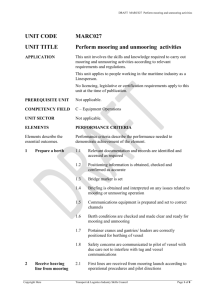

Cosalt Offshore Mooring Systems

advertisement

Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Single Point Moorings Mark Brooks IEng MIIE Business Development Manager Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery The major business activities of Cosalt: safety & protection Rope – Fibre, Wire & Combination Rigging & Lifting Marine Safety Equipment Life Saving Appliance Servicing Fire Fighting & Inspection “the complete marine service provider” Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Cosalt: safety & protection Cosalt plc turnover ~ £Stg 151 million Cosalt: Safety & Protection ~ £Stg 35 million 18 UK Businesses in port based locations The markets of Cosalt: safety & protection Harbour & Rivers 24% Industrial & Waterside 23% Onshore 17% Retail & Cash Sale 5% Offshore, Ocean & Coastal 31% Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Major Rope Constructions 3-Strand 6-Strand Circular Braided - Ultraline 8-Strand Double Braided (2-in-1) 12-Strand Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Fibres & Ranking Aramid UHMPE Polyester / Nylon Polypropylene Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Rope Properties – Wear & Tear Fiber type Testing rope wear is always machine dependent Dyneema polyester nylon PP aramid Cut abrasion resistance resistance dry wet +++ ++ +++ ++ ++ ++ ++ +++ + + + o +++ + - rope on metal Tests can be used to rank Static load materials & rope constructions Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Rope Testing - Abrasion Yarn on Yarn or Rope on rope long lengths chafing against each other: - type of wear (abrasive, melting) - environment (dry, wet) Yarn on metal or Rope on metal long lengths chafing over an object: rope on rope - type of wear (abrasive, melting) - environment (dry, wet) - protection rope on metal Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Marine Finish Marine Finish is used to improve the Safe Working Life in marine environment Y arn -o n -Y arn Ab rasio n cycles to failure 100000 10000 1000 100 M arine Finish standard 10 0% 2% 4% 6% Applied Tensio n (N/tex) Test conform ASTM D6611-00 Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery 8-Strand Multiplait Rope Construction Advantages of 8-strand rope: + efficient construction + torque-free + easy to handle + easy to splice Points of attention: yarns can be pulled in winching: only on a split drum Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery 12-Strand Multiplait Rope Construction Advantages : better abrasion resistance; smooth surface (strands/yarns will not get caught easily) rope is round : visual aspect easy to use on the winch (no burying because of round construction) non-rotating endless ropes possible very easy to splice ideal for lifting with free end (non rotating + round) Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Ultraline Construction Rope Construction cores cover - Cover not only protects against abrasion, but also UV - Small repairs are possible if inner strength has not been ccompromised – strength will not be affected. - All rope strength is contained within central cores. Typical penetration of UV into rope is 1-2 mm Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Double Braided Construction Rope Construction - Strength is shared 50/50 between braided core and braided cover / sheath - Most common type of rope used for SPM mooring hawsers Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery OCIMF GUIDELINES Type approval of nylon SPM Hawsers is conducted under the OCIMF 2000 Guidelines, 1st Edition Major Difference between OCIMF 1987 and OCIMF 2000 Number of tests required Should be repeated every 5 years Larger than 20” ropes are to now be tested Quantification of the behaviour of the marine finish Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Oil Companies Int. Marine Forum standard fatigue test Thousand Cycle Load Level TCLL values (8 strand): polypropylene polyamide (standard) steel (laid) 52% 55% 60% polyester Ultraline® Nylon Double Braid Nylon Deltaflex 70% 75% 69.1% 80% Dyneema 100% 90 % MBL 80 70 60 50 40 0 1000 2000 3000 4000 5000 6000 cycles TCLL is an accelerated fatigue test to obtain a quick comparison between ropes and materials > Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery BL3 The effect of different TCLL values is translated back to load levels representative for practical loading conditions (here these are assumed to be less than 40% of the MBL). Other tension-tension fatigue life TR 100% TCLL values As recommended the cyclic curve is represented by a linear line, going through 1 cycle @100% and the TCLL load value obtained for a 1 000 cycles. When translating the differences in TCLL to load levels encountered in practical situations, their importance becomes clear. 80% Peak load (% MBL) Following the OCIMF the cyclic fatigue curve is represented as the peak load versus the logarithmic of the cycles to failure. 