Products and Services - Prof.Dr. Şevkinaz GÜMÜŞOĞLU

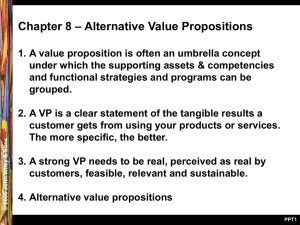

P RODUCTS P LANNING AND P ROCESS

S ELECTION

Prepared by Şevkinaz Gümüşoğlu using different references about POM

Planning new products and geting them to market quickly is the challenge facing manufacturers in industries .

In our changing world today customers demand that a company’s offerings be individualized to meet particular meets, situations and lifestyles.

They want product and services of superior quality available promptly. The firms requirements are innovation, flexibility, improvement, new practical competencies, design and redesign ways. They must orientate themselves to their customers in a new way.

5-2

Management must developed and meet the customer’s need by using the available resources and the technological capabilities of the organization.

New-product design is crucial to the survival of most firms.

While a few firms experience little product change, most firms must continually revise their products. In fastchanging industries, new-product introduction is a way of life and highly sophisticated approaches have been developed to introduce new product.

Product design is seldom the responsibility of operations functions but operations is greatly affected by new-product introduction. Sometime, new products are constrained by existing operations and technology.

5-3

Therefore, it is extremely important to understand the new product design process and its interactions with operations. Product decisions affect each of the decision making areas of operations. Therefore they should be closely coordinated with operations to ensure the operation is integrated with production design.

There are three strategies for new-product introduction process:

5-4

Market-driven: According to this view, “You should make what you can sell” In this case, new products are determined by the market with little regard to existing technology and operations process. Customer needs are the primary basis for new-product introduction. Customer want products and services of superior quality available promptly. The requirements are for innovation, flexibility, quality based on active listening to customer so as to determine their concerns. Being prepared to deliver on such requirements will require companies to cultivate new practical competencies, to redesign the ways they do their work through business processes and to orient themselves to their customers in a new way.

(kano system- voice of costumer)

Technology-driven: This approach would suggest that “ You should sell what you can make” Accordingly, new products should be derived from production technology. This view is dominated by vigorous use of technology and simplicity of operations changes.

Interfunctional view: New-product introduction is interfunctional in nature and requires cooperation among marketing, operations, engineering and other functions Using this approach the new-product design will fall some where between “making what you can sell” and

“selling what you can make”.

5-5

The top manager of miraculously successful Sony is saying; “

Our plan is to lead the public to new product rather than ask them what they want. The public does not know what is possible but we do.” No customer expressed a need for a

Walkman sound system, but soon after Sony invented it, every one had to have music with them wherever they most.

A similar example is air condition (Wills Carrier invened it and humanbeing had to use it wherever they want).

All enterprises today must use quick-connect electronic interfaces to coordinate product creation resource chains

(CAD). Chrysler reduced its product development cycle from over 60 months to 36 month or less in the late 1980 s.

Nowaday this cycle is about 12 month in the automotıve industry. For example this year Audio will offer 13 new models automobile to the market.

5-6

Chrysler old chairman Le Iacocca as declaring “We got to do cars differently. We got to do modular stuff.”

These approaches is required;New Product idea

Product Design

Rapid Prototyping

Rapid Tooling

Usuability

Production Design

Industrial Design Firms

Prototyping companies

Standard Communication interfaces, Design Files of

CAD software for Product Creation.

Manufacturing companies supported CAM software to produce designed files of CAD

5-7

M AJOR FUNCTIONS OF P RODUCT P LANNING

Desingning for the customer; industrial design

Reducing Time-to-Market;speed

Improving Quality of Design;QFD

Product Development:generating new product ideas

Desing Process;linking desing and manufacturing, design for manufacturability, process selection

Special Considerations in Service Design

5-8

F ORM AND F UNCTIONAL D ESIGN

Form Design

how product will look?

Functional Design

reliability

maintainability usability

5-9

R APID P ROTOTYPING

Build a prototype

form design functional design production design

Test prototype

Revise design

Retest

5-10

U SABILITY

Ease of use of a product or service

ease of learning ease of use ease of remembering how to use

frequency and severity of errors user satisfaction with experience

(Simplicity& Compexity&Technology)

5-11

HTTP :// WWW .

