics Publishing,

Bristol, 169pp.

•

Field, D.P. 1997. Recent advances in the application of orientation imaging. Ultramicroscopy 67, 1-9.

•

Wilkinson, A.J. & Hirsch, P.B. 1997. Electron diffraction based techniques in scanning electron

microscopy of bulk materials. Micron 28, 279-308.

•

Humphreys, F.J. 1999. Quantitative metallography by electron backscattered diffraction. Journal of

Microscopy 195, 170-185.

•

Prior, D.J. 1999. Problems in determining the orientation of crystal misorientation axes for small

angular misorientations, using electron backscatter diffraction in the SEM. Journal of Microscopy 195,

217-225.

•

Prior, D.J. et al. 1999. The application of electron backscatter diffraction and orientation contrast

imaging in the SEM to textural problems in rocks. American Mineralogist 84, 1741-1759.

•

Trimby, P.W. and Prior, D.J. 1999. Microstructural imaging techniques: a comparison between light

and scanning electron microscopy. Tectonophysics 303, 71-81.

•

Wilkinson, A.J. 1999. Measurement of small misorientations using electron back scatter diffraction.

Electron Microscopy and Analysis, Institute of Physics Conference Series, 161, 115-118.

Crystallographic data sources

• Pearson’s Handbook, Desk Edition, Crystallographic data for

intermetallic Phases, ASM international, 1997. ISBN 0-87170603-2.

• American Mineralogist - http://www.geo.arizon.edu/xtal-cgi/test

• International Tables for Crystallography Volume A: Space Group

Symmetry. Edited by T. Hahn, revised edition, 1996. ISBN 07923-2950-3; see also:

http://ylp.icpet.nrc.ca/SGHT/1983/

http://www.cryst.ehu.es/cryst/

• Altwyk site: http://ylp.icpet.nrc.ca/altwyk/

Laboratory demonstration

• Aims to show:

basic SEM/EBSD set-up

orientation contrast imaging

EBSD pattern capture & indexing (including crystal & diffraction

database construction)

automation

questions & answers (?) plus general advice