View ePoster - 2015 AGU Fall Meeting

advertisement

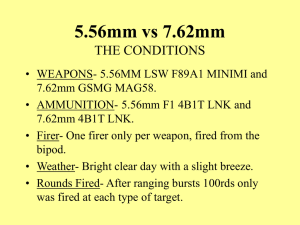

Acoustic Signature of Evaporation from Porous Media Nicholas Grapsas, Nima Shokri Department of Earth and Environment, Boston University, Boston, MA, USA o Evaporative AEs were studied for 3 grain sizes of sand (with mean diameters of 0.34 mm, 0.58 mm, and 0.89 mm) and for 2 sizes of glass beads (with mean diameters of 0.15 mm and 0.53 mm) all water-saturated in Hele-Shaw glass columns with dimensions 8cm x 8cm x 1cm. o AE sensors were mounted on the centers of the cells which were left to evaporate in an environmental chamber set to 35°C and 30% RH. o AE sensors could detect amplitudes between -23dB to 117dB. A 26dB minimum threshold was used to filter ambient noise. o Changes in mass, relative humidity, temperature, and liquid phase distribution were recorded every five minutes using digital balances, a HygroClip, and a camera set to image every 20 minutes. Cumulative fraction (%) o AE event (hit) characteristics were recorded for each hit. 100 80 60 40 20 0 0.0 S 0.34 S 0.58 S 0.89 GB 0.15 GB 0.53 0.5 1.0 1.5 Particle size (mm) mm mm mm mm mm 2.0 FIG. 1. Particle size distributions. FIG. 2. Experimental setup. References o Lehmann, P., S. Assouline, and D. Or (2008), Characteristic lengths affecting evaporative drying of porous media, Phys. Rev. E, 77, 056309. o Moebius, F., D. Canone, and D. Or (2012), Characteristics of acoustic emissions induced by fluid front displacement in porous media, Water Resour. Res., 48 (12), 11507-11519. o Shokri, N, and D. Or (2011), What determines drying rates at the onset of diffusion controlled stage-2 evaporation from porous media?, Water Resour. Res., 47. o Shokri, N., and D. Or (2013), Drying patterns of porous media containing wettability contrasts, J. Colloid Interface Sci., 391, 135–141. o Shokri, N., and M. Sahimi (2012), The structure of drying fronts in three-dimensional porous media, Phys. Rev. E 85, 066312. 0 1 2 3 4 5 6 Time (days) 0 8 4 4 0 0 0 0 2 2 4 6 8 Time (days) 4 6 8 Time (days) 16 14 12 10 8 6 4 2 0 10 FIG. 3. The measured cumulative number of hits and cumulative mass loss during evaporation versus time for particles (a) S 0.34 mm and S 0.89 mm (b) S 0.58 mm and GB 0.53 mm. S 0.34 S 0.58 S 0.89 GB 0.15 GB 0.53 40 30 mm mm mm mm mm o This data is evidence to suggest that meniscus jumps and invasion of the medium are the source of the generated AE’s during evaporation. FIG. 8. The average hit amplitude during evaporation for each particle type. 0 2 3 4 5 Mass Loss (g) 6 FIG. 4. The cumulative number of AE hits during evaporation from each particle type as a function of mass loss. Sand Glass Beads (b) 103 102 101 S 0.34 mm S 0.58 mm S 0.89 mm 30 GB 0.15 mm GB 0.53 mm 100 40 50 60 Amplitude (dB) 30 40 50 60 70 Amplitude (dB) FIG. 9. The amplitude distributions of AEs observed during evaporation for each particle type. The data for (a) S 0.34 mm, S 0.58 mm, and S 0.89 are described by beta values of -0.14, -0.05, and -0.06 and for (b) GB 0.15 mm and GB 0.53 mm by -0.11 and -0.04 respectively. o The data are described by the power law N = α*10β where N is the number of hits observed and the exponent β represents the scaling exponent. o AE amplitude distributions generated during motions of air-water interfaces have been shown to exhibit similar power law behavior with beta’s magnitude covarying with particle size [Moebius et al., 2012]. o AE hits are correlated with the area invaded by air (IA) for all particles. o Smaller particles and rougher surfaces exhibit larger hit/IA ratios, trends consistent with those exhibited by the hits per unit mass loss analysis. (a) 102 100 6. Covariation Between AE Hits and Invaded Area o At the pore scale, air invasion is underpinned by Haines jumps. Thus any change in invaded area necessarily stems from these meniscus motions. This implies that the number of AE hits recorded directly corresponds to the number of Haines jumps that have occurred in the medium. Particle Size (mm) 104 103 10 1 0.34 0.58 0.89 0.15 0.53 8. Energy and Amplitude of AE Hits vs. Grain Size 20 0 26 o Since wave energy is proportional to the square of amplitude, AE hits should display this relationship. A power law with an exponent of 2 emerges when hit energy is plotted against hit amplitude for each particle size. 101 o Due to the irregular shapes of the sand grains compared to the spherical glass beads, more porescale interfacial jumps are expected during drying of sand particles compared to glass beads which is supported by our experimental data. 28 o On the pore scale, a meniscus is pinned to the pore surface by the cohesive forces acting on the contact line along a meniscus’s perimeter. Thus, more energy is released when a Haines jump occurs in coarse-textured media due to the longer contact line. 104 50 30 o Results show that AE hit energy (averaged over all recorded hits) trends with