YOUTUBE .

COM / WATCH ?

V = O F JQ M2

B1 E RE SAP

HTTP :// WWW .

YOUTUBE .

COM / WATCH ?

V =WU GSY

Y OT L K Q YOUR CAR

http://www.youtube.com/watch?v=9pIW62ZEEhE http://www.youtube.com/watch?v=DN__D5ixme0 mobilephone

http://www.youtube.com/watch?v=2IMoctL1C2g

Mercedes-mehmettunga http://www.youtube.com/watch?v=F5vULbhGQu8

Bicycles http://www.youtube.com/watch?v=r2PzpiD-Sh0

Levitation http://www.youtube.com/watch?v=eVJtOO7mS3I

Future phone

5-12

P RODUCTION D ESIGN

Simplification

reducing number of parts, assemblies, or options in a product

Standardization

using commonly available and interchangeable parts

Modularity

combining standardized building blocks, or modules, to create unique finished products

5-13

Design Simplification

(b) Revised design (a) Original design (c) Final design

Assembly using common fasteners

One-piece base & elimination of fasteners

Design for push-and-snap assembly

5-14

M EASURE D ESIGN Q UALITY

% of revenue from new products or services

% of products capturing

50% or more of market

% of process initiatives yielding a 50% or more

improvement in effectiveness

% of suppliers engaged in collaborative design

% of parts that can be recycled

% of parts used in multiple products

% of parts with no engineering change orders

Average number of components per product

Things gone wrong (TGW)

5-15

Q UALITY F UNCTION D EPLOYMENT (QFD)

Translates voice of customer into technical design requirements

Displays requirements in matrix diagrams

first matrix called “house of quality” series of connected houses

5-16

HTTP

://

WWW

.

.

COM

.

TR

/

IMGRES

?

Q

=

QUALITY

+

FUNCTION

+

DEPLOYMENT

&

START

=116&

HL = TR & SA =X& BIW =1280& BIH =654& TBM = ISCH & PRMD = IMVNSB & TBNID =6 A PCQN Q C U J9I

_M:& IMGREFURL = HTTP :// WWW .

OSAKA -

GU .

AC .

JP / PHP / NAKAGAWA /TRIZ/ E TRIZ/ EPAPERS / E 2010P APERS / E K ATAGIRI TRIZS YMP 2009/

E K ATAGIRI -TRIZS YMP 2009-

100507.

HTML

&

DOCID

=5

JT

_

PH

HT

BH

D

N

XM&

IMGURL

=

HTTP

://

WWW

.

OSAKA

-

GU .

AC .

JP / PHP / NAKAGAWA /TRIZ/ E TRIZ/ EPAPERS / E 2010P APERS / E K ATAGIRI TRIZS YMP 2009/

E F IG K ATAGIRI -

5QFD.GIF& W =370& H =279& EI =S U V Z UN6 R C6 N T4QS XY 4G O CA& ZOOM =1& IACT = HC & VPX

=883& VPY =220& DUR =1094& HOVH =195& HOVW =259& TX =101& TY =86& SIG =10510997252

9429050487&

PAGE

=6&

TBNH

=151&

TBNW

=200&

NDSP

=24&

VED

=1

T

:429,

R

:4,

S

:116,

I

:95

5-17

"

A GROUP OF COURAGEOUS PEOPLE WORKING

IN HARMONY PURSUING THE FINEST DETAIL TO

UNLOCK THE ORGANIZATION AND ROLL OUT

PRODUCTS THAT THE MULTITUDES IN THE

MARKETPLACE WILL VALUE

."

G LENN M AZUR

5-18

V OICE OF THE C USTOMER

THROUGH EACH STAGE OF THE PRODUCT DEVELOPMENT

AND PRODUCTION PROCESS , THAT IS , THROUGH THE

PRODUCT REALIZATION CYCLE .

T HESE REQUIREMENTS ARE THE COLLECTION OF

CUSTOMER NEEDS , INCLUDING ALL SATISFIERS ,

EXCITERS / DELIGHTERS , AND DISSATISFIERS .

5-19

CONCEPT

What Does QFD Do?

CUSTOMER

Better Designs in Half the Time!