60% 40% 20% 0% 1 10 100 1000 10000 100000 100000 1E+07 cycles to failure Based on the result for the OCIMF TCLL test a Cosalt/Bexco ULTRALINE BL3 will last some 10 000 000 cycles when cycling to 40% of its MBL. A.N. OTHER with a TCLL of 68% will last some 380 000 cycles for examples, and ropes with a lower TCLL even less cycles Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Components Typical SPM Assembly - Buoy / FPSO Chafe Chain - Heavy Duty Shackles - Rope Thimbles - Mooring Hawser - FPSO / Shuttle Tanker Chafe Chain - Support Buoy / Pick-up Buoy - Pick-up Ropes / Messenger Lines - Load Monitoring Systems Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Components Buoy / FPSO & FPSO / Shuttle Tanker Chafe Chains - Vetted & approved suppliers only - ISO 9001/9002 - Close working partnership - Majority is European Manufacture / Far Eastern can be supplied if requested - Production Range 16mm - 120mm Diameter in various grades - Laboratory & testing facilities Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Components Heavy Duty Shackles & Thimbles - Vetted & approved suppliers only - ISO 9001/9002 - Close working partnership - European Manufacture - Laboratory & testing facilities Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Components Heavy Duty Shackles - Forged alloy steel - Finish painted / Galvanised - Double nuts & S/S cotter pins - MBL is 5 x SWL Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Components SPM Cast Thimble - High strength cast corrosion resistant steel (Galvanised) - Stainless steel - Shackle retaining bar Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Components Tubular Thimble - Fabricated construction - Mild steel - Finish galvanised / plastic coated Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Components Bellmouth Thimble - Reusable - Mild steel (galvanised) - Stainless steel Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Components Mooring Hawsers - Manufactured by BEXCOropes - All hawsers supplied manufactured & supplied to OCIMF 2000 - Over 8 years experience, SPM hawsers - Reference history Selection of mooring Constructions Enhancements available hawser - PU Repeat BL3 coating Ultraline loading Nylon - Additional OCIMFDouble DB12 TCLL protection value Braid Nylon sleeves - Tubular Abrasion DF8 Deltaflex rope resistance floats Composite - Energy absorption Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Components Support Buoy / Pick-up Buoy - Vetted & approved supplier only - Close working partnership - UK Manufacture - Central steelwork - Galvanised swivel ends - Resiliant closed cell foam Cylindrical Chain Support Buoy Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Components Support Buoy / Pick-up Buoy - Vetted & approved supplier only - Close working partnership - UK Manufacture - Through steel tube - Chain lock plate one end - Resiliant closed cell foam Cylindrical Through Chain Support Buoy Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Components Support Buoy / Pick-up Buoy - Vetted & approved supplier only - Close working partnership - UK Manufacture - Fixed eye each end - Central steelwork - Resilient closed cell foam Pick-up Buoy Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Components Pick-up Ropes / Messenger Lines - Nutech brand - High strength co-polymer yarn - High visibility yellow colour* Available in 8 or 12 strand construction - Permanent flotation - SG 0.91 - Non-rotating, torque-free rope - Fully UV stabilised - Excellent abrasion resistance - Flexible, easy to handle & splice * other colours available on request Also available SPUNSTAPLE POLYPROPYLENE Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Components Load Monitoring Systems - Vetted & approved suppliers only - ISO 9001/9002 - Close working partnership - European Manufacture Benefits of Load Monitoring - Laboratory & testing facilities - Safe operation - Hawser life prediction - Optimise hawser service life - ‘Bells & whistles’!! Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Mooring Hawser Supply Manufacturing hawsers since 1997 160 141 140 113 120 100 80 60 40 90 76 31 67 57 68 63 25 20 06 20 05 20 04 20 03 20 02 20 01 20 00 20 99 19 98 19 19 97 0 Active Areas / Representation Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Operation & Maintenance Guidelines “To achieve optimum life operators need to develop inspection, handling and maintenance procedures based on local conditions” We are here to help you with this IF THERE IS ANY DOUBT ABOUT THE CONDITION OF A ROPE IT SHOULD BE REJECTED Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Supporting Documentation FactFile [Bulletin No.14] Offshore Mooring Systems Offshore Mooring Systems Offshore Mooring Systems “Total System Management” www.cosalt.co.uk / www.bexco.be also on CD-Rom Cosalt/Bexco Offshore Mooring Systems for operational performance, reliability, safety & on-time delivery Any questions? Cosalt International Limited Fish Dock Road Grimsby N.E. Lincolshire DN31 3NW United Kingdom Telephone 44 (0) 1472 504258 Facsimile 44 (0) 1472 504257 e-mail: rope@cosalt.co.uk Photographs courtesy of Bluewater Engineering BV & Geolitel Corporation