particle size and is higher for glass beads than sand. 5. Number of AE Hits vs. Mass Loss o AE hits per unit mass loss trend inversely with particle size. Since the mass that can be contained within a pore co-varies with the pore’s volume, under a same evaporative mass losses, more AE hits are generated in the case of a medium with finer texture. Sand Glass Beads 32 AE Hits 0 34 FIG. 7. The average hit energy during evaporation for each particle type. AE hits (1000) 2 8 AE hits (1000) 4 12 GB 0.53 mm 36 Particle Size (mm) Mass loss AE hits 6 0.34 0.58 0.89 0.15 0.53 5 S 0.58 mm 8 10 Sand Glass Beads Average hit amplitude (dB) 0 20 Average hit energy (aJ) 0 2 3 4 Time (days) (b) AE hits (1000) 2 AE hits (1000) Mass loss (g) 8 4 140 120 100 80 60 40 20 0 AE Hits 3. Materials and Methods 4 30 o Beta’s magnitude also tends to increase with particle size during evaporation and is greater for rough surfaces than for smooth surfaces. This is consistent with the notion smaller Haines jumps preferentially produce fainter, less energetic AEs. 9. Summary and Conclusions Acoustic emission techniques can be used to non-invasively to detect the evaporative water losses and general drying behavior of porous media. FIG. 5. Typical invasion time progression. White, red, green, and blue regions represent areas invaded by air 5, 10, 15, and 25 hours after the onset of evaporation. 3.0 S 0.58 mm 6 2.5 Invaded area AE hits 2.0 4 2 0 0.0 6 4 2 0 GB 0.53 mm 0 1 2 Time (days) 0.5 1.0 1.5 Time (days) 4 3 2 1 0 1.5 1.0 0.5 IA (1000 mm2) 2. To identify the source mechanism of evaporative AEs and link their characteristics to the texture of porous media potentially revealing non-invasive methods to investigate drying of porous media 10 1 S 0.89 mm IA (1000 mm2) 1. To study the acoustic signature of the evaporation process from porous media 0 40 12 AE hits (1000) 2. Objectives o Our results indicate that the observed cumulative number of AE hits is strongly correlated to the mass loss and drying curves. 50 Mass Loss AE Hits Mass loss (g) o The air invasion of liquid-filled pores underpinned by pore-scale interfacial jumps generates a crackling noise that consists of acoustic “hits” which can be detected using acoustic emission (AE) methods. o In stage two evaporation, the hydraulic connectivity is disrupted, leading to slower invasion of the medium and as a result fewer AE hits. 7. Energy and Amplitude of AE Hits vs. Grain Size S 0.34 mm (a) AE Hits (1000) o Displacement of the drying front at pore-scale proceeds in discrete, rapid interfacial bursts (Shokri and Sahimi, 2012) called “Haines jumps.” In a Haines jump, the liquid meniscus spanning a pore space destabilizes, retreats, and re-stabilizes across another stable orientation due to changes in capillary pressure. o In stage one evaporation, hydraulic connectivity with the surface causes a drying front to propagate relatively fast through the medium generating more AE hits. 12 10 8 6 4 2 0 AE hits (1000) o This process occurs in two distinct stages. During stage one, hydraulic connectivity between the receding drying front (i.e. the interface between saturated and unsaturated zone) and the surface causes liquid vaporization to occur at the surface leading to high evaporation rates. In the second stage, the hydraulic connectivity breaks once the drying front reaches a characteristic, mediumdependent depth inducing much lower evaporation rates (Lehmann et al., 2008; Shokri and Or, 2011; Shokri and Or, 2013). o Across all particle sizes and roughnesses, typical stage one and stage two evaporation were observed. Mass loss (g) o Evaporation from porous media is a key process in mass and energy exchange between land and atmosphere, affecting various hydrological processes as well as biodiversity in the vadose zone. 4. AE Hits and Cumulative Mass Loss Mass loss (g) 1. Introduction 0.0 2.0 FIG. 6. The time evolution of AE hits during evaporation plotted alongside the corresponding invaded area for particles S 0.58 mm and GB 0.53 mm. Similar correlations were found for all particles evaluated. The texture of porous media significantly impacts the acoustic signature of drying in porous media. Rapid interfacial bursts due to the invasion of saturated zone by air are the source of individual AEs. This research demonstrates the potential of AE as a technique to non-invasively investigate the drying of porous media. 10. Future Direction Effort is needed to quantitatively relate the mass lost per AE hit for a given pore geometry, potentially a non invasive method to determine evaporative fluxes. To apply these findings in field scenarios, the influence of fluid properties such as viscosity on the observed AEs must be better understood. The exact moment of AE generation remains unknown. If this can be pinpointed, source inversion models can be applied to deduce information about the porescale dynamics of individual meniscus displacements.