Plan Design Redesign

“Traditional Timeline”

Manufacture

Plan

Design Redesign Manufacture

Benefits

QFD Is a Productivity Enhancer

Manufacturing

Environment

Customer Wants

Software

Environment

Service

Environment

Customer Wants Customer Wants

Technical Requirements

Product Functionality Service Requirements

Part Characteristics

Manufacturing Process

Production Requirements

System Characteristics Service Processes

Design Alternatives Process Controls

Flowdown Relates The

Houses To Each Other

1. Identify Customer Attributes

These are product or service requirements IN THE CUSTOMER’S TERMS.

Market Research;

Surveys;

Focus Groups.

“What does the customer expect from the product?”

“Why does the customer buy the product?”

Salespeople and Technicians can be important sources of information – both in terms of these two questions and in terms of product failure and repair.

OFTEN THESE ARE EXPANDED INTO Secondary and Tertiary Needs /

Requirements.

HOWS

The Cascading Voice of the Customer

NOTES:

“Design Attributes” are also called “Functional Requirements”

“Component Attributes” are also called “Part Characteristics”

“Process Operations” are also called “Manufacturing

Processes” and the “Quality Control Plan” refers to “Key

Process Variables.

Y

Critical to Quality

Characteristics

(CTQs)

Key Manufacturing

Processes

X

Key Process Variables

A S ERIES OF C ONNECTED

QFD H OUSES

Product characteristics

A-1

House of quality

Part characteristics

A-2

Parts deployment

Process characteristics

A-3

Process planning

Operations

A-4

Operating

5-24 requirements

25

H ISTORY OF QFD

Dr. Mizuno, Prof. Emeritus

Mitsubishi Heavy Industries

Kobe Shipyards, 1972

Toyota Minivans (1977 Base)

1979 - 20% Reduction In Start-Up Costs

1982 - 38%

1984 - 61%

Dr. Clausing, Xerox, 1984

Any Manufacturing Or Service Industry

H OUSE OF Q UALITY

1

Customer requirements

5

Trade-off matrix

3

Design characteristics

4

Relationship matrix

2

Competitive assessment

6 Target values

5-27

C

OMPLETED

H

OUSE OF

Q

UALITY

(

TEA POT EXEMPLA

)

SS = Silverstone

MG = Mirorrglide

T = Titanium

5-28

B ENEFITS OF QFD

Promotes better understanding of customer demands

Promotes better understanding of design interactions

Involves manufacturing in design process

Breaks down barriers between functions and departments

Provides documentation of design process

5-29

Product Selection

Product is the structuring of competent parts or activities so that as a unit they can provide a specified value. Product specification is typically an engineering function. In service industries requirement. Design, production an marketing costs are reduced by standardizing and simplifying the product. After prototype units one designed and produced, the products are further analyzed and tested to see how well the quality, performance and costs conform to the design objectives.

Simplification may take place to reduce unnecessary variety in the product line by discussing the number and variety of product produced.

Product selection are influenced by;

1.The firm’s resource and technology base

2.The market environment

3.The firm’s motivation to use capabilities to meet the need of the market place.

5-30

Product-Mix Decision

Within the product-line grouping, decision must be made to select which mix of products to in view of costs, capacity and other limitation.

Linear programming is a useful technique for assisting in product-mix decisions.

It applies to situations where there firm has a demand for whatever quantity of two or more products it can produce. Another typical application is for the selection of the least costly mix of raw materials .

Linear Programming

LP is a mathematical technique for maximizing or minimizing a linear objective function, subject to linear constraints. It has wide variety of applications. It assumes that

cost and revenue values are known (certainty) profits from various activities are additive, resource quantity for various activities are additive (additivity) it doesn’t allow negative production values (non-negativity)

It has widespread application such as mix product decision, capacity planning capital budgeting, line balancing, agregate planning and scheduling.

5-31

Objective (Goal)

To maximize total profit

Decision Variables

What do we have to decide on?

What are the variables that we can control ?

We have to decide on amounts of products to be produced.

x

1

: the number of Pr oduct 1 to be produced x

2

: the number of P roduct 2 to be produced

5-32

1-Graphical solution method:

For the simple linear problems, the easiest procedure is the graphical method.

Example1. A chemical firm produces automobile cleaner X and polisher Y and realizes $10 profit on each box of X and $30 on Y. Both products require processing through the same machines A and B, but X requires 4 hours in A 8 in B, where as Y requires 6 hours in A and 4 in B. During the forthcoming week machines A and B have 12 and 16 hours of available capacity, respectively Assuming that demands exists for both products, how many boxes of each should be produces to realize the optimal profit P?

