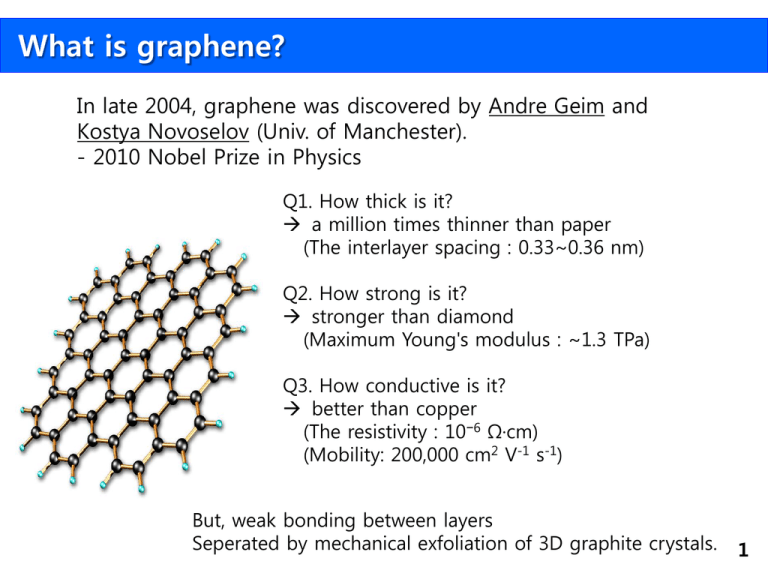

What is graphene?

advertisement

What is graphene? In late 2004, graphene was discovered by Andre Geim and Kostya Novoselov (Univ. of Manchester). - 2010 Nobel Prize in Physics Q1. How thick is it? a million times thinner than paper (The interlayer spacing : 0.33~0.36 nm) Q2. How strong is it? stronger than diamond (Maximum Young's modulus : ~1.3 TPa) Q3. How conductive is it? better than copper (The resistivity : 10−6 Ω·cm) (Mobility: 200,000 cm2 V-1 s-1) But, weak bonding between layers Seperated by mechanical exfoliation of 3D graphite crystals. 1 Molecular structure of graphene 2D graphene sheet Carbon Electrons move freely across the plane through delocalized pi-orbitals bucky ball CNT 3D graphite 2 Electronic structure of graphene Effective mass (related with 2nd derivative of E(k) ) Massless Graphene charged particle is massless Dirac fermion. Zero gap semiconductor or Semi-metal Pz anti bonding Conduction band Ef K Fermi energy K’ Pz bonding Valence band 2DEG K K’ 3 Electrical properties of graphene High electron mobility at room temperature: Electronic device. Si Transistor, HEMT devices are using 2D electron or hole. μ (mobility) = vavg / E (velocity/electric field) Jdrift ~ ρ x vavg 4 Optical properties of graphene Optical transmittance control: transparent electrode Reduction of single layer: 2.3% F. Bonaccorso et al. Nat. Photon. 4, 611 (2010) 5 Mechanical properties of graphene Mechanical strength for flexible and stretchable devices Young’s modulus =tensile stress/tensile strain Diamond ~ 1200 GPa Force-displacement measurement C. Lee et al. Science 321, 385 (2008) 6 Graphene growth by chemical vapor deposition SiC sublimation Metal catalysis CVD Ni: non uniform multi Cu: uniform single Cu: layer by layer growth Current Status Solid Carbon : Low temp. Nat.mat.2009.203. Ar1atm,1450~1650°C Terrace size increase. Nat.2010.549. Pros& Cons High temperature growth :1200~1500°C Non-uniform growth in Step edge and terrace. High cost SiC wafer : SiC growth on Si No transfer required ACS nano,2011 Low temperature growth :below 1000°C Unform growth : Capet like (Large area) Si CMOS compatible process. “Transfer required” 7 Large area graphene K. S. Kim et al. Nature 457, 706 (2009) S. Bae et al. Nat. Nano. 5, 574 (2010) 8 PSCs with graphene anodes b -2 Current density (mA cm ) PEDOT PTB7 TiOx Al :PSS -F40 3.3 4.3 5.4 4.3 4.3 5.0 5.1 6.0 GR/PEDOT: PSS (DT) PC71BM 8.0 eV 0 -4 IPCE (%) a 50 CT DT 25 0 400 600 800 (nm) -8 -12 0.0 0.2 0.4 0.6 Voltage (V) PCE (%) Device Substrate Electrode Method Voc (V) Jsc (mA cm-2) FF Average Best ITO RF sputtering 0.68 14.1 0.61 5.80 ± 0.06 5.86 CT 0.65 11.1 0.55 2.69 ± 1.80 3.92 DT 0.68 12.1 0.67 4.85 ± 0.24 5.49 ITO RF sputtering 0.64 14.3 0.52 4.52 ± 0.18 4.74 GR DT 0.64 12.5 0.60 4.57 ± 0.21 4.81 Glass GR PSC PET 9 OR' x y z Ca Al 0 100 0 50 -2 J (mA cm ) 50 CT DT 0 0 2 4 6 8 10 12 14 -1 4.3 4.8 eV 2.0 -2 2.9 GR/PEDOT: 5.4 PSS (DT) 150 4 Voltage (V) 2.4 5.1 200 L (cd m ) PEDOT SY :PSS Luminous efficiency (lm W ) RO -1 OR 250 CE (cd A ) -2 OR' Current density (mA cm ) PLEDs with graphene anodes 1.6 1.2 3 10 1 10 0 0.8 5 10 V (V) CT DT 0.4 0.0 -3 0 3 6 Voltage (V) 9 12 10 -1 Luminous efficiency (lm W ) 250 -2 L (cd m ) -2 Current density (mA cm ) PLEDs with graphene or ITO anodes 200 150 100 3 10 1 10 0 5 10 V (V) 50 0 0 2 4 6 8 10 12 2.0 1.6 1.2 2 cm 0.8 ITO GR/PEDOT:PSS (DT) 0.4 0.0 -2 Voltage (V) Device PLED Substrate Glass 0 2 4 6 8 10 12 Voltage (V) Electrode Method LEmax (lm W-1) CEmax (cd A-1) VT (V) Lmax (cd m-2) ITO RF sputtering 1.87 5.15 4.5 4750 CT 1.37 3.69 4.5 3150 DT 1.87 4.14 4.0 4000 GR 11