First step: Formulate the problem in ten of linear objective function and linear const.

X: No.of cleaner X to be produced.

Y: No. of polisher Y to be produced.

Objective function is:

Maximize

The constraints are:

P = $10 x + $30y

4x + 6y 12

8x + 4y 16

Also x and y 0 in two dimensions.

We begin by constructing a graph that represents the LP

5-33

Second step: Variables are X and Y. The constraint.

Are plotted as equalities. We use a ruler to make a heavy horizontal line for the X axis and a heavy vertical line for the Y axis.

To graph:

A: if x=0 y=2 if y=0 x=3

B: ifx=0 y=4 ify=0 x=2

Note that the graph established a feasible region bounded by the explicit capacity const of A and B and the implicit constraints that production of x>0 and production y>0

5-34

Third step: The slope of the objective function.

P =10x+30y

The standard slop intercept form of a linear equation is

Y= mX + b where m is the slope of the line 8that is, change in Y pen unit change in x) and b is there Y intercept.

Expressing our objectives in this form , we have.

30 y = -10x +P

Y= (-1/3) x + P/30

The slope = -1/3; that is, the line decreases one unit in Y for every three positive units of X. This is plotted at any convenient spot within the feasible solution region. We could plot a similar line for any other value of Z. These profit lines are parallel.

Fourth step: The slope of the objective function is moved away from the origin until restrained by the furthermost intersection of A and the implicit constraint x>0. The optimal solution will always be at a corner in the feasible region. This corner will be the last point in the feasible solution region 5-35

Fifth step: The arrow point to the solution, within is determined by the x and y coordinates at time co.

In this example x=0 y=2 P = $10 (0) + $30(2) = $60

4(0)+6(2) 12 12=12

8(0)+4(2) l6 8 16

In this example the firm should produce no cleaner and two boxes of polisher for a profit $60.

We can see from the graph, the constraint imposed by machine B (8x+4y <16) has no effect, for it is the 12 hours of machine A (4x+6y<12) that are constraining production of the more profitable polisher.

The graph also reveals that profit would continue to increase if more hours could be made available on machine A up to the point of doubling output (to x=0 end y=4)

At this point, the time available from machine B would become constraining

5-36

L INEAR P ROGRAMMING :E XAMPLE 2

M ODEL F ORMULATION

Resource requirements

Labor Clay Revenue

Product (hr/unit) (lb/unit)

Bowl 1 4

($/unit)

40

Mug 2 3 50

There are 40 hours of labor and 120 pounds of clay available each day

Decision variables x x

2

1

= number of bowls to produce

= number of mugs to produce

© 2000 by Prentice-Hall Inc

Russell/Taylor Oper Mgt 3/e

Ch 11 Supp - 4

O BJECTIVE F UNCTION & C ONSTRAINTS

Maximize Z = $40 x

1

Subject to x

4 x

1

1

+ 50 x

2

+ 2 x

2

40 hr (labor constraint)

+ 3 x

2

120 lb (clay constraint) x

1

, x

2

0

Solution is x

1

= 24 bowls x

2

= 8 mugs

Revenue = $1,360

© 2000 by Prentice-Hall Inc

Russell/Taylor Oper Mgt 3/e

Ch 11 Supp - 5

G RAPHICAL S OLUTION M ETHOD

1. Plot model constraint on a set of coordinates in a plane

2. Identify the feasible solution space on the graph where all constraints are satisfied simultaneously

3. Plot objective function to find the point on boundary of this space that maximizes (or minimizes) value of objective function

© 2000 by Prentice-Hall Inc

Russell/Taylor Oper Mgt 3/e

Ch 11 Supp - 6

G RAPH O F P OTTERY P ROBLEM x

2

60

50

40

30

20

10

4 x

1

+ 3 x

2

120 lb

Area common to both constraints x

1

+ 2 x

2

40 hr

10 20 30 40 50 60 x

1

© 2000 by Prentice-Hall Inc

Russell/Taylor Oper Mgt 3/e

Ch 11 Supp - 7

P LOT O BJECTIVE F UNCTION

© 2000 by Prentice-Hall Inc

Russell/Taylor Oper Mgt 3/e x

2

40

30

20

10

$800 = 40x

1

+ 50 x

2

.

B

Optimal point

10 20 30 40 x

1

Ch 11 Supp - 8

C OMPUTING O PTIMAL V ALUES x

2 x

1

+ 2 x

2

= 40

4 x

1

+ 3 x

2

= 120

4 x

1

+ 8 x

2

= 160

-4 x

1

- 3 x

2

=

120

40

4 x

1

+ 3 x

2

= 120

5 x

2

= 40

30

20

10

8

A

10

.

B x

1

+ 2 x

2

= 40

C

20 30 40 x

1 x

2

= 8 x

1

+ 2 (8) = 40 x

1

= 24

Z = $50(24) + $50(8)

Z = $1,360

© 2000 by Prentice-Hall Inc

Russell/Taylor Oper Mgt 3/e

Ch 11 Supp - 9

E XTREME C ORNER P OINTS x

2

40

30

20

10

A x

1

= 0 bowls x

2

= 20 mugs

Z = $1,000 x

1

= 224 bowls x

2

= 8 mugs

Z = $1,360

10

.

B

C

20 30 40 x

1

© 2000 by Prentice-Hall Inc

Russell/Taylor Oper Mgt 3/e x

1

= 30 bowls x

2

= 0 mugs

Z = $1,200

Ch 11 Supp - 10

O BJECTIVE F UNCTION D ETERMINES

O PTIMAL S OLUTION x

2

40

30

20

10

A

4 x

1

+ 3 x

2

120 lb

Z = 70 x

1

+ 20 x

2

Optimal point: x

1

= 30 bowls x

2

= 0 mugs

Z = $2,100

10

B

20 30

C

40 x

1

+ 2 x

2

40 hr x

1

© 2000 by Prentice-Hall Inc

Russell/Taylor Oper Mgt 3/e

Ch 11 Supp - 11

G RAPHICAL SOLUTION METHOD EXAMPLE 3:

A company is already producing some products.

However there are some idle capacities of the facilities.

There are three plants. The idle capacities in terms of labor hours per week are as follows

Plant Idle Capacity(hours/week)

Plant -1 4

Plant -2 12

Plant -3 18

The management wants to utilize the unused capacities by producing two new products.

Product-1: An 8 foot glass door with aliminum framing

Product-2: A 4x6 double hung window with woodframing

5-45

The products are produced in batches

Plant-1 produces aliminum frames

Plant-2 produces wood frames

Plant-3 produces glass and assembles the products

The unit profits per products are 3000 and

5000 respectively.

The labor hours required to produce different parts of the products at different plants are as follows :

Production Time per Batch

(hours)

Product -1 Product-2 Plant

Plant -1

Plant-2

Plant-3

1

0

3

0

2

2

5-46

Constraints

Resources are limited x

1

4 4 hours available at Plant -1

2x

2

12 12 hours available at Plant -2

3x

1

2 x

2

18 x

1

0 , x

2

0

18 hours available at Plant-3

Objective Function

Z

3 x

1

5 x

2

Total profit to be maximized

5-47

x2

G RAPHICAL

S OLUTION

Solution space for x

1

0 and x

2

0

x1

x2 x

1

4

4 x1

6 x2

4

2 x

2

12 x1

6 x2

4

3 x

1

2 x

2

18 x1

6 x2

Z

3 x

1

5 x

2

10

4 x1

6 x2

Z

3 x

1

5 x

2

10

Z

3 x

1

5 x

2

20

4 x1

6 x2

4

Z

3 x

1

5 x

2

30 x1

6 x2

Z

3 x

1

5 x

2

36

4 x1

E XAMPLE :4

The Primo Insurance Company is introducing two new product lines: special risk insurance and mortgages. The expected profit is $5 per unit on special risk insurance and

$2 per unit on mortgages. Management wishes to establish sales quotas for the new product lines to maximize total expected profit. The work requirements are as follows:

(a) Formulate a linear programming model for this problem.

(b) Use the graphical method to solve this model.

5-56

X1= no. of special risk insurance

X2= no. of mortgage.

Z

Max

= 5X

1

+2X

2 s.t. 3X1+2X2<=2400

X2<=800

2X1<=1200

X1,X2>=0

5-57